Patents

Literature

283results about How to "Reduce construction safety risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real-time monitoring and early warning system for a subway station foundation pit, and a monitoring and early warning method thereof

InactiveCN109594591ATimely adjustment of construction scheduleImprove construction efficiencyGeometric CADFoundation testingData acquisitionSubway station

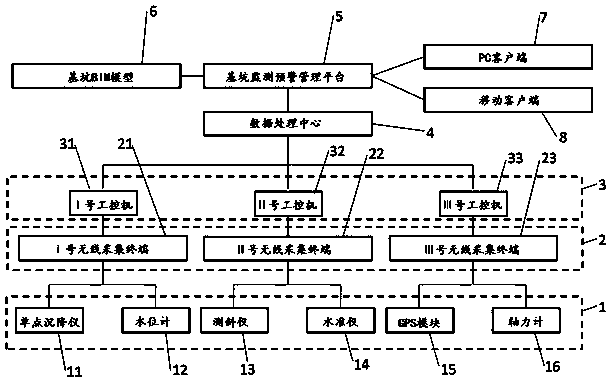

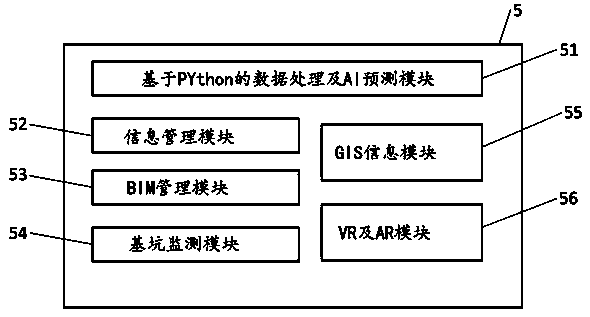

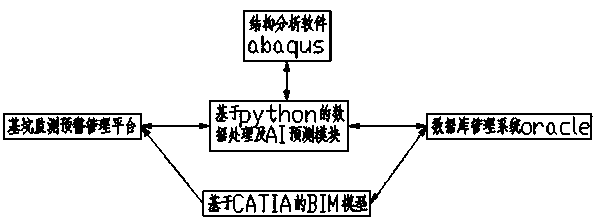

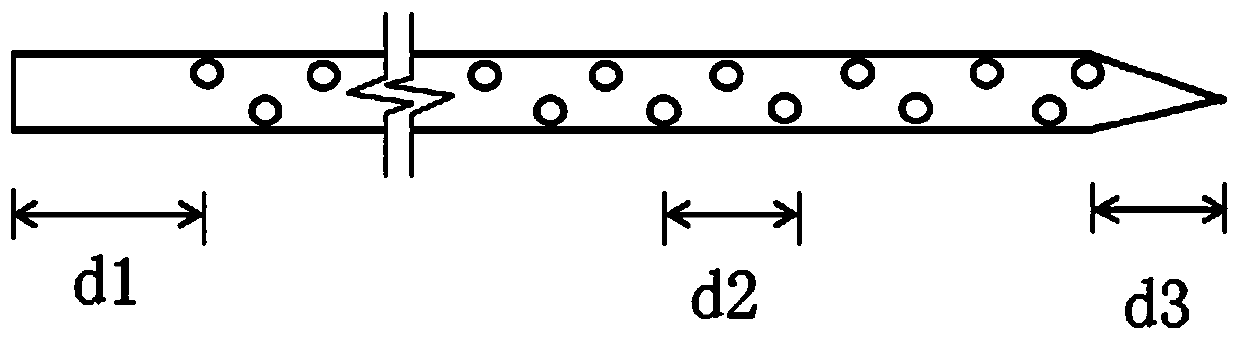

The invention discloses a real-time monitoring and early warning system of a subway station foundation pit and a monitoring and early warning method thereof. The monitoring and early warning system comprises an on-site sensor arranged in the foundation pit. The field sensor transmits the acquired foundation pit data to a front-end data acquisition module and a front-end data processing and transmitting module; the front-end data processing and transmitting module is used for transmitting the data to a data processing center and a foundation pit monitoring and early warning management platform, and the foundation pit monitoring and early warning management platform is connected with a foundation pit BIM model to realize corresponding mapping of the measurement data in the model; the monitoring and early warning method comprises the following steps that a foundation pit excavation time-varying BIM model is built, a control network is built, information interaction is carried out, real-time visual monitoring of the BIM model 4D is achieved, the foundation pit monitoring and early warning management platform carries out calculation and analysis according to actual measurement data, and construction process simulation or prediction analysis is carried out. According to the method, through the BIM technology, the dynamic processes of foundation pit excavation, support system construction and construction equipment are closely connected with foundation pit monitoring to form a whole.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Construction method used after tunnel integral type collapse

ActiveCN107165652AStable supportAvoid the disadvantages of inoperabilityUnderground chambersTunnel liningStructural engineeringImpact area

Owner:DATANG LINZHOU THERMAL POWER CO LTD

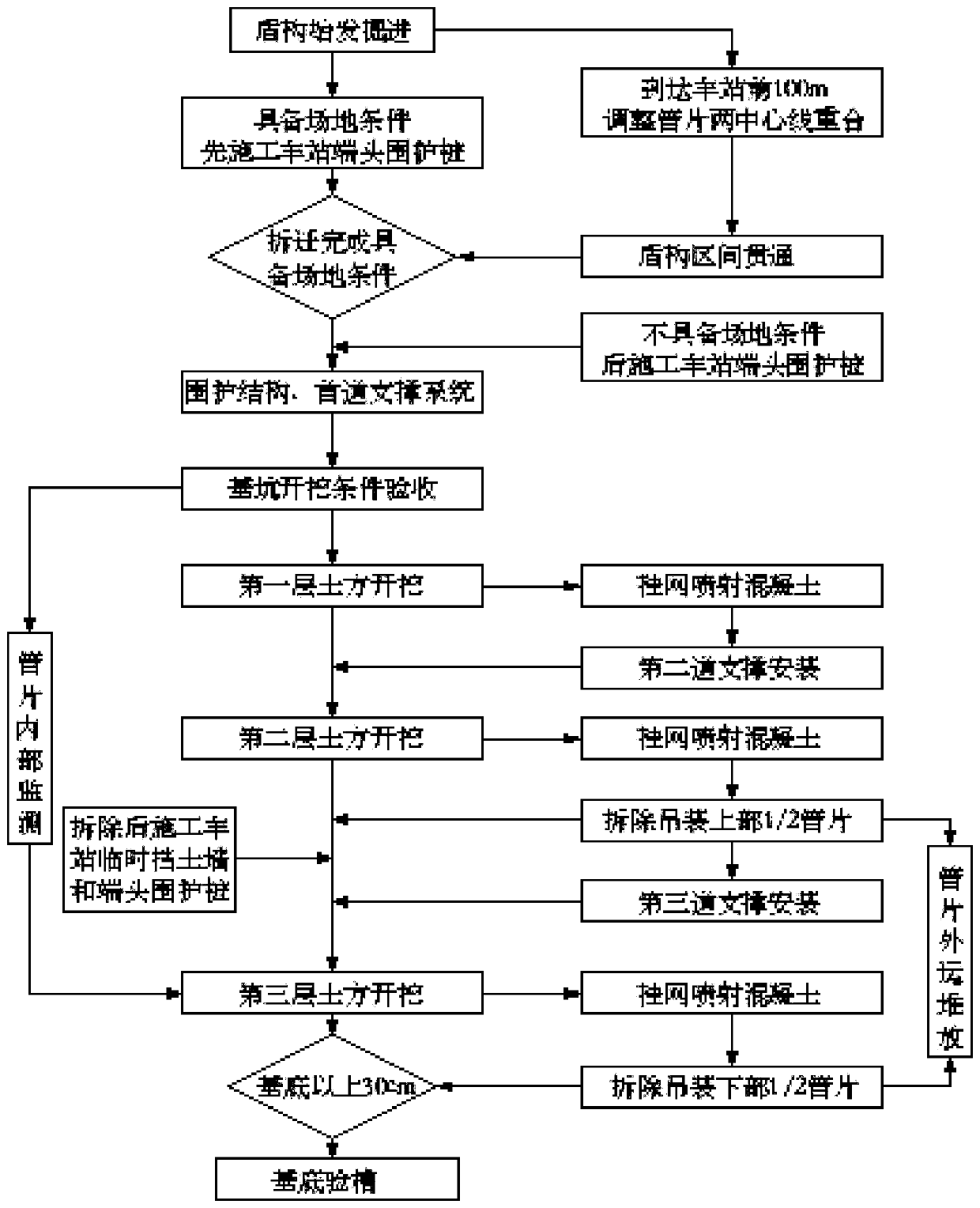

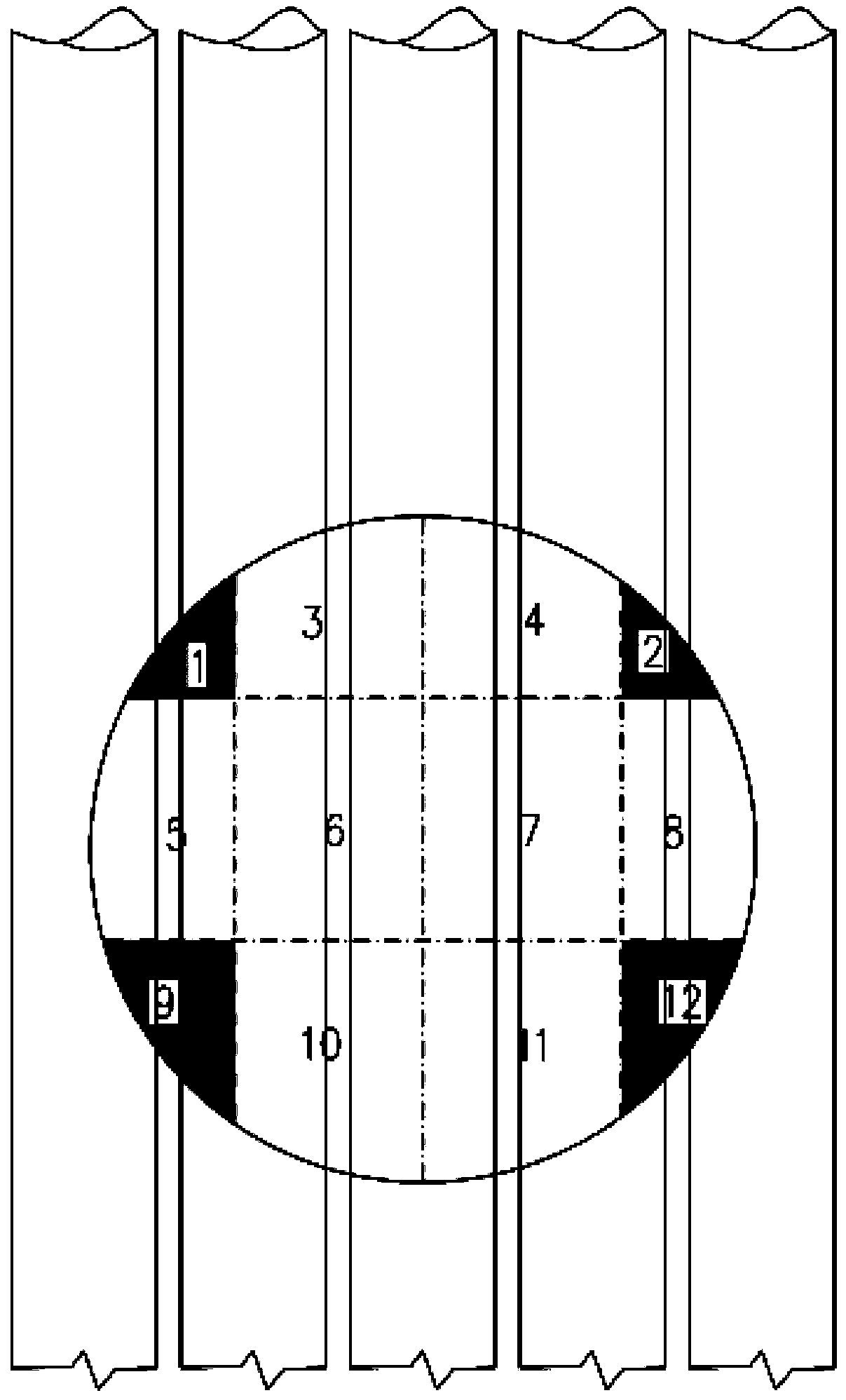

Tunnel-before-station open-cut station construction method

ActiveCN110424969ANot affected by land acquisition and demolitionControllable start timeArtificial islandsUnderground chambersArchitectural engineeringShield tunneling

The invention provides a tunnel-before-station open-cut station construction method. A shield tunneling machine carries out tunneling in advance to pass through the station range, and the problems that a station is influenced by land requisition and demolishing and does not have construction conditions, and starting and receiving conditions cannot be provided for the shield tunneling machine are solved; and the aim that the sections can be cut through firstly, and then the station is constructed is achieved.

Owner:中铁一局集团厦门建设工程有限公司 +1

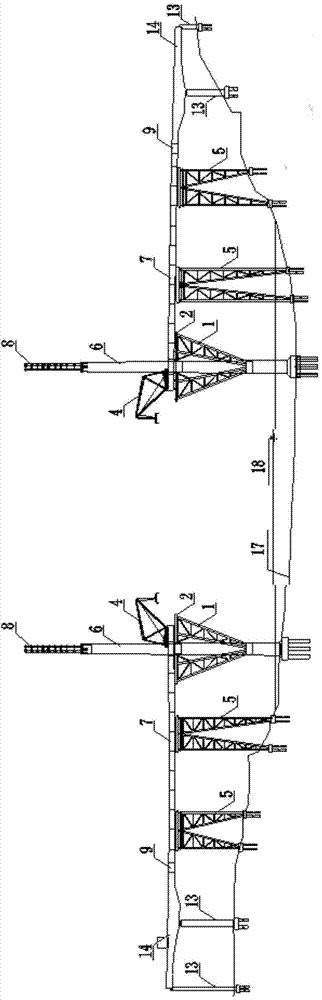

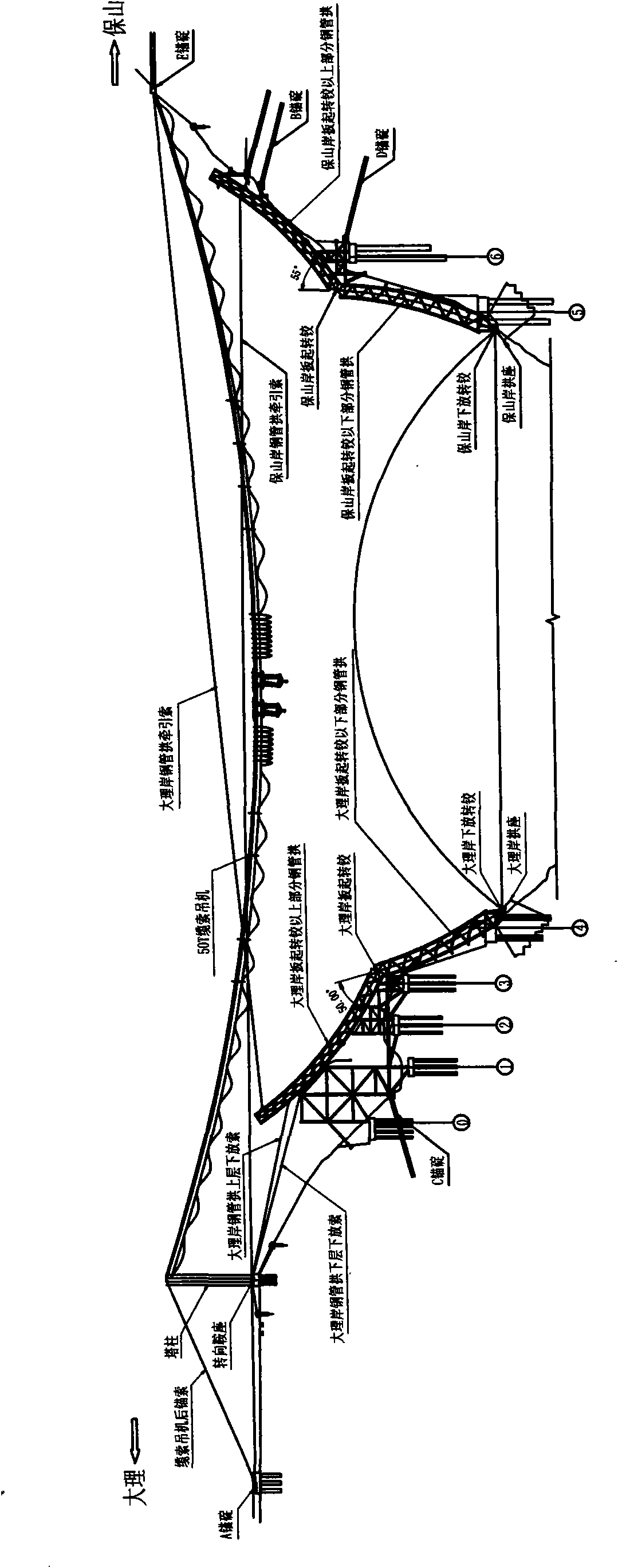

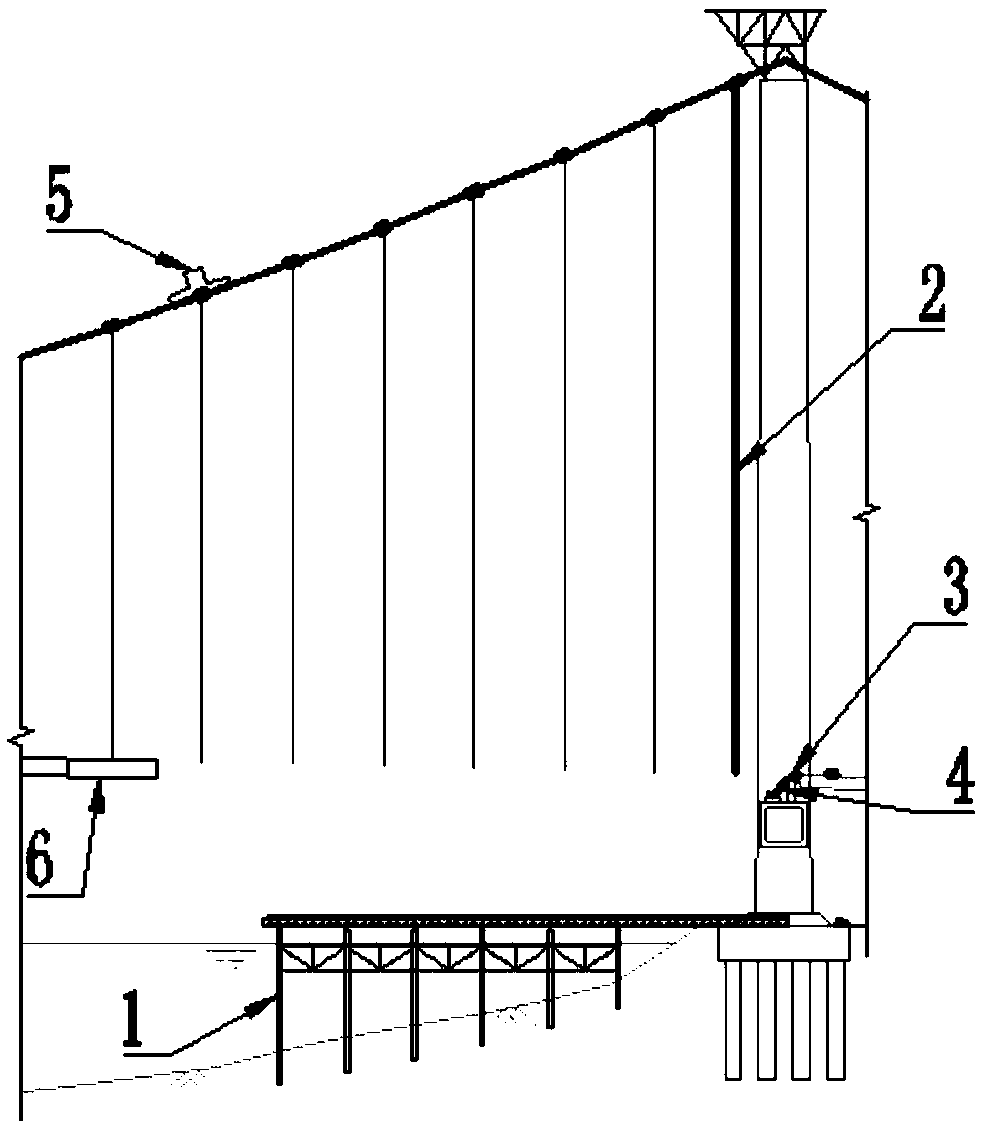

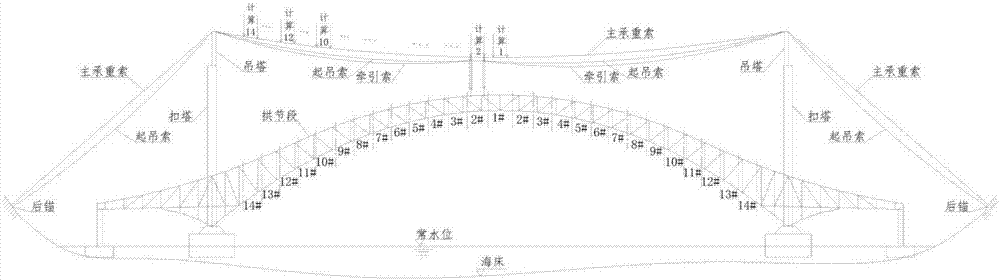

Self-anchoring type mounting method of suspension bridge

The invention provides a self-anchoring type mounting method of a suspension bridge. The method comprises the steps of constructing a main pier and a side pier; erecting beams and splicing through a crane; mounting a medium supporting pier of a side span steel box beam; mounting the side span steel box beam; mounting a temporary steel tower; mounting a main span steel box beam and a temporary cable; mounting a main cable and a lifting cable; converting the systems. The method is free of the limitation of navigation of a waterway; an ultrahigh bracket cannot be constructed in the river at a gorge region with steep bank slopes, so that the input is reduced; the longitudinal moving load can be decreased, and the longitudinal moving range, so that the long-distance and large-tonnage propping and pushing can be avoided, and as a result, the risk of construction safety in longitudinal moving can be reduced; a propping pushing bracket can be avoided being scoured by flood and floating articles, so that the safety risk of construction is reduced, and the construction is sped up.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

