Patents

Literature

114results about How to "Save on machinery costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

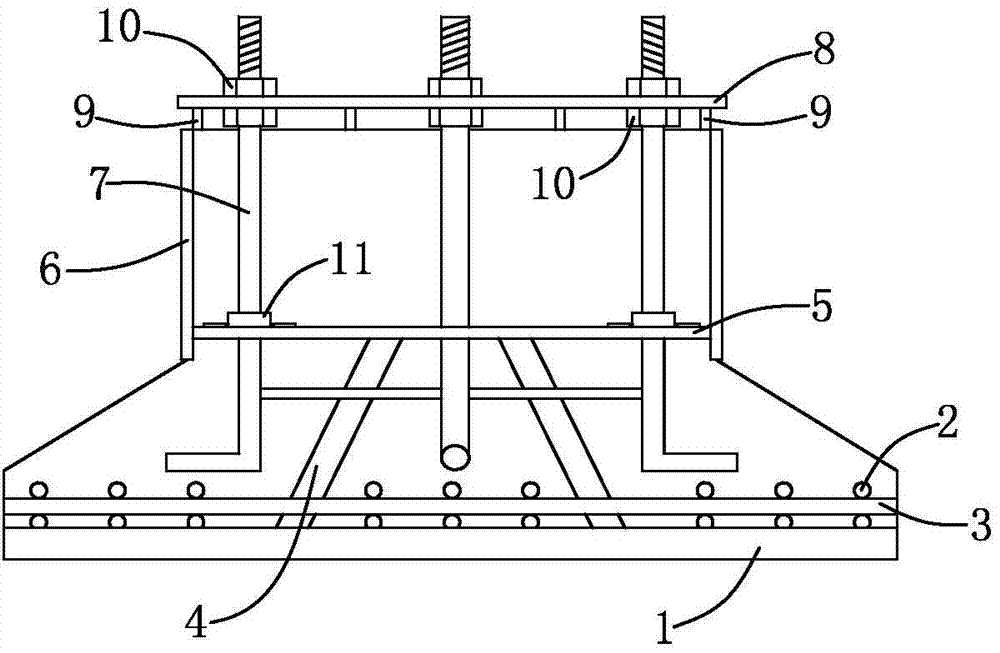

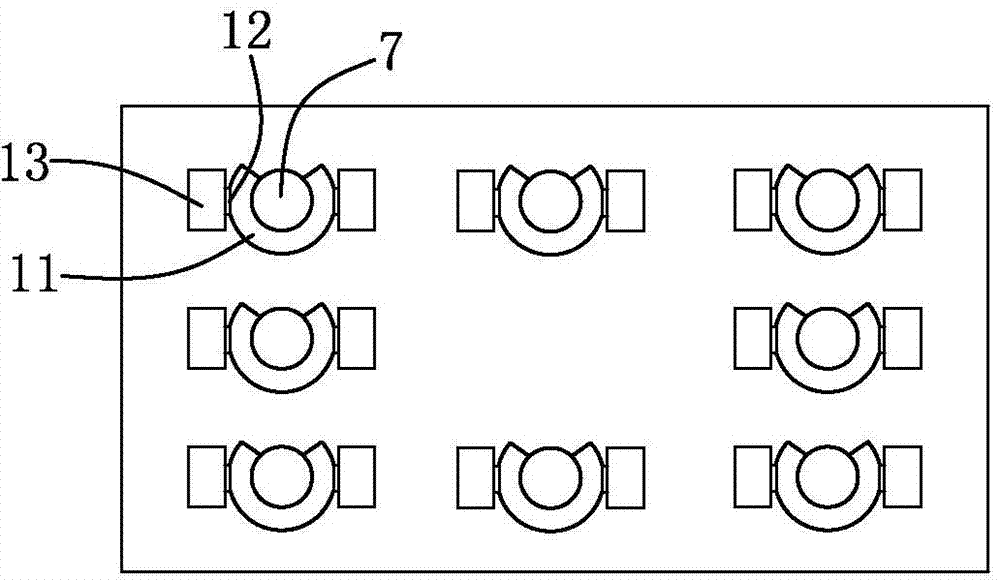

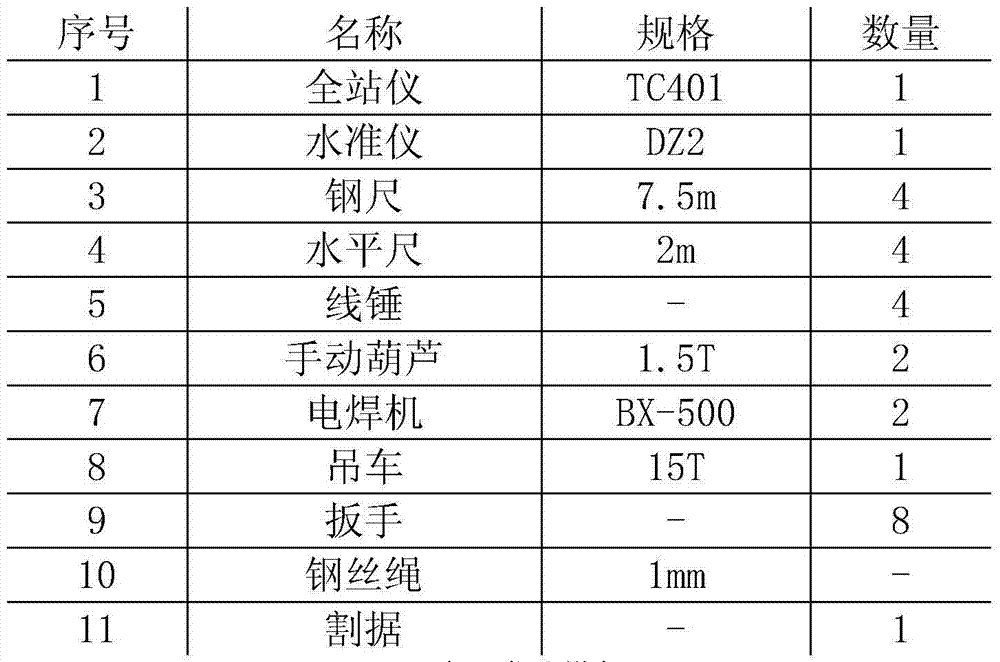

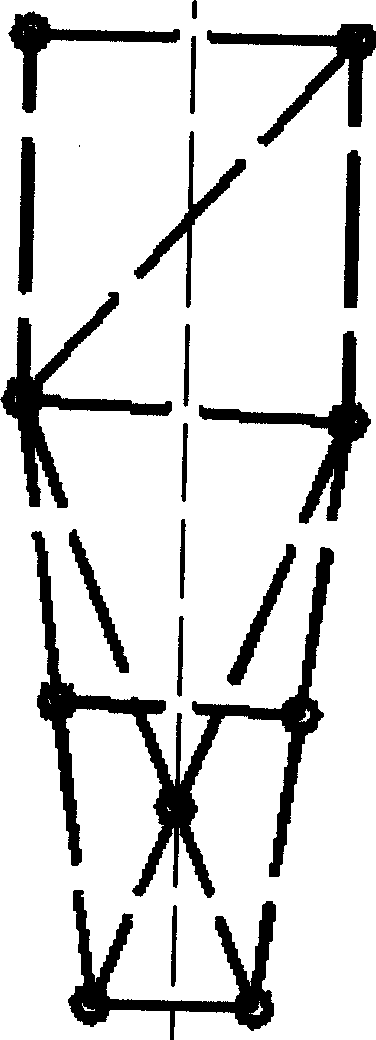

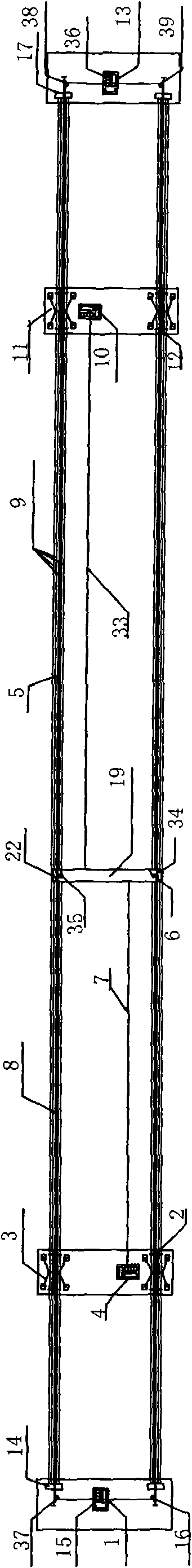

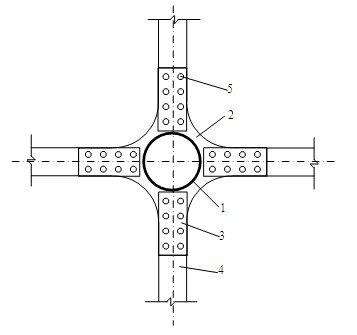

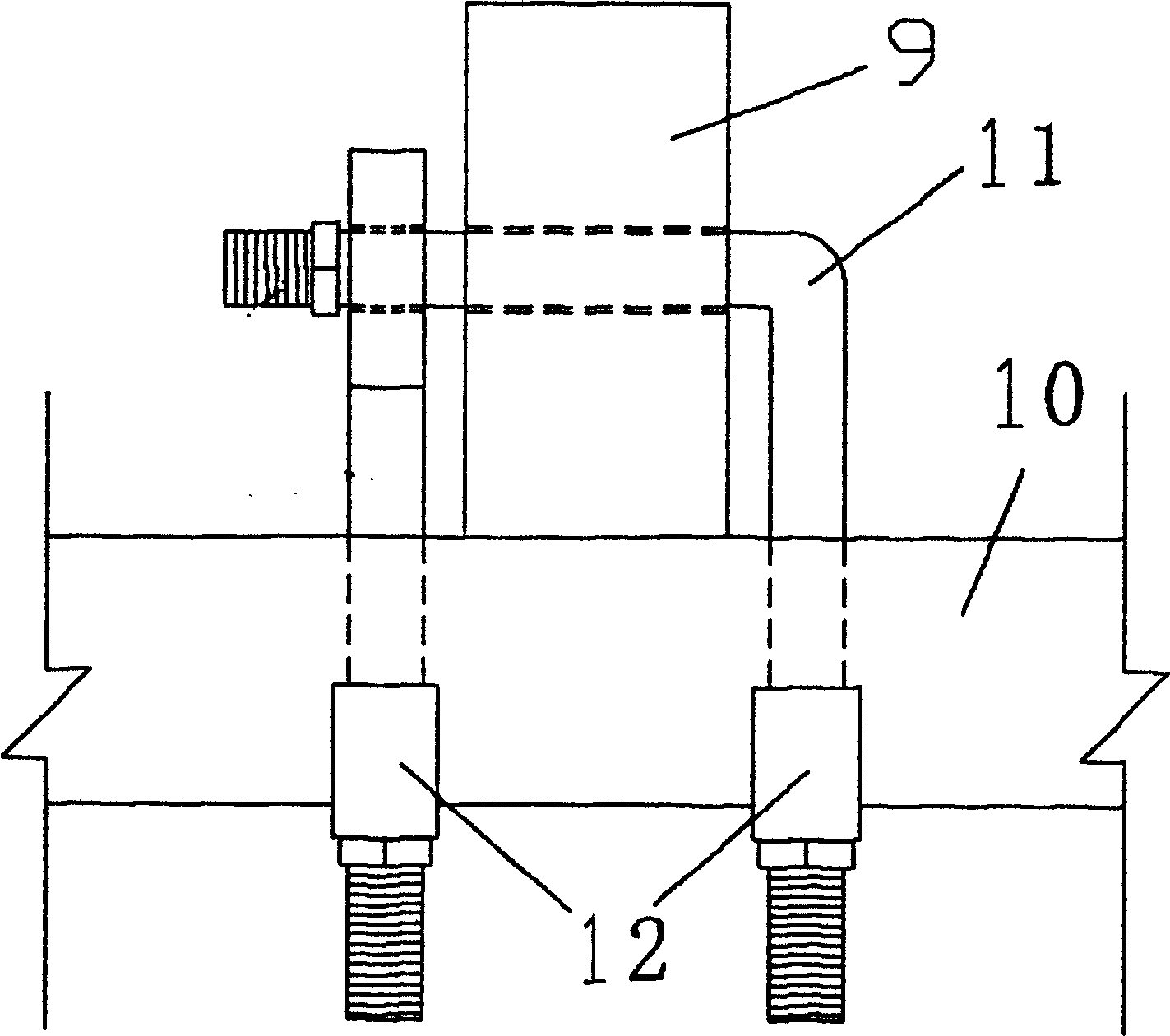

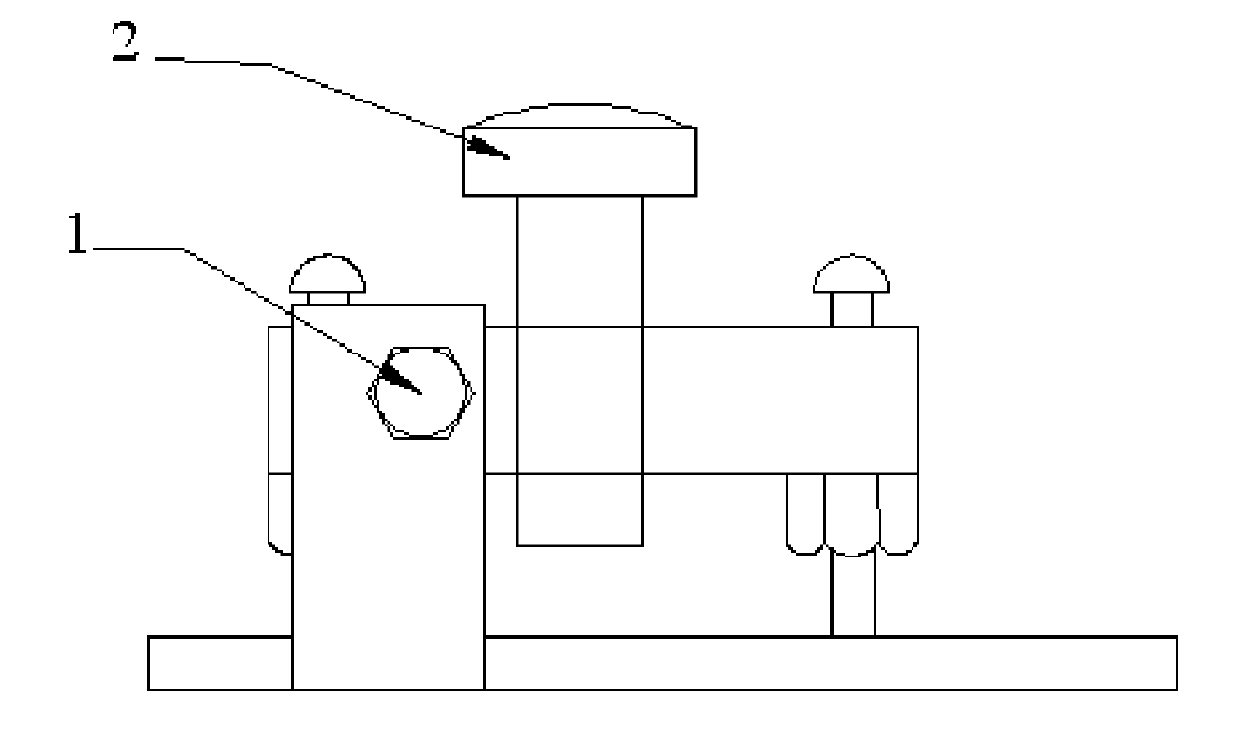

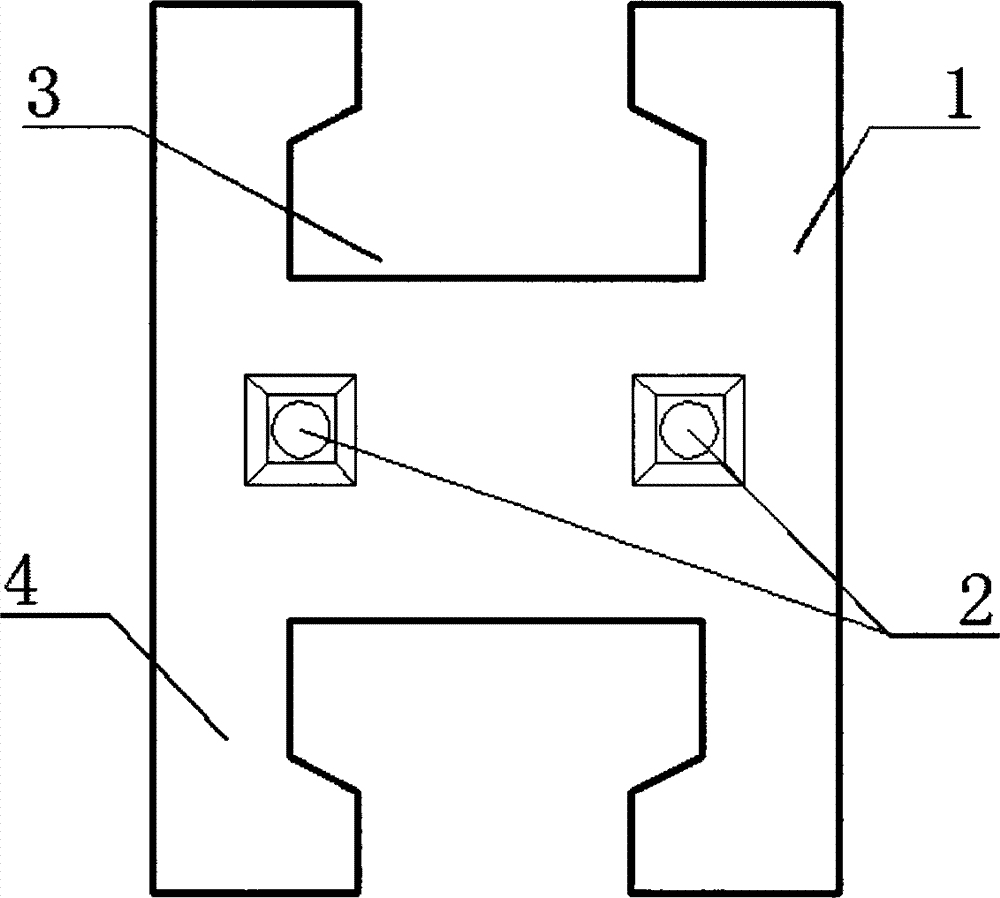

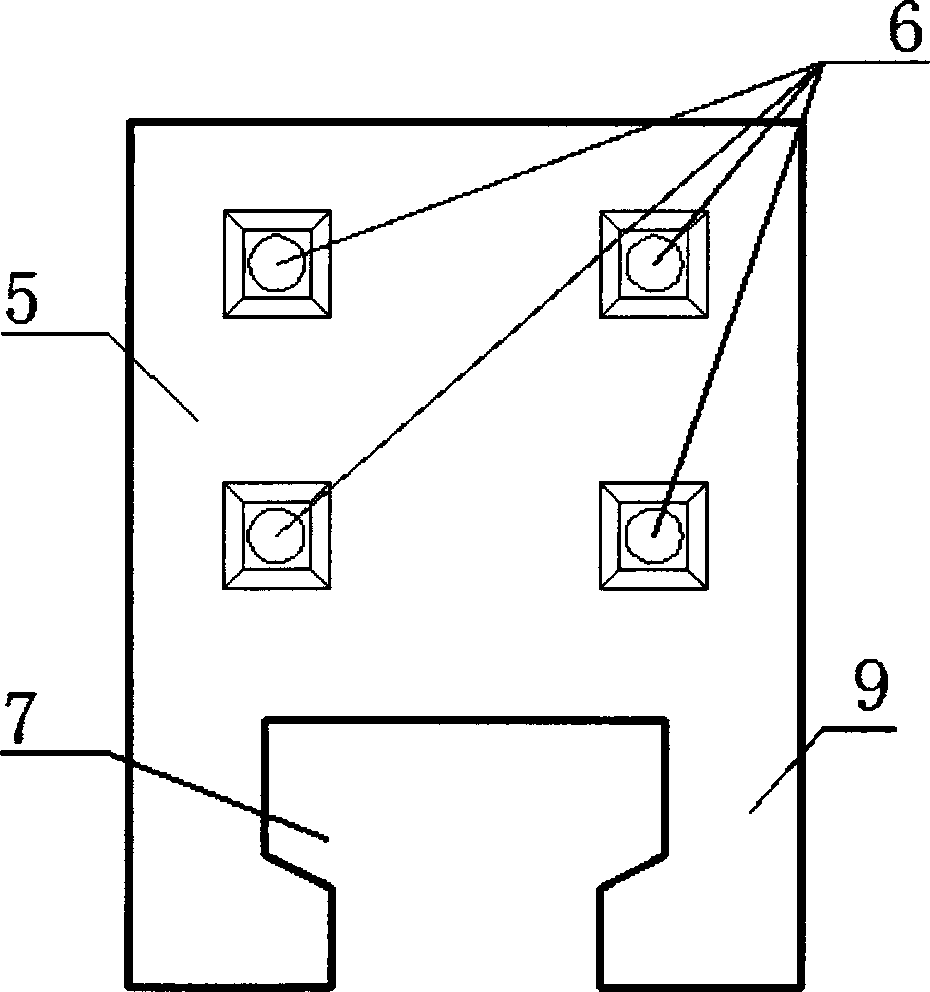

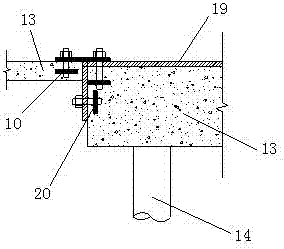

Pre-buried construction method for high-precision foundation bolts

The invention discloses a pre-buried construction method for high-precision foundation bolts. The method includes the following steps that (a), construction preparation is performed; (b), a control net is established; (c), a positioning clamp and a positioning control plate are manufactured; (d), foundation steel bars are buried in advance; (e), the positioning clamp is installed; (f), the foundation bolts are installed; (g), the foundation bolts are reinforced and protected; (h), concrete pouring is performed; (i), the clamp is dismantled; (j) acceptance inspection and handover are performed to finish the pre-buried construction. The manufactured high-precision positioning clamp is adopted for performing clustering control over the pre-buried foundation bolts of each set of equipment foundations, elastic clamping tools are arranged on the outer sides of the foundation bolts, supporting legs of the elastic clamping tools are embedded into clamping holes in the positioning clamp, and the elastic clamping tools are clamped on the positioning clamp of the foundation bolts, so that the foundation bolts are further reinforced and prevented from loosening. The pre-buried construction method has the effects of being reliable in technology, high in construction precision, easy to understand and master and convenient to operate, and meanwhile is short in construction period and low in cost.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

