Construction tool and construction method for continuous excavation of underwater large-diameter shield with deformed tail shield

A large-diameter, tail shield technology, applied in shaft equipment, earth-moving drilling, hydropower generation, etc., can solve the problems of long construction period, high safety risk, complex structural processing, etc., to improve construction efficiency, reduce damage, and reduce construction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of shield tunneling with a diameter of 12.12m.

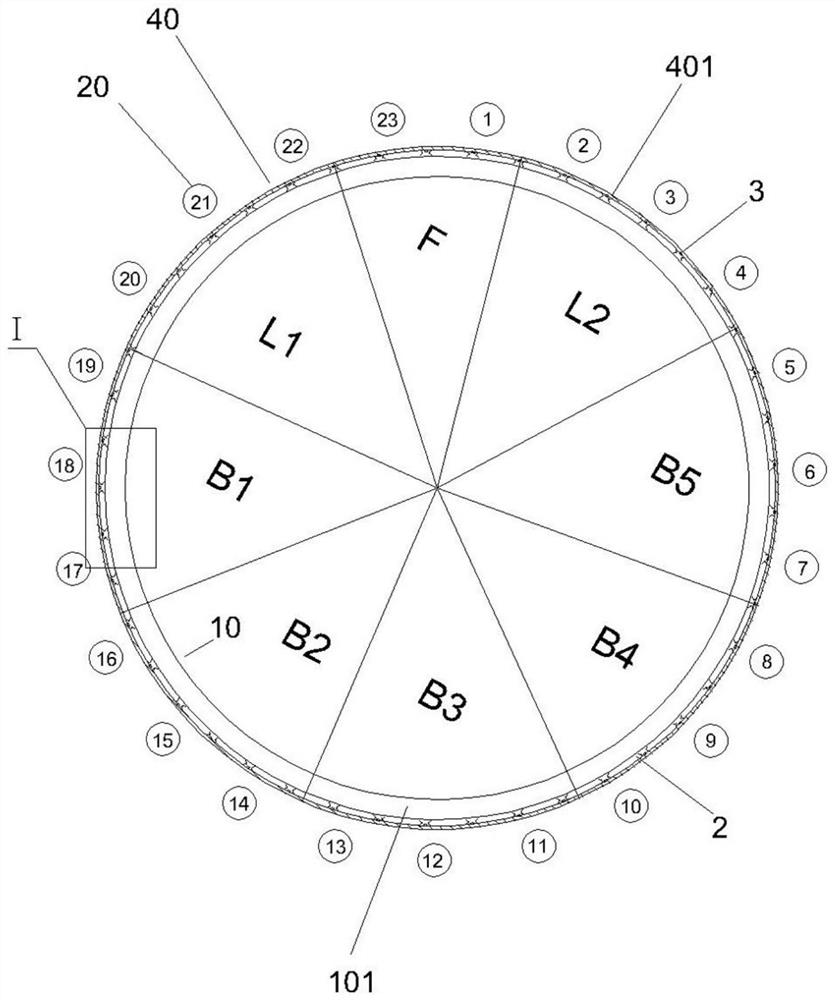

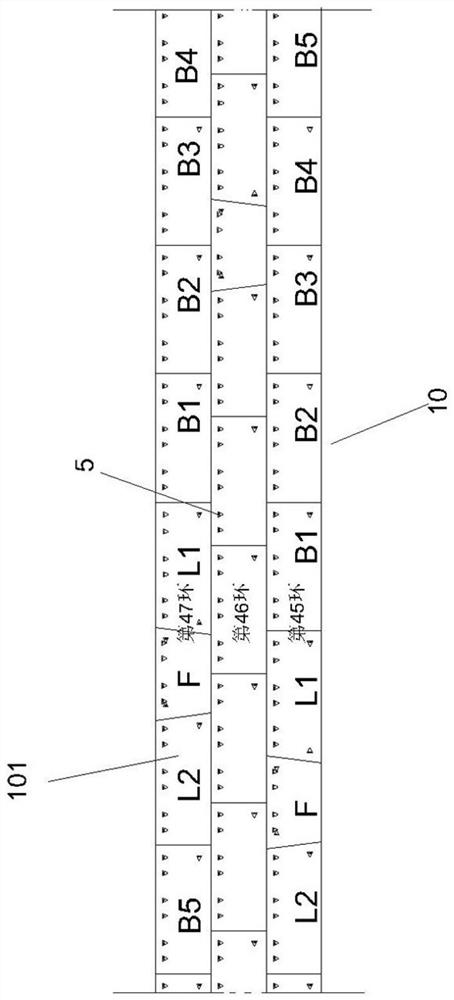

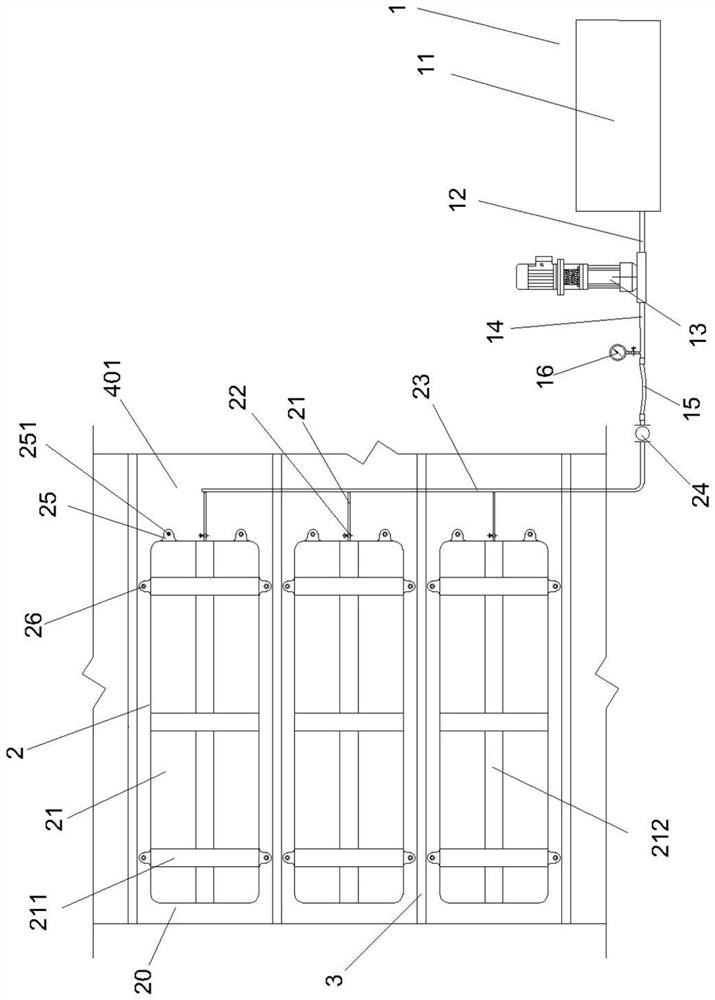

[0027] Such as figure 1 and figure 2 As shown, the segment ring 10 installed in the tail shield is from the B3 segment block at the bottom to the F segment segment block at the top, including B1 to B5, L1, L2 and F, a total of eight segment segments, among which the last installed F The two ends of the segment block are inclined, and the segment block 101 adjacent to the two ends of the F segment block are respectively the L1 adjacent block and the L2 adjacent block, and the inclined surface at one end of the L1 adjacent block and the inclined surface at one end of the L2 adjacent block are respectively connected to the F tube The inclined surfaces at both ends of the segment are matched, so that the F segment segment can be axially embedded and installed between the L1 adjacent block and the L2 adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com