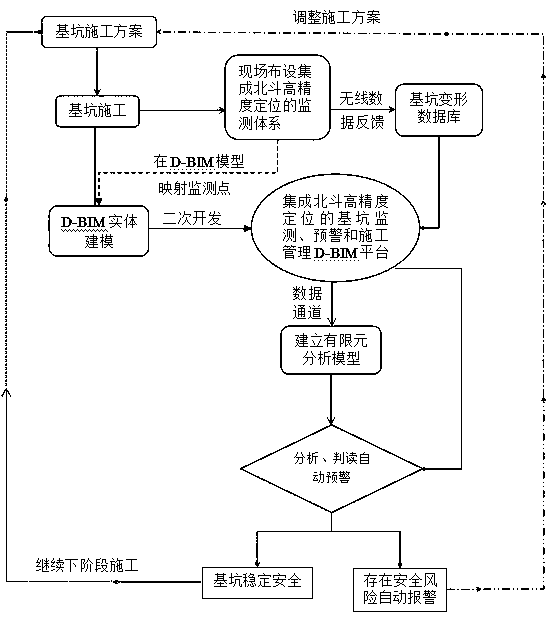

Foundation pit monitoring, early warning and construction management D-BIM platform integrated with Beidou high-accuracy positioning system

InactiveCN108385691AAdjust construction timingImprove construction efficiencyGeometric CADFoundation testingElement analysisPositioning system

The invention discloses a foundation pit monitoring, early warning and construction management D-BIM platform integrated with a Beidou high-accuracy positioning system. Firstly, through the foundationpit D-BIM platform, the excavation progress of a foundation pit, construction of a foundation pit supporting and protecting system and the influence of surrounding buildings on construction of the foundation pit are reflected in real time; secondly, a real-time monitoring system is composed of the Beidou high-accuracy positioning system, mapping equipment, a stress-strain sensor, a groundwater stage gauge and the like, monitoring signals are collected by the D-BIM platform in real time, and a database is built; thirdly, monitoring data of the foundation pit deformation database can be directly retrieved and analyzed through the D-BIM platform, and when the monitoring data are larger than an early warning threshold value, an alarm is directly given out; and fourthly, the D-BIM platform cantransmit a model to software of finite element analysis in real time, and the foundation pit supporting and protecting system, groundwater movement and the stability of the foundation pit are analyzed and forecasted. According to the foundation pit monitoring, early warning and construction management D-BIM platform integrated with the Beidou high-accuracy positioning system, the correlation between the supporting and protecting structure and the stability of the foundation pit in the construction process can be visually displayed through the D-BIM model, early warning is achieved for potential safety hazards, and field management decision makers can be effectively helped to find problems and take corresponding remedial measures.

Owner:NANTONG SIJIAN CONSTR GRP

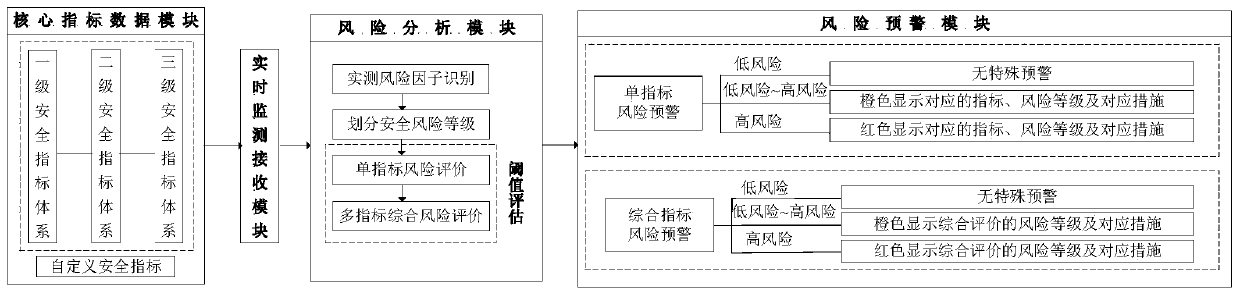

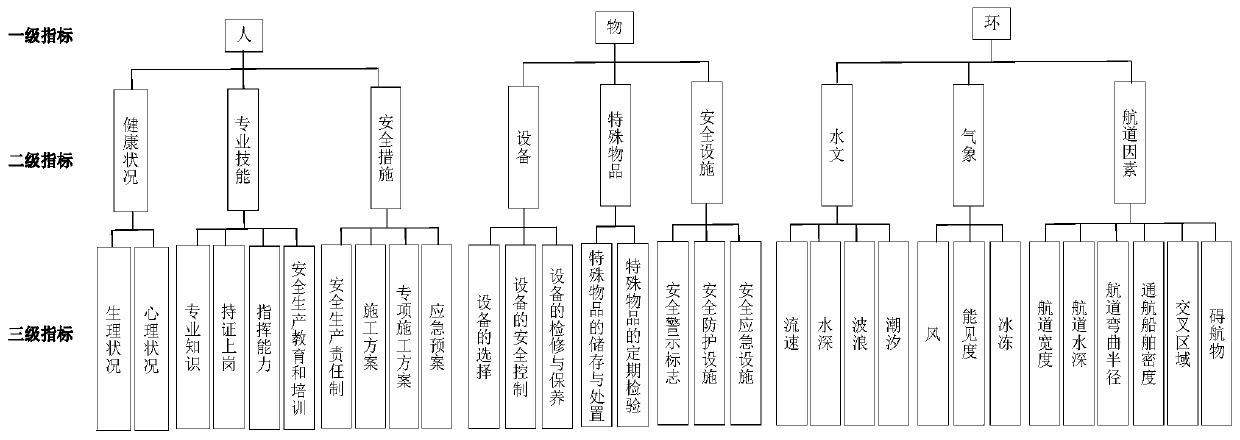

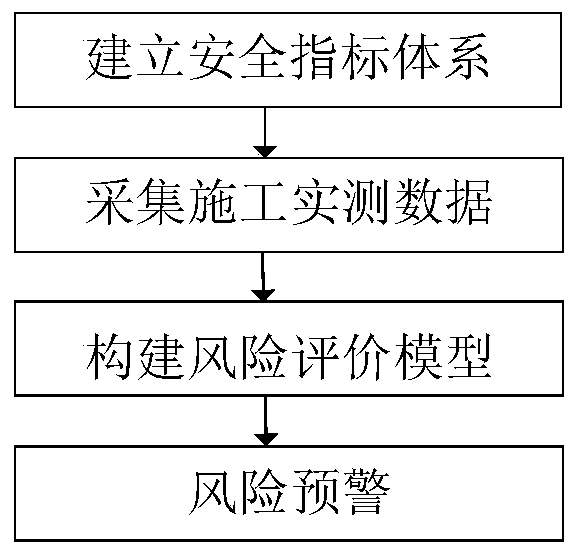

Navigation water area overwater construction safety risk early warning grading method and system

PendingCN111507586AReduce construction safety risksGuarantee the safety of life and propertyResourcesData transmissionMonitoring data

The invention discloses a navigation water area overwater construction safety early warning grading method and system. The system comprises a core index data module, a real-time monitoring receiving module, a risk analysis module and a risk early warning module. The core index data module comprises a three-level safety index system unit and a user-defined safety index unit, and quantification of each safety index is based on national laws and regulations, industry specifications and experience of industry experts; the real-time monitoring receiving module is used for displaying the construction monitoring data of each safety index in real time and transmitting the monitoring data to the risk analysis module regularly; the risk analysis module comprises an actual measurement risk factor identification unit, a safety risk grade division unit, a single-index risk evaluation unit and a multi-index comprehensive risk evaluation unit, and is used for evaluating the safety risk degree of allfactors and the overall construction environment coupled with the multiple factors; and the risk early warning module displays the risk levels of the safety index factors and the comprehensive evaluation result and the corresponding safety measure suggestions to the construction personnel through the visual safety early warning platform, and is used for risk early warning.

Owner:NAT ENG RES CENT OF DREDGING TECH & EQUIP

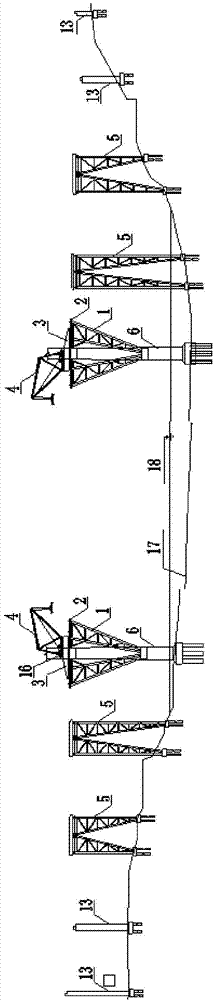

No-balance-weight horizontal-rotation construction method of steel truss girder bridge spanning railway operating line

ActiveCN102116011ASolve design problemsSolve construction problemsBridge erection/assemblyArchitectural engineeringHydraulic ram

The invention discloses a no-balance-weight horizontal-rotation construction method of a steel truss girder bridge spanning a railway operating line. The construction method comprises the following construction steps: 1) the design and the construction of a rotation body facility at the rotating end is conducted, wherein the rotation body facility at the rotating end comprises a rotation body running track girder and a pier top facility No.25; 2) the design and the construction of a rotation body facility at the rotating shaft end is conducted, wherein the rotation body facility at the rotating shaft end comprises a positioning shaft, a bearing arm brace, a slide ship, a slide way and a pier pillar widening structure; and 3) the design and the construction of a rotation body running mechanism is conducted, wherein a rotation process adopts a walking type incrementally-launching running mechanism, and the running mechanism comprises the slide ship, a slide groove, an incrementally-launching hydraulic oil cylinder and an incrementally-launching counterforce device. Through technical economy comparison and selection, the invention adopts the construction scheme that a steel truss girder is assembled at a high level on the lateral side of the railway operating line by using a bracket method, and the girder is lowered and emplaced after being rotated to a design position by using the no-balance-weight horizontal-rotation method.

Owner:THE SECOND CONSTR OF CTCE GROUP

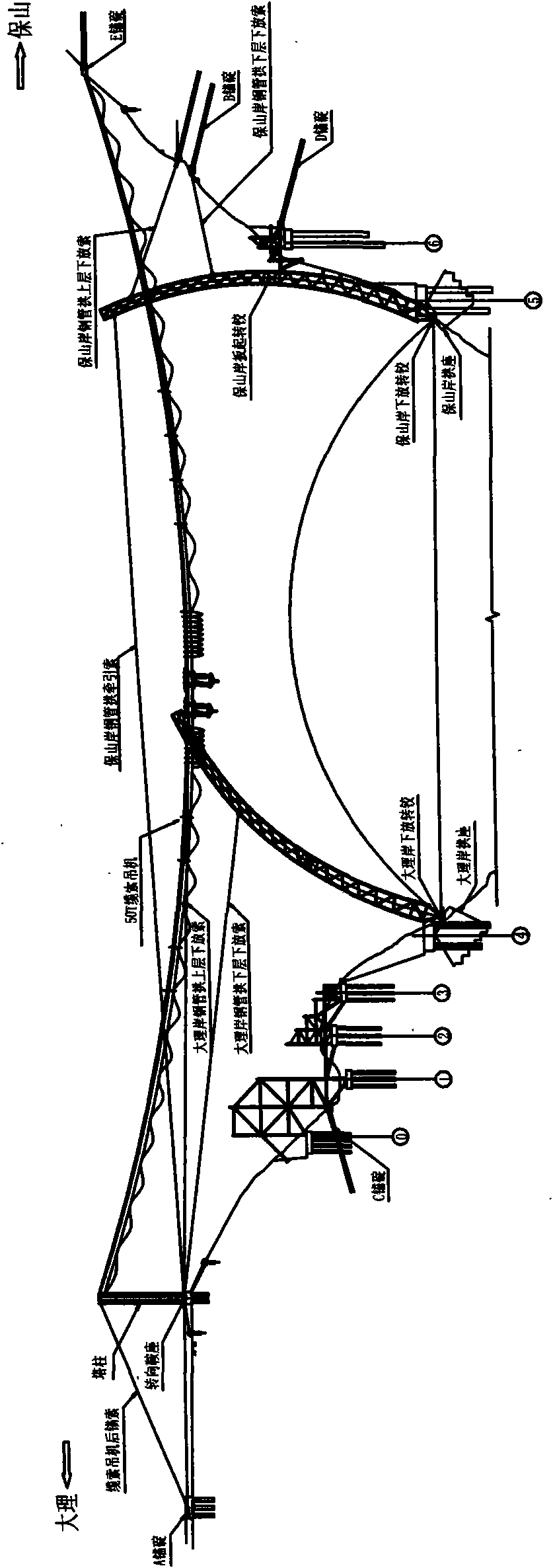

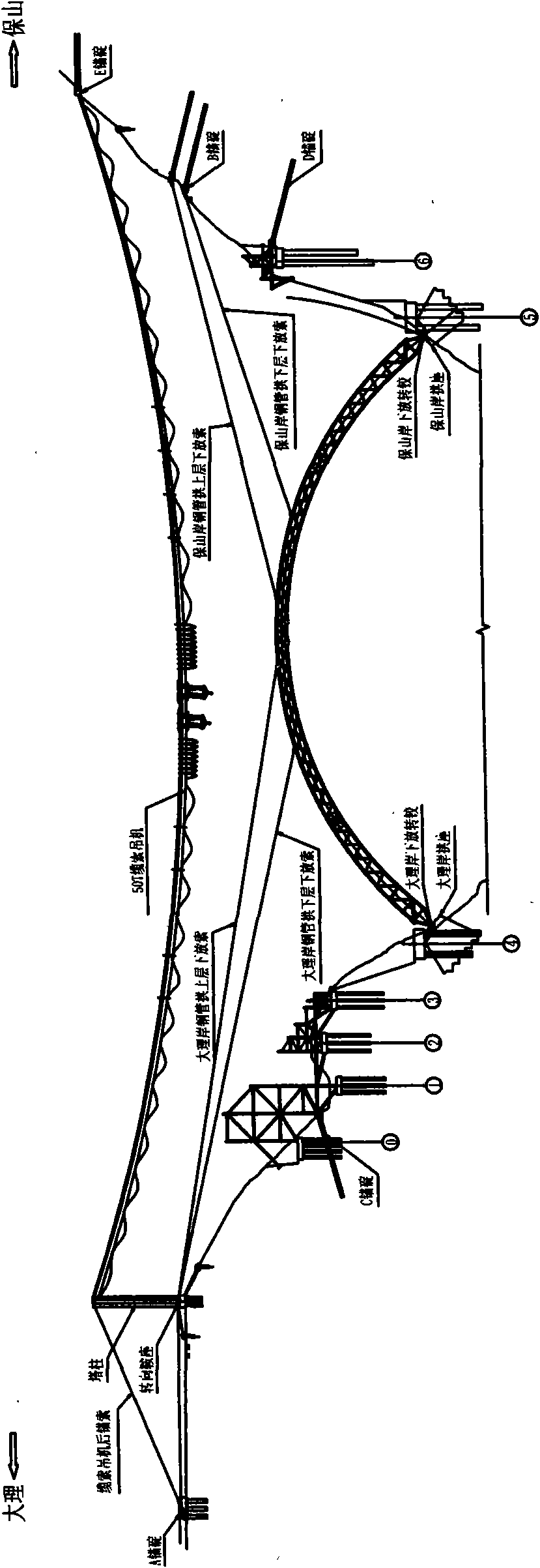

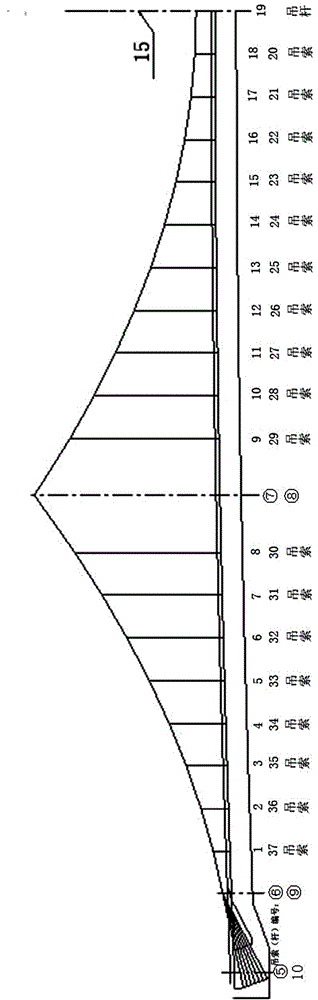

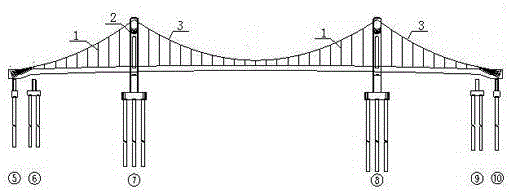

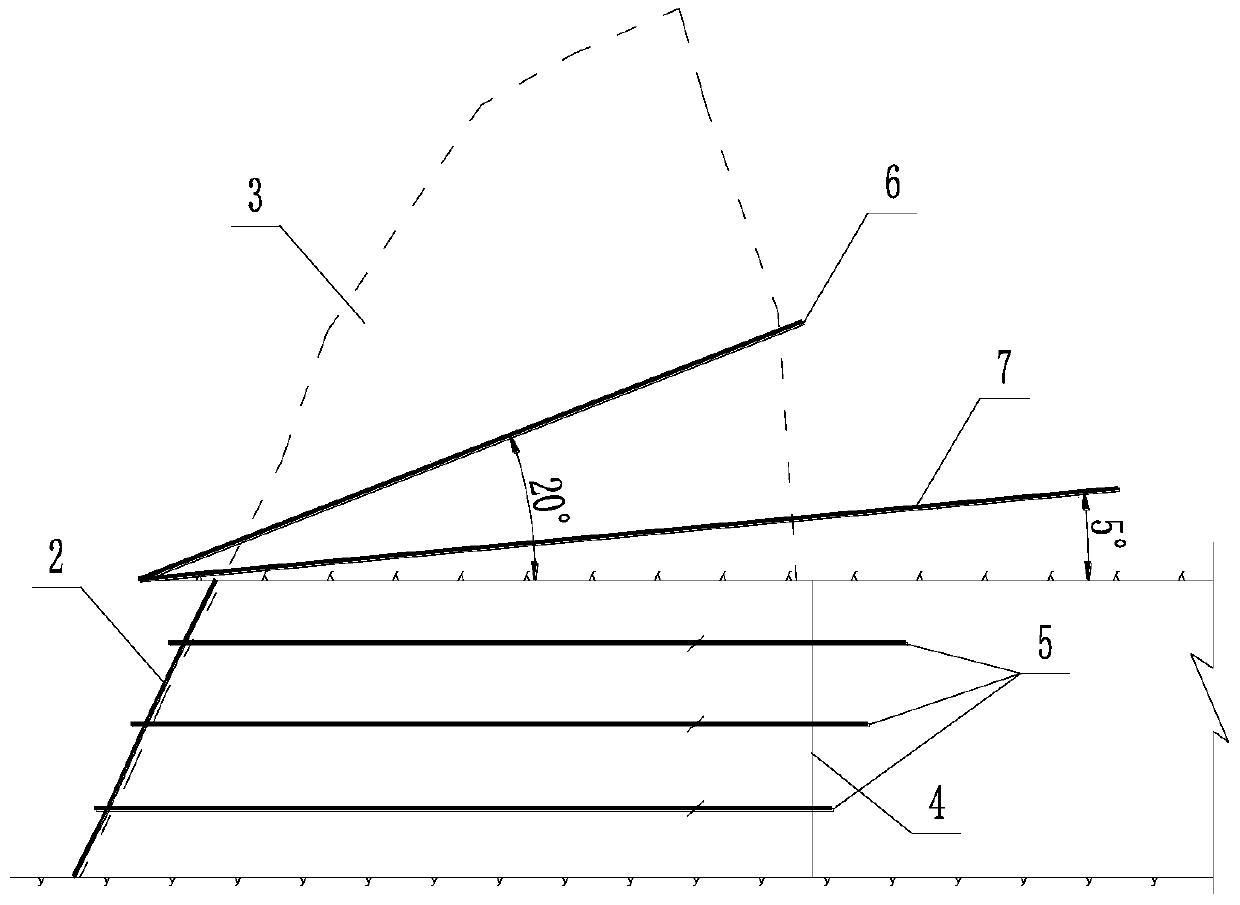

Secondary vertical rotation construction method of long-span steel pipe arch bridge

InactiveCN101619563AGuarantee the quality of the projectImprove construction efficiencyBridge erection/assemblyArch-type bridgeTerrainLong span

The invention discloses a secondary vertical rotation construction method of a long-span steel pipe arch bridge, which comprises the following steps: arranging lifting rotation hinges and lowering rotation hinges according to terrains, backward bending steel pipe arches at the upper parts of the lifting rotation hinges, dispersedly splicing the steel pipe arches on a supporting frame along a mountain body, carrying out upward lifting and downward vertical rotation construction by technology which uses a computer to control integral lifting and lowering operation and sequentially installing an arch top closure section and an arch springing closure section so as to complete the installation of the steel pipe arches. The invention has the advantages of ensuring the construction quality, improving the construction efficiency and reducing the construction safety risk and can be popularized to bridge construction under the similar condition.