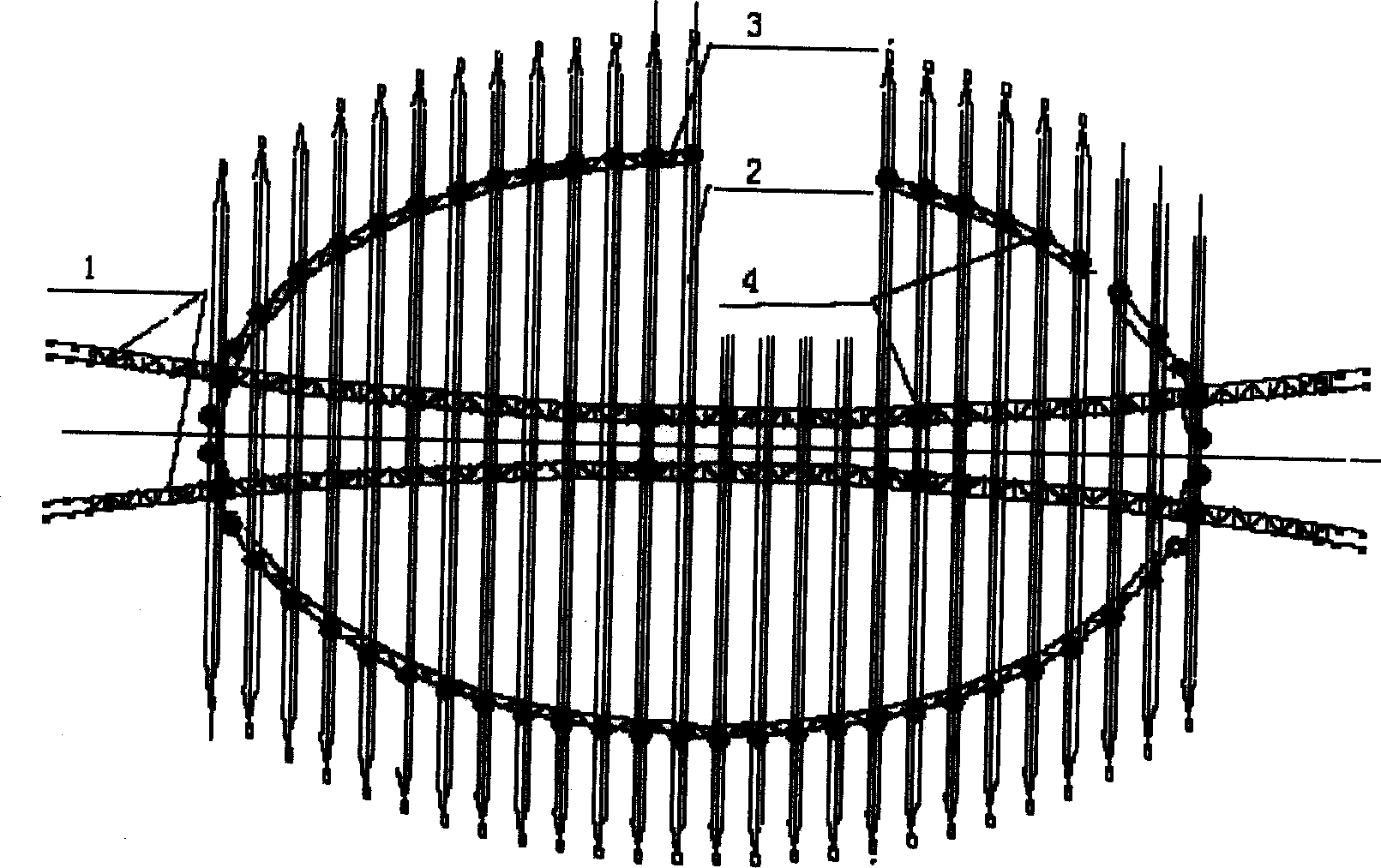

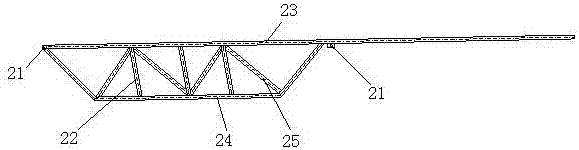

Building truss integral lifting method and equipment thereof

The integral building truss lifting method features that the lifting process includes assembling the main truss on ground in two units; manufacturing and installing corresponding lifting frame; setting cable system on the elevating frame and installing hydraulic elevator in corresponding position; installing the truss ground end shifting units; lifting the two elevated ends of the truss units with the hydraulic elevator synchronously while ensuring the horizontal shift of the ground ends of the truss units under the control of main computer; dismantling the ground end shifting units after the overhead butt joints are in place; elevating and fixing the ground ends; and assembling the overhead butt joints.

Owner:中国机械工业建设总公司

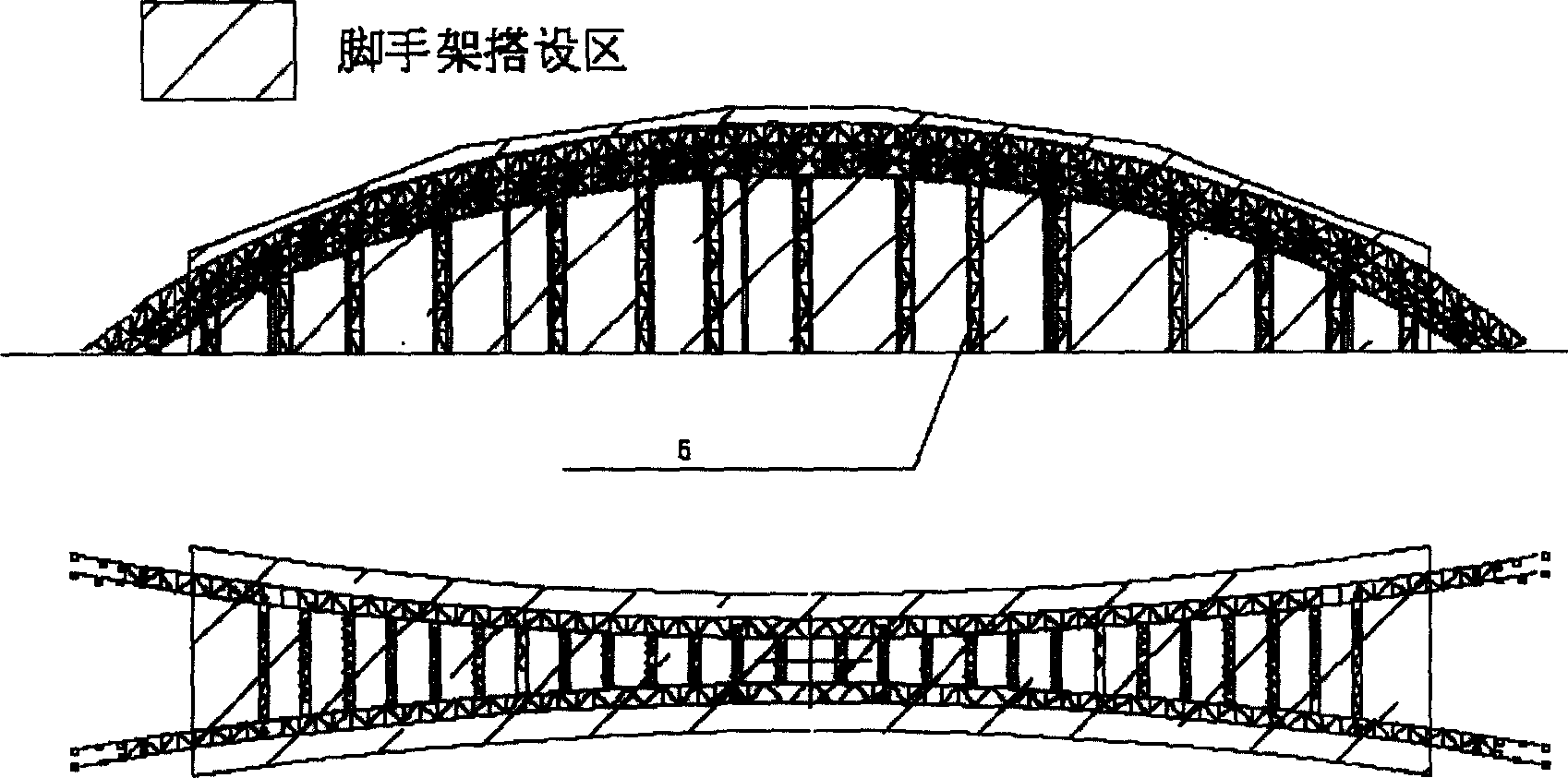

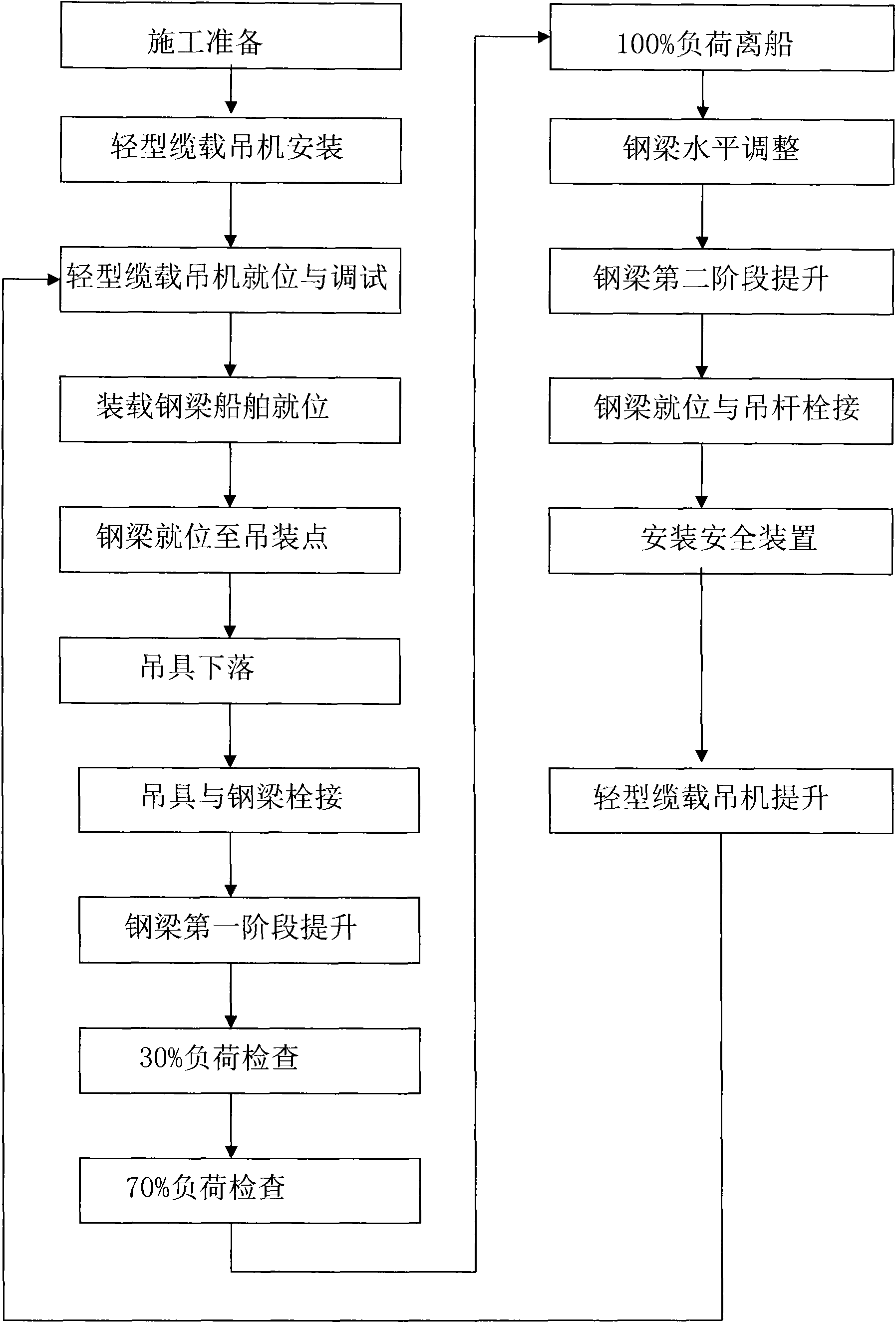

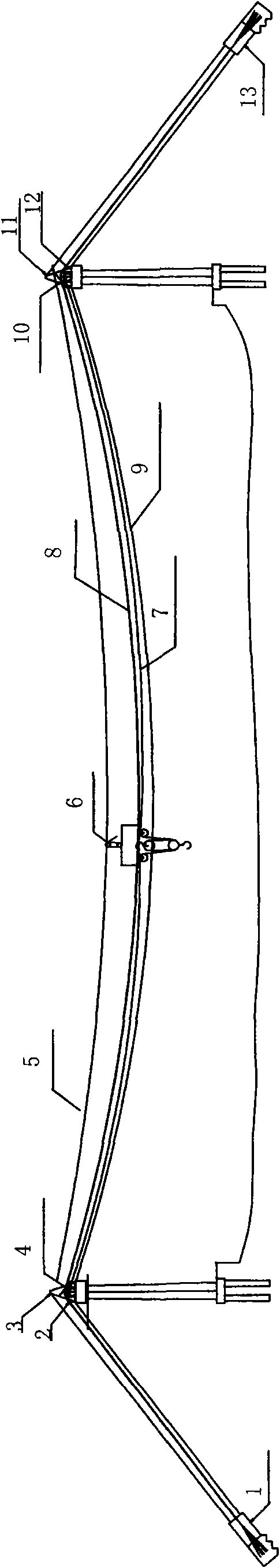

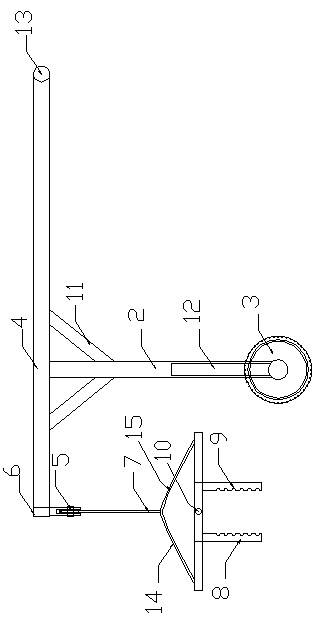

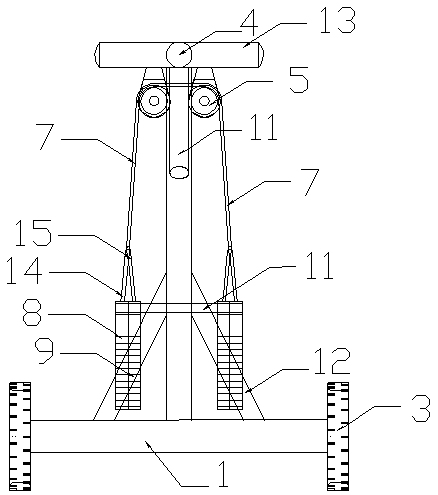

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

Acid liquid fertilizer for drip irrigation and its prepn

The present invention relates to one kind of acid liquid fertilizer for drip irrigation and including nitrogen fertilizer, phosphate fertilizer, potash fertilizer, rooting promoter, dissolution promoter, trace elements and sulfuric acid. It is prepared through the steps of: dissolving phosphate fertilizer, potash fertilizer, trace elements and dissolution promoter in water through stirring, dissolving nitrogen fertilizer, adding sulfuric acid and adding rooting promoter. Its preparation process is scientific, low in power consumption and low in cost and uses simple apparatus. Its dissolution promoter can raise the dissolution degree of routine phosphate fertilizer and its rooting promoter can promote the growth of plant root system and the plant absorption capacity to nutrients. Its acidity can prevent jamming of drip holes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Quick installation method of coke oven guard plate and oven column

The invention discloses a quick installation method of a coke oven guard plate and an oven column, comprising the following steps: 1) after a coke oven body is built, a temporary fixed mount is respectively arranged on the positions on two sides of an oven top machine, which correspond to the installation positions of a guard plate and an oven column; 2) after the guard plate is hung to the proper position and adjusted, a binding piece connects the upper part of the guard plate with the temporary fixed mount so as to temporarily fix the guard plate; 3) after the guard plate is temporarily fixed, the oven column is hung to the proper position, and then the oven column is adjusted, the binding piece connects the upper part of the oven column with the temporary fixed mount so as to temporarily fix the oven column; 4) the cross-brace of the oven column is installed to formally fix the guard plate and the oven column; and 5) the binding piece and the temporary fixed mount are disassembled.The invention is simple and easy to realize, is easy to operate and master, can be flexibly adjusted according to the conditions, such as manpower, equipment and the like, can centralize the superiorforce of relevant type of work and improves quality and efficiency; the coke oven guard plate and the oven column can be intensively installed so as to reduce lifting machine transit shipment time and save installation time and machinery cost.

Owner:TIANJIN 20 CONSTR

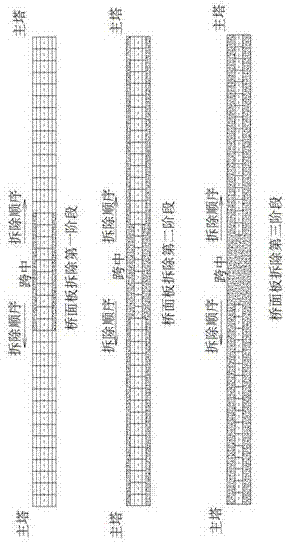

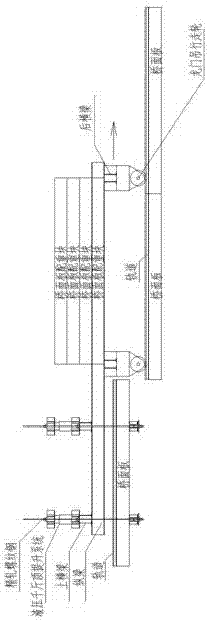

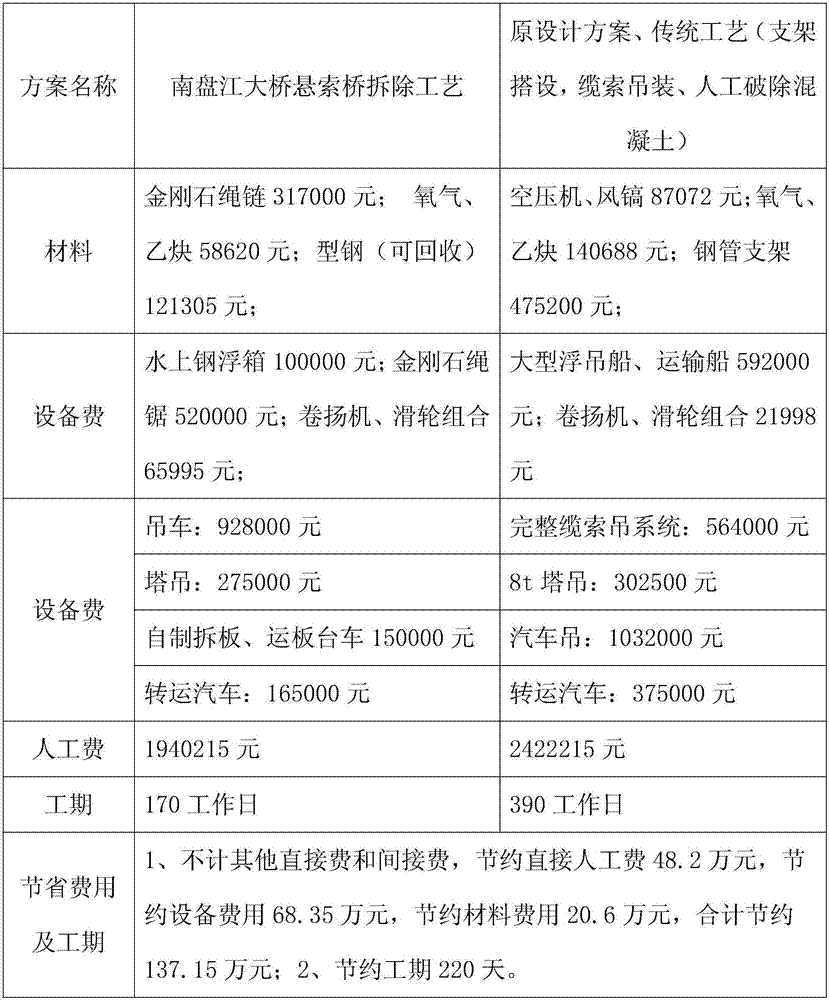

Demolition construction method for long-span highway suspension bridges

ActiveCN106978784AEnsure safetyShorten the construction periodBuilding repairsBridge strengtheningReinforced concreteDiamond wire saw

The invention discloses a demolition construction method for long-span highway suspension bridges. The construction method specifically comprises the following steps that 1, steel structure counter-force frames are installed at the top of a main tower, cable saddling and pushing are conducted, and the deflection of the main tower is corrected; 2, bridge surface plates and bridge surface paving layers are cut, and blocking and whole hoisting are conducted; 3, demolition of steel truss beams is conducted, and after the steel truss beams are cut off from the midspan, the beams are lowered in a segmental mode as a whole; 4, demolition of main cables are conducted, remaining main cable hangings and catwalks are utilized as an operation platform, the main cables are cut off in situ, and the demolition of the main cables is conducted; 5, demolition of the main tower is conducted, diamond wire saws are utilized to cut reinforced concrete with static force, upper cross beams are lowered as a whole through the adoption of a suspension system, after the main tower is cut and divided into blocks, vehicle cranes are used for hoisting, and cutting and hoisting are conducted after holes are drilled in lower cross beams. The demolition construction method for the long-span highway suspension bridges is applicable to the complex demolition of suspension bridges in geological environment, and the construction method is not only relatively little in resource waste and relatively low in economic cost, but also conductive to environmental protection.

