High viscosity slurry for water-rich sandy gravel stratum slurry shield construction

A mud-water shield, high-viscosity technology, which is used in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of low viscosity of the Marsh funnel, engineering accidents, affecting the normal excavation of the shield, so as to maintain stability and ensure normal The effect of excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

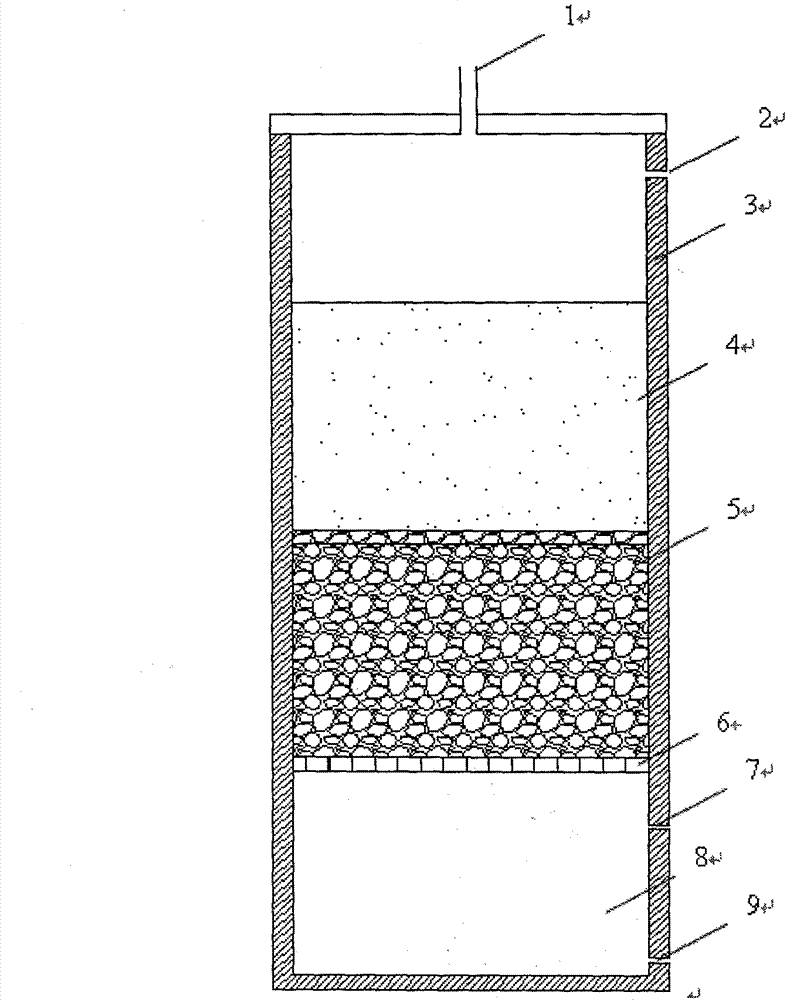

[0021] The present invention is a high-viscosity mud used for mud-water shield construction in water-rich sand and pebble formations. The high-viscosity mud can form a homogeneous mud film on the face of water-rich sand and pebbles to effectively maintain the face. stability.

[0022] High-viscosity mud contains type I pulping agent, type II pulping agent, type III pulping agent and bentonite. Type I pulping agent, type II pulping agent and type III pulping agent are all used for shield tunneling Agents, these pulping agents can be purchased from the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com