Owner:THE 5TH ENG MBEC

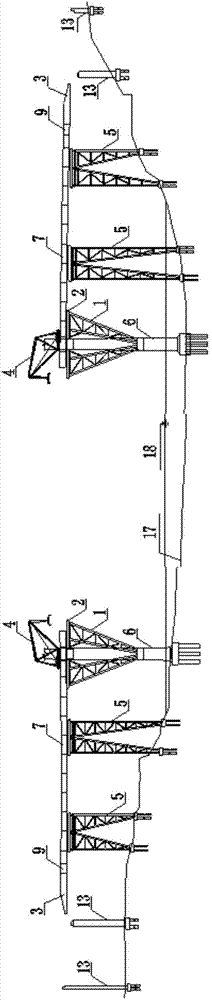

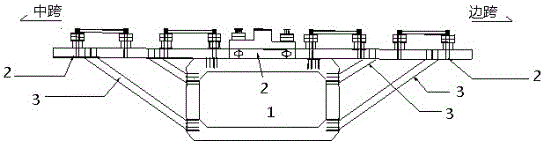

Few-circulation sling graded tension construction method of concrete self-anchored suspension bridge

ActiveCN103334378AReduce the number of pushesReduce occupancyBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a few-circulation sling graded tension construction method of a concrete self-anchored suspension bridge. Sling tension adopts few-circulation graded tension control; grading refers to that each sling is tensioned in three stages; sling force of an ideal sling is P, and then the tension is conducted in three stages, namely 2 / 4P, 3 / 4P and P; and few-circulation refers to that the 74 slings of the whole bridge are tensioned in three batches totally; a sling tension facility and a main sling saddle pushing facility are required to be designed and constructed before tension construction; the sling tension facility comprises tension arm braces, tension jacks, tension nuts, and tension extension bars; and a counterforce rack is the key device in the main sling saddle pushing construction. With the adoption of the few-circulation sling graded tension construction method of the concrete self-anchored suspension bridge, the time of sling tension is reduced to 3; the construction method has the advantages that (1) the times of the repeated sling tension and cable saddle pushing are reduced; (2) a construction safety risk is reduced; (3) a construction period is shortened; (4) the occupation of project department personnel and machine resources is reduced; and (5) the construction cost is lowered.