Owner:GUIZHOU BRIDGE CONSTR GROUP

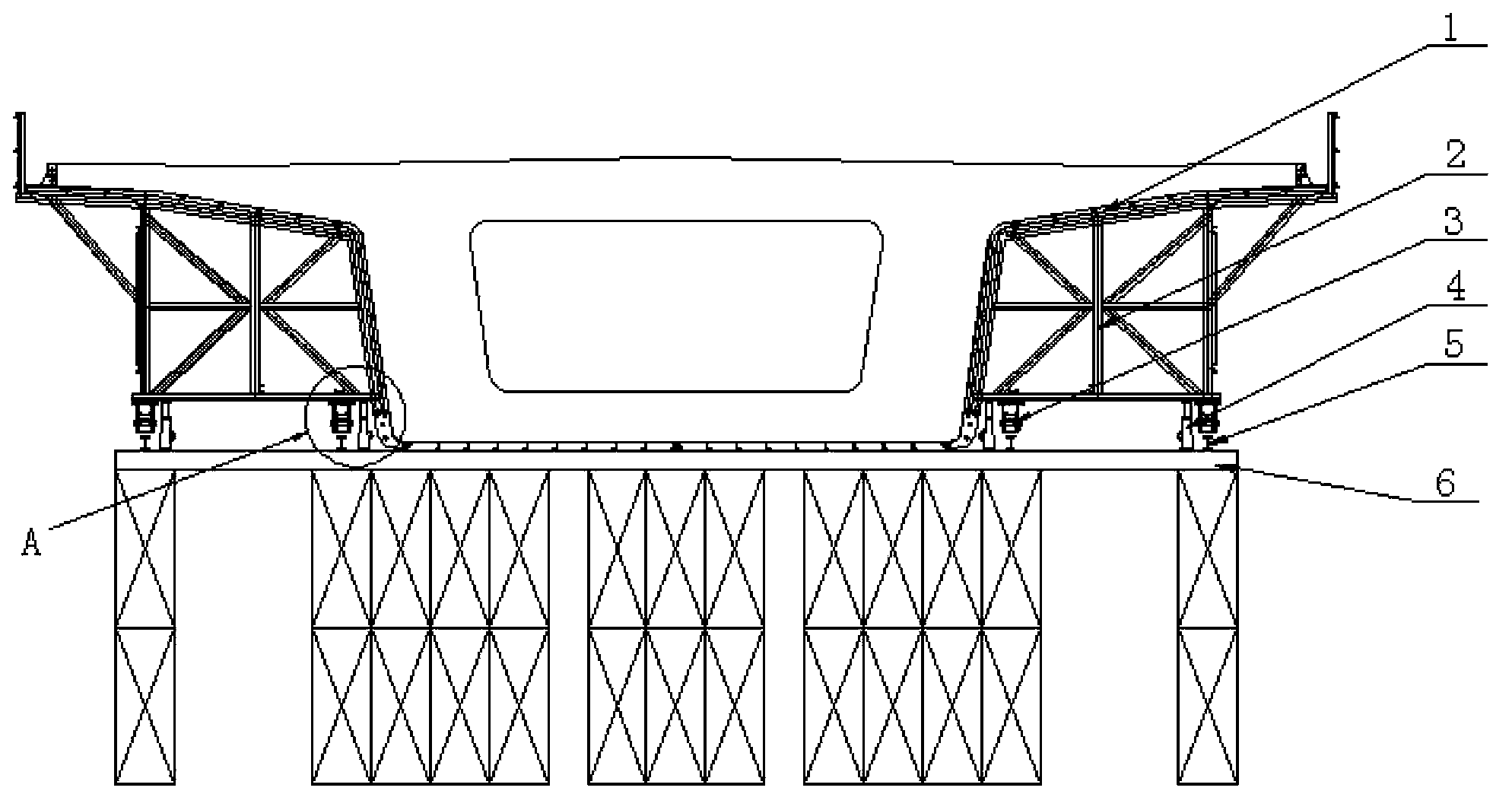

Cast-in-place box beam lateral die sliding construction device and method

InactiveCN103352427AEasy to operateSave moneyBridge erection/assemblySocial benefitsEconomic benefits

The invention relates to a cast-in-place box beam lateral die sliding construction device. The cast-in-place box beam lateral die sliding construction device is characterized by comprising a movable lateral die, a sliding rail and a lifting jack. The movable lateral die is composed of a lateral die body and a walking pulley which is fixedly arranged at the bottom of the lateral die body, the sliding rail is fixedly arranged on a support, the movable lateral die is movably installed on the sliding rail, and the lifting jack is installed between the upper portion of the support and the bottom of the lateral die. The invention further relates to a cast-in-place box beam lateral die sliding construction method. By the adoption of the cast-in-place box beam lateral die sliding construction device and method, the phenomenon that in the construction process of a traditional cast-in-place beam, a large number of hoisting devices and transport vehicles are needed for demounting, reshipping and hoisting the lateral die is effectively avoided, and the cast-in-place box beam lateral die sliding construction device and method are economical, practical, simple in operation, and capable of effectively saving expenditures, shortening labor hours, and possessing obvious economic benefits and social benefits.

Owner:中铁建大桥工程局集团电气化工程有限公司

Self-dropping type box girder steel pipe bailey door opening bracket and supporting method thereof

ActiveCN103469733AEliminate uneven settlementAvoid crackingBridge erection/assemblyButtressReinforced concrete

Owner:CCFEB CIVIL ENG

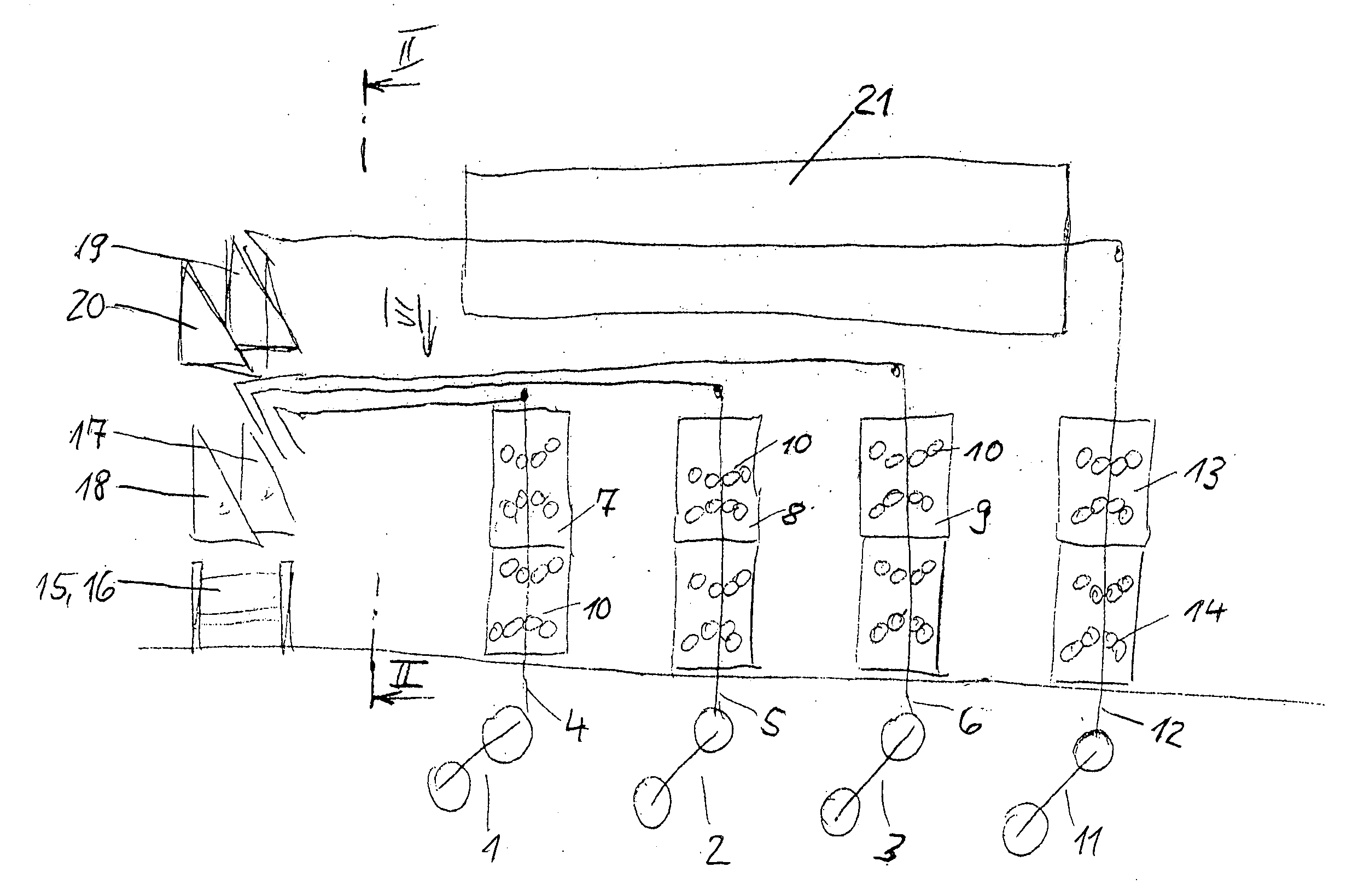

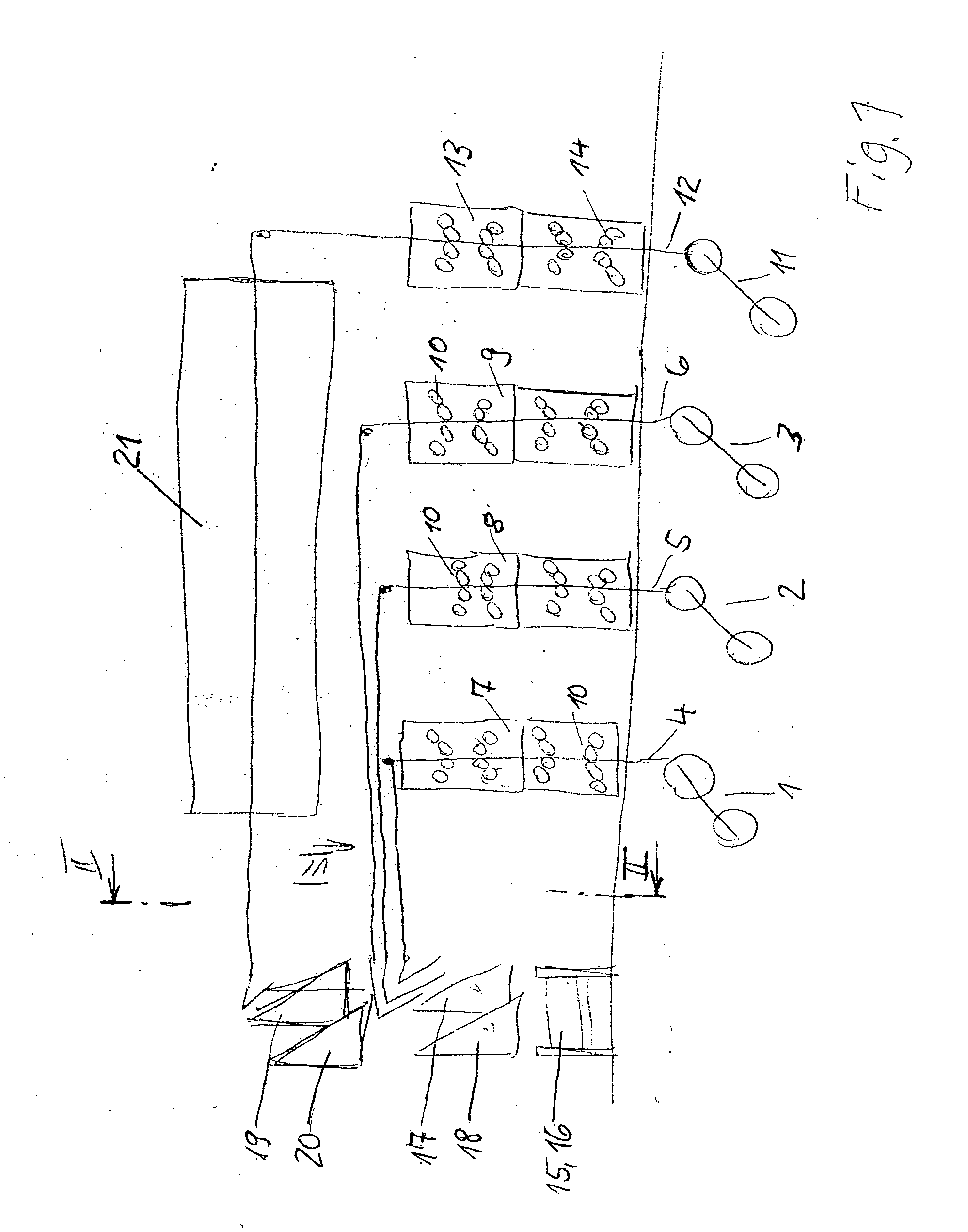

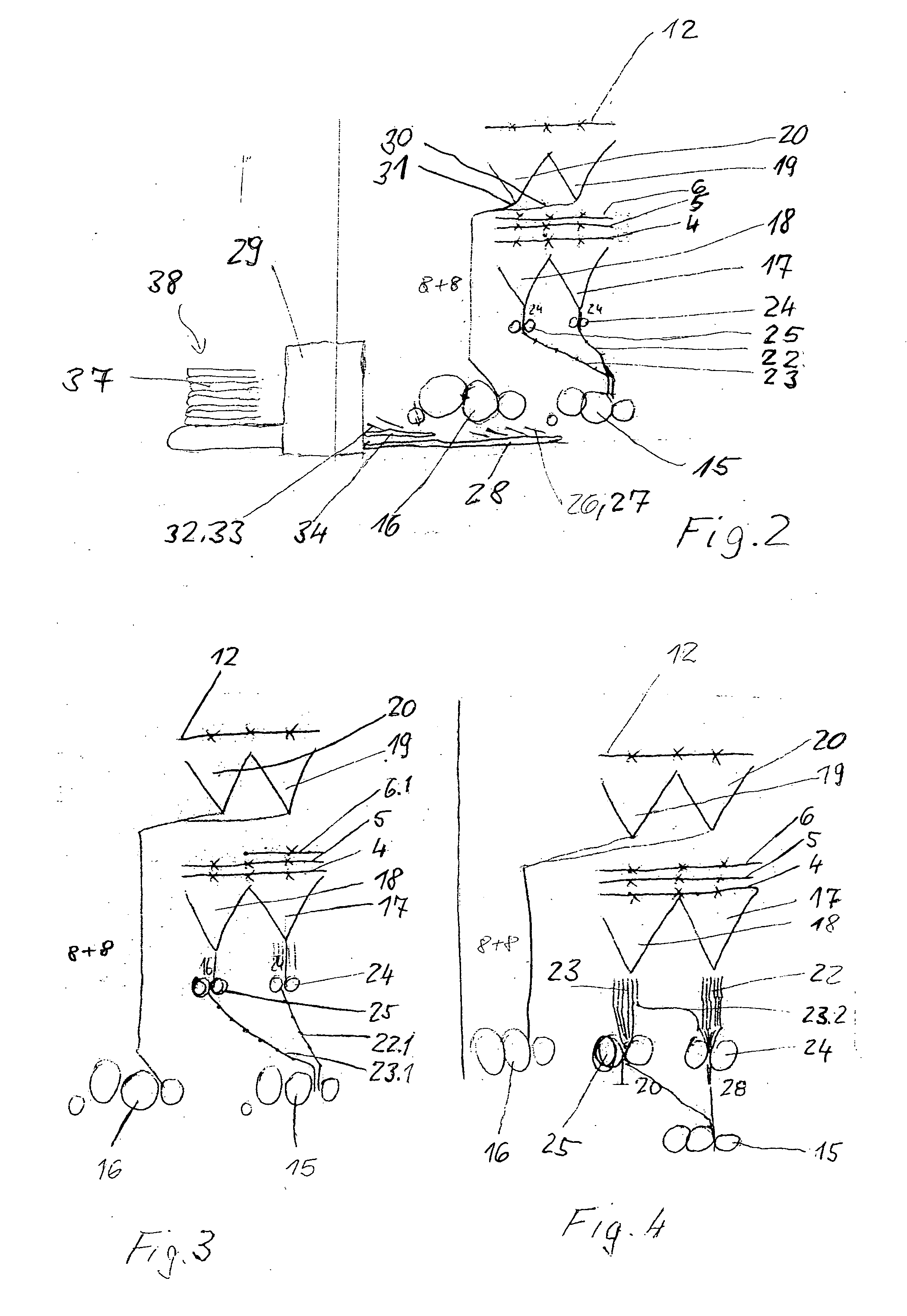

Printing press and method for the production of newspapers

InactiveUS20070101881A1Reduce effortSave on machinery costsRotary pressesNewspapersEngineeringPrinting press

The printing press for producing newspapers includes several unwinders from which coldset webs can be unreeled, coldset printing couples for printing the coldset webs with coldset inks, coldset formers and a coldset folder for processing the coldset webs into longitudinally and transversely folded coldset signatures. The printing press also includes an additional unwinder from which a heatset web can be unreeled, heatset printing couples for printing the heatset web with heatset inks, a dryer for drying the printed heatset web, a heatset former and a heatset folder for processing the heatset web into a longitudinally and transversely folded heatset signature. Finally, a processing device processes the heatset signature into a magazine.

Owner:M A N ROLAND DRUCKMASCHINEN AG

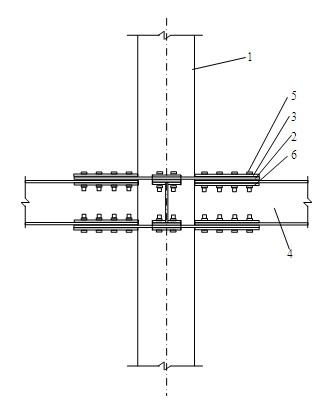

On-site assembling type extending arm combined node

InactiveCN102425237AImprove bearing capacityImprove plasticityBuilding constructionsEngineering structuresFire resistance

The invention provides an on-site assembling type extending arm combined node, which is adapted to the big-span, high-rise and heavy-load development of a modern engineering structure and the requirement of enduring a mal-condition. The on-site assembling type extending arm combined node comprises a steel tube concrete column, H-type girder mounting plates for extending arms, outer base plates for the extending arms, an H-type girder, and the like. Two H-type girder mounting plates for the extending arms are welded on the steel tube concrete column; cross-shaped node H-type girder mounting plates for the extending arms, T-shaped node H-type girder mounting plates for the extending arms, straight node H-type girder mounting plates for the extending arms and L-shaped node H-type girder mounting plates for the extending arms are respectively selected according to different node forms of a central column of a middle frame, a side pillar of the middle frame, the central column of a side frame and the side pillar of the side frame; and the H-type girder is assembled on site. The on-site assembling type extending arm combined node has the effects and advantages of high bearing capacity, excellent plasticity and toughness, convenience in construction, better fire resistance, excellent economic effects and beautiful and safe nodes and meets the demand of industrialization of the modern construction technology.

