Strata reinforcement system of shield tunneling in shallow overburden area and its construction method

A construction method and a technology of shallow overburden, which are applied in earthwork drilling, construction, underground chambers, etc., can solve the problems of looseness and cracks in the stratum above the tunnel, cracks in the segment and water leakage, poor implementation effect, etc. Construction risk and operation risk, high economic and social benefits, ensuring the effect of normal excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in combination with specific embodiments.

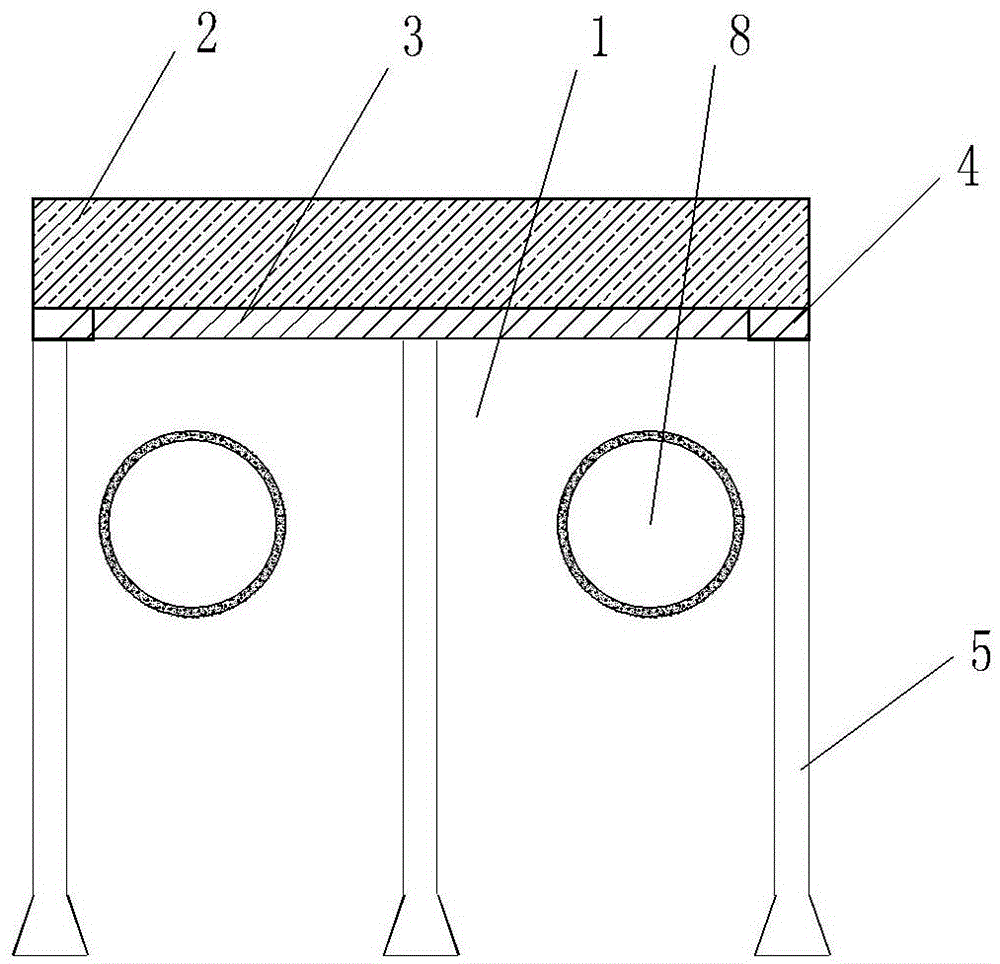

[0035] Theoretically speaking, when the earth pressure balance shield is excavated, the jacking pressure of the excavation face is generally greater than the static earth pressure and less than the passive earth pressure, so that the front stratum presents a slight uplift deformation trend. The matching of the machine rotation speed (muck discharge) achieves dynamic balance, and the fluctuation of the jacking pressure on the excavation face is affected by the shield tunneling speed, the rotation speed of the screw machine, the plastic flow and permeability of the dregs in the soil chamber, and the construction personnel's technology. Influenced by many factors such as shield level, under the current construction technology level, the fluctuation of the jacking pressure of the excavation face is inevitable to a certain extent. After the bearing capacity is improved, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com