Owner:THE SECOND CONSTR OF CTCE GROUP

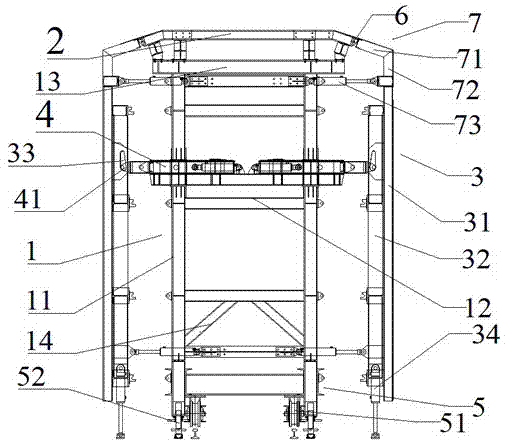

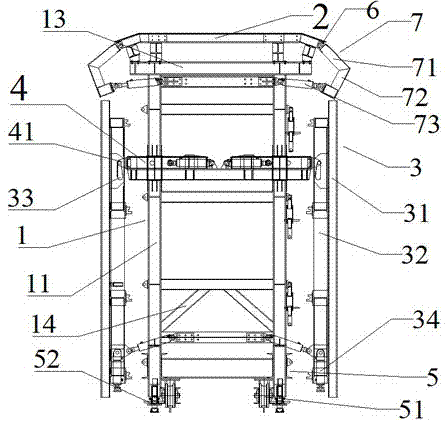

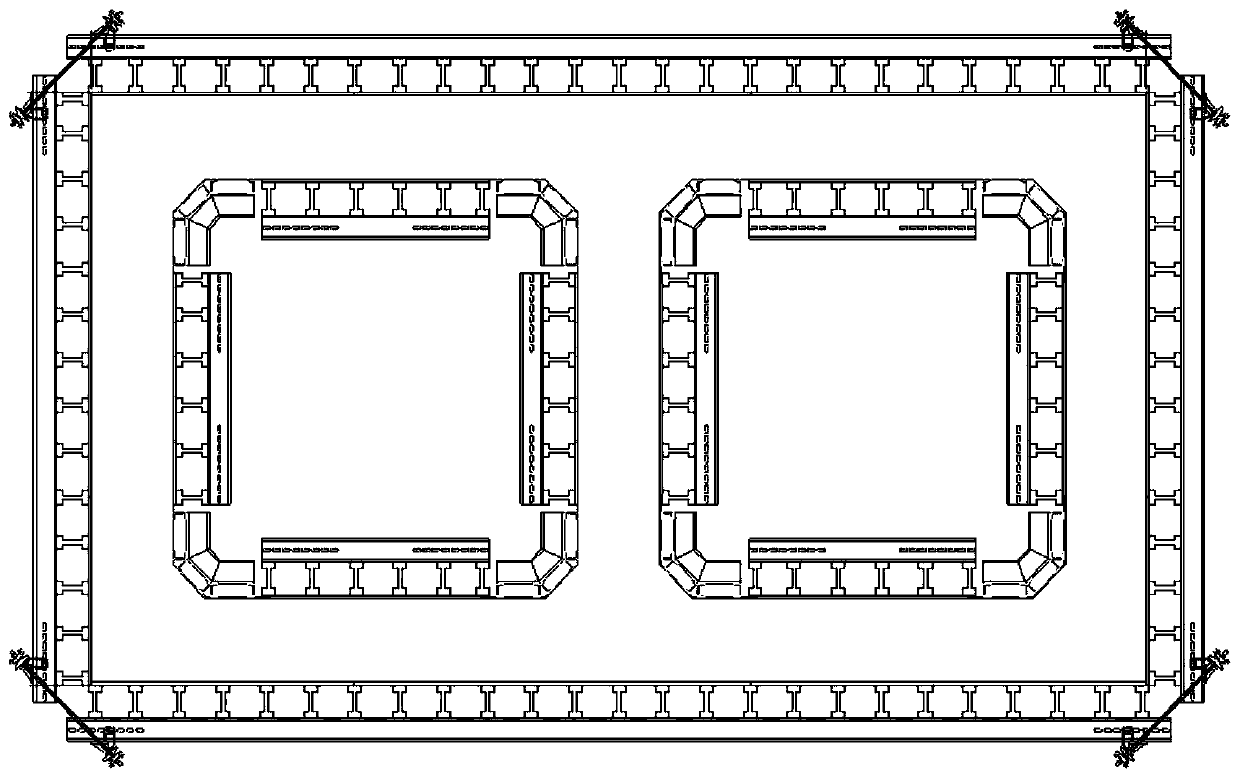

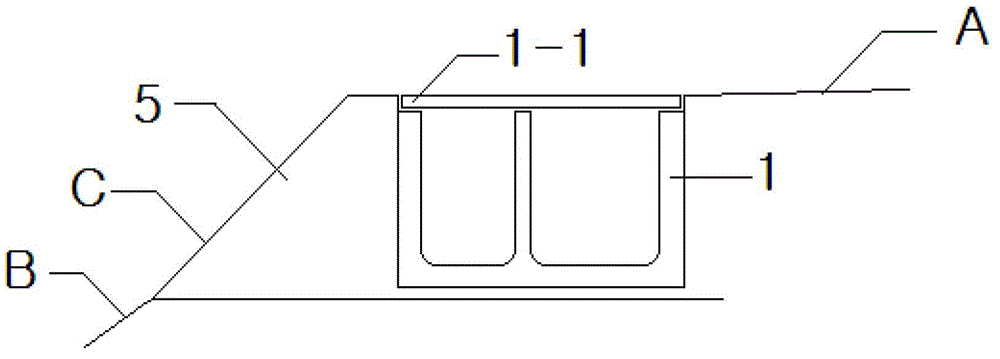

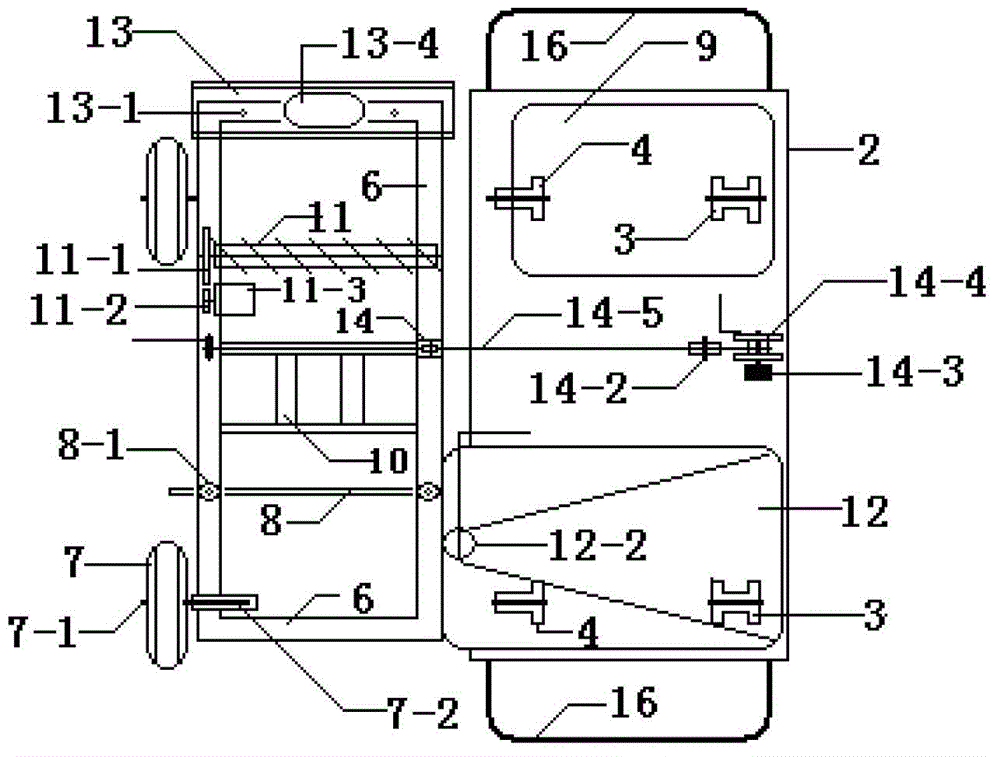

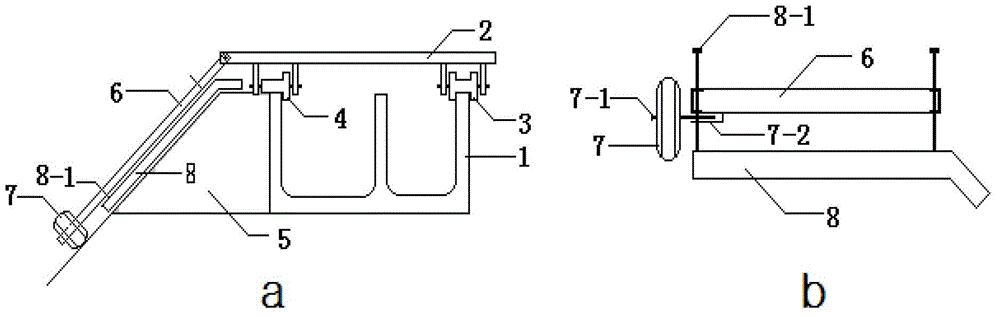

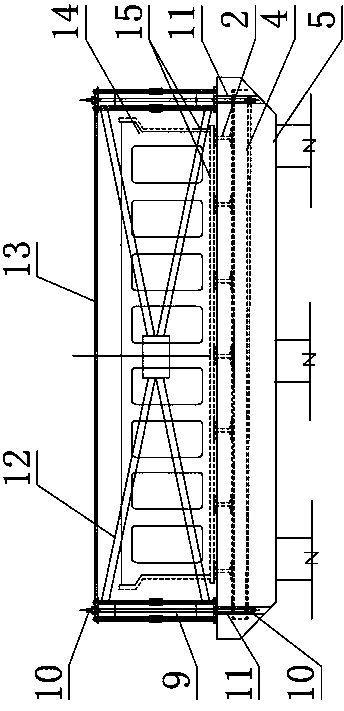

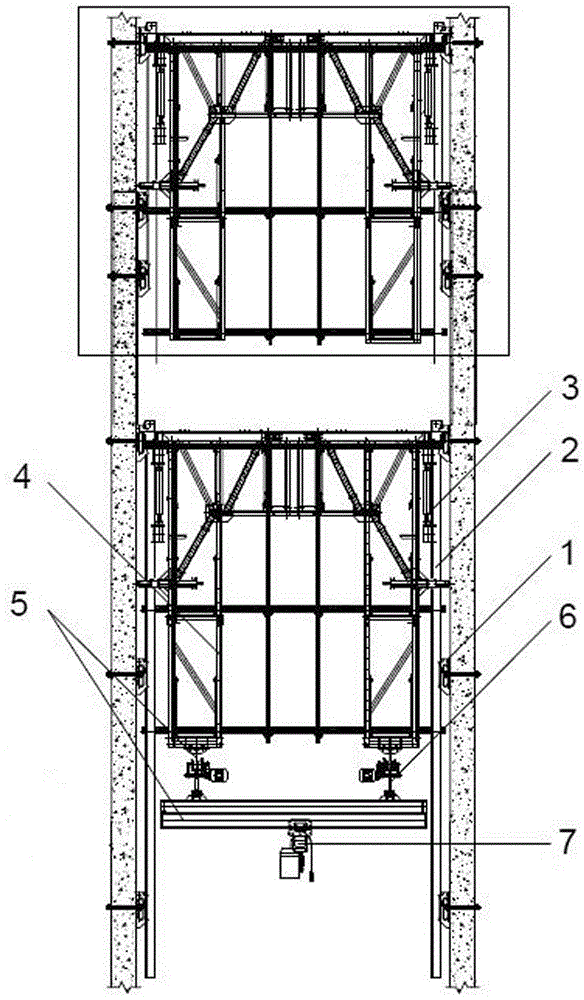

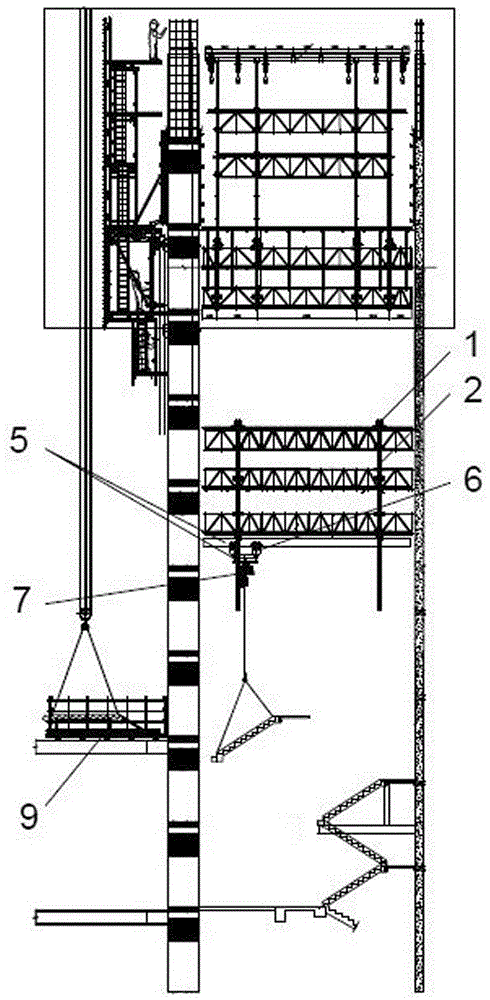

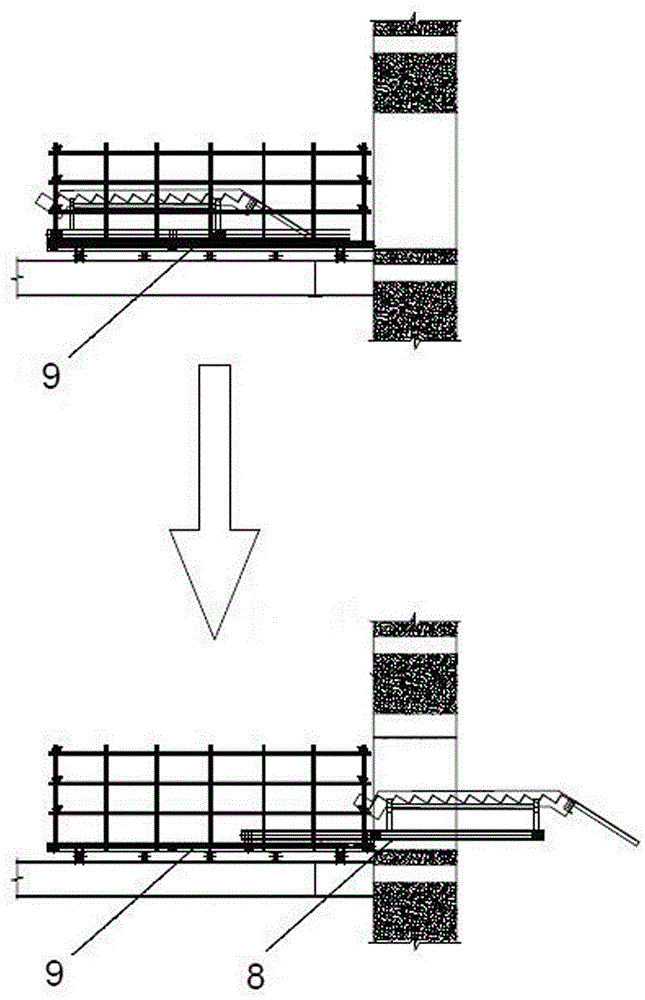

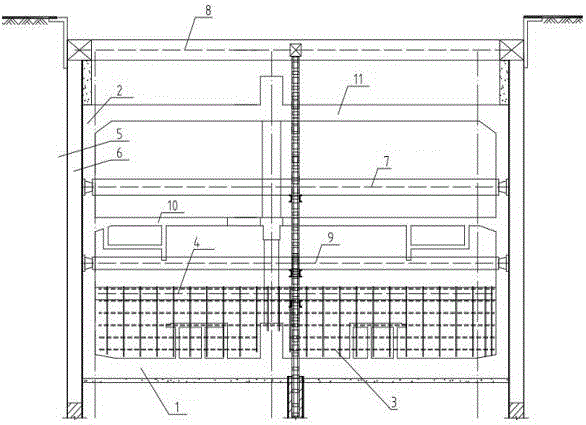

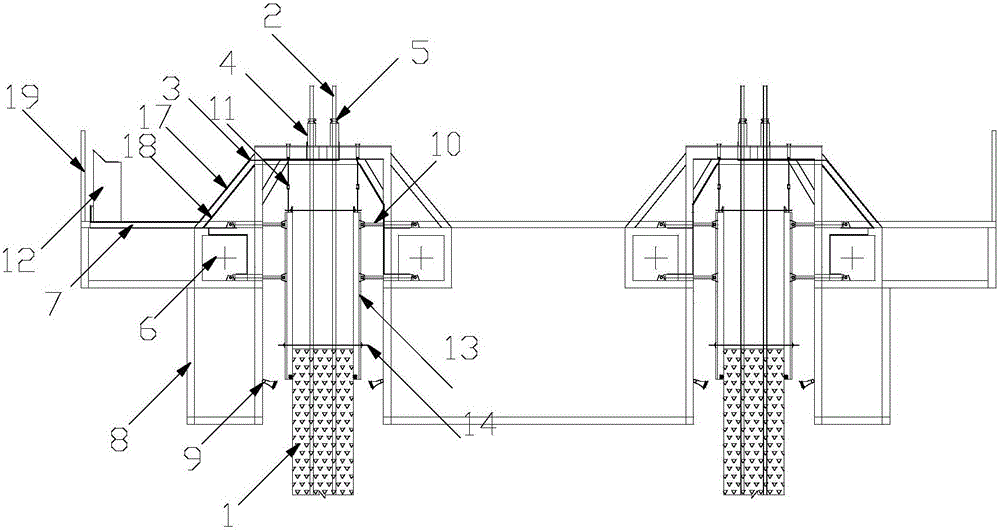

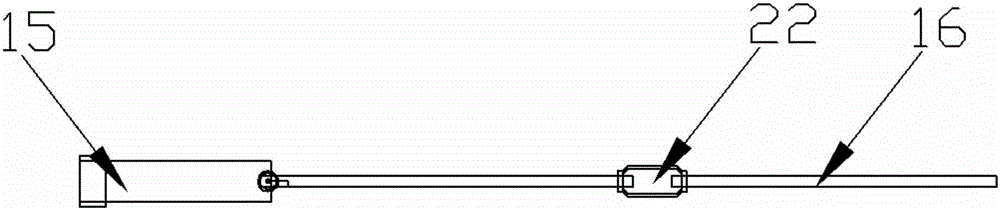

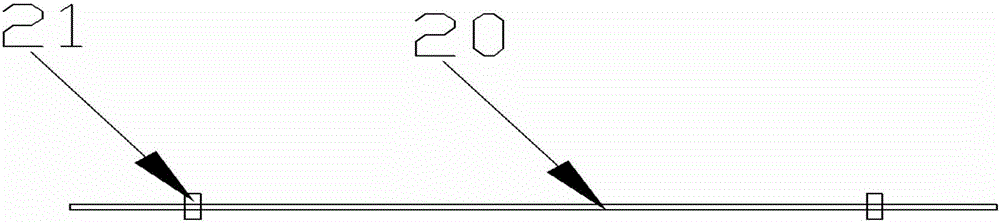

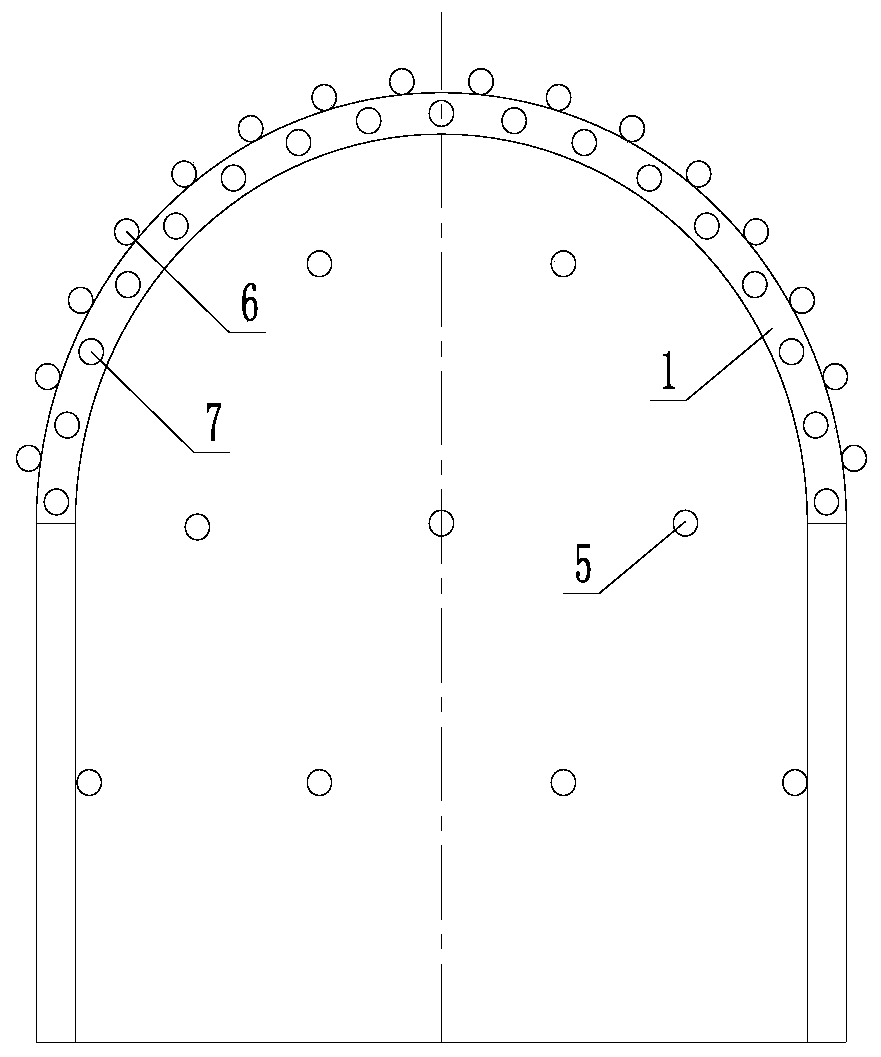

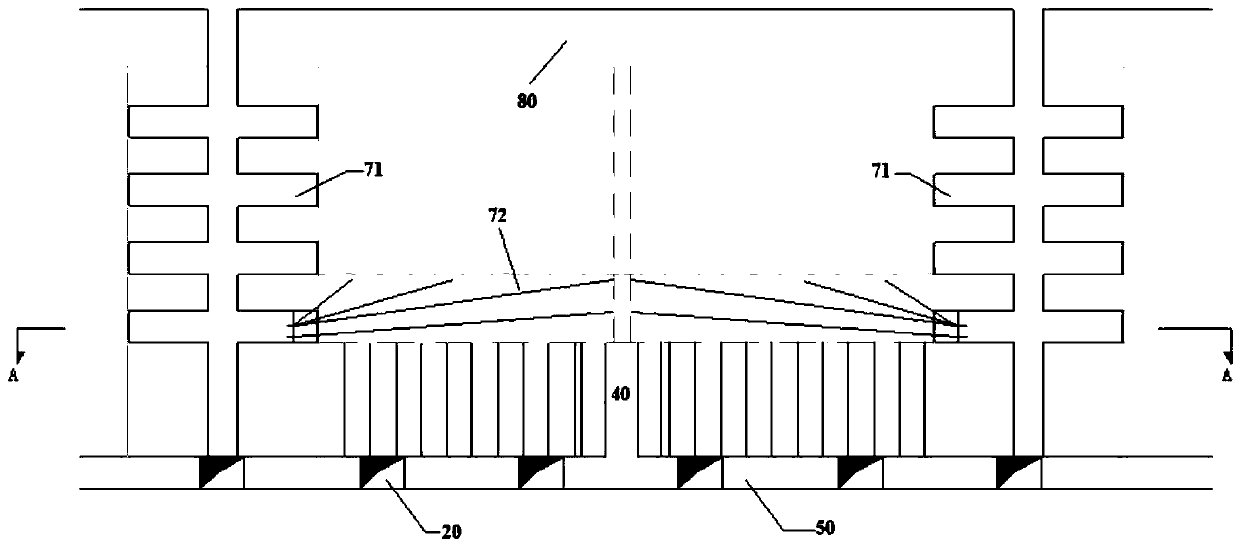

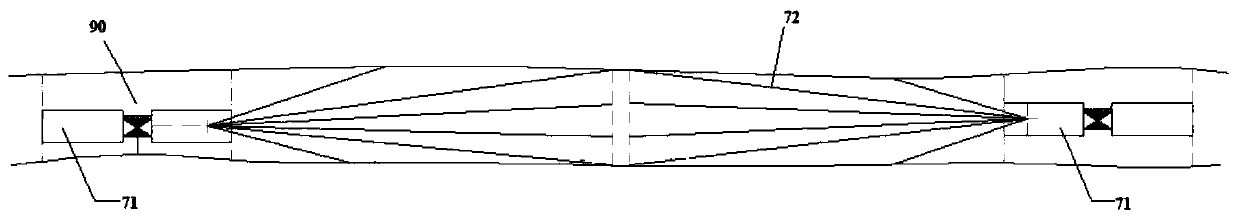

Multi-functional trolley for subway station construction

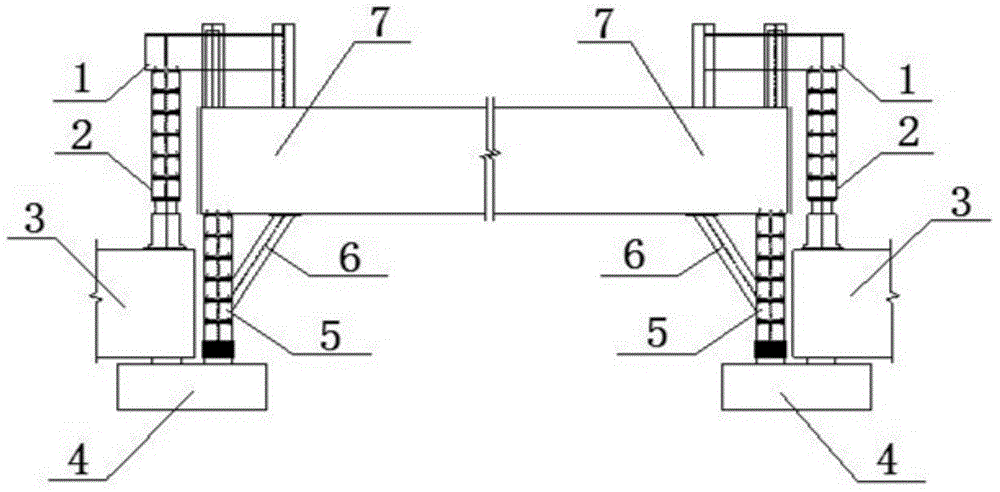

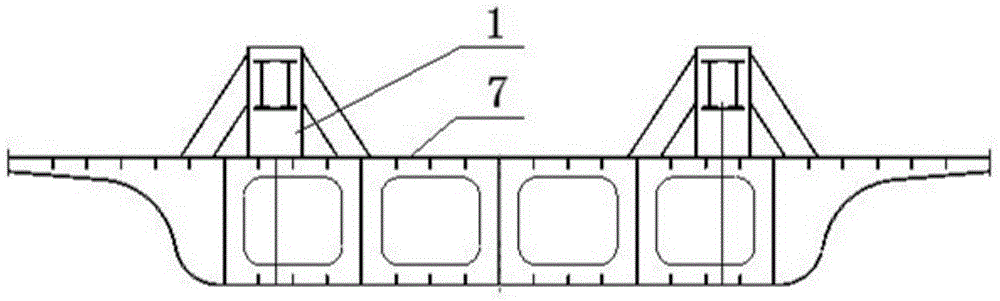

ActiveCN104763446AQuick releaseImprove construction efficiencyUnderground chambersTunnel liningSubway stationSafety risk

The invention discloses a multi-functional trolley for subway station construction. The multi-functional trolley comprises a trolley main frame (1), a top form (2), side forms (3) and a trolley base (5); the trolley base (5) is located below the trolley main frame (1) and fixedly connected with the bottom of a column (11); the side forms (3) are located on the bilateral sides of the trolley main frame (1) respectively and fixedly connected with the column (11); each side form (3) is fixedly connected with the column (11) through at least two rows of side form oil cylinders (4); each end of the top form (2) is provided with a hinged rotating shaft (6) which is connected with an axillary angle formwork (7). According to the multi-functional trolley for the subway station construction, the construction is performed through the steel form trolley and accordingly side wall concrete and roof concrete can be poured simultaneously and accordingly the construction efficiency is improved, the construction quality of a station structure is improved, the construction safety risk is reduced, the working intensity of workers is reduced, and the safe, high quality, efficient and harmonious construction purpose is achieved.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +1

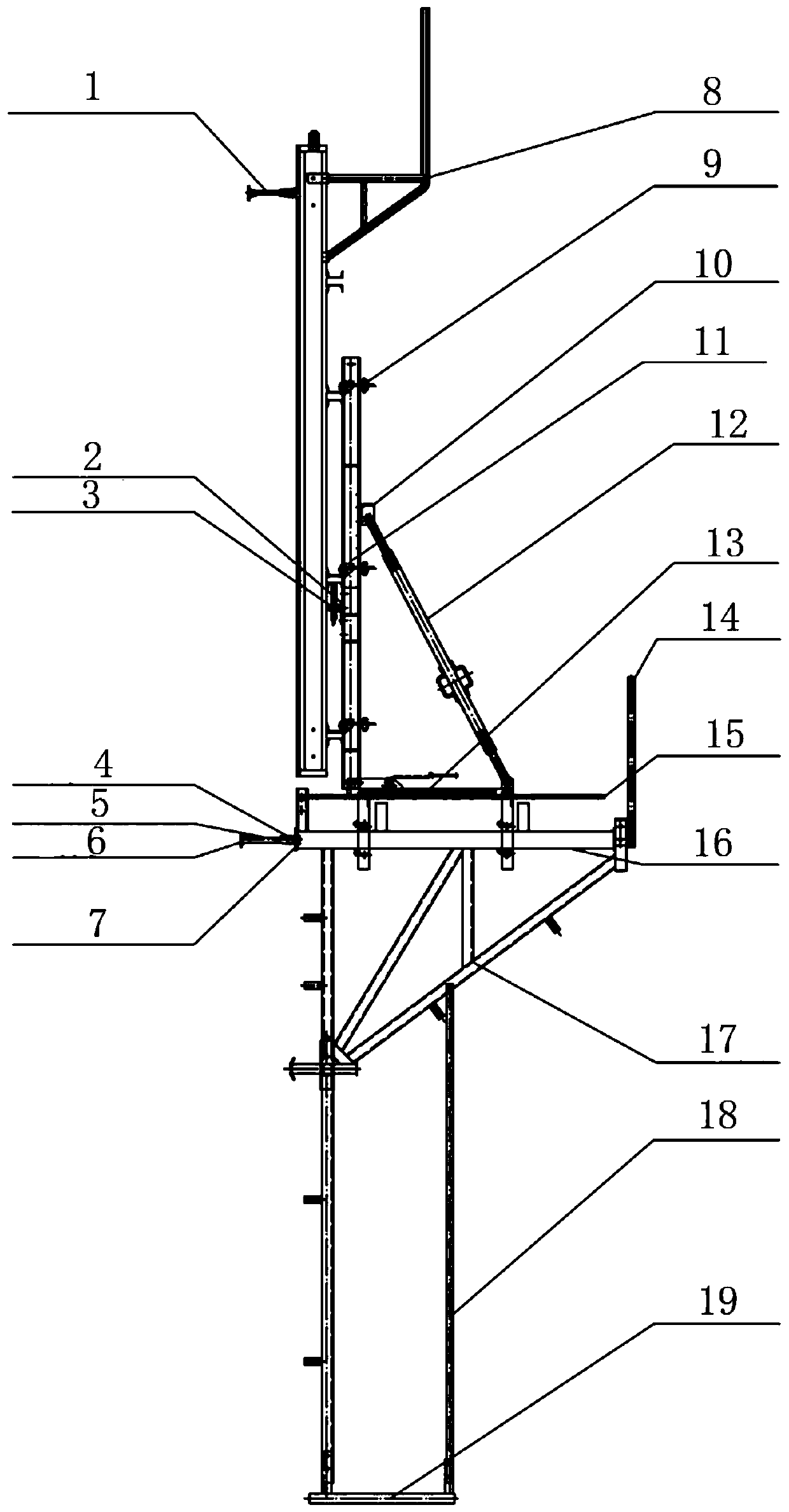

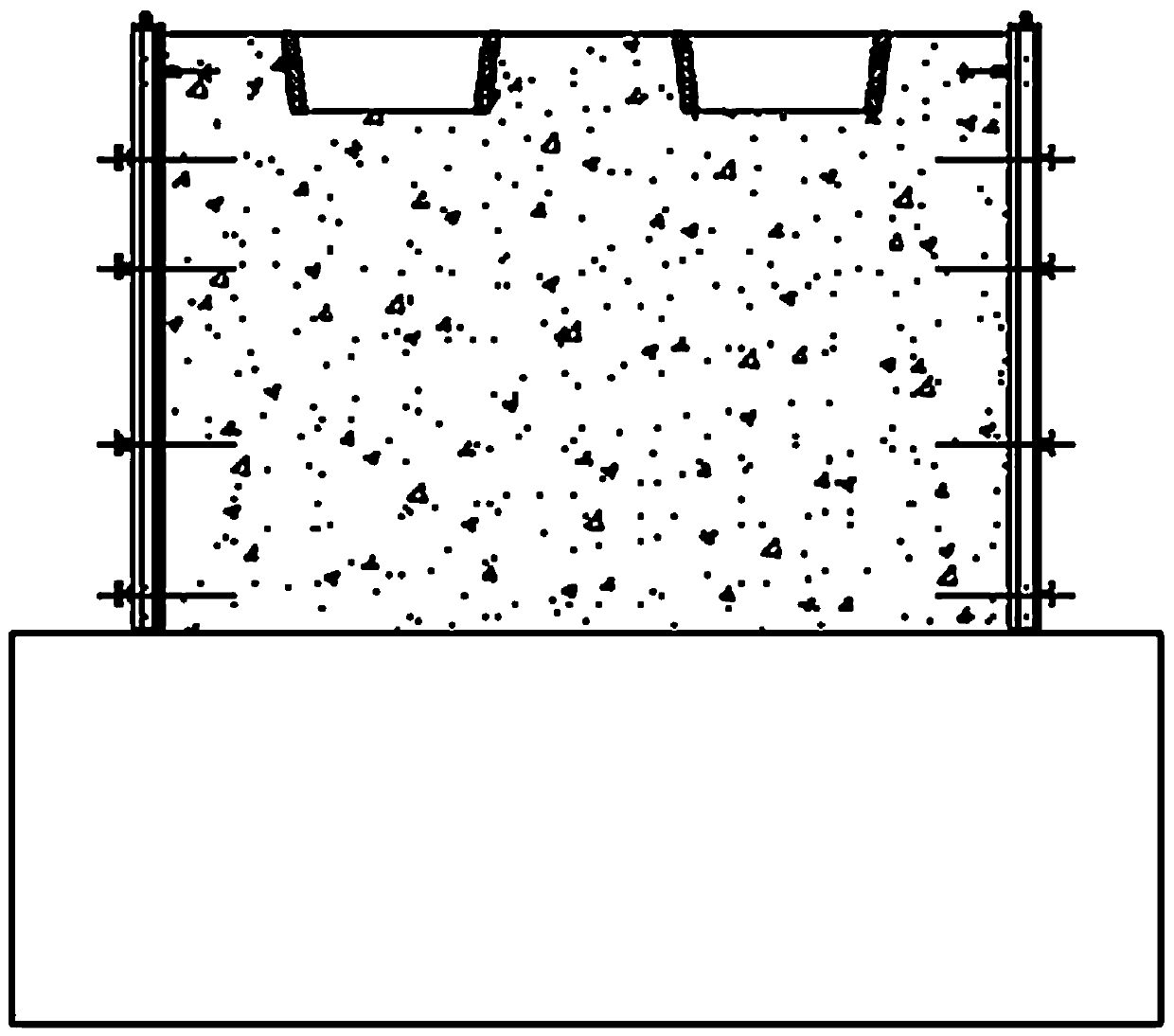

Bridge hollow-pier cantilever formwork and construction method thereof

InactiveCN109989347AEasy constructionEasy to installBridge structural detailsBridge erection/assemblyEngineeringCantilever

The invention discloses a bridge hollow-pier cantilever formwork and a construction method thereof and belongs to the technical field of road construction. The problems of long construction period, poor quality effect and high safety risk existing when an existing bridge high-pier column is in the form of a hollow pier and a shaped steel mold is adopted are solved. The bridge hollow-pier cantilever formwork is short in construction period, good in overall appearance quality, free of layered casting marks and does not need subsequent large-area modification, a construction process is simple, the technology is easy to master, the bridge hollow-pier cantilever formwork is convenient to operate and reliable in quality, is suitable for construction on a narrow site, is beneficial to clean and safe civilized construction on the site, creeping formwork equipment, a hanging operation platform and safety protectors are connected into a whole, aerial work is relatively safe, construction heightis not limited, a creeping formwork and the operation platform rise layer by layer, and compared with conventional formwork turnover construction, construction safety risks are greatly reduced.

Owner:中交中南工程局有限公司 +1

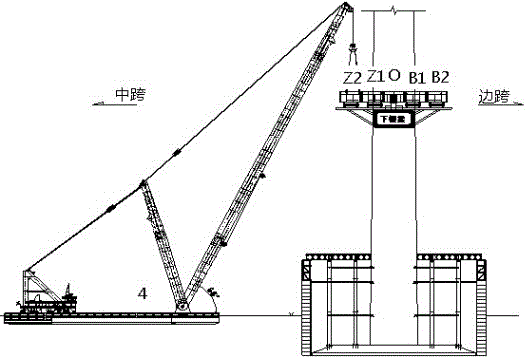

Construction method of superlong cable beam-free sections of cable-stayed bridge

ActiveCN106522101AIncrease the number ofIncrease construction costsBridge erection/assemblyCable stayedTower

The present invention relates to a construction method of superlong cable beam-free sections of a cable-stayed bridge. The first stage refers to the construction of five middle beam sections: the bracket+floating crane installation method is adopted, that is, the five cable beam-free sections in the middle of a tower area are sequentially hoisted up and placed on a lower beam bracket by using a floating crane, and tower beam temporary restraints are installed after the beams are connected into a whole. The second stage refers to the construction of two beam sections at the two ends: the platform+deck crane installation method is adopted, that is, the beam sections at each end are connected together on the backfield in advance and then stored on cofferdam top platforms on the both sides of a main tower, a deck crane above lifts and installs the beam sections, the lifting of the deck crane is conducted by using a midspan-and-then-sidespan asymmetry method, and the counterweight is increased or decreased in the construction process to decrease the unbalanced bending moment in the construction process. The construction method has unique advantages in terms of construction economy, construction cycle and construction safety, and the purpose of not applying floor steel pipe piles is realized.