Owner:SHENYANG JIANZHU UNIVERSITY

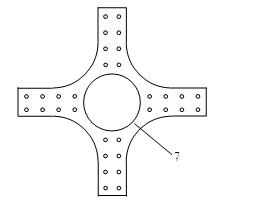

Installation and construction method of mechanical grate type waste incineration boiler

InactiveCN109000261AGive full consideration to reuseReduce the amount of work at heightIncinerator apparatusSteel frameSuperheater

The invention discloses an installation and construction method of a mechanical grate type waste incineration boiler. The installation and construction method includes the following specific steps ofconstruction preparation, specifically, unpacking inspection of boiler parts and equipment, retesting and paying off of boiler foundation, and configuration and installation of parallels; and installation and construction method, specifically, preparation and manufacturing of auxiliary tools, installation of boiler internal equipment, installation of rainproof shed, hydrostatic test of boiler, installation of boiler wall, steam tightness test of drying and boiling boiler, and safe trial operation, wherein the auxiliary tools includes a steel frame, a platform escalator, a temporary climbing ladder, an aisle guardrail, a temporary platform, a temporary platform guardrail, a scaffold lifting platform and a simple removable support, and the internal equipment includes a boiler grate, a watercooling system, a drum, a superheater and an economizer. The installation and construction method of the mechanical grate type waste incineration boiler is applicable to installation of the mechanicalgrate type waste incineration boiler with a daily garbage disposal of about 500t / d by a single unit in a domestic garbage power plant, the degree of mechanized construction is improved, the labor intensity is reduced, the project quality is guaranteed, the construction period is shortened, and the productivity and economic benefits are improved.

Owner:POWER CHINA HENAN ENG CO LTD

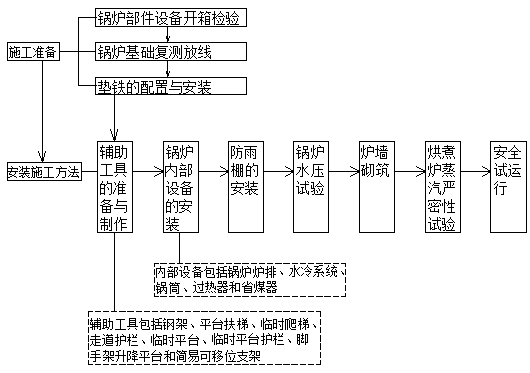

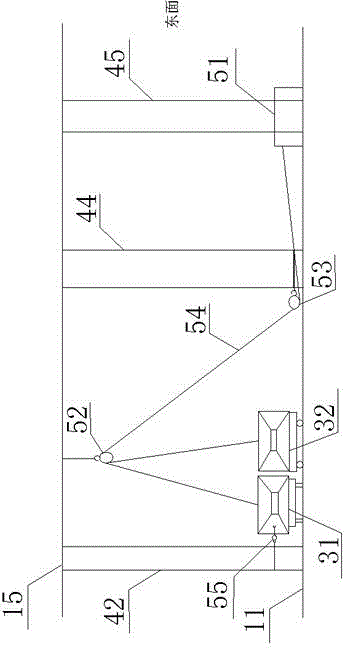

Automatic spraying positioning bracket

InactiveCN103015692AShort construction periodImprove efficiencyBuilding constructionsWork periodElectric machinery

The invention provides an automatic spraying positioning bracket, which comprises a lifting gear, a first limiting switch, a first guide rod, a first motor, a second limiting switch, a second guide rod, a spraying nozzle, a spraying nozzle fixing cart, a horizontal spraying track control framework, a transverse reciprocating traveling spraying positioning framework, a screw rod, a second motor, a gearbox, a falling ash recovering disc and a direction-adjustable traveling wheel. The automatic spraying positioning bracket has the beneficial effects that the work period is short, the efficiency is improved by 2 to 3 times, the labor is reduced, the cost is reduced, and one layer of neat cement mortar is saved; in the civil engineering of one building with an area of 10,000m<2>, the neat cement per 1m<2> needs approximate 3kg of cement, so approximate 30t of cement is saved; the adhering force of the spraying mortar is high, the density is high, the adhering is firm, the cement surface is firm, empty drums are avoided, the flatness of the wall surface is improved, and the plastering quality is ensured; and the pollution of air environment of a construction site is reduced, and the splashing amount of wastes of the plastering engineering can be controlled to be less than 2%.

Owner:天津一建建筑工程有限公司

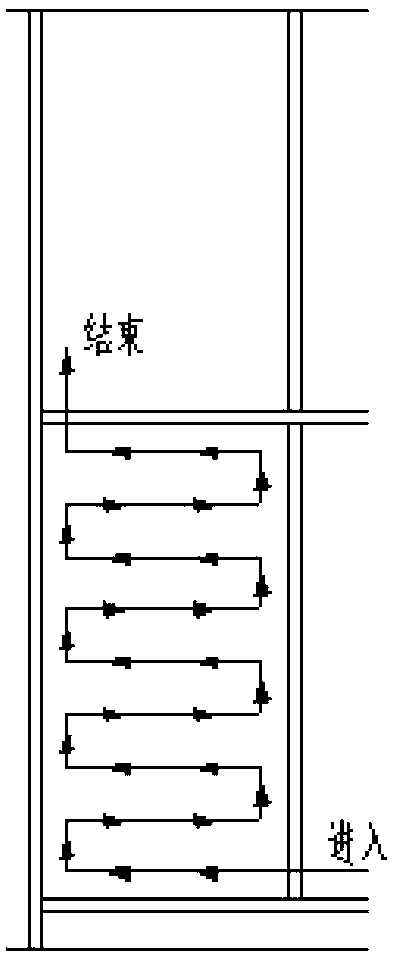

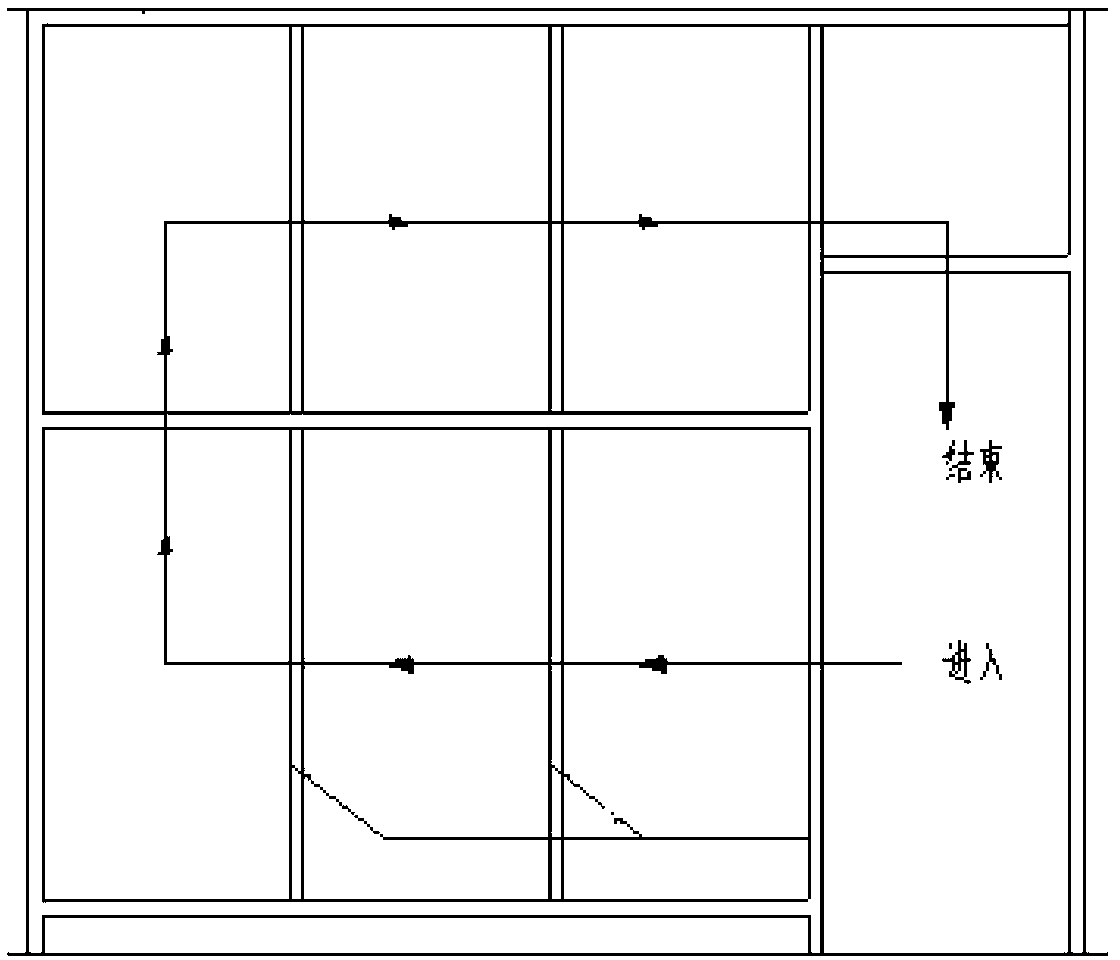

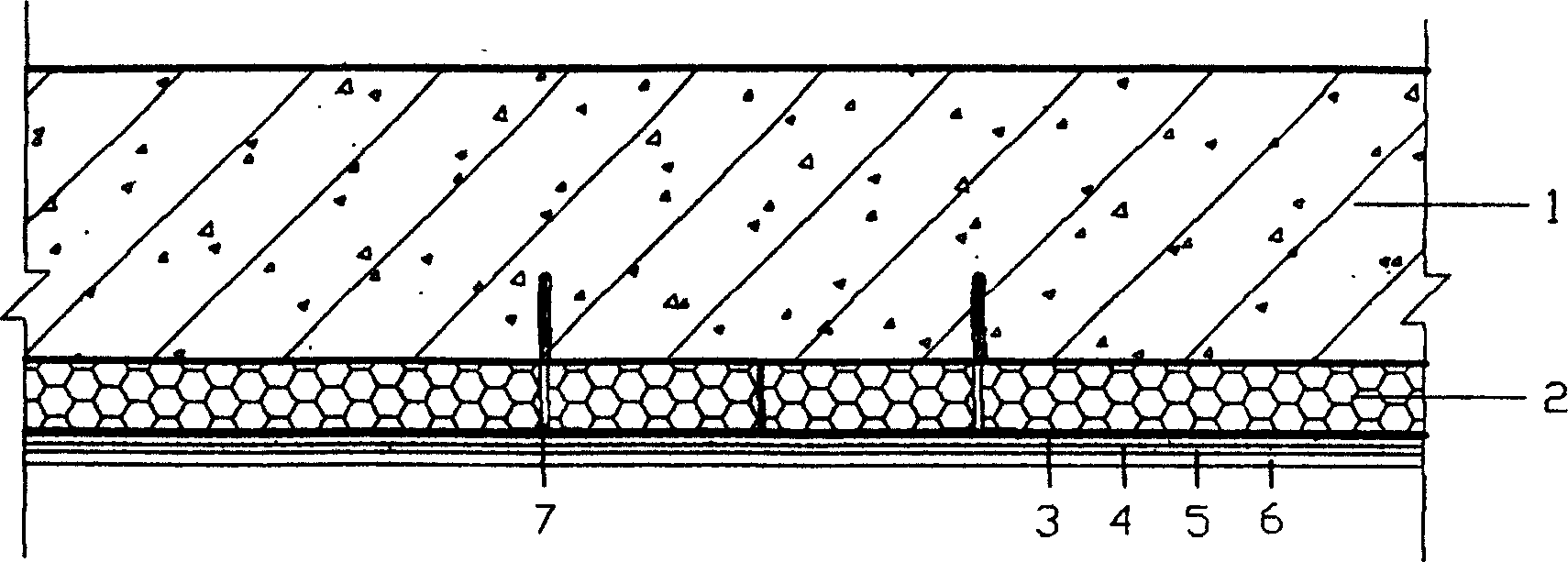

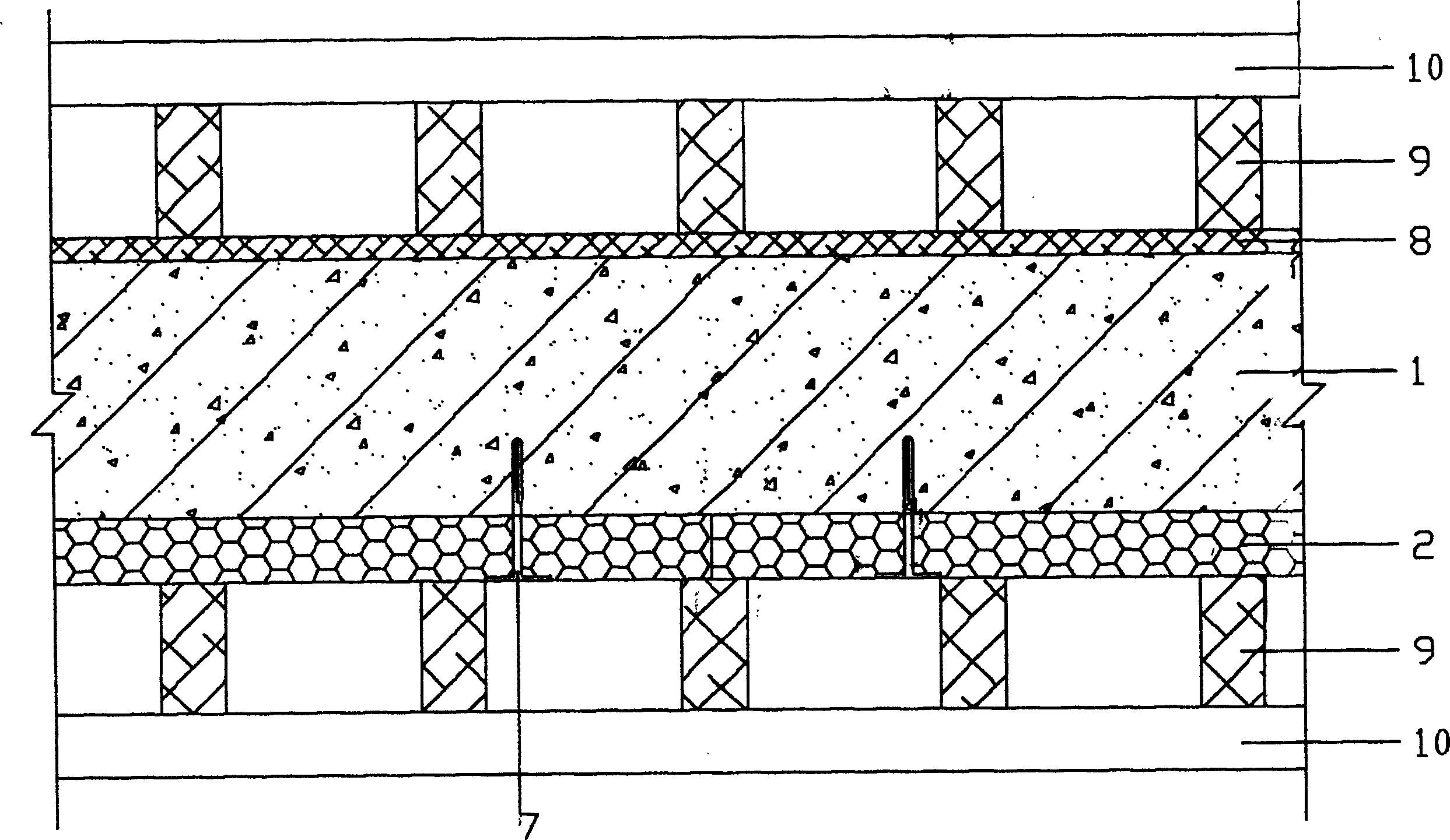

Wall body heat insulating construction method

ActiveCN1651674AReduce labor costsSave on machinery costsHeat proofingSurface constructionEngineering

The present invention discloses a wall body heat-insulating construction method. Said method includes the following main construction steps: firstly, making heat-insulating form and its support, binding steel bar of base wall body, supporting general form at inside of basewall body position, and placing support, then placing heat-insulating form embedded stay bolt at outside of base wall body position, placing wood square at outside of heat-insulating form, placing steel pipe at outside of wood square, concreting, after the concrete is formed, repairing heat-insulating form and making surface treatment, using grooving machine to cut recessed groove on heat-insulating form to make dividing seam, brushing interfacial agent, applying first layer of polymer mortar, laying grid fabric, applying second layer of polymer mortar, finally making surface construction.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

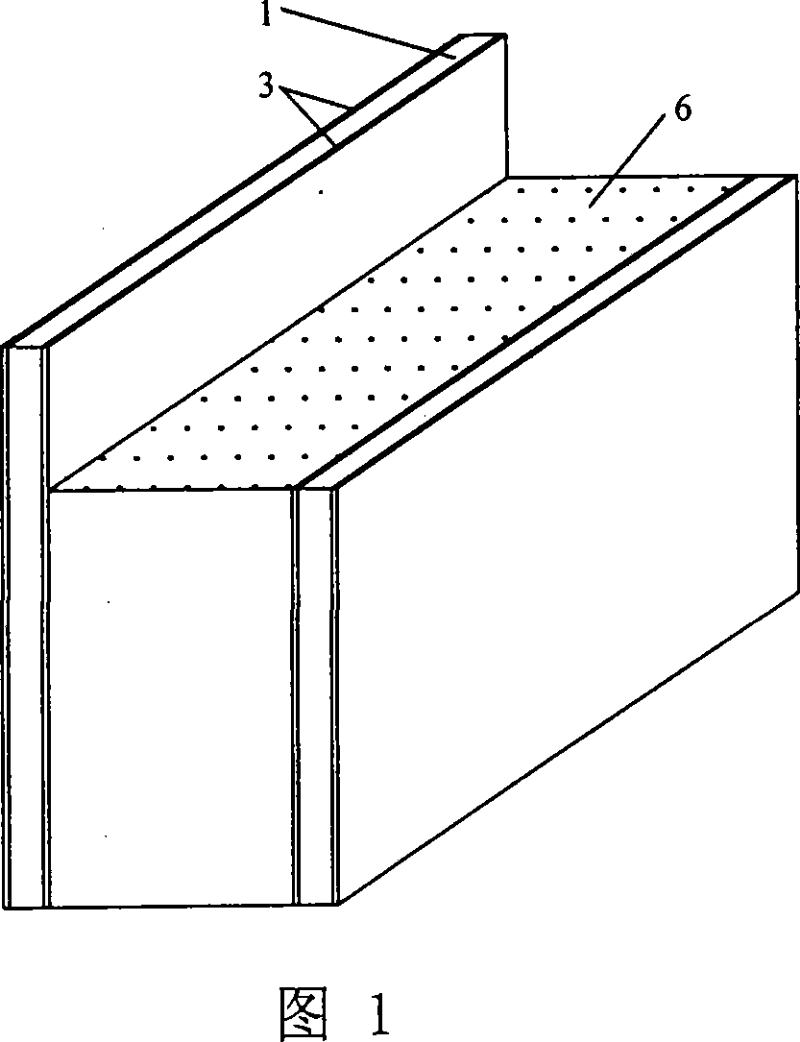

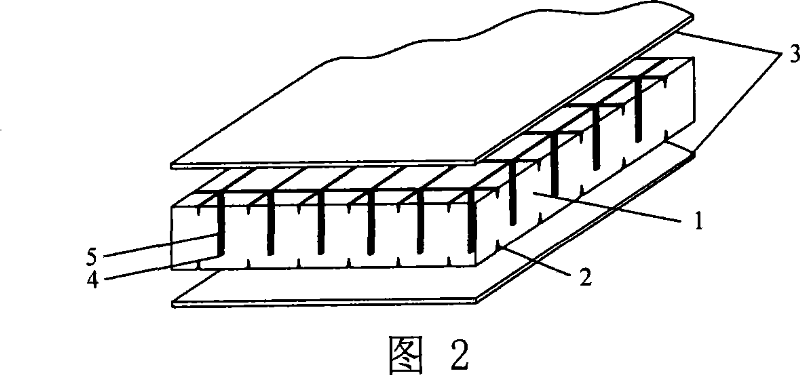

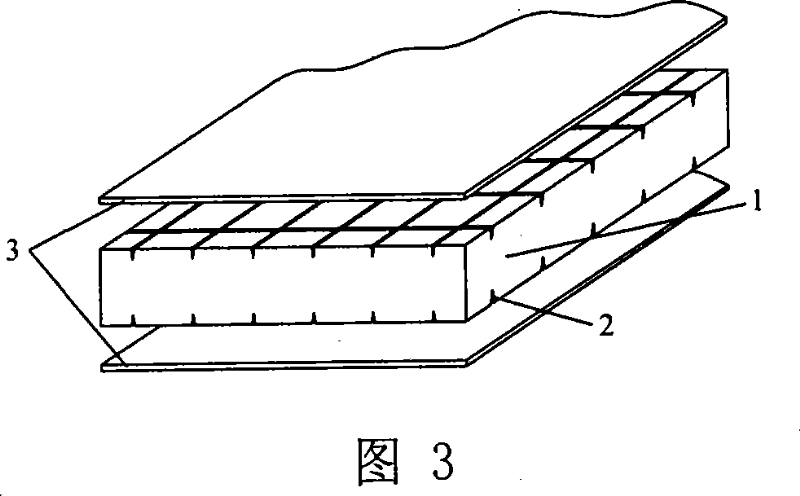

Composite material formwork

InactiveCN101042018AImprove mechanical performanceImprove bonding performanceConstruction materialForming/stuttering elementsFiberMaterials science

The composite material made mold plate comprises the core material, featuring in the slots on the surface of the core material, fiber cloth layer on the top and bottom surface of the core material, setting through holes that stuffed with resin pegs along the thickness direction of the core material at the crossing section of the slots based on requirement. It features in its lightness, high strength, obvious improvement of concrete building speed, not only being able to saving constructing expenses, but also applicable to construction under special conditions.

