Construction method of superlong cable beam-free sections of cable-stayed bridge

A construction method and technology of cable-stayed bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of time-consuming and consumable materials, high construction safety risks, and inability to adapt to changes in the length of cable-free girder sections and installation heights, etc. Achieve the effect of less mechanical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

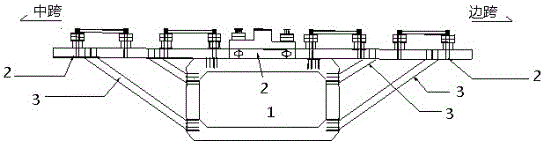

[0033] The invention discloses a construction method for an ultra-long cable-free beam section of a cable-stayed bridge, which is carried out in two stages.

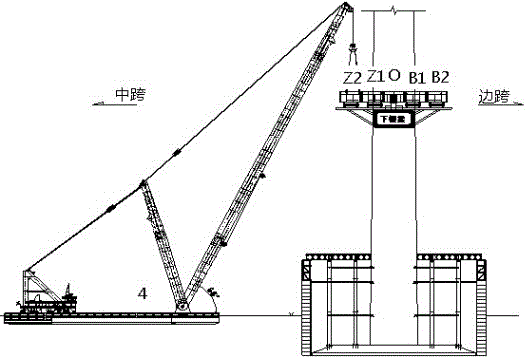

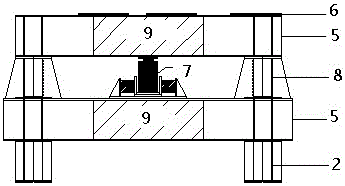

[0034] The first stage is the construction of the five beam sections in the middle: the bracket + floating crane installation method is adopted, that is, the five cable-free beam sections in the middle of the tower area are hoisted and placed on the lower beam brackets in sequence by using the floating crane, and the beams are connected to form a whole After that, install the tower beam temporary restraint;

[0035] The second stage is the construction of two beam sections at both ends: the platform + bridge deck crane installation method is adopted, that is, the beam sections at each end are connected together in the back field in advance and stored on the cofferdam top platform on both sides of the main tower, using the upper The bridge deck crane is used for hoisting and installation, and the hoisting of the bridge de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com