Owner:ROAD & BRIDGE EAST CHINA ENG +1

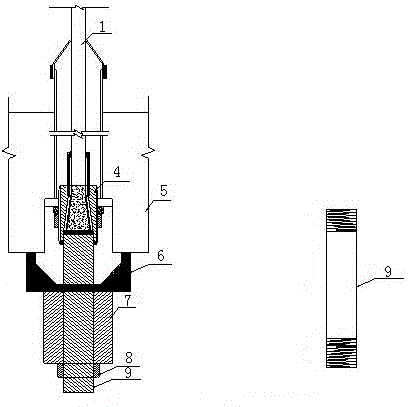

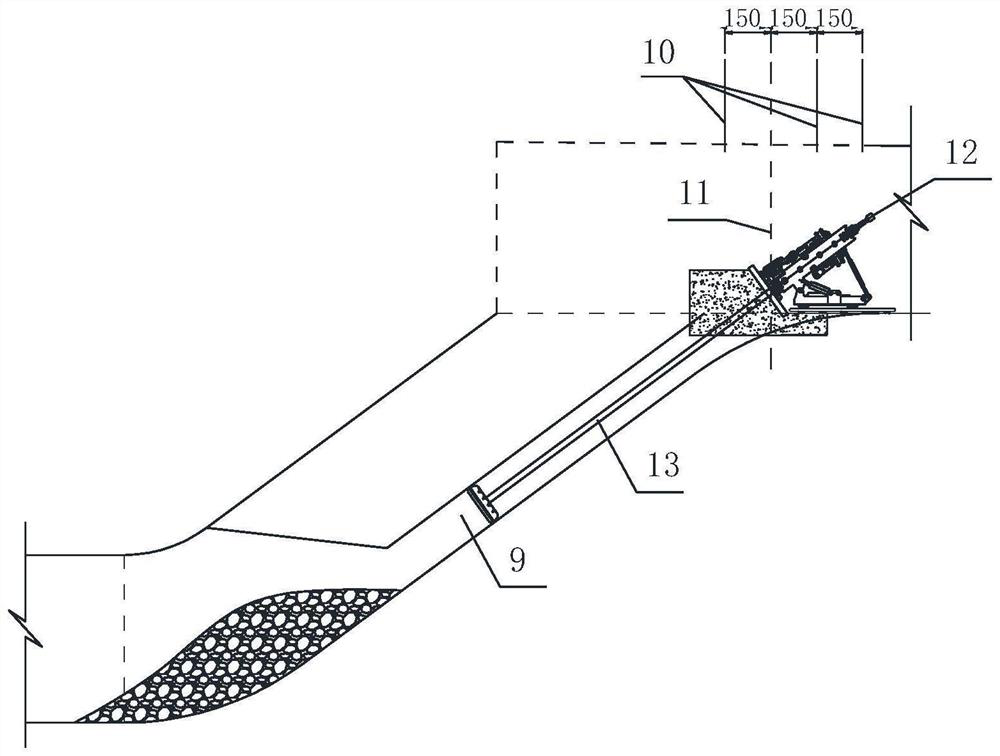

Pouring machine and pouring method for concrete of road shoulder on high-speed railroad bed section

ActiveCN102747733AAchieve improvementEffectively control the slope of the slopeFoundation engineeringEngineeringSubgrade

The invention discloses a pouring machine and a pouring method for concrete of a road shoulder on a high-speed railroad bed section. The pouring machine comprises a rectangular frame, wherein a hopper is arranged on the upper front part of the rectangular frame; a generator is arranged on the rear part of the rectangular frame; a pair of travelling wheels are respectively arranged on front and rear sides under the rectangular frame and are just arranged on a travelling rail on a railroad bed cable slot; an operating shelf is hinged with one side of the rectangular frame; an auxiliary wheel is arranged on a longitudinal beam outside the operating shelf; and a paving scraper, a vibrating operation pedal, a leveling roll and a plaster plate are successively arranged above the operating shelf from front part to rear part. During a pouring process, the travelling wheels of the frame and the travelling rail on the railroad bed cable slot are arranged on the railroad bed in a matching form, the operating shelf is placed bias above a concrete pouring area and the auxiliary wheel is arranged on a side slope of the railroad bed; the hopper is used for receiving and storing materials and the concrete is poured into the pouring area through a discharging port; the paving scraper is used for uniformly paving and scraping the concrete; after vibrating, the leveling roll is used for upward leveling the downward flowing concrete; and lastly, the plaster plate is used for realizing the smoothing of the concrete surface.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

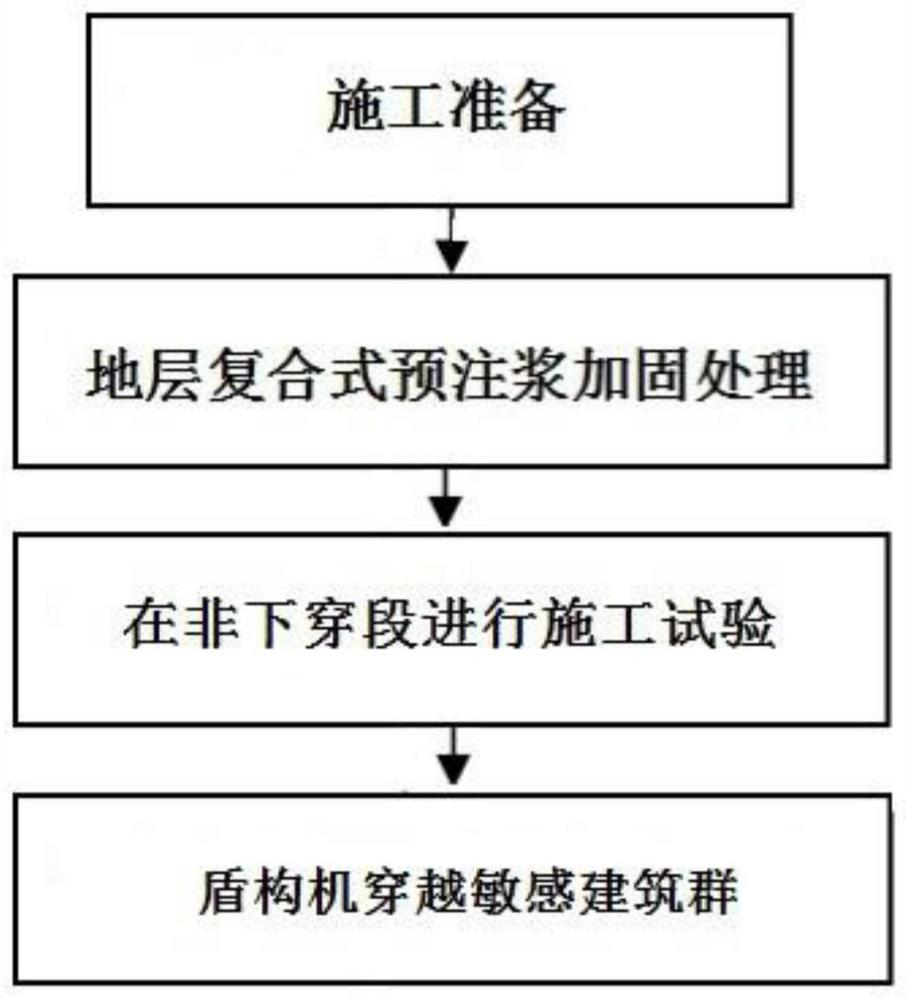

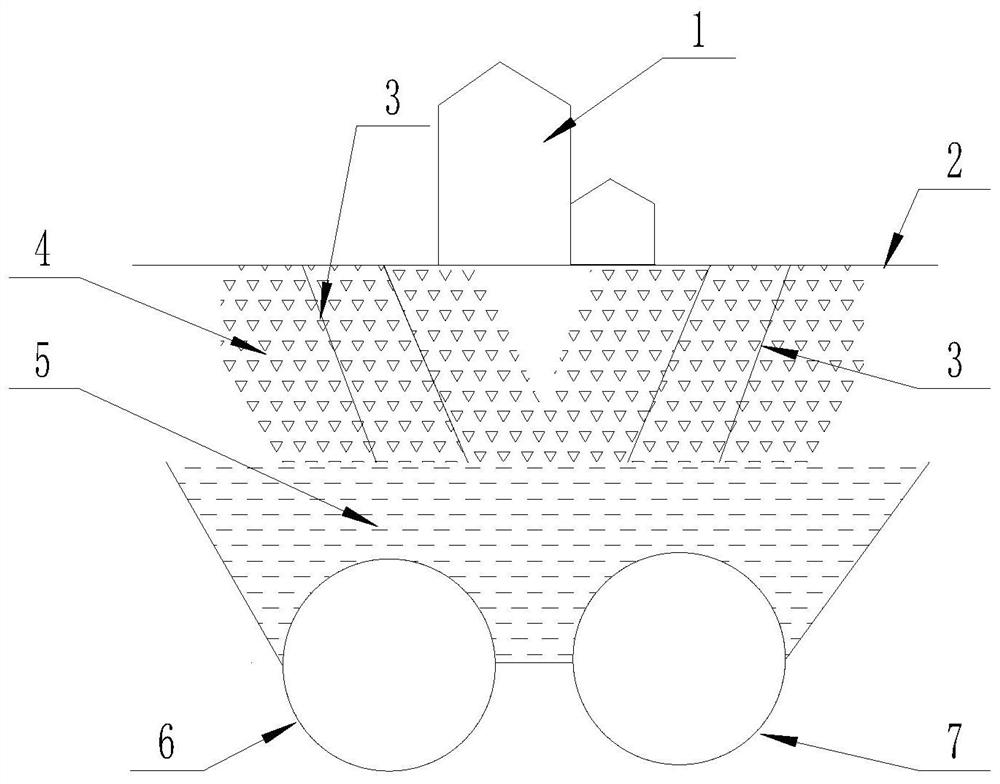

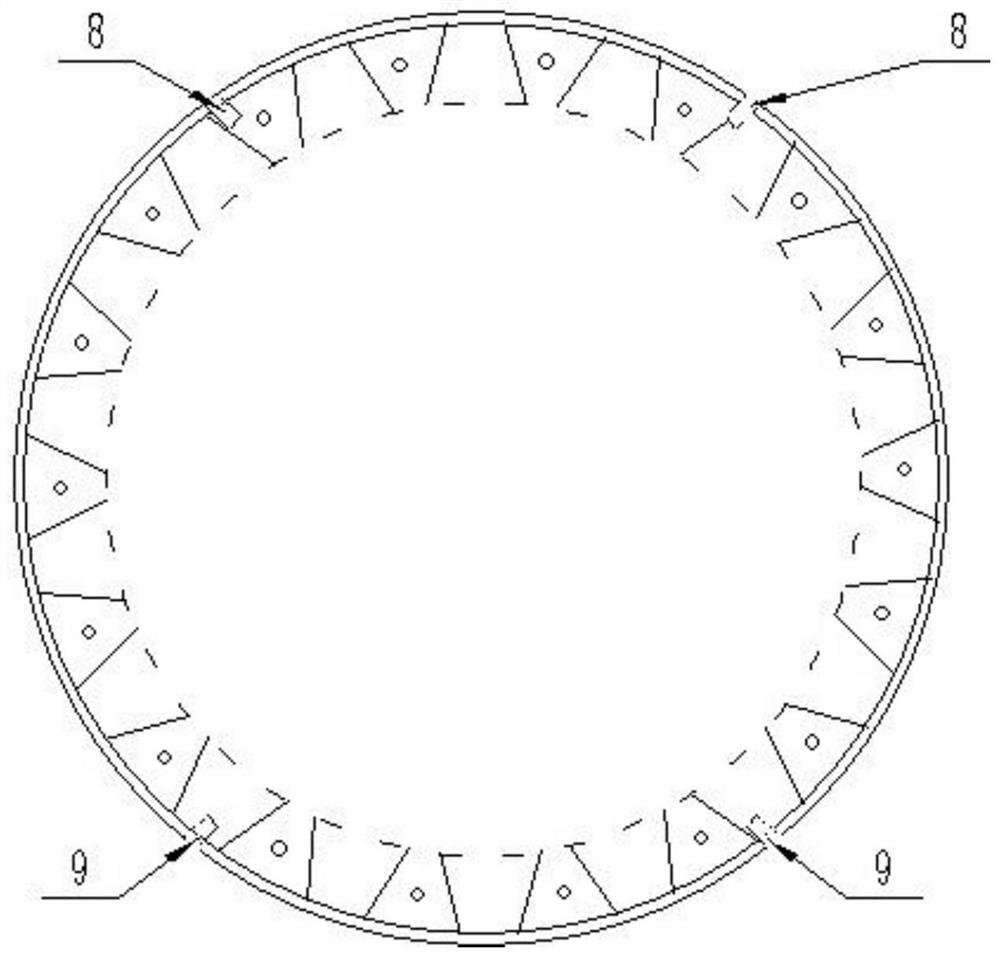

Construction method for shield tunnel to underneath pass through sensitive buildings in shallow-buried soft stratum

ActiveCN111852485ASimple stepsEasy constructionUnderground chambersTunnel liningStructural engineeringShield tunneling

The invention belongs to the technical field of subway construction, and particularly relates to a construction method for a shield tunnel to underneath pass through sensitive buildings in a shallow-buried soft stratum. Through the four steps of construction preparation, combined type pre-grouting reinforcement treatment on the stratum, construction testing in a non-underpass section, and passingthrough the sensitive buildings by a shield tunneling machine, ground surface settlement and deformation are effectively controlled during underneath passing of the shield tunneling machine, and the safety of the sensitive buildings is guaranteed.

Owner:CCCC SECOND HIGHWAY ENG CO LTD

Suspension bridge main span suspension-cable-free beam section mounting method

InactiveCN109653094AAdvantages of installation methodOptimize layoutSuspension bridgeBridge erection/assemblyTowerCost savings

The invention provides a suspension bridge main span suspension-cable-free beam section mounting method. The method includes steps: (1) installing a beam storage slide supporting frame, a cable loading crane, a temporary suspension cable and a temporary stay cable, and guaranteeing that the cable loading crane is positioned at a hoisting position at the front end of the beam storage slide supporting frame; (2) sequentially transferring land and shoal beam sections, a closure section and a suspension-cable-free beam section to the beam storage slide supporting frame; (3) sequentially hoisting the last normal beam section and land and shoal beam section by the cable loading crane; (4) moving the closure section and the suspension-cable-free beam section towards the front end of the beam storage slide supporting frame by a certain distance; (5) transferring the suspension-cable-free beam section to a main tower crossbeam; (6) closing. The suspension bridge main span suspension-cable-freebeam section mounting method has advantages that beam storage supporting frames close to piers are avoided, so that cost saving is realized, and construction safety risks are reduced.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP +1

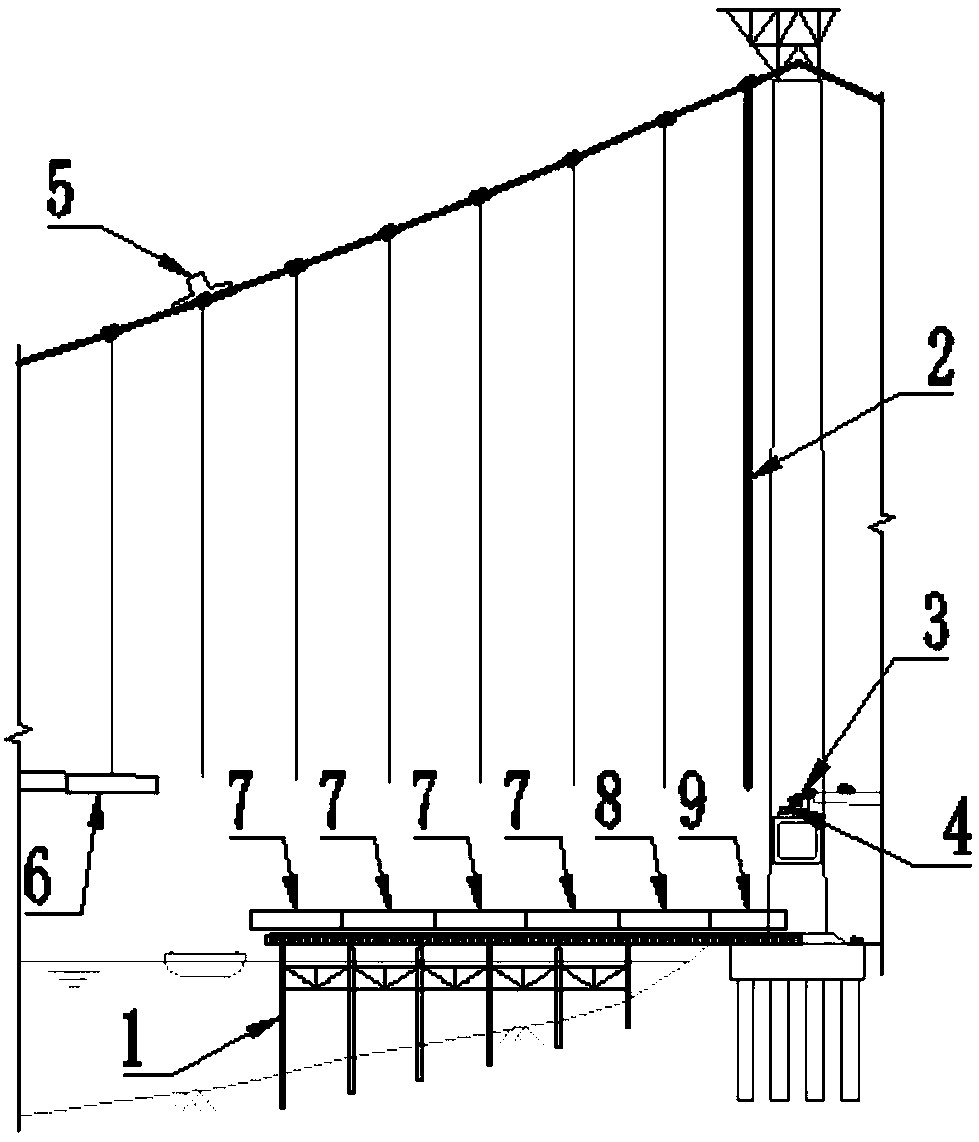

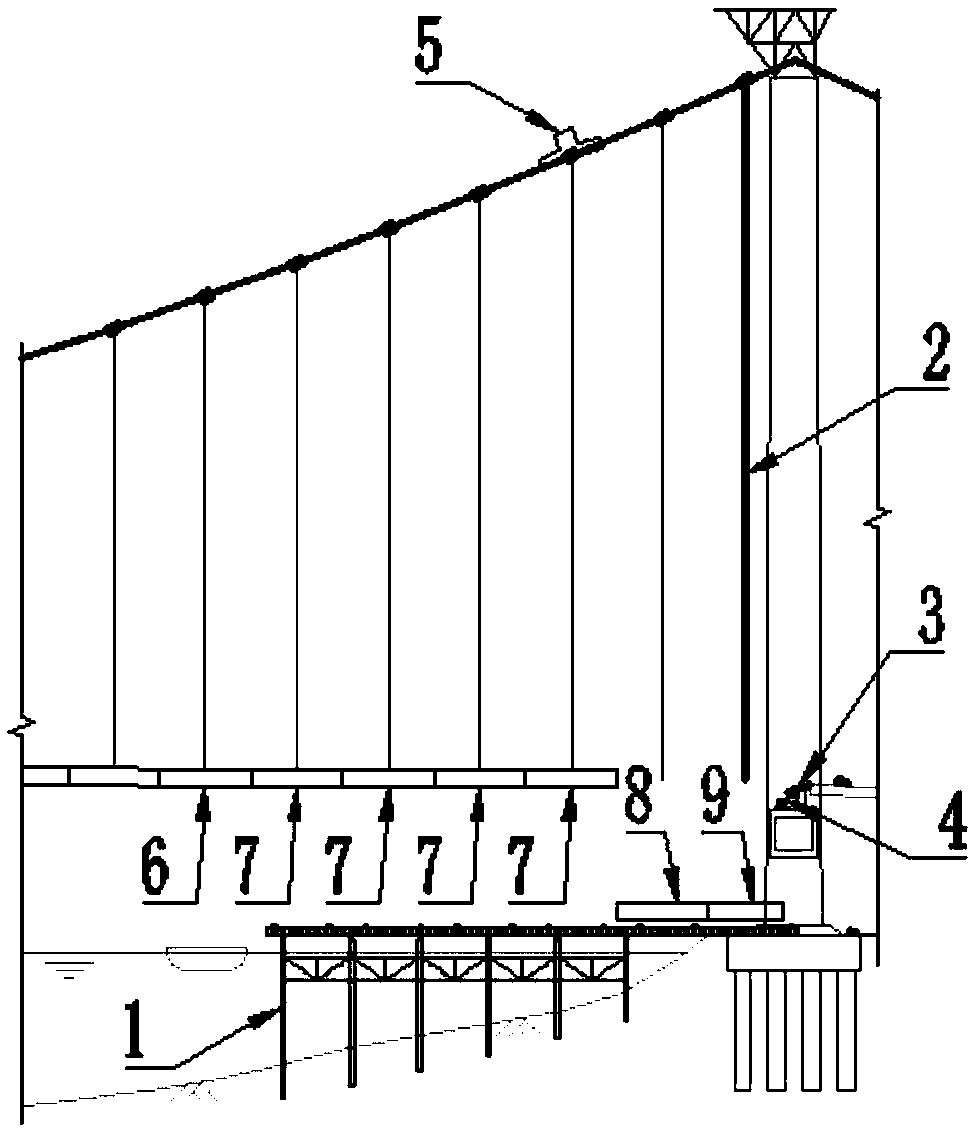

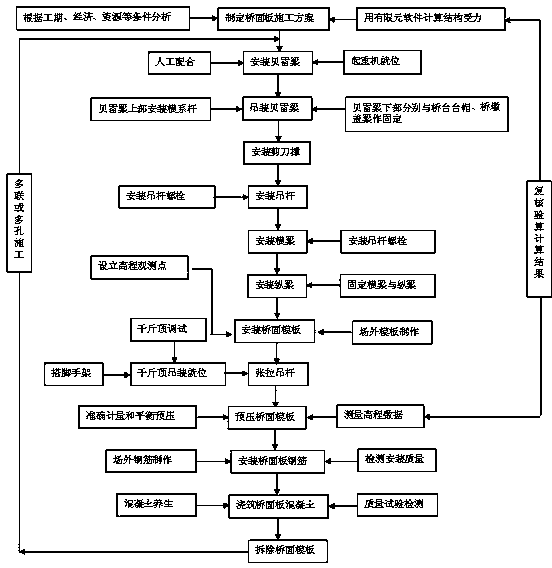

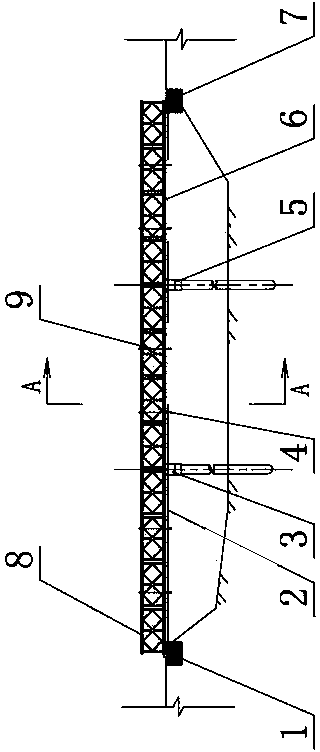

Suspension type cast-in-place template curved bridge construction method

ActiveCN103774560AImprove carrying capacityEasy to dismantleBridge erection/assemblyEcological environmentEngineering

The invention discloses a suspension type cast-in-place template curved bridge construction method which is a construction method adopting a curved bridge faceplate cast-in-place template to be suspended on a longitudinal BeiLei beam. In the construction method, interrelated members involved comprise two BeiLei beams, cross bars, a shearing support, a cross beam, a longitudinal beam, a fixed steel plate, a suspender, a suspender bolt, an inner trapezoid block, aan outer trapezoid block, a deck form and the like, the characteristics of high bearing capability of the BeiLei beams, easiness in demounting and assembling operations, and repeated use of recycled material are mainly used, the entire structure is safe and reliable, not only can the problem of erecting a support template under a bridge be solved, but also the construction risks and engineering cost are reduced, the construction speed is increased, a better effect on an aspect of protecting ecological environment can be played, and the method is particularly suitable for cast-in-place construction of all straight, oblique, curved and slope cast-in-place deck slabs of half roadbeds and half bridges in mountainous areas or scenic areas.