Owner:NANJING UNIV OF TECH

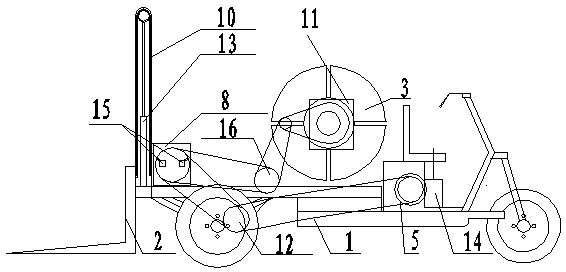

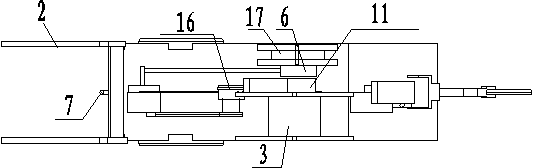

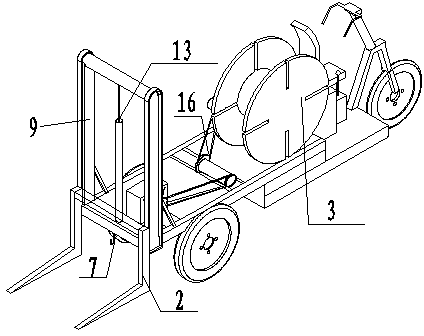

Multifunctional construction vehicle for high-tension line construction

ActiveCN103072513AEasy to useImprove efficiencyItem transportation vehiclesApparatus for overhead lines/cablesArchitectural engineeringHigh tension line

The invention relates to a multifunctional construction vehicle for high-tension line construction, which comprises a power vehicle head and a chassis, wherein the power vehicle head and the chassis are connected with each other; wheels are arranged under the chassis; an engine is arranged on the power vehicle head; the multifunctional construction vehicle is characterized by further comprising a lifting bracket for a forklift, a wire spool and a wire tensioning plate; the wire tensioning plate and the wire spool are mounted on the chassis; and the lifting bracket for the forklift is mounted at the rear end of the chassis. The multifunctional construction vehicle for the high-tension line construction has the beneficial effects of convenience in use, high efficiency, and time-saving and labor-saving properties; the multifunctional construction vehicle is suitable for the wire pole carrying, wire de-spooling and wire tensioning for 10kv line construction on the field of a power supply department; and under the condition of constructing by using the multifunctional construction vehicle for the high-tension line construction, the workers can be reduced to two workers per group and the construction time is saved by a half.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

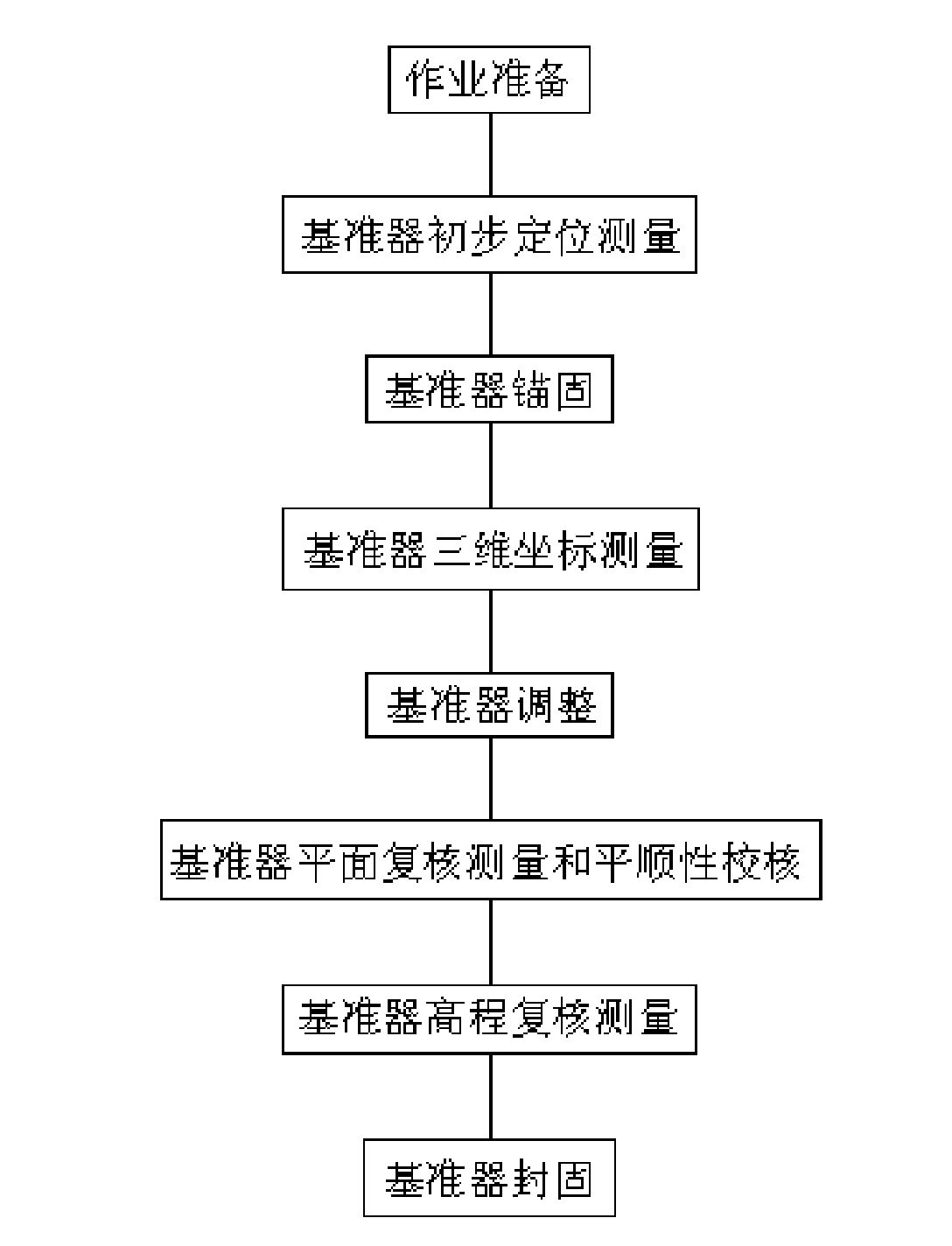

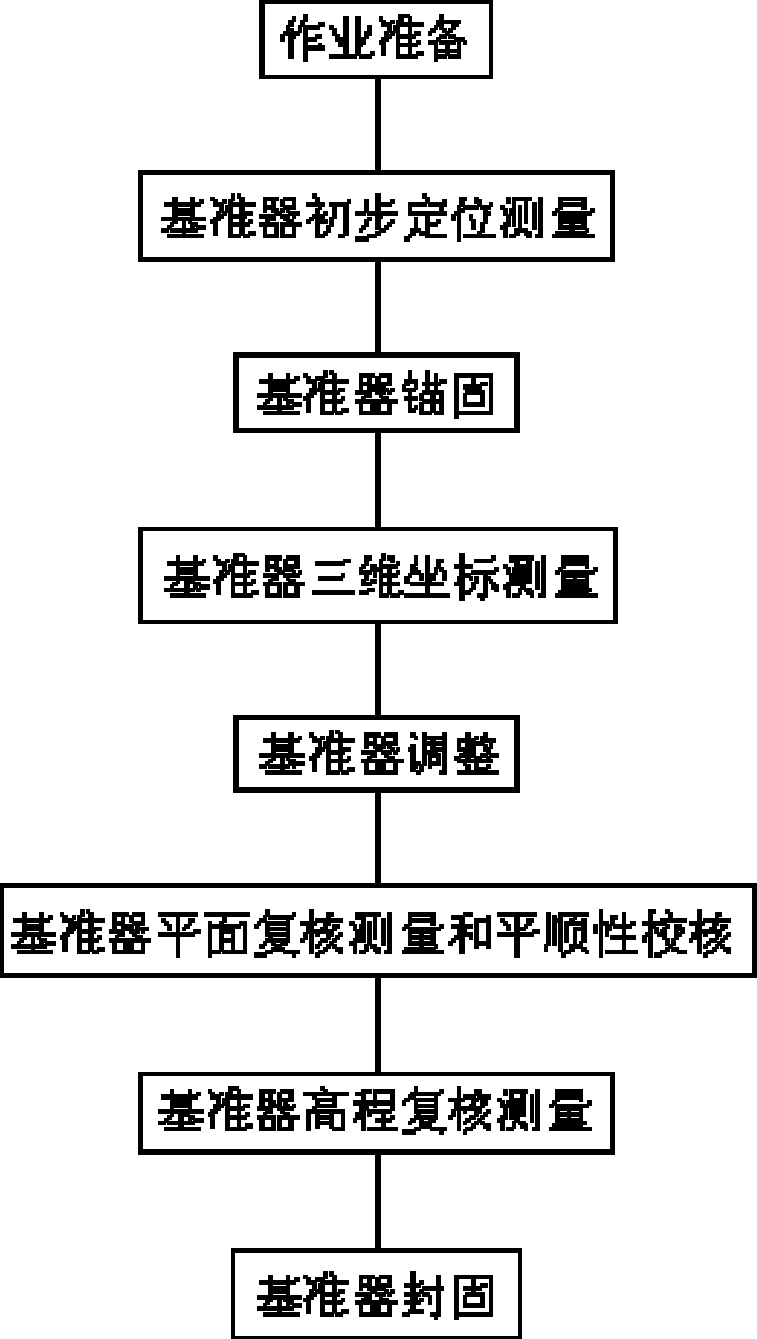

Measurement and installation method of plate-type ballastless track primary standard

ActiveCN101768904ASmall measurement transfer errorHigh precisionMeasuring apparatusPrimary standardEngineering

The invention discloses a measurement and installation method of a plate-type ballastless track primary standard, comprising the following steps of preparing job, preliminarily locating and measuring a primary standard, anchoring the primary standard, carrying out three dimensional coordinate measurement on the primary standard, adjusting the primary standard, carrying out plane re-check measurement and smoothness check on the primary standard, carrying out altitude re-check measurement on the primary standard and sealing the primary standard. The method has small measurement transfer error, high precision, few intermediate job links of the measurement, high work efficiency, material saving and simple, convenient and rapid operation.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

Ecological and environmentally friendly method for controlling pests

InactiveCN104521635AGood control effectReduce the impactAnimal trapsPlant protectionOrganismEnvironmentally friendly

The invention discloses an ecological and environmentally friendly method for controlling pests, which comprises the steps as follows: (1) luring: the pests are attracted by inducing substance or inducing technology; (2) contraceptive sucking: appropriate quantity of mixture of phagostimulant and natural contraceptive for pest sucking is placed; (3) sterile pests competing for mating: the pests sucking the natural contraceptive are sterile, and compete with the pests of the same kind, which do not suck the contraceptive, for mating with opposite sex pests, thereby causing the female pests not to lay eggs or to lay addle eggs so as to reduce the number of the next generation of pests. By means of providing a combination of the natural contraceptive with the substance or technology that has luring ability, the ecological and environmentally friendly method can control the ability of last generation of pests to reproduce next generation of pests so as to reach the purpose of reducing or even exterminating the number of the next generation of pests, so that the purpose of controlling the pests is reached, and simultaneously, the method is safe for environment and personnel.

Owner:刘润玺

Method for treating cotton field straw and residual biodegradable mulch films

InactiveCN105777342AHigh temperature for a long timeSave on machinery costsBio-organic fraction processingBioloigcal waste fertilisersSaw dustAgricultural engineering

The invention provides a method for treating cotton field straw and residual biodegradable mulch films.The method comprises the following steps that before autumn ploughing of a cotton field, the straw and the surface residual biodegradable mulch films are collected, and the smashed straw and the residual biodegradable mulch films are loosely stacked together and are not treated any more in the current year; composting treatment is carried out and completed from 25th May to 10th September of the next year, the cotton field straw and residual biodegradable mulch films stacked in the last year are evenly mixed with waste fungus bag residues or saw dust and animal manure in proportion, and a proper number of biological bacteria are mixed; stack turning and humidification are carried out, and fermentation is started when water content in the materials reaches the level that water stains are left on the hand and no water drop is pinched out when the materials are pinched by hand; the water content is controlled, stack turning is carried out in time, and the humidity of the material stack is controlled; the materials are covered when it rains in the composting process, and composting is completed in 40-60 days.According to the method, bacteria and pests of the straw can be killed, and increase of the cardinal number of cotton field bacterium sources and the population cardinal number of pests is effectively restrained, so that the straw is returned to the field safely and effectively, and meanwhile all the residual biodegradable mulch films are degraded.

Owner:石河子农业科学研究院

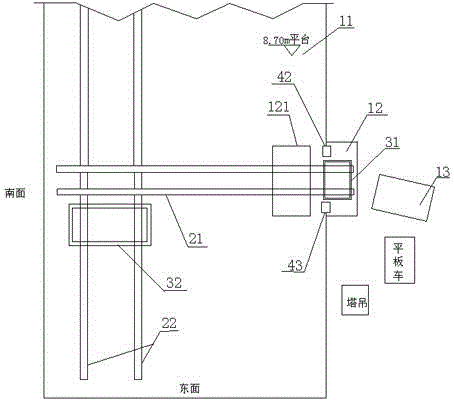

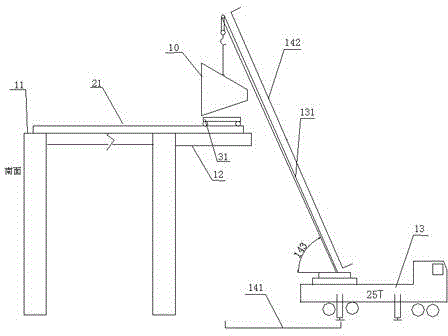

Compartment funnel slipping mounting method and slipping mounting mechanism

ActiveCN104016260AReduce movementLabor savingPortable liftingRunwaysWork productivityIndustrial engineering

The invention discloses a compartment funnel slipping mounting method. The compartment funnel slipping mounting method comprises the following steps: lifting and transferring a compartment funnel, conveying the compartment funnel, and mounting the compartment funnel. The compartment funnel slipping mounting method has the advantages that a rail platform is adopted for completing massive component transportation operation, movement of a crane is greatly reduced, and labour is saved, so that machine cost and labour cost are greatly saved, inclined pulling and lifting caused by movement of a chain block is avoided, construction safety is greatly guaranteed, movement of the crane is reduced while working efficiency is improved, and a construction period is shortened. The invention also discloses a slipping mounting mechanism. The slipping mounting mechanism is a device adopted for implementing the compartment funnel slipping mounting method, safe and stable implementation of conveying, transportation and mounting of the compartment funnel can be effectively guaranteed, massive manual dragging steps in the previous mounting method are eliminated, structure is simple and stable, and implementation is convenient.

Owner:CHINA MCC5 GROUP CORP

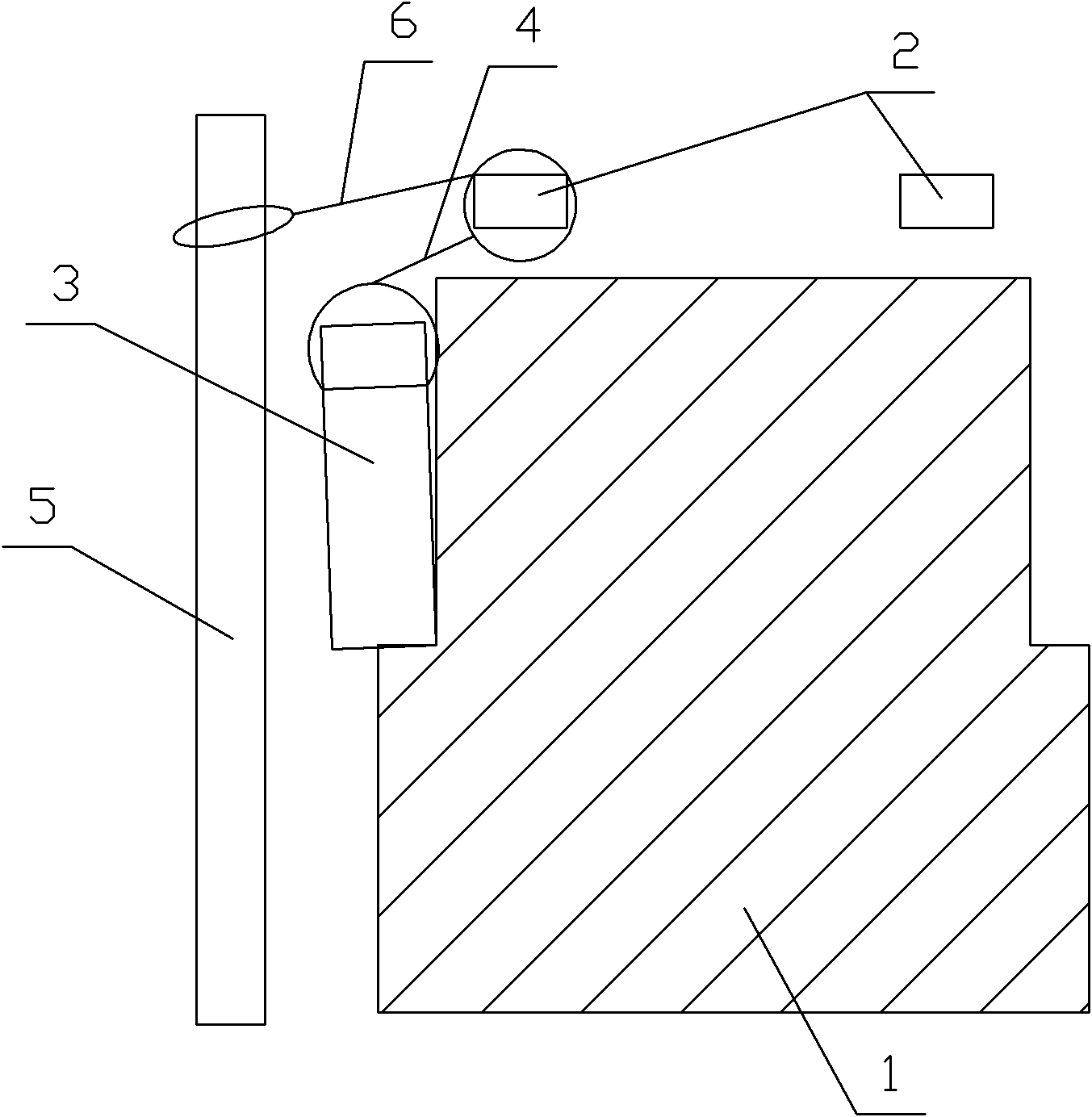

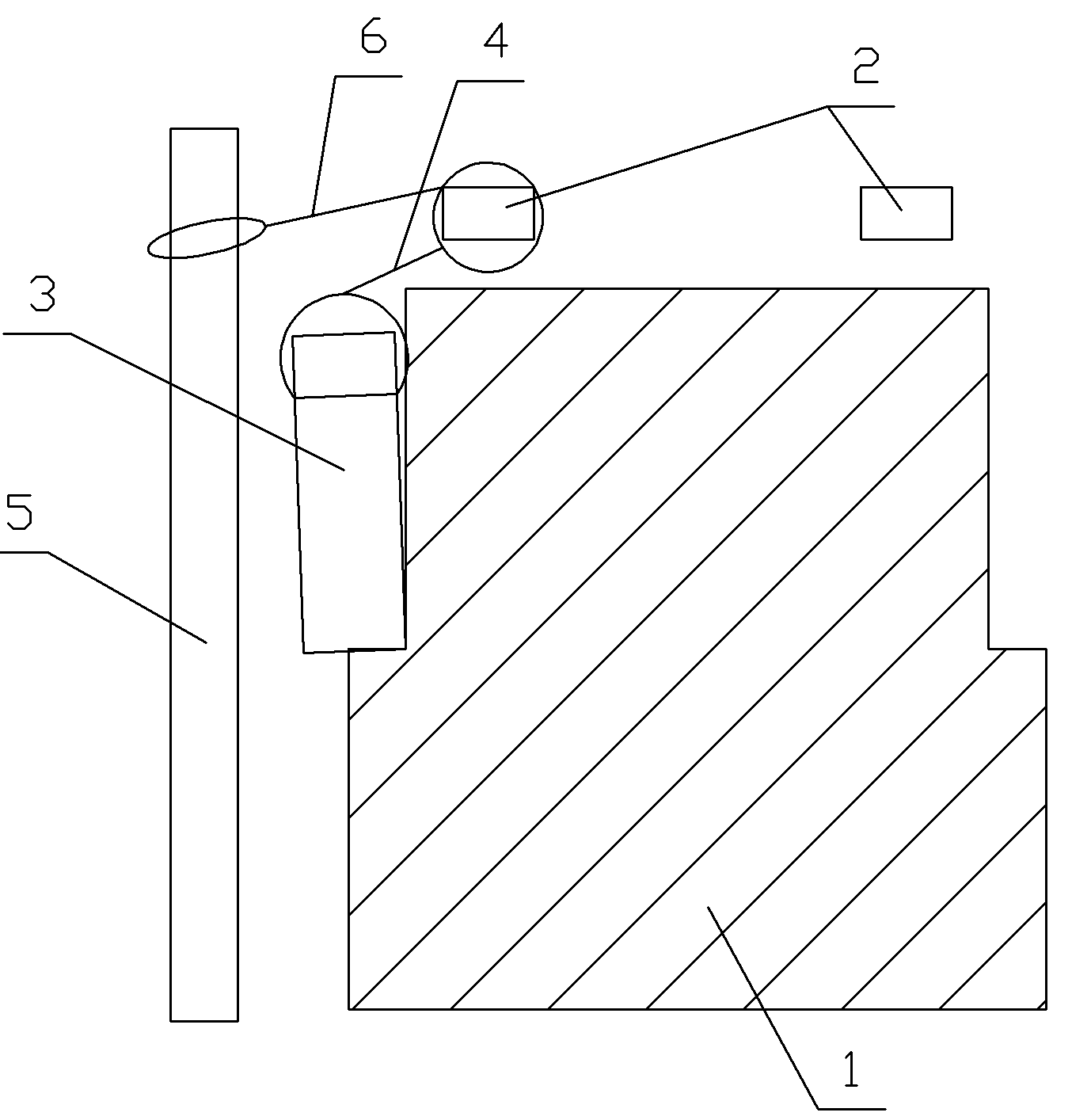

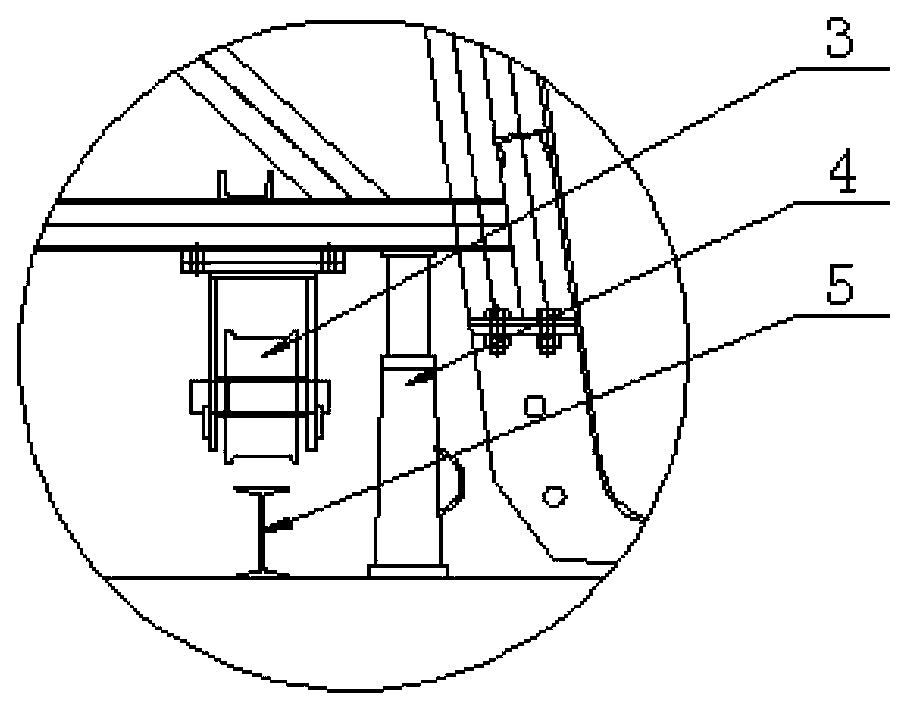

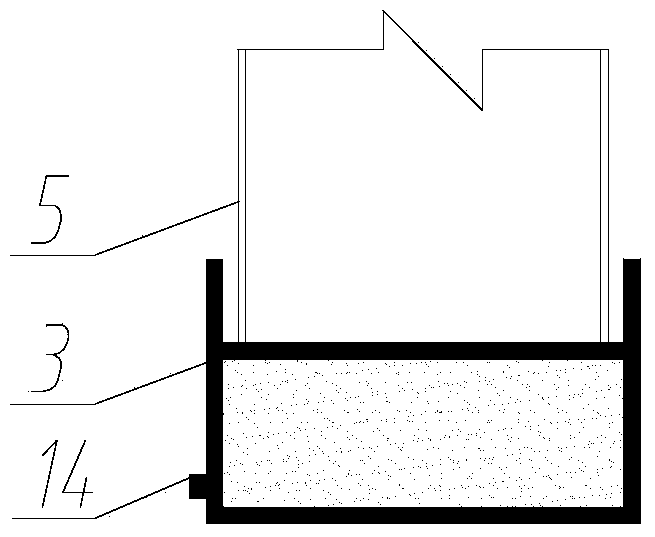

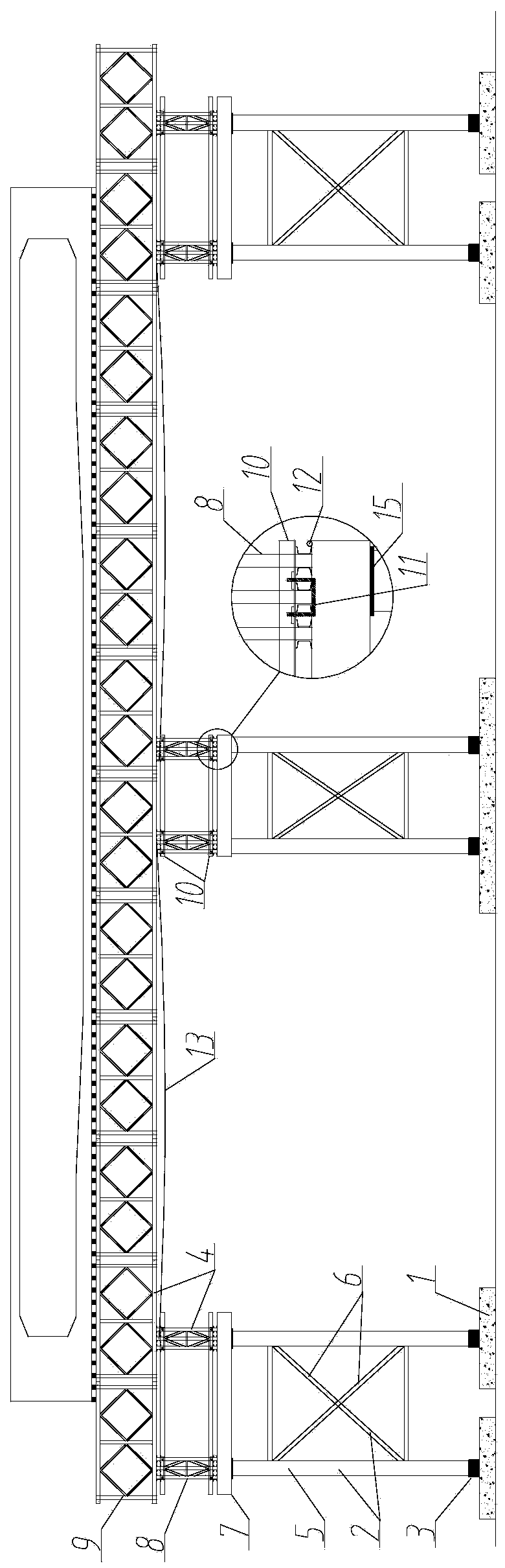

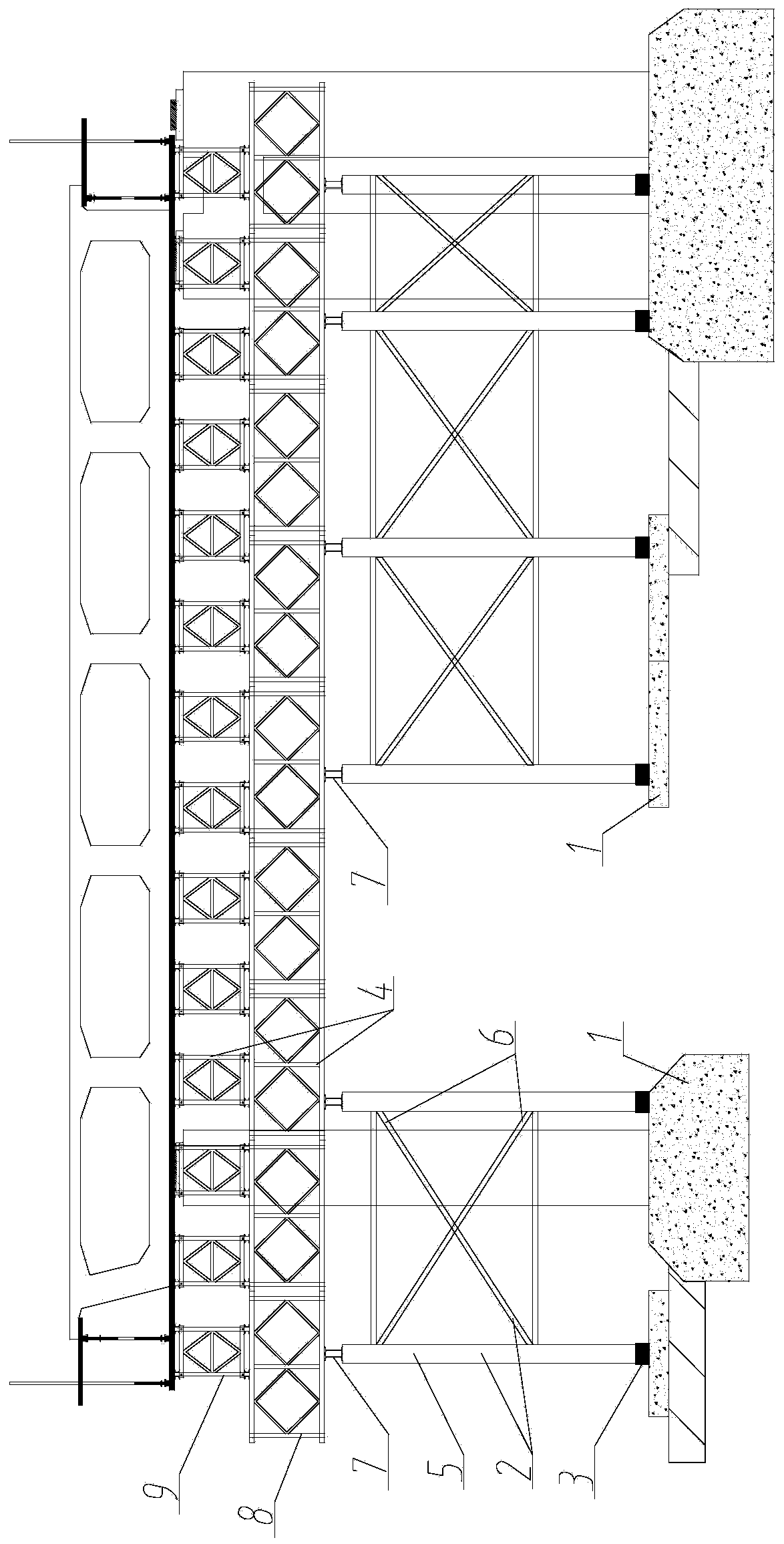

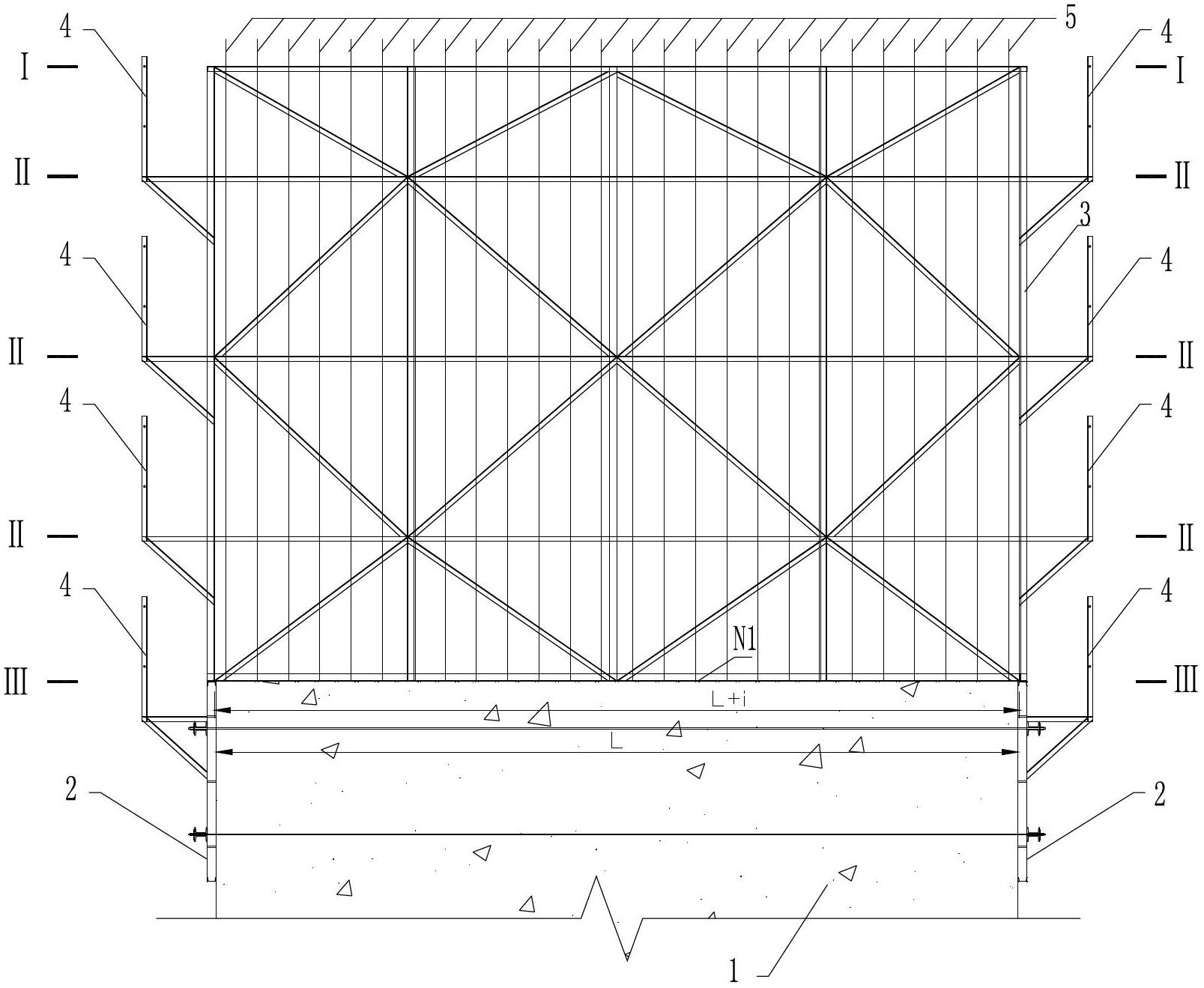

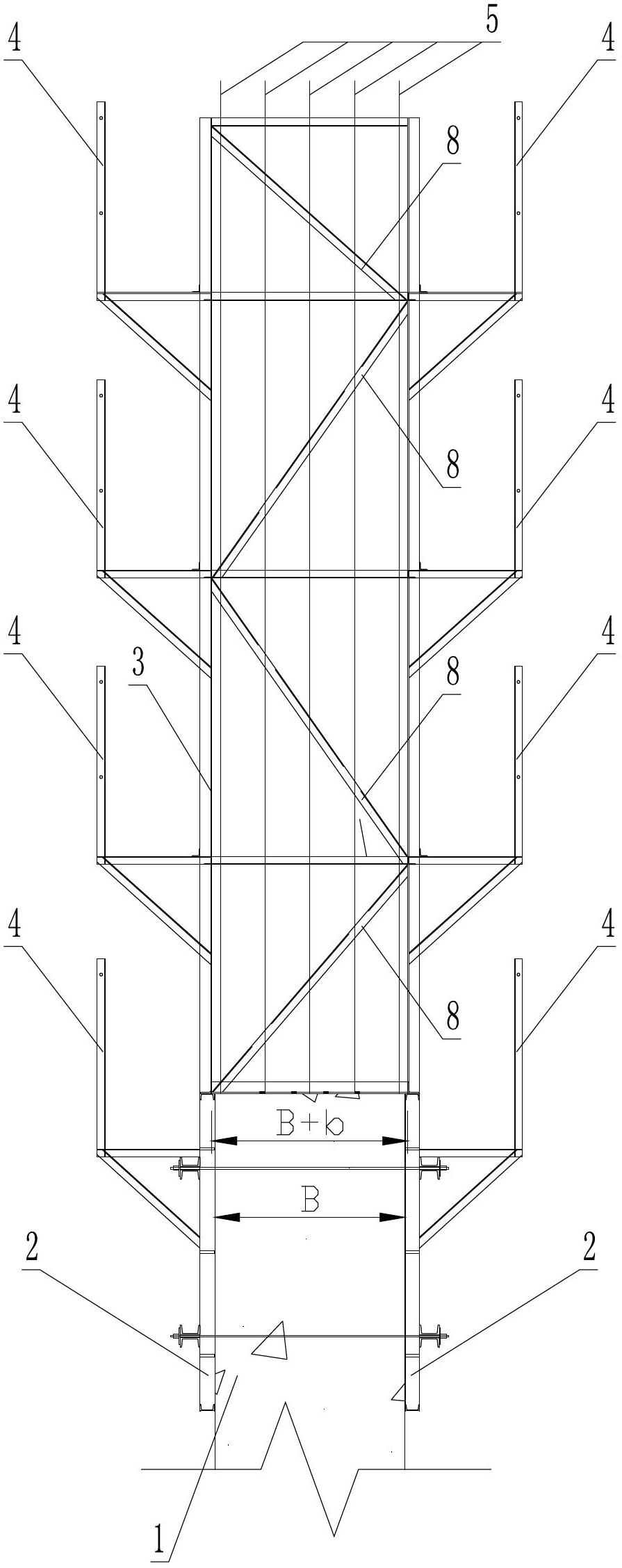

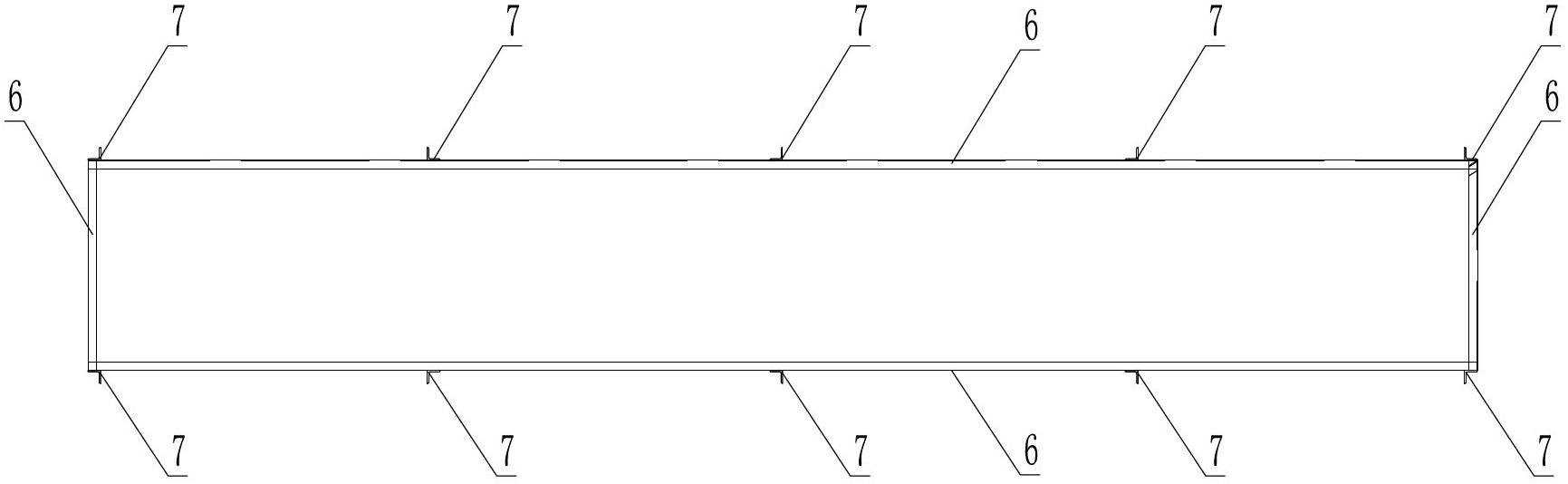

High pier construction method for external whole operation platform

The invention relates to a high pier construction method for an external whole operation platform. The construction method comprises the following steps that: firstly, the external whole operation platform (3) is machined according to the size of the outline of a pier body; before pier body construction, the external whole operation platform (3) is wholly hoisted to the top of a poured pier body (1) and is connected with a poured pier body template (2) on the outer surface of the poured pier body (1) by bolts; when steel bars are installed, construction is carried out on a safety operation platform (4) of the external whole operation platform by workers and installation and positioning of the steel bars are assisted by utilizing the external whole operation platform; and after the installation of the steel bars is finished, the connecting bolts between the external whole operation platform (3) and the poured pier body template (2) are dismantled, and the external whole operation platform (3) is wholly hoisted and dismantled by a crane... According to the high pier construction method for the external whole operation platform, the external whole operation platform is adopted in the steel bar construction of the high pier body, the thickness of a concrete protection layer of the steel bars of the high pier as well as construction safety can be ensured, and the construction efficiency can be improved.