Owner:ZHEJIANG DASHUN HIGHWAY CONSTR

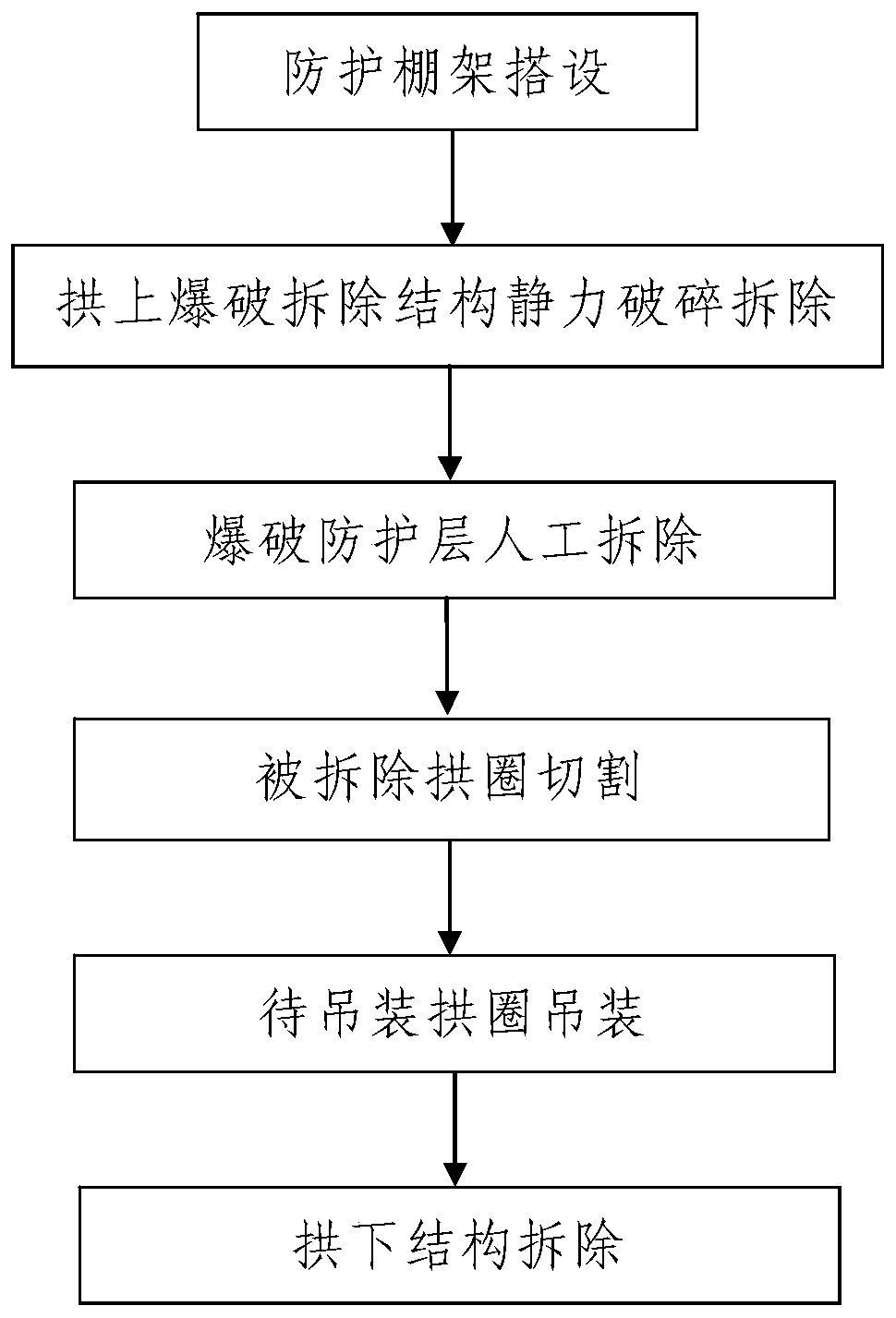

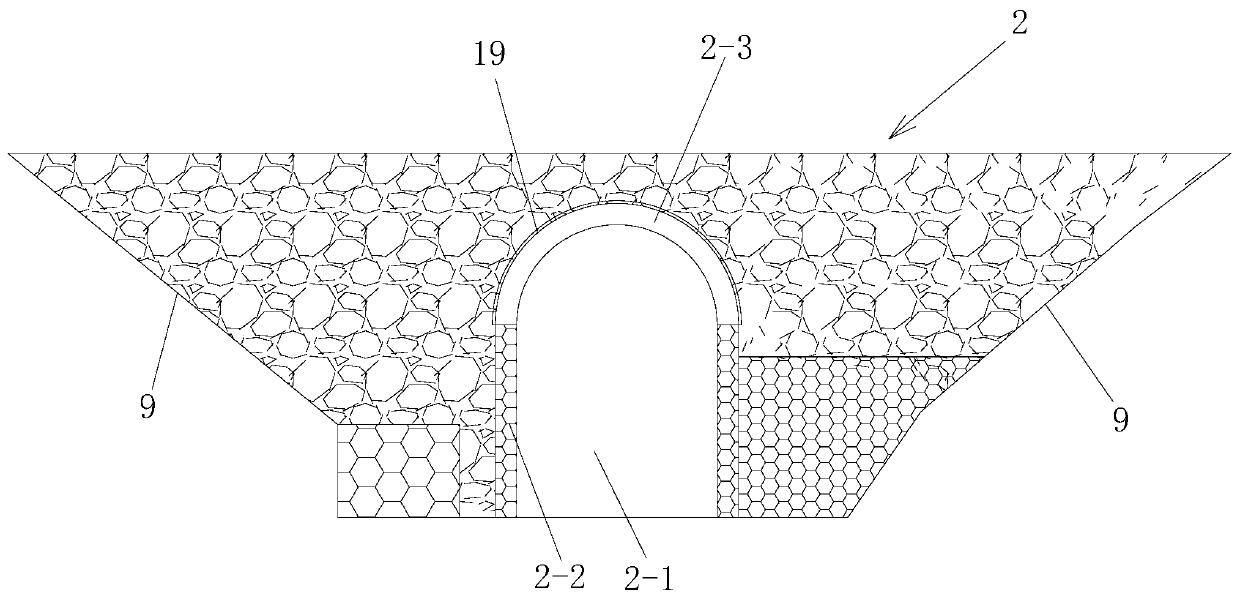

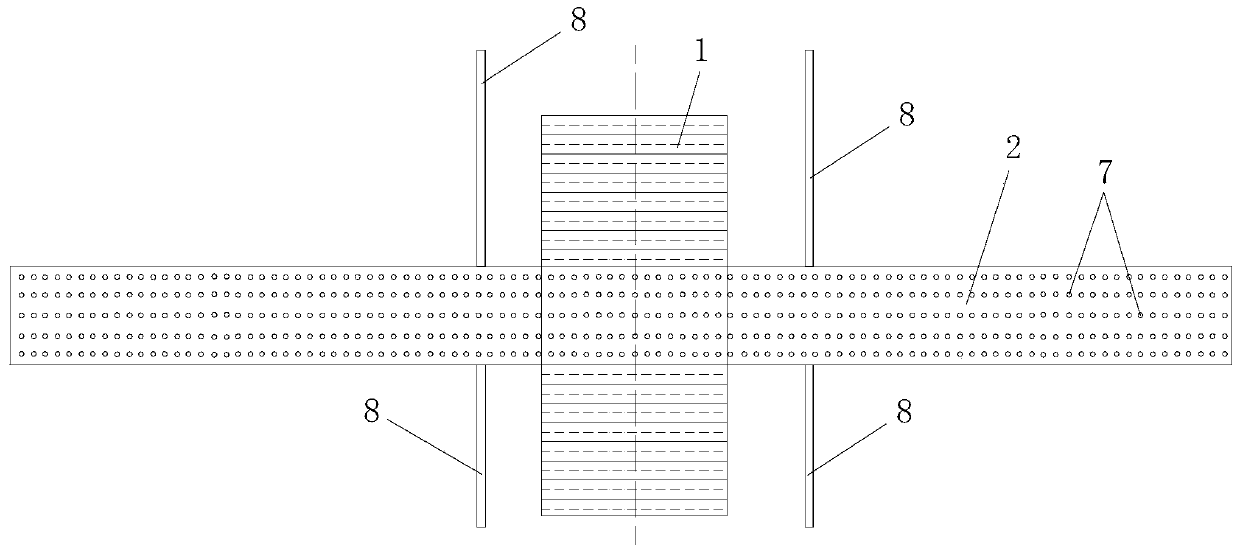

Demolition construction method for overpass existing line arch bridge

ActiveCN110904867AThe method steps are simpleReasonable designBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a demolition construction method for an overpass existing line arch bridge. The demolition construction method comprises the steps: 1, erecting a protective shed frame; 2, carrying out static crushing demolition on the arch blasting demolition structure; 3, manually removing the blasting protection layer; 4, cutting the removed arch ring; 5, hoisting the arch ring to be hoisted; and 6, dismantling the under-arch structure. The method is simple, reasonable in design, easy and convenient to construct and good in using effect; the protection shed frames fixed to the frontside and the rear side of the removed arch bridge are adopted for effective protection, meanwhile, the structure on the arch of the removed arch bridge is removed in the mode that static crushing andmanual chiseling are combined, it is guaranteed that a plain concrete arch ring cannot be damaged in the static crushing process, and an existing spanned railway line cannot be disturbed. After the arch ring is exposed, the removed arch ring is cut and decomposed through a rope saw and then hoisted and removed, then the under-arch structures on the left side and the right side are rapidly removed,the construction period can be effectively shortened, the arch bridge removing efficiency is improved, and the removing process is safe and reliable.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

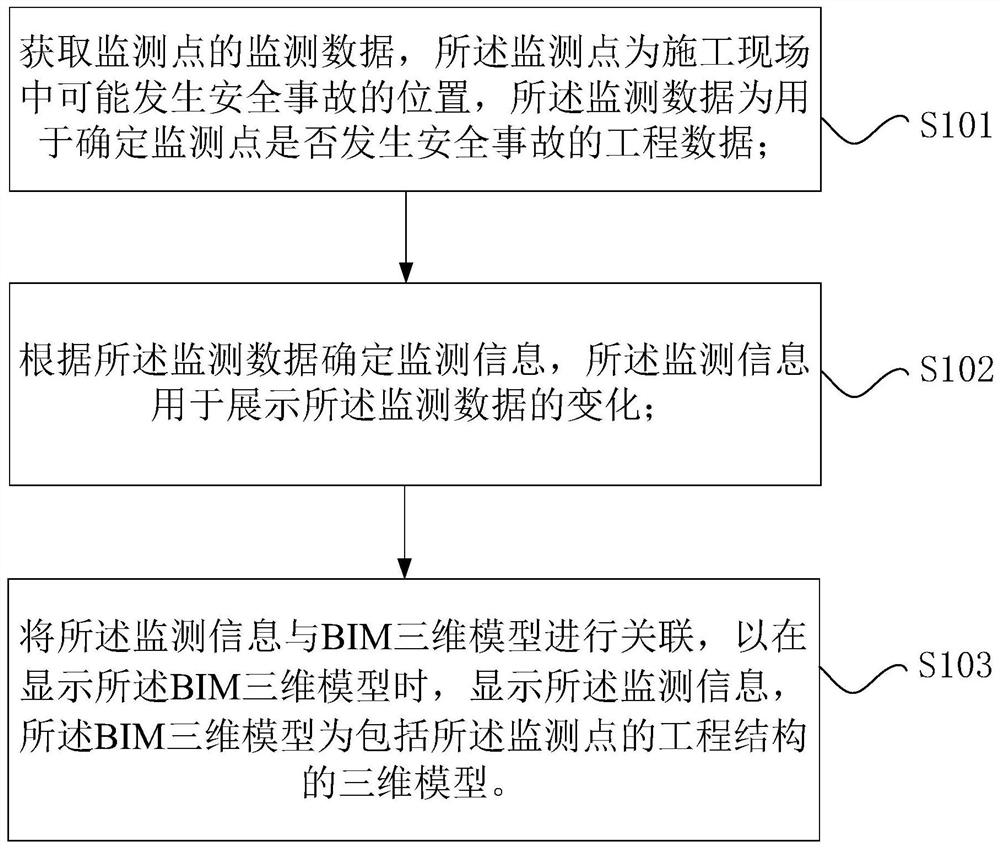

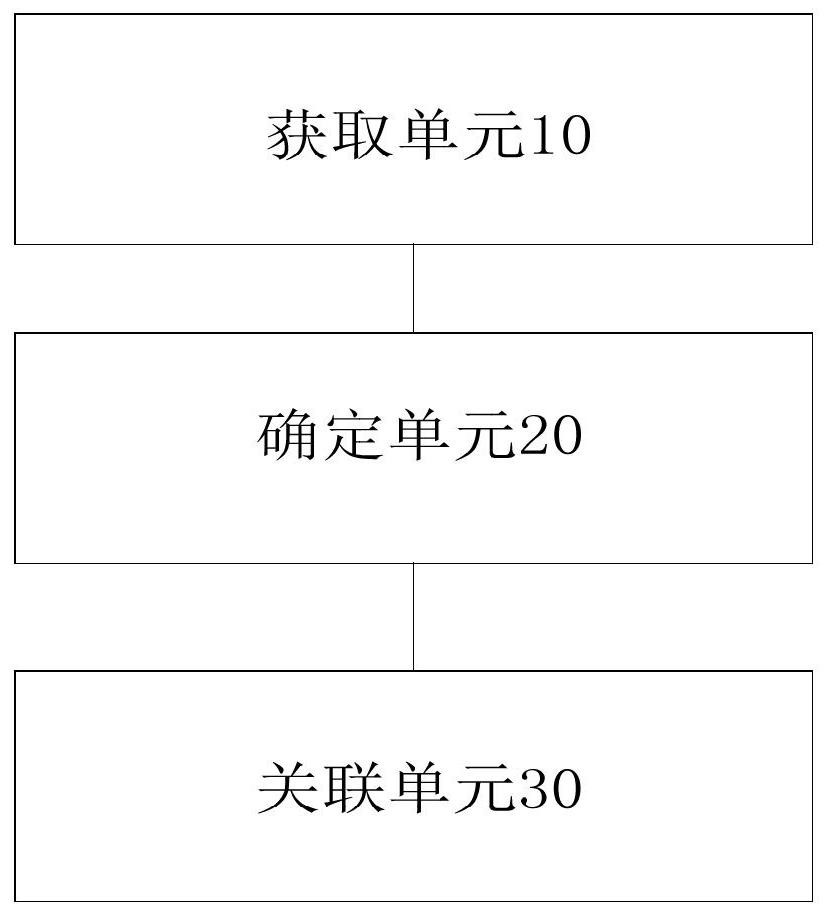

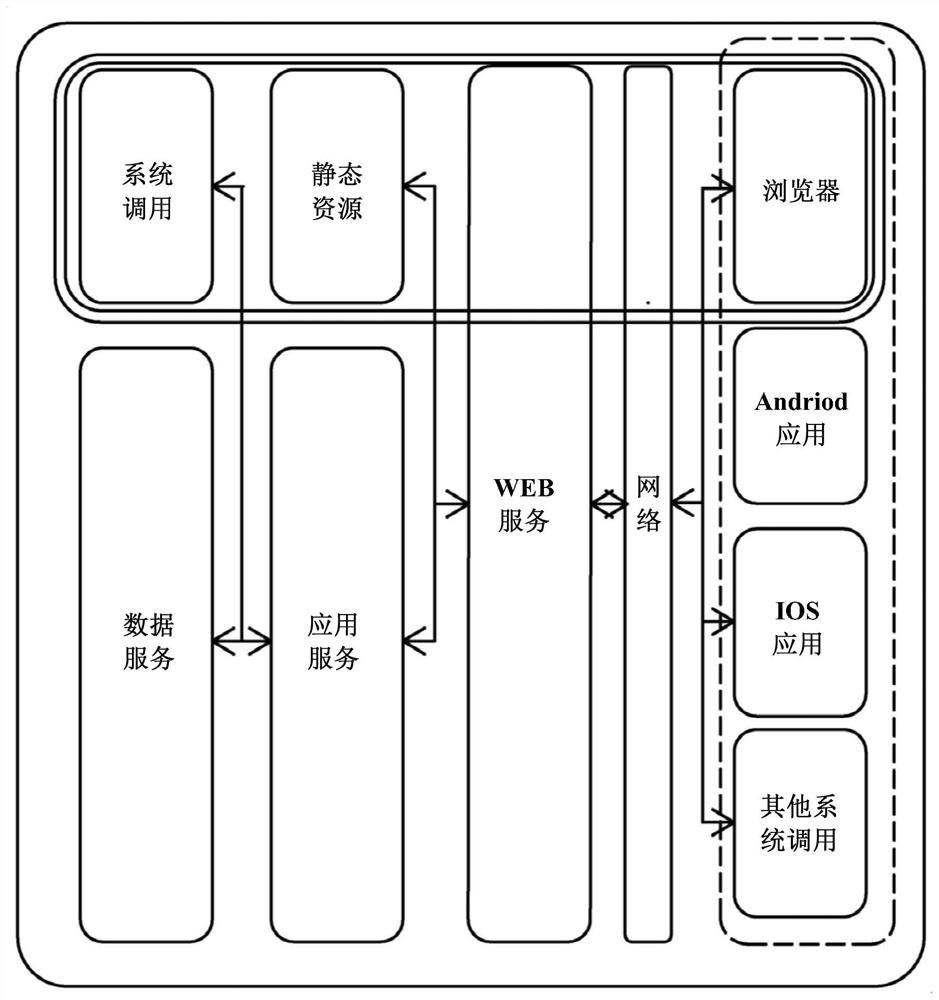

Engineering data monitoring method, engineering data monitoring device and engineering data monitoring system

InactiveCN111741098AIncrease profitSecurity incident fastAlarmsTransmissionMonitoring siteData mining

The invention provides an engineering data monitoring method, an engineering data monitoring device and an engineering data monitoring system. The engineering data monitoring method comprises the following steps: acquiring monitoring data of a monitoring point; determining monitoring information according to the monitoring data, wherein the monitoring information is used for displaying changes ofthe monitoring data; and associating the monitoring information with the BIM three-dimensional model so as to display the monitoring information when the BIM three-dimensional model is displayed. According to the method, the corresponding monitoring information is determined according to the monitoring data of the monitoring points; the monitoring information can be alarm information, prompt information, an analysis curve and the like; the monitoring information is displayed when the BIM three-dimensional model is displayed; the monitoring information is matched with monitoring points in the BIM three-dimensional model, all positions where safety accidents may occur in a construction site can be monitored, and corresponding monitoring points can be quickly locked according to the monitoring information, so that the occurrence of the safety accidents can be timely reminded and avoided, the information utilization rate is greatly improved, and the construction safety risk is further reduced.

Owner:CHINA RAILWAY 14TH BUREAU GRP LARGE SHIELD ENG CO LTD +1

Semiautomatic self-climbing hoisting mechanism of light steel structure under closed structure

InactiveCN106013818AShorten the interval between working hoursImprove construction efficiencyBuilding material handlingSocial benefitsSemi automatic

The invention relates to a semiautomatic self-climbing hoisting mechanism of a light steel structure under a closed structure. The semiautomatic self-climbing hoisting mechanism comprises a main load-bearing truss body and a hydraulic jacking mechanism, which are arranged in a core drum, wherein a climbing guide rail which extends along the vertical direction is also arranged inside the core drum, the main load-bearing truss body is matched with the climbing guide rail, and the hydraulic jacking mechanism can drive the main load-bearing truss body to move along the climbing guide rail; and a material to be hoisted is driven to transfer between the interior and the exterior of the core drum by virtue of a material platform (particularly an article to be hoisted from the exterior of the core drum is transported into the core drum). The construction efficiency is improved, the interval of the construction period is shortened, the construction period is greatly shortened, the construction cost is greatly saved, the construction safety risk is effectively reduced, and good social benefit, environmental benefit and economic benefit can be achieved.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Construction method capable of replacing steel support substitution by full space supports

InactiveCN106567395ASave engineering expensesReduce construction safety risksArtificial islandsCellarsSubway stationEngineering

The invention discloses a construction method capable of replacing steel support substitution by full space supports. The construction method particularly comprises the following steps: (1) after the bottom plate construction of a subway station main body structure is finished, constructing side walls at the bottom, utilizing side pressure generated during concrete pouring and auxiliary providing a fastener to guarantee that the horizontal direction of the full space supports to be closely attached and propped tightly, and pouring the side walls and middle plates simultaneously; (3) after the bottom plate and the side walls under the steel support substitution are poured and reach the strength, continuously erecting the full space supports; (3) after erecting the full space supports in the step (2), disassembling third steel supports on part of the full space supports, continuously erecting the full space supports and constructing the middle plates and the side walls of the main body structure; and (4) after the construction of the main body structure is finished and the strength reaches the design requirement, disassembling the full space supports. According to the construction method, the procedures can be simplified, the work efficiency can be improved, the construction period can be shortened, construction safety and convenience are improved, the construction cost is saved and the construction efficiency is improved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD

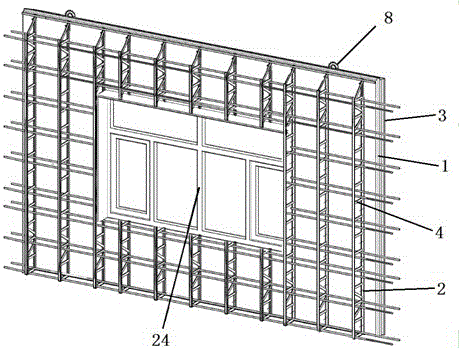

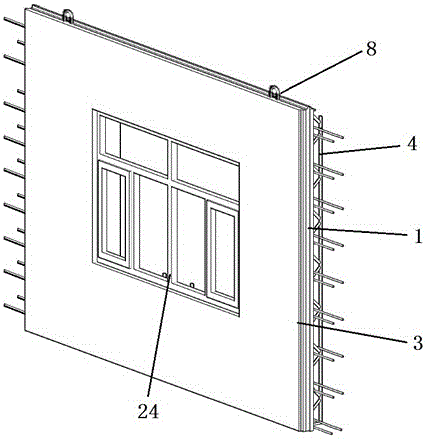

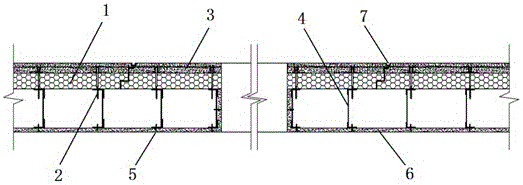

Fabricated cast-in-place concrete sandwich insulation wall steel frame formwork system and connecting parts

The invention provides a fabricated cast-in-place concrete sandwich insulation wall steel frame formwork system (for short, a system) and connecting parts. The system is mainly composed of a concrete protection layer, an insulation layer, a truss, horizontal steel bars and non-dismantling cement boards or formworks. The insulation layer is formed by assembling insulation modules (boards) in a tongue-and-groove insertion mode, each insulation module (board) is fixed to one side of the truss through the connecting parts, and the concrete protection layer is laid outside the insulation layer. Each connecting part comprises a connection tap bolt, a positioning disc and a wire mesh fixing head, wherein a limiting protrusion is arranged on the outer side of the positioning disc. The system can be horizontally assembled on the ground, poured to be molded and integrally hoisted, the truss can be one part of steel bars of a bearing wall, after bearing wall concrete is poured, the system and the concrete structure are integrated, and the concrete composite wall with a sandwich insulation layer is formed. By means of the fabricated cast-in-place concrete sandwich insulation wall steel frame formwork system and the connecting parts, construction procedures of the sandwich insulation composite wall of an energy-saving building can be made simple, the easy construction property is high, the overall construction speed and labor efficiency of the energy-saving building can be greatly improved, construction safety risks are reduced, construction precision is effectively improved, and engineering quality is guaranteed; and meanwhile, technical support is provided for building industrialization.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

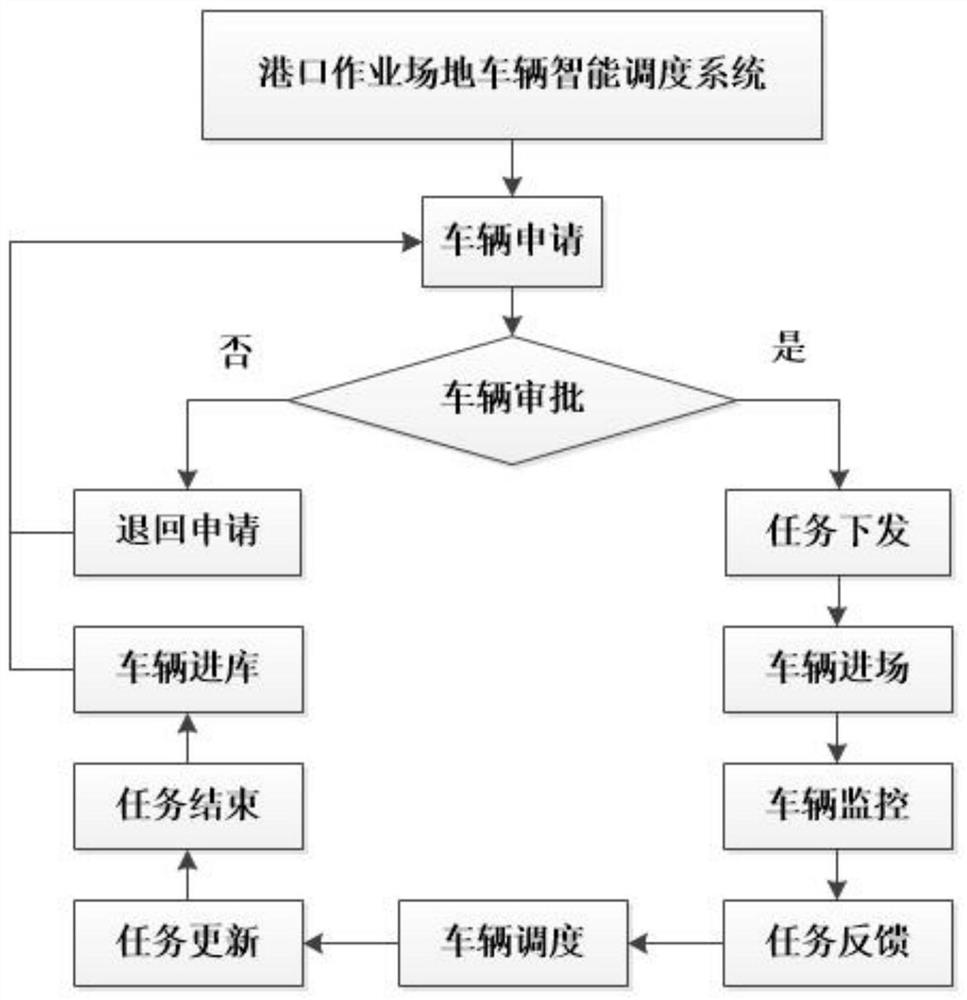

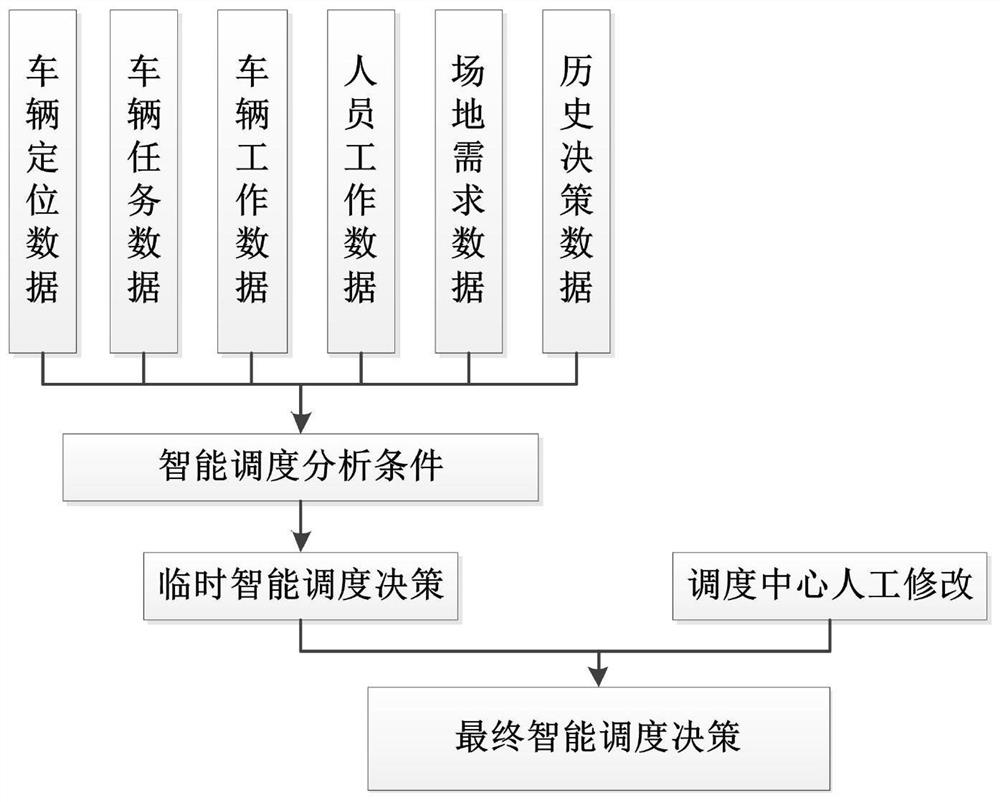

Intelligent scheduling decision-making method and decision-making system for vehicles in port operation site

InactiveCN111815122APromote standardization of managementImprove informatizationOffice automationResourcesVideo monitoringDecision system

The invention discloses an intelligent scheduling decision-making method and decision-making system for vehicles in a port operation site. The method comprises the steps of vehicle application, personnel allocation, task issuing, vehicle entry, vehicle monitoring, task feedback, vehicle scheduling, task updating, task ending and vehicle warehouse entry. The system belongs to the technical field ofvehicle intelligent scheduling and management, and comprises a data processing module, a vehicle application module, a GPS positioning module, a voice intercom module, a video monitoring module, a vehicle scheduling module and an APP module. According to the invention, the problems of inaccurate vehicle monitoring, unintelligent scheduling, unknown actual situation and the like in the prior art are solved; management of the project in the aspect of vehicle use is improved, the use condition of each vehicle is monitored in real time, reasonable distribution and timely exchange of work are ensured, remote dispatching and long-time idle standby state are avoided, and standardization, informatization and intellectualization of vehicle management are promoted. Meanwhile, the system is easy toinstall, maintain and operate, stable in operation, safe and reliable to use to the maximum extent.

Owner:安徽创米信息技术有限公司

Support beam falling method for surfaces of middle and small bridges and special support device

ActiveCN103981809ASolve the problem of narrow working surface and low construction efficiencyReduce the risk of falling beamsBridge erection/assemblyEconomic benefitsFalling risk

The invention aims to provide a bridge surface support mode, and aims to solve the difficult problem of the falling and supporting of the existing bridge. A support beam falling method for the surfaces of middle and small bridges comprises the steps that assistant support piers and jacking support piers are separately arranged; the assistant support piers are positioned at the lower parts of two ends of a steel girder; the tops of the assistant support piers are connected with the lower part of the steel girder; the jacking support beams are positioned at two side parts of the bridge and are connected to the top surface of the steel girder by jacking supports; the falling of the position of the steel girder is realized in a mode that the steel girder is alternatively supported by the assistant support piers and the jacking support piers. A special support device comprises the assistant support piers and the jacking support piers, wherein the assistant support piers are positioned at the lower parts of two ends of the steel girder and the tops of the assistant support piers are connected to the lower part of the steel girder; the jacking support piers are positioned at two side parts of the steel girder and are connected to the top surface of the steel girder by the jacking support. The assistant support piers and the jacking piers are separately arranged, so the problems of low construction efficiency and narrow work surface as all support piers are arranged at the position of bridge pier cover beams are solved, the beam falling risk is reduced and the economic benefits are improved.

Owner:中铁宝桥(宝鸡)路桥建设有限公司

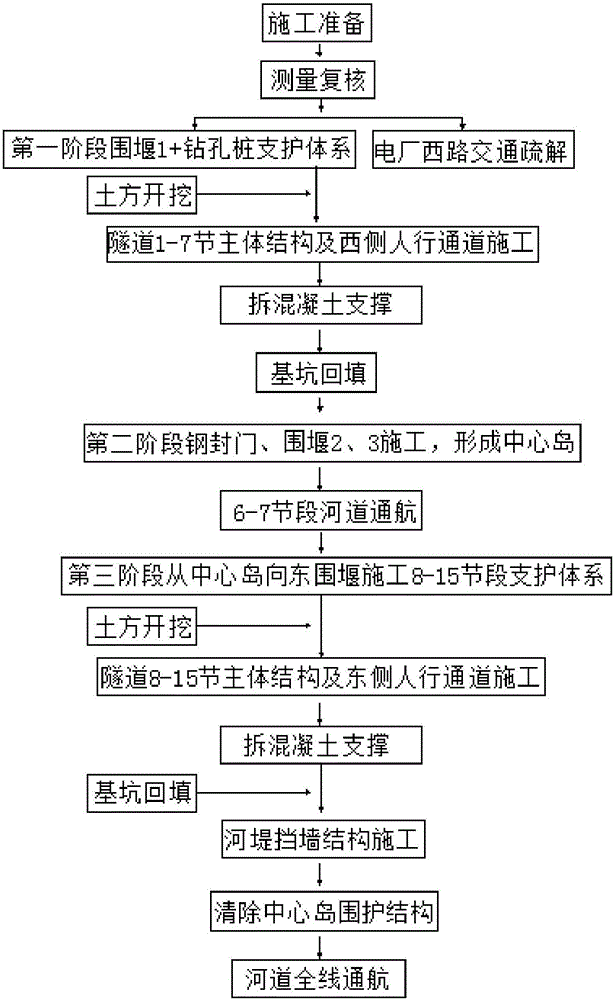

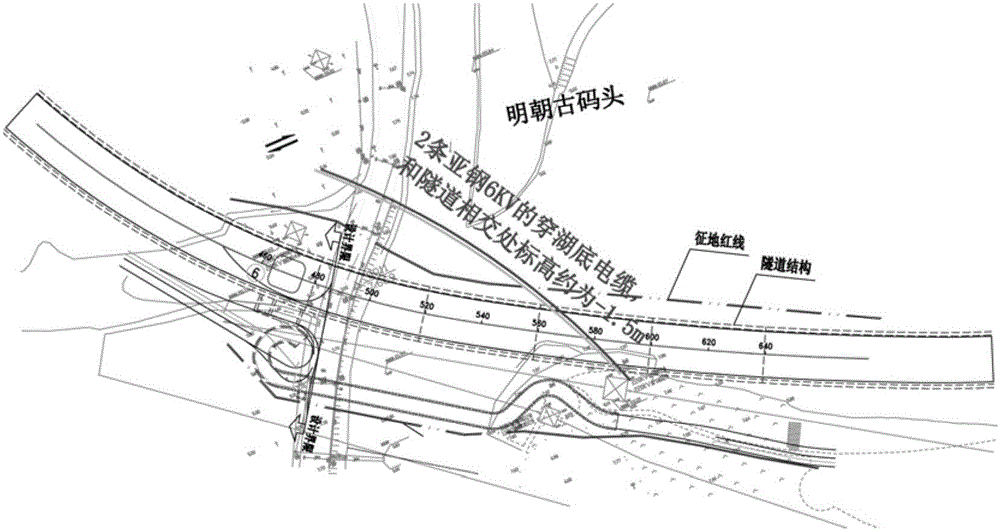

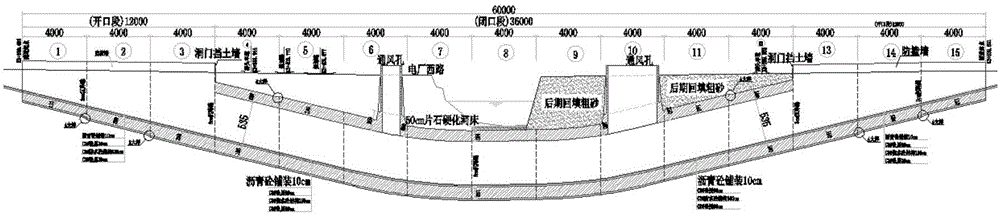

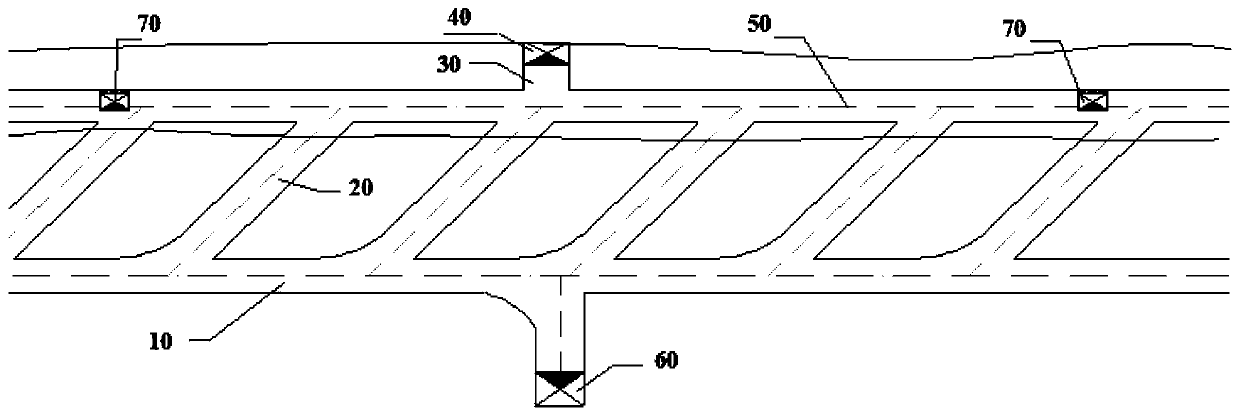

Shallow-buried tunnel section construction method

ActiveCN106640091AReduce the technical difficulty of constructionReduce construction safety risksFoundation engineeringTunnelsSteel platesMarine navigation

A shallow-buried tunnel section construction method comprises the following steps that tunnel front half section construction is carried out, wherein a supporting structure and a waterproof curtain are constructed from one side of a riverway to the center of the riverway to form a first cofferdam; tunnel center island construction is carried out, wherein a steel seal door and an inserted and hit steel plate pile are mounted at the position, on the inner side face of the riverway, of the first cofferdam, then the two sides of the position, of the inner side face of the riverway, of the first cofferdam are finished to form island heads, and a center island is formed; tunnel rear half section construction is carried out, wherein the center island and the other side of the riverway are utilized for constructing a supporting structure and a waterproof curtain to form a second cofferdam, tunnel rear half section construction is carried out after water drawing is carried out, and after construction is completed, full-line navigation opening up is restored. The shallow-buried tunnel section construction method has the advantages of being feasible in technology, economical, reasonable, simple in process, easy and convenient to operate and safe in construction and meets the development direction of the modern engineering technology, and therefore wide popularization prospects are achieved.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

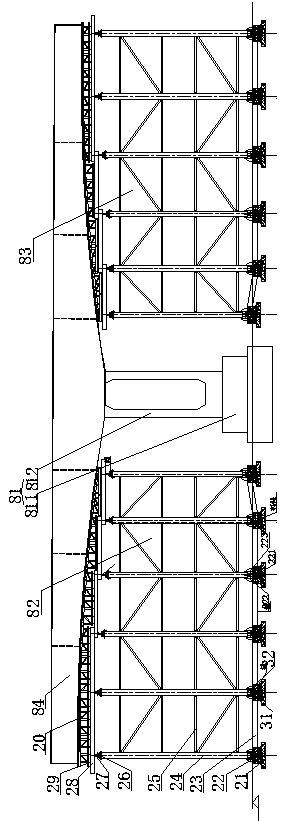

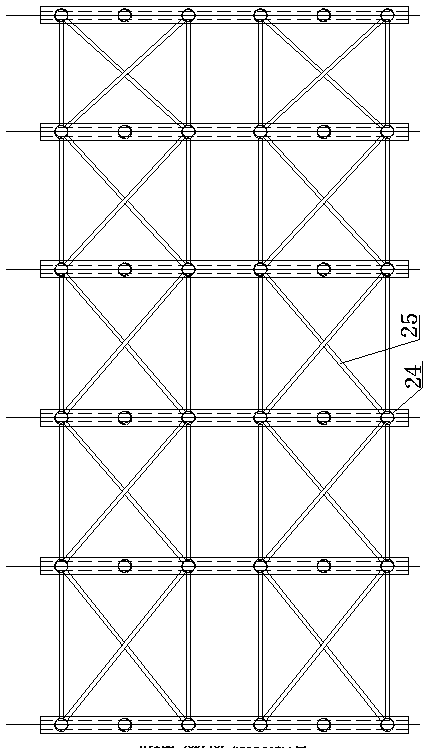

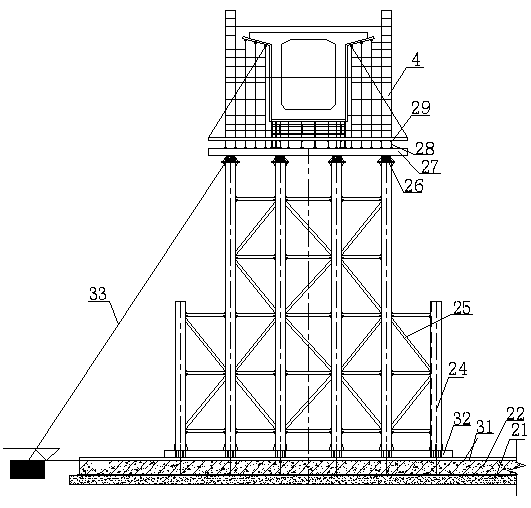

Construction support device and construction method for bridge adjacent to business line

PendingCN110725209AAchieve supportEasy to moveBridge erection/assemblyConstruction engineeringArchitectural engineering

The invention discloses a construction support device and a construction method for a bridge adjacent to a business line. The construction support device for the bridge adjacent to the business line comprises a middle support (81) used for supporting the middle of the bridge, a side support group used for supporting the side face portion of the bridge and a disc buckle frame (84) arranged on the side support group and used for supporting a template on the side face portion of the bridge. The construction support device for the bridge adjacent to the business line realizes supporting for the template on the side face portion of the supported bridge through the disc buckle frame (84), realizes supporting for the middle of the supported bridge through the middle support (81), and realizes moving for the bridge through the side support group, thereby realizing construction for the bridge far away from an existing rail traffic business line, and improving construction efficiency of the bridge.