Owner:CHINA MAJOR BRIDGE ENG +2

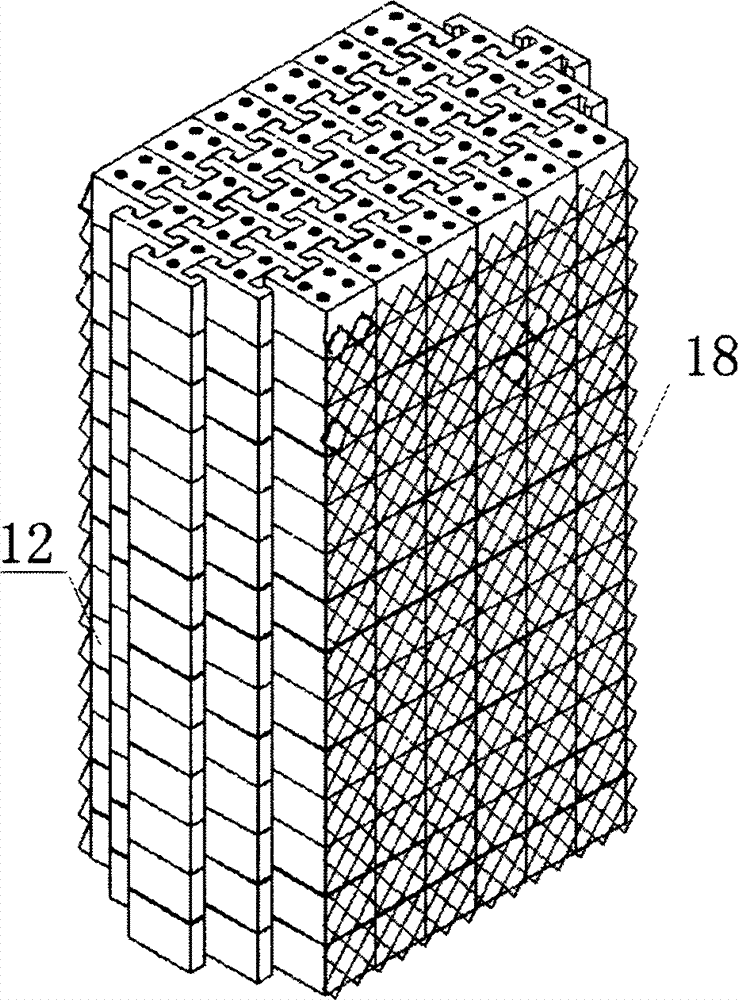

Assembled type reinforced concrete bridge construction technology

InactiveCN103572706AEasy to installSuspension traverse is simpleBridge erection/assemblyReinforced concreteBridge deck

An assembled type reinforced concrete bridge construction technology is characterized by comprising the steps that A, a plurality of reinforced concrete transverse block bodies (1), a plurality of reinforced concrete longitudinal block bodies (5), a plurality of reinforcing steel bars (8) with the two ends being provided with threads in a tapping mode, nuts matched with the threads, a capping beam (16) with holes (13), a rubber support (17), a bridge deck slab (11), cement, sand stone, a gabion box (15), heavy wires, plain round bars, soilbags (14), tapping screws and a steel wire mesh (18) are prepared; B, ground treatment is carried out; C, bridge pier and abutments (12) are assembled; D, the capping beam (16) is moved onto the bridge pier and abutments (12) by the adoption of a derrick mast method; E, the bridge deck slab (11) is moved onto the rubber support (17) of the capping beam (16) by the adoption of a derrick mast method; F, cement mortar is poured into gaps among block bodies of the bridge pier and abutments (12) and gaps between the reinforcing steel bars (8) and the block bodies; G, the steel wire mesh (18) is nailed on the surfaces of the bridge pier and abutments (12), and a fine aggregate concrete layer is further sprayed.

Owner:SOUTHWEAT UNIV OF SCI & TECH

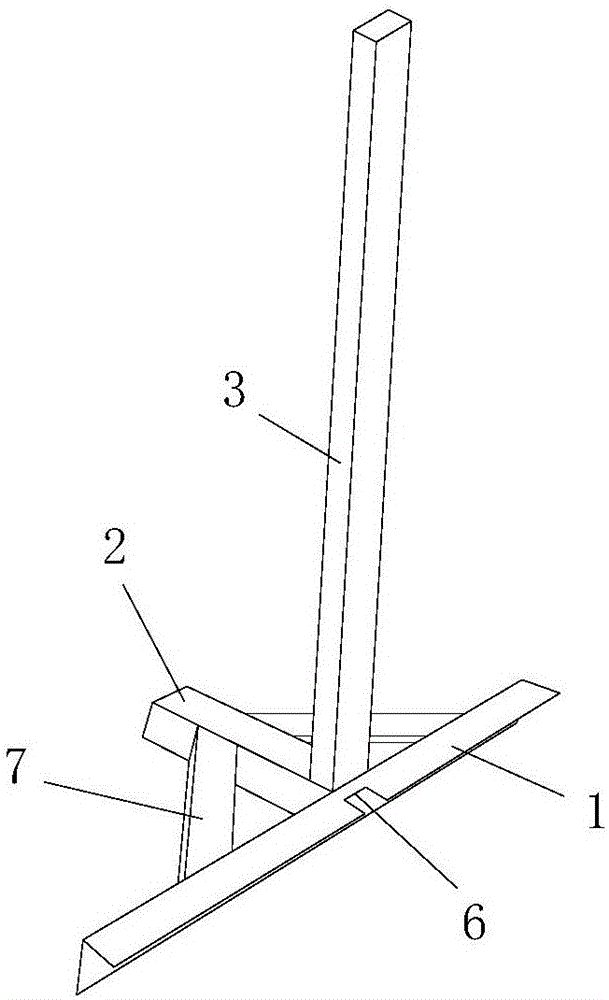

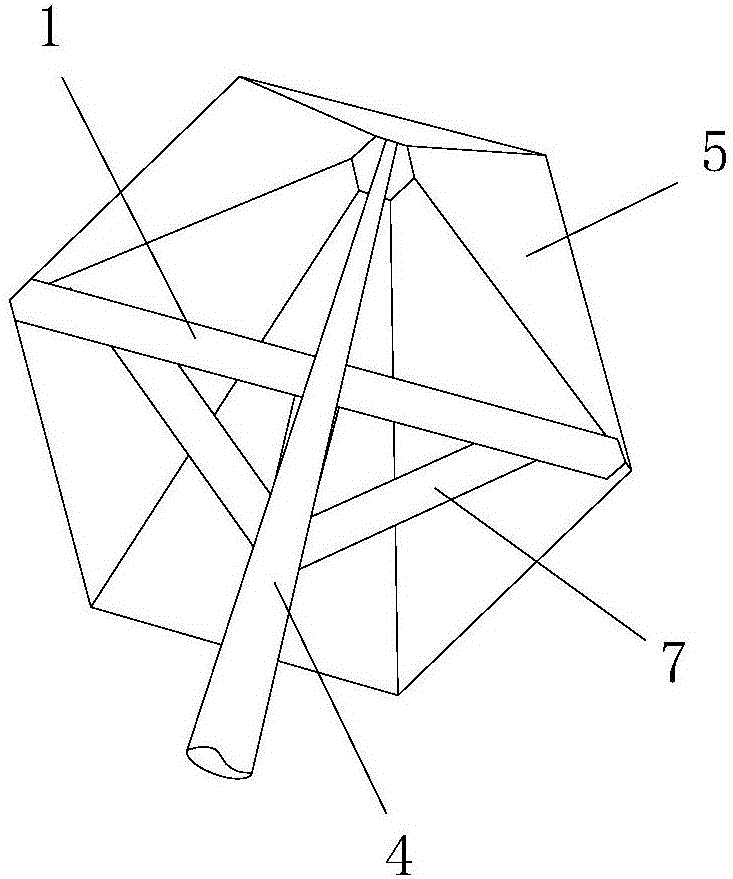

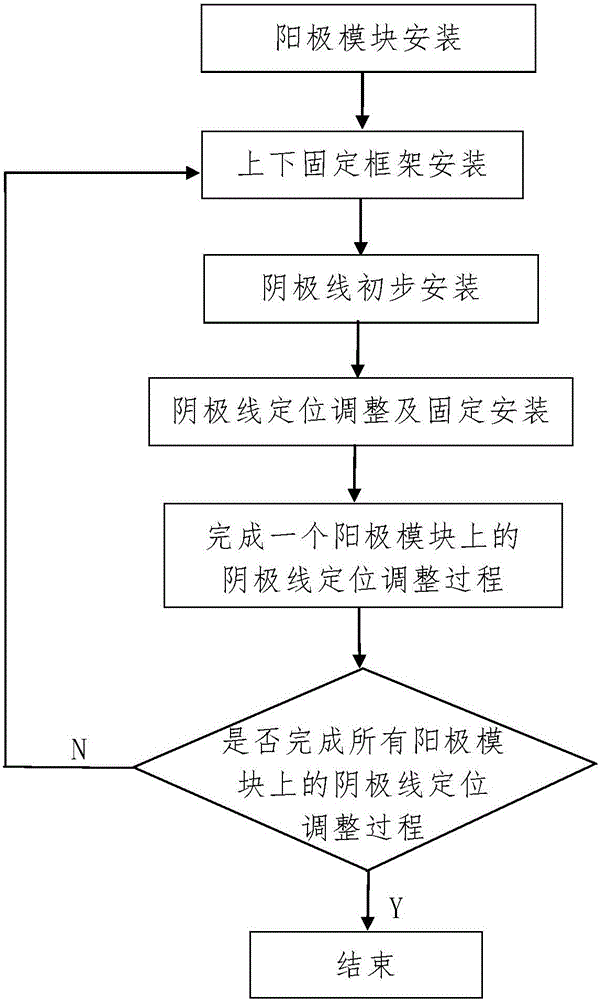

Cathode line positioning die and cathode lien positioning and adjustment construction method

ActiveCN106238212ASimple structureEasy to processElectrostatic separation detailsArchitectural engineeringAnode

The invention discloses a cathode line positioning die and a cathode lien positioning and adjustment construction method. The positioning die comprises a rear measuring rod, a front measuring rod arranged on the front side of the middle of the rear measuring rod and a vertical rod fixed behind the rear portion of the front measuring rod, wherein the front measuring rod and the vertical rod are located in front of the rear measuring rod, the rear measuring rod, the front measuring rod and the vertical rod are straight rods, the rear measuring rod and the front measuring rod are arranged in a perpendicular mode, the rear measuring rod and the front measuring rod form a horizontal positioning rack, and a clamping groove for positioning an adjusted cathode line is formed in the rear side of the middle of the rear measuring rod. The constriction method comprises the steps that 1, anode module installation is performed; 2, cathode line installation construction is performed: when the cathode line is installed on any group of anode modules, the process is that 201, upper and lower fixing frames are installed; 202, preliminary cathode line installation is performed; 203, cathode line positioning, adjustment and fixing installation are performed. The cathode line positioning die is reasonable in design, simple and convenient to use and operate, good in using effect and capable of simply, conveniently and rapidly perform accurate cathode line positioning and ensuring cathode line installing precision.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