Owner:中铁十局集团第八工程有限公司 +1

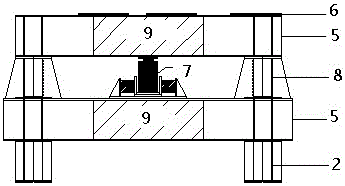

High pier sliding and turning integrated construction formwork system

ActiveCN105780661ASolve health problemsEliminate frictionBridge erection/assemblyBuilding construction

A high pier sliding and turning integrated construction formwork system comprises steel pipe upright pipes (2) embedded in concrete (1). The steel pipe upright pipes (2) penetrate cross beams of carrying frames (3) and penetrate hydraulic jacks (4) installed on the cross beams of the carrying frames. A surrounding ring (6) is fixed to the side surface of each carrying frame, a work platform (7) is laid above each surrounding ring, and a decorative lifting basket (8) provided with an automatic sprinkling maintenance device (9) is installed below each surrounding ring. Each formwork (13) is located on the inner side of the corresponding carrying frame and adjusted through connection of hydraulic levers (10) capable of transversely adjusting the position of the formwork and the corresponding surrounding ring. The top end of each formwork is lifted to the cross beam of the corresponding carrying frame through lifting rods (11) capable of transversely sliding along the part of the cross beam of the corresponding carrying frame. Steel channels for filling of rubber rods are arranged below the formworks. After the formworks are installed, the rubber rods are compressed to be tightly attached to the concrete poured last time. The formwork system is high in safety, good in construction appearance quality, good in maintenance effect and capable of greatly improving the construction efficiency and effectively preventing paste leakage in the concrete pouring process.

Owner:NO 6 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

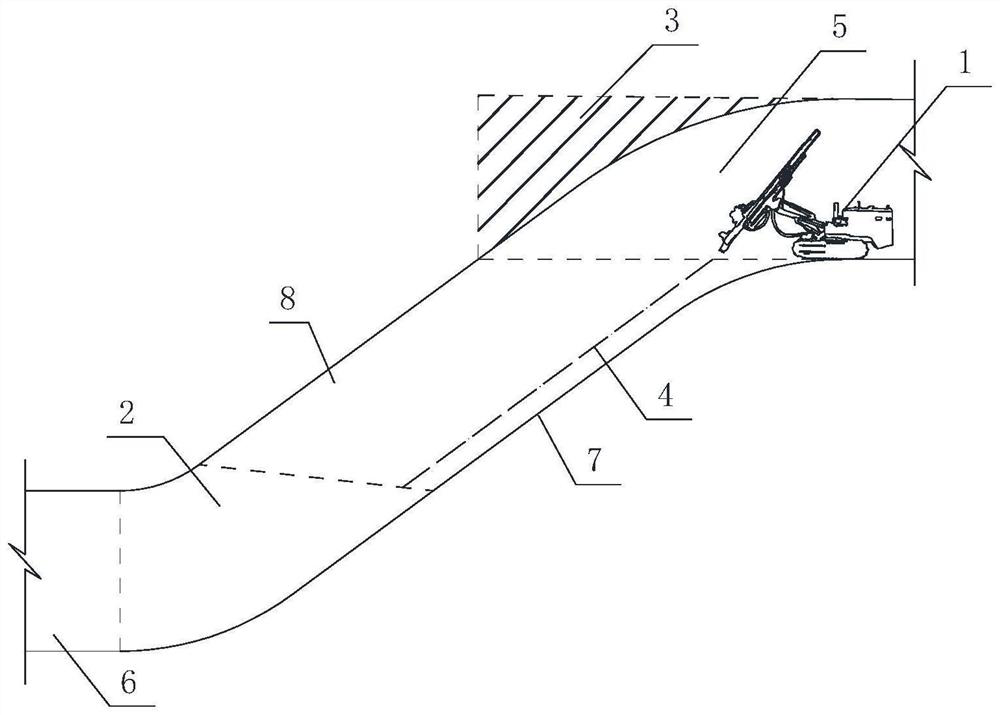

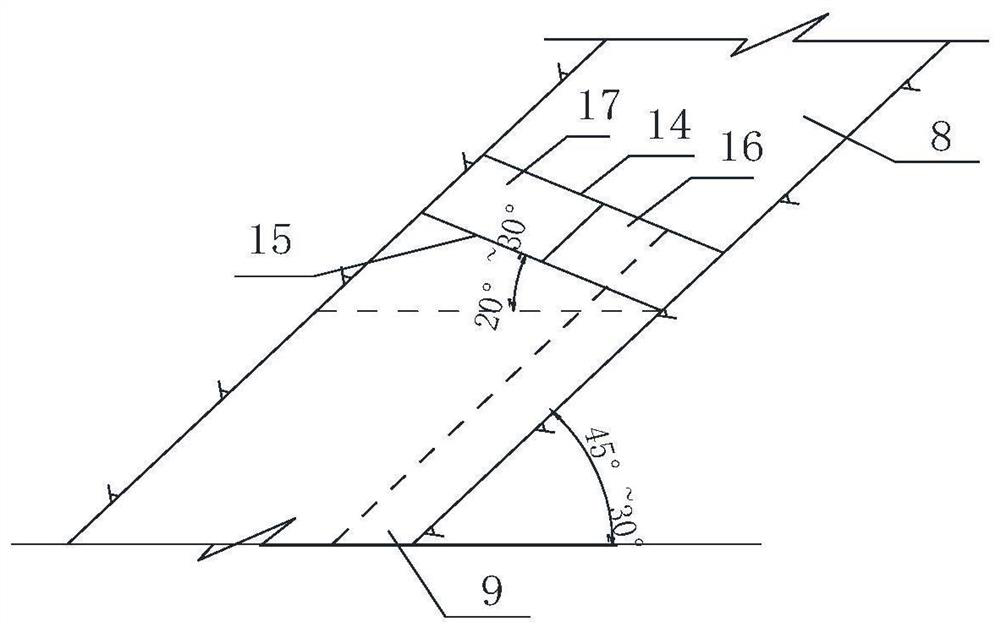

Accurate excavation method for gentle slope inclined shaft

ActiveCN112012751AReduce construction safety risksReduce construction costsClimate change adaptationDirectional drillingAditSlag

The invention discloses an accurate excavation method for a gentle slope inclined shaft. The accurate excavation method comprises the steps that expanding excavation is carried out on a lower adit andan upper adit; a hole guiding and drilling are carried out by a directional drilling machine; a MWD inclinometer and an RMRS rotating magnetic field distance measuring system are adopted for drill bit positioning; hole guiding forward reaming is carried out by a raise boring machine; and then the raise boring machine is used for reverse expanding excavation of a pilot shaft, the pilot shaft is used for slag sliding and is parallel to the bottom of a designed contour line of an inclined shaft bottom plate, forward control of blasting excavation is carried out after the pilot shaft is communicated, and finally, slag sliding is completed. According to the accurate excavation method for the gentle slope inclined shaft, the method of directional drilling, inverse shaft expanding and forward blasting excavation is adopted for the 30-45-degree gentle slope inclined shaft, the pilot shaft is arranged on the inclined shaft bottom plate, the slagging-off efficiency is effectively improved, an included angle between an excavation tunnel face and the horizontal plane is 20-30 degrees, and blasting rock ballast is conveniently accumulated to the bottom and slides to the lower adit along the pilot shaft; the maximum blasting work amount is reduced through segmented blasting, and the rock ballast shaft blocking risk is reduced; forward one-time blasting excavation is carried out, and the blasting procedure construction time is shortened; and the construction efficiency is effectively improved, and the construction safety risk is reduced.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

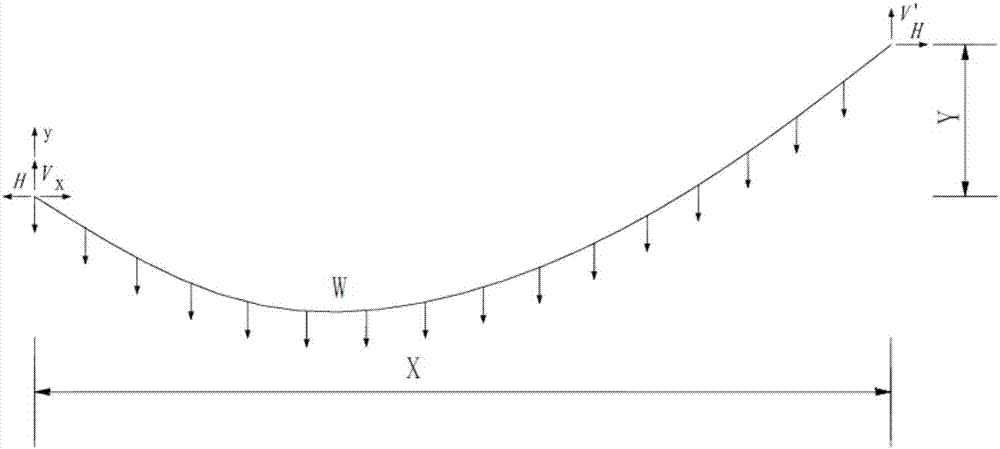

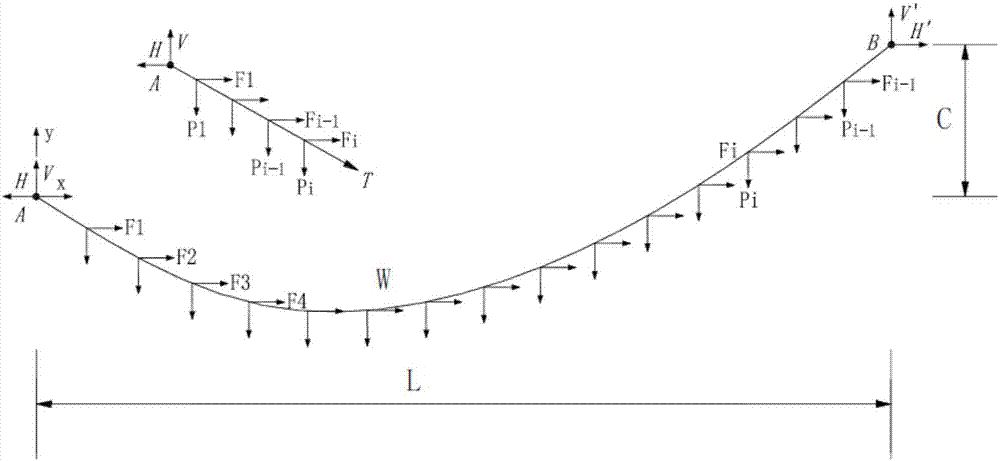

Large-tonnage steel truss arch segment non-moving lifting method based on cable hoisting system accurate calculation

InactiveCN107503514AReduce dosageReasonable selection of sizeBuilding material handlingComplex mathematical operationsContinuation methodEngineering

The invention discloses a large-tonnage steel truss arch segment non-moving lifting method based on cable hoisting system accurate calculation. A segmental catenary numerical iteration method and a tower top cable force continuation method are adopted for conducting cable hoisting system construction stage accurate calculation; by means of the method, steel truss components of different positions and different weights are lifted and installed successfully, the dosage of cable hoisting system suspension clasp tower system materials is less, selection of the size of a cable main load-bearing rope is reasonable, the construction cost is greatly reduced, the construction efficiency is improved, wide-range traction after load lifting is reduced through component non-moving lifting, the construction safety risk is lowered to the maximum extent, the problems that for a traditional lifting technology, cable system and suspension clasp tower system arrangement is conducted according to the maximum lifting weight, a larger number of materials are used, and the control difficulty is high are solved, and the method is a lifting method which is closer to practice, scientific and reasonable.

Owner:四川路桥华东建设有限责任公司

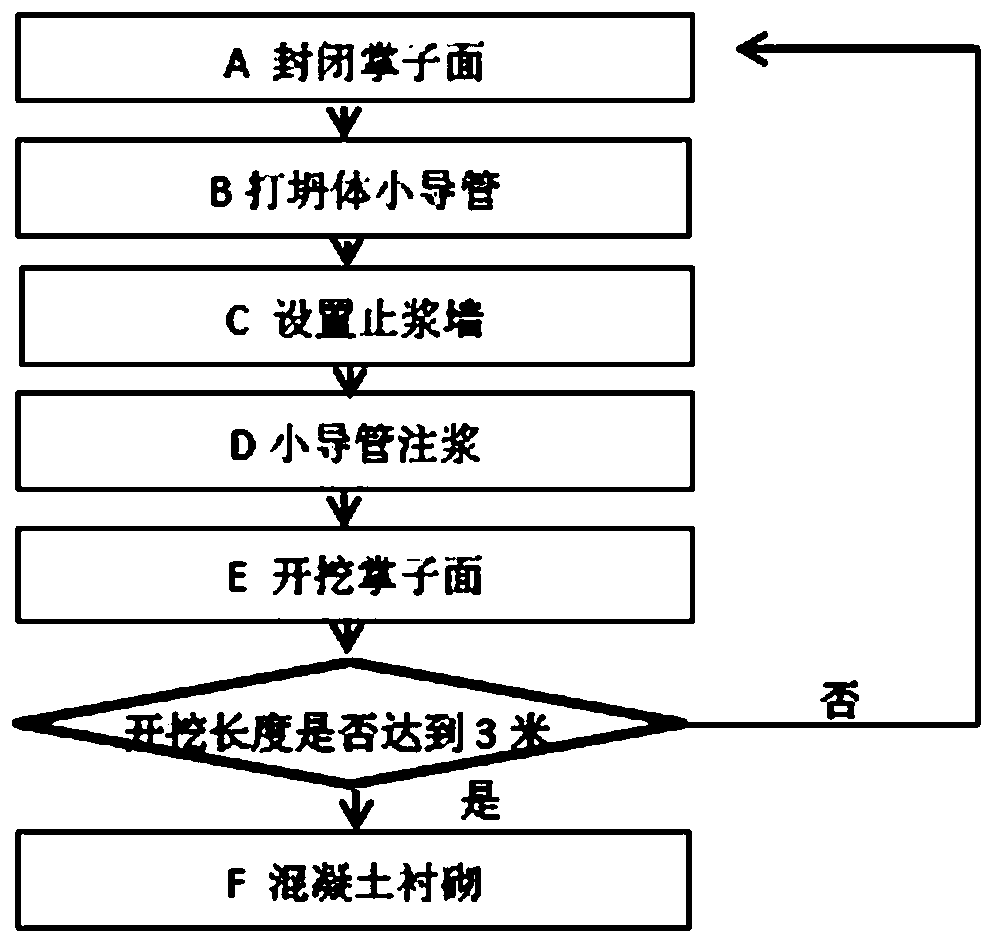

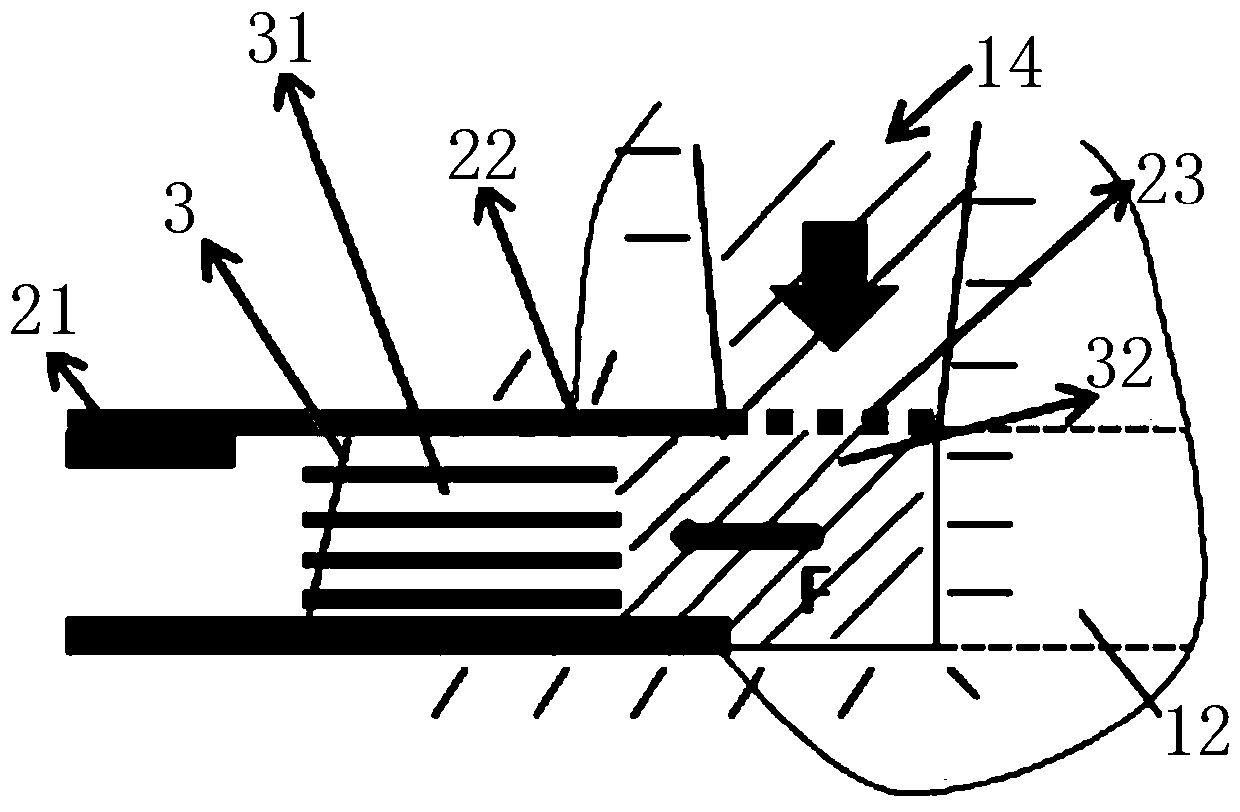

Method for treating light section tunnel collapse

The invention discloses a method for treating light section tunnel collapse, relates to the technical field of tunnel construction, aims to treat larger collapse in a light section tunnel soft-crackedsurrounding rock tunnel section, and provides a practical and effective pre-act support method with a simple technology, high operability and the low manufacturing cost. According to the technical scheme, the method for treating the light section tunnel collapse comprises the steps that by reinforcing loose slag bodies of collapse bodies in tunnel, above a springing line, a small pipe and a grouting body are integrated to form a shell to effectively support loose rock mass on the upper part; and collapse bodies under the springing line are pre-consolidated, in the process of slag draining, areserve core soil method is used for conducting excavation support, and then a collapse section is safely and quickly passed.According to the method, aiming at the light section tunnel soft-cracked surrounding rock tunnel section, the method is suitable for treating conditions of the larger collapse on the tunnel face and the top part and unable continuing slag draining, the technology is simple,the operability is high, the method is practical and effective, a construction process can be accelerated, and the safety risk of the construction is reduced.

Owner:POWERCHINA CHENGDU ENG

Horizontal deep hole stage slicing and caving mining method and stope for crushing thin ore body

ActiveCN110295907AAvoid homeworkImprove recovery rateUnderground miningSurface miningEngineeringSteep slope

The invention discloses horizontal deep hole stage slicing and caving mining method and stope for crushing a thin ore body. The method comprises the following steps: arranging the stope along the orebody, and arranging an ore gathering roadway at the bottom of the stope; arranging footway ventilation shafts at both ends of the stope; arranging a cutting well and a cutting lane in the middle of the ore gathering roadway, wherein the cutting well communicates with the ore gathering roadway through the cutting lane; in the footway ventilation shafts, arranging drilling chambers at intervals along the height direction, and arranging horizontal medium-deep holes in the drilling chambers; adopting medium-deep hole slicing for cutting blasting and undercutting blasting to provide compensation space. The method can quickly recover the stope, avoid the safety hazard of the operation in the stope by adopting an original shallow-hole shrinkage method, greatly improve the mining operation efficiency, simplify the ore removal bottom structure, and improve the undercutting and ore removal efficiency; the method is suitable for crushing the thin ore body of a steep slope, can improve the safetyof the operation and the ore recovery rate, and can effectively reduce the loss rate and the dilution rate.

Owner:CHINA HUAYE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com