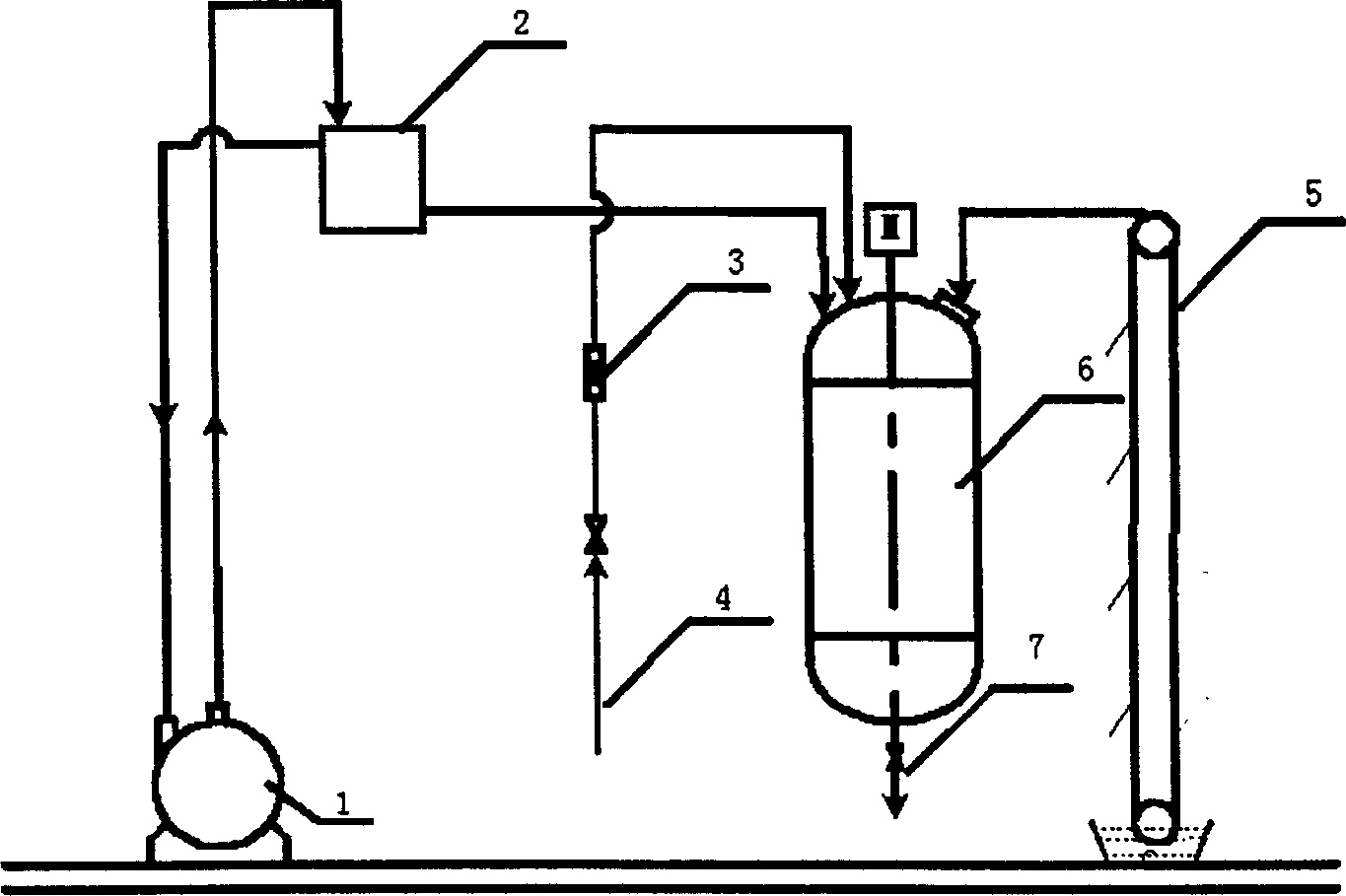

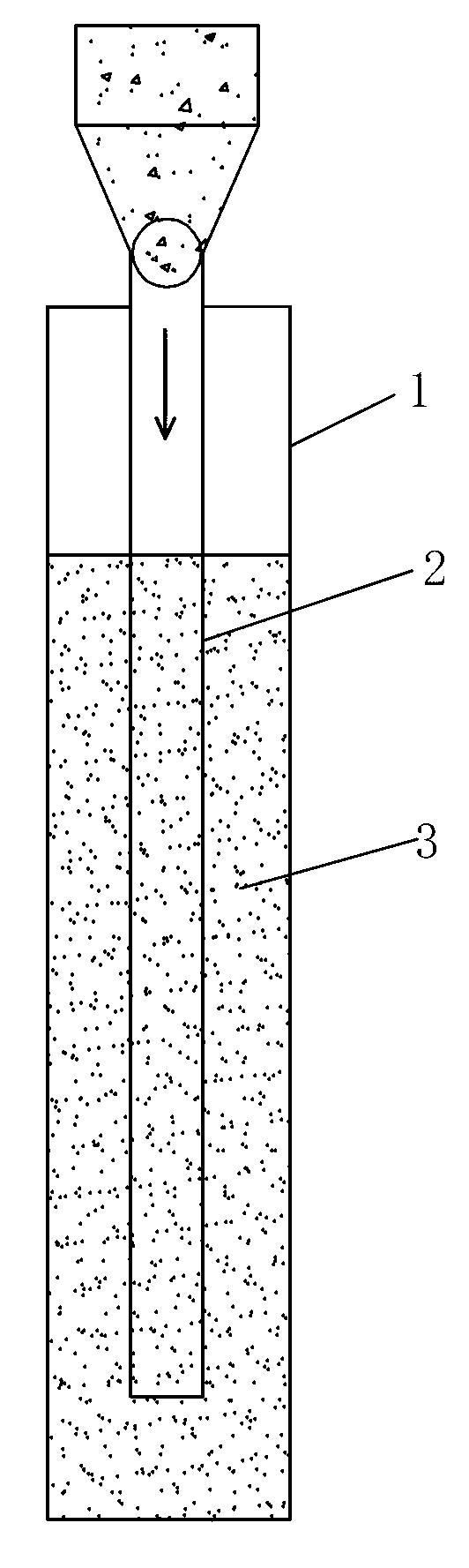

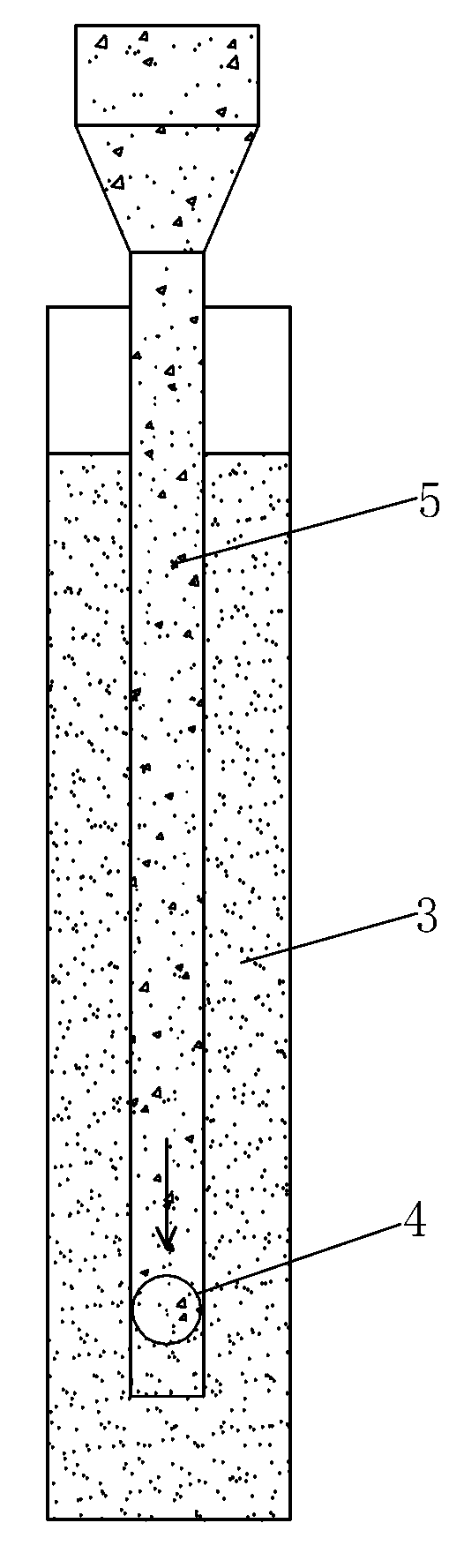

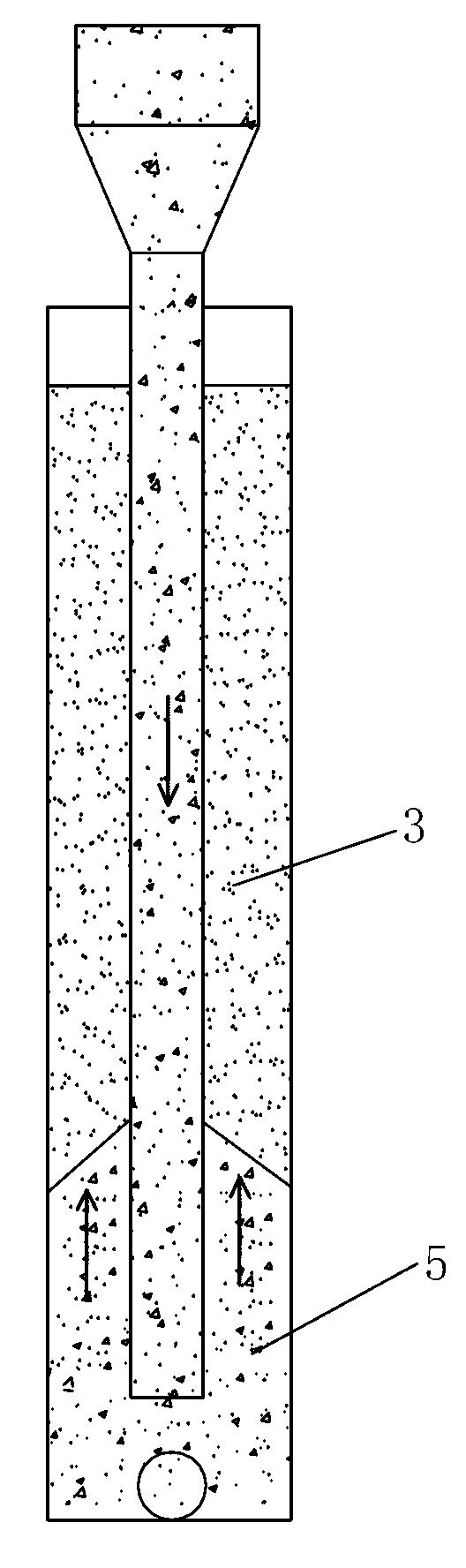

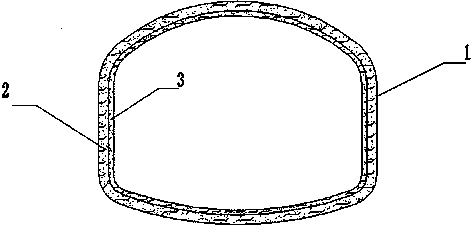

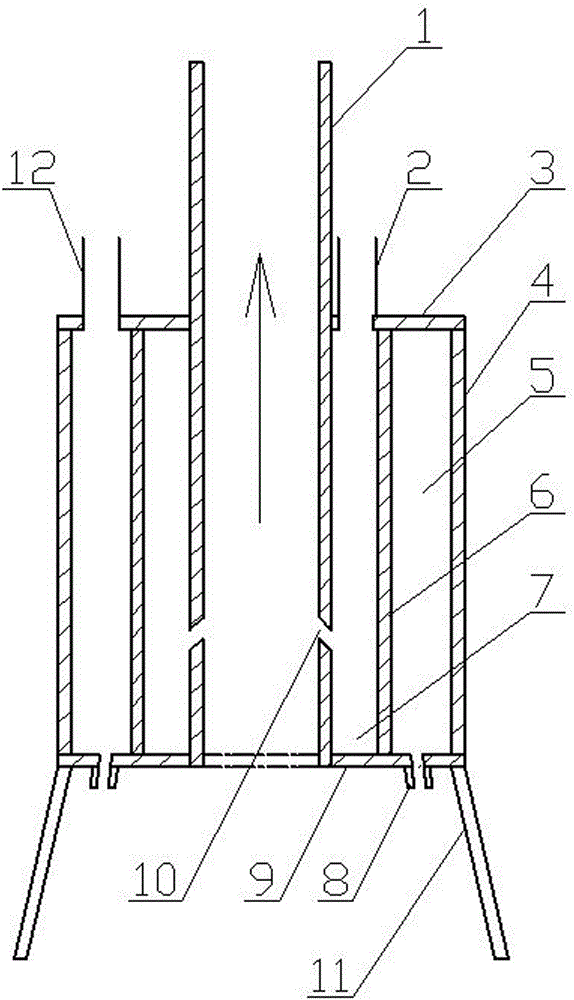

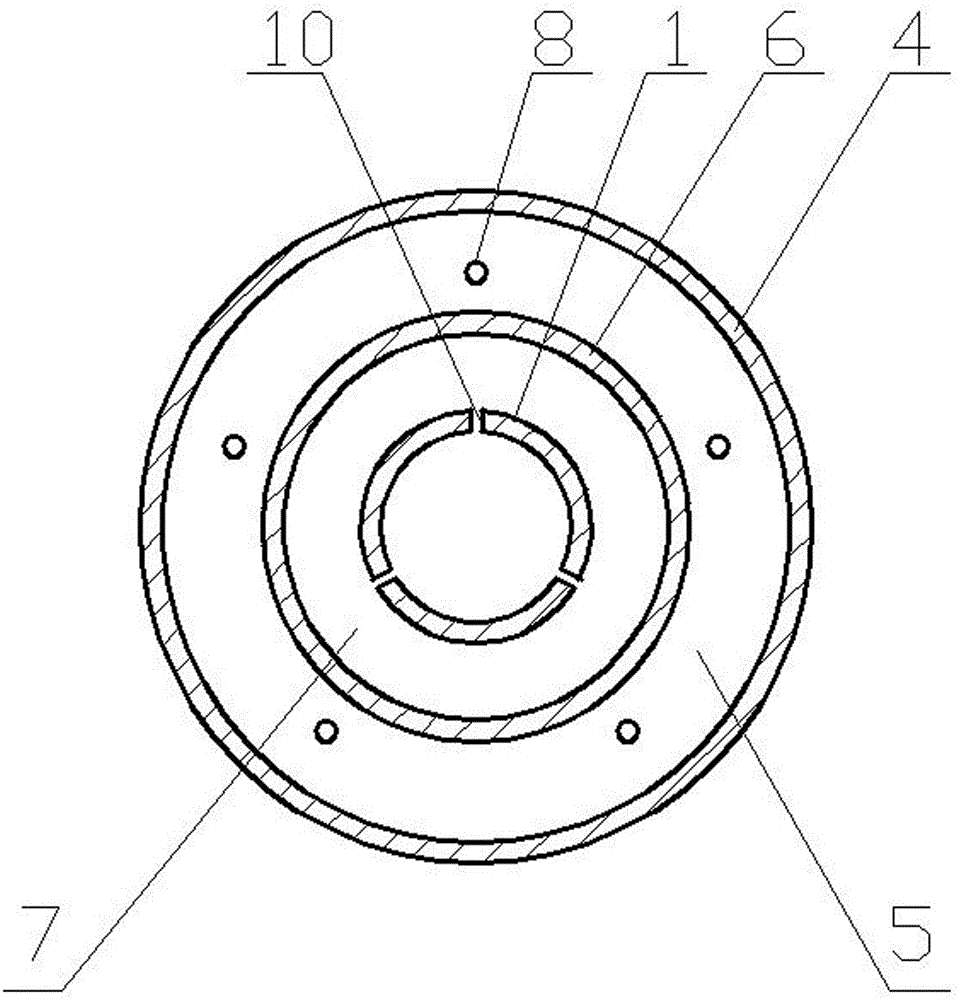

Underwater concrete spouting laitance prevention water-proof device

The invention relates to an underwater concrete spouting laitance prevention water-proof device, which relates to the field of building engineering. The spouting laitance prevention water-proof device comprises an annular water-proof board, a rubber barrier ring, an elastic hair brush and an air chamber; the annular water-proof board is arranged between the outer side of a spouting guide tube and the inner wall of a steel reinforcement cage inside a pile body; the rubber barrier ring is arranged inside the inner ring of the annular water-proof board and sleeved on the outer wall of the spouting guide tube; the elastic hair brush is uniformly connected with the outer circumference of the annular water-proof board and is extended to the outer wall of the pile body from the outer circumference of the annular water-proof board; the air chamber is connected with the upper side of the annular water-proof board; and the air chamber is connected with an inflating guide tube. The underwater concrete spouting laitance prevention water-proof device disclosed by the invention can be submerged underwater successfully, and also can be tightly attached to the concrete spouting surface, so that the concrete spouting surface is isolated from water, the concrete strength of pile head is efficiently ensured, and the device is simple in construction, convenient to operate, low in cost and short in time limit for a project.

Owner:GUANGXI CONSTR ENG GROUP THE THIRD CONSTR ENG +1

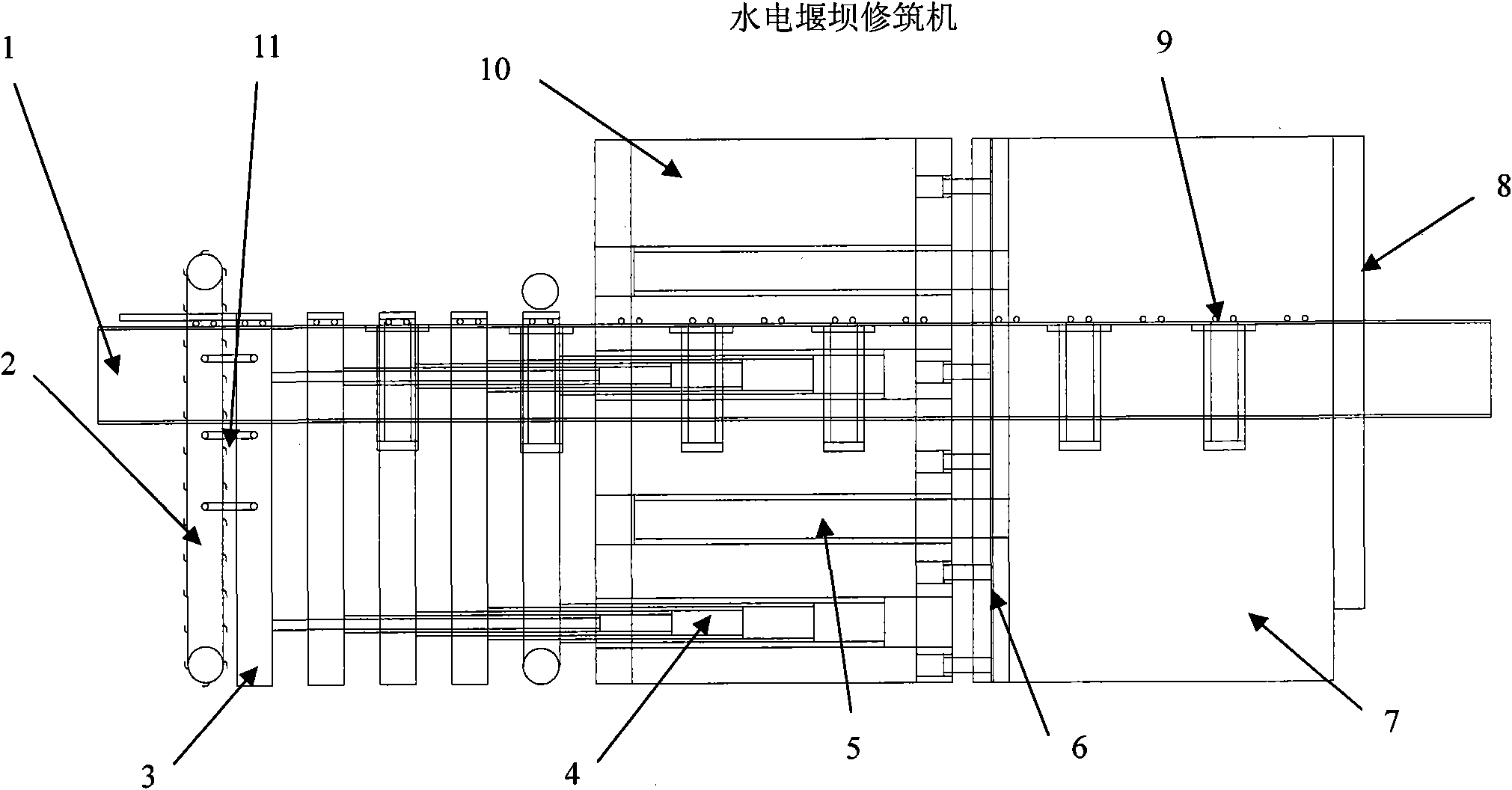

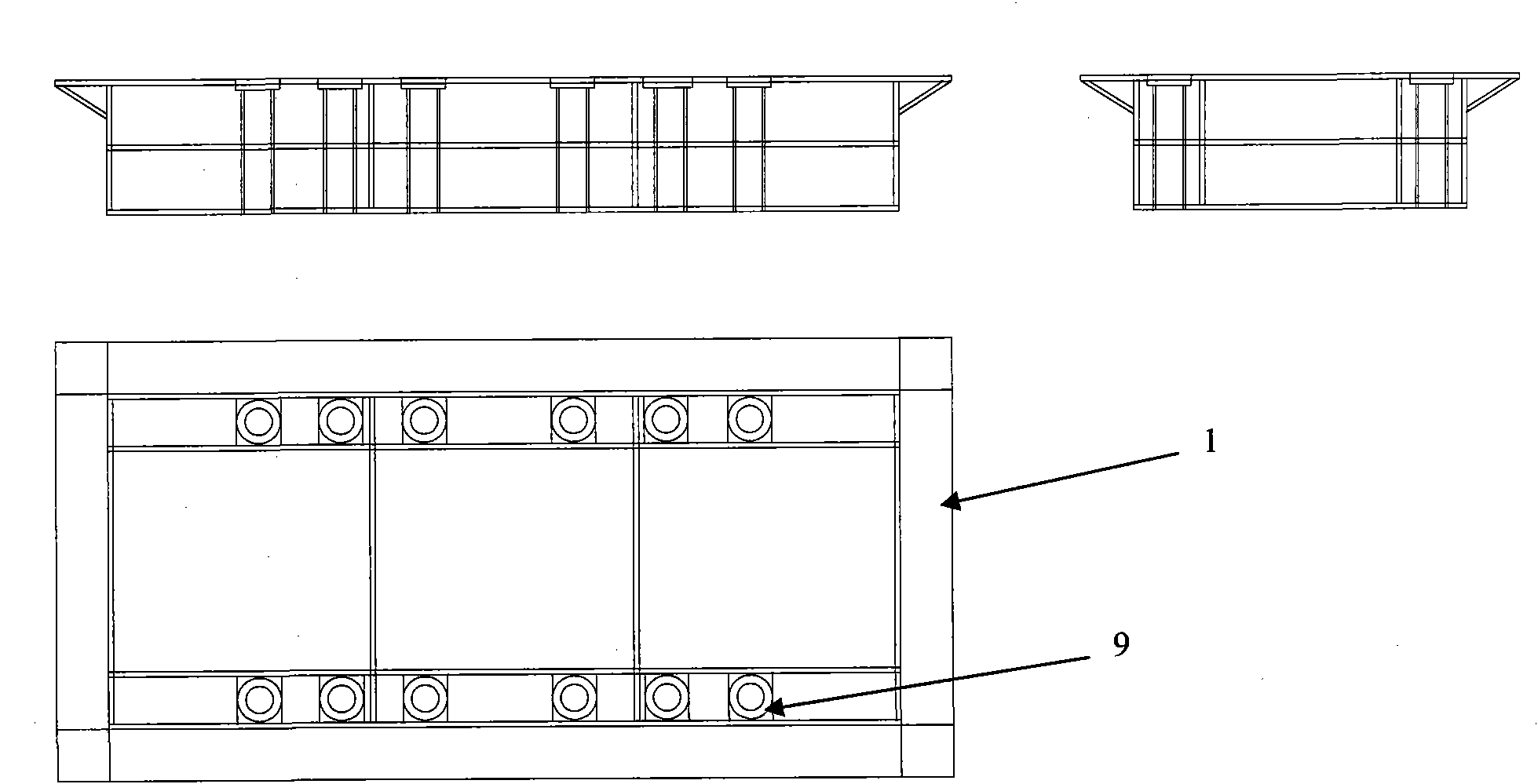

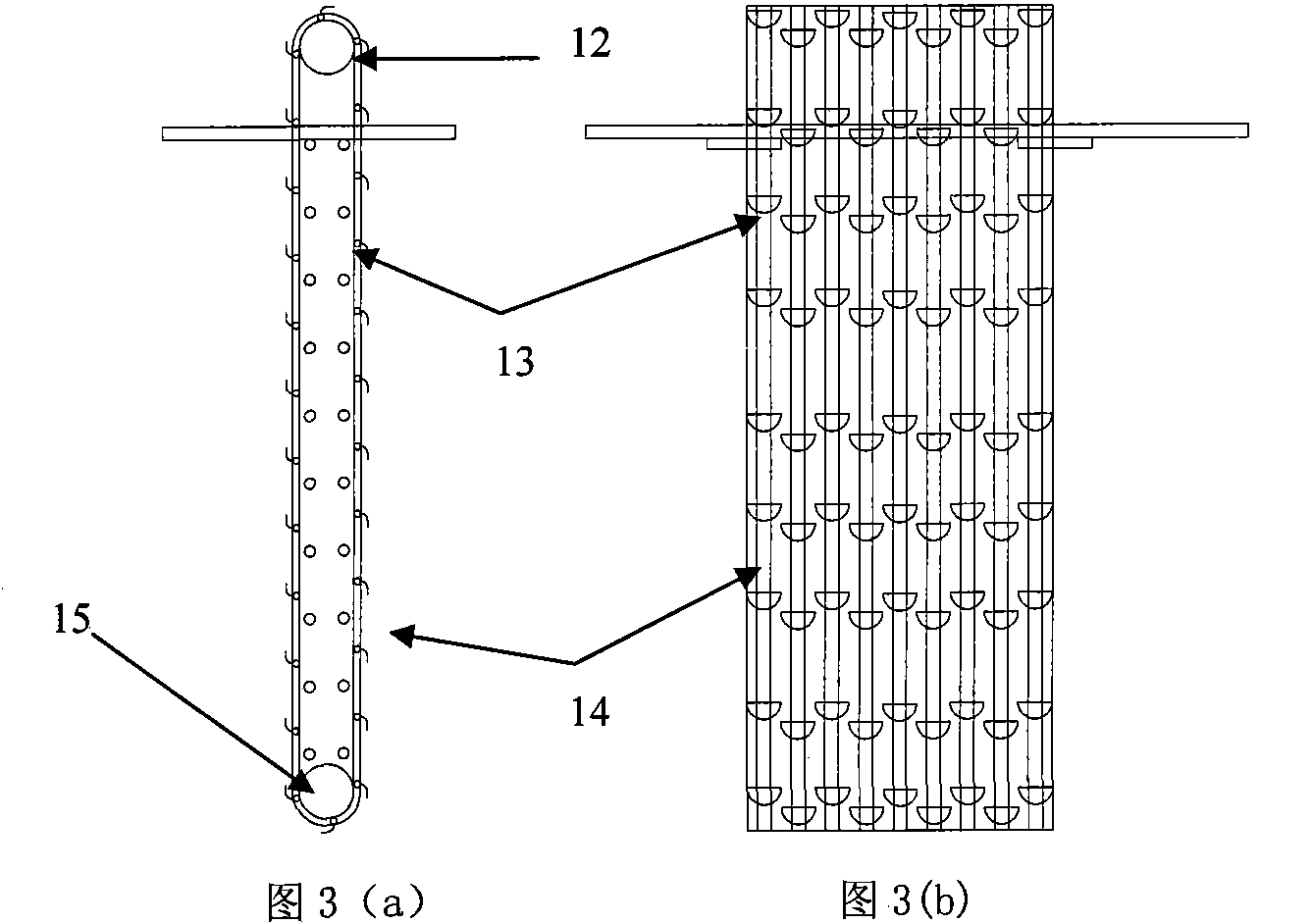

Hydroelectric barrage building machine

InactiveCN102031766AMeet the design requirementsIncrease construction costsBarrages/weirsExcavationsPower stationCofferdam

The invention relates to a hydroelectric barrage building machine. A method comprises the following steps of: building a cut-off dam in a concrete pouring way by mainly utilizing the characteristics of concrete materials so as to change a silty sand earth and stone material intercepting method used for thousands of years up to now; and carrying out cut-off dam building through one-stop operation including cleaning excavation, propelling and concrete pouring, water-intercepting barrage engineering, riverbed platform engineering, marginal slope protection engineering, and the like on a riverbed dam foundation by adopting a mechanized construction technology and integrating mechanical collecting saw slot excavation, hydraulic supporting wall protection, hydraulic propelling and hydraulic box type concrete pouring into a whole. The invention is mainly used for the engineering of building a riverbed water-intercepting barrage, a riverbed platform foundation and a river and lake marginal slope protection foundation under the conditions that a dam type power station needs to build the cut-off dam and a dam-free power station does not need to build a cofferdam.

Owner:符卫平

Tunnel lining construction method

ActiveCN103670439AImprove adhesionSimple processSolid waste managementUnderground chambersFiberShotcrete

The invention discloses a tunnel lining construction method which includes the following steps: constructing full-fracture-surface steel arches along the longitudinal surrounding rock excavation face of a tunnel at intervals, spraying two layers of low-carbon type fiber concrete layers at the position, between adjacent steel arches, of the surrounding rock excavation face at a high speed with a wet spraying machine depending on air pressure, and forming a tunnel lining structure until the tunnel is through. The tunnel lining construction method is simple in construction process and safe in construction procedure, the sprayed concrete rebound rate can be lowered, the spraying performance is improved, the energy consumption is reduced, and the formed tunnel lining structure is high in toughness, good in anti-permeability, good in durability and particularly suitable for weak surrounding rock tunnel supports constructed with the mining method.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

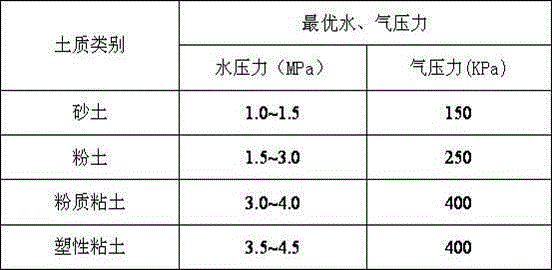

Water knife mud suction device applied to hardened soil body structure

InactiveCN105113562ALess machinery and laborImprove suction efficiencyMechanical machines/dredgersWater jet cutterOpen structure

The invention belongs to the technical field of underwater dredging construction, and particularly relates to a water knife mud suction device applied to a hardened soil body structure. The device aims to solve the problem that a common mud suction device is low in mud suction efficiency. The water knife mud suction device applied to the hardened soil body structure comprises a mud discharge pipe, a water pressure system and an air pressure system are arranged on the periphery of the lower section of the mud discharge pipe, a high-pressure water outlet is formed in the bottom of the water pressure system, the air pressure system is provided with a high-pressure air inlet which is inclined upwards and communicated with the interior of the mud discharge pipe, and the upper end and the lower end of the mud discharge pipe are of open structures. Firstly, the hardened soil body structure is cut into fragments or slurry suitable for being discharged through the water pressure system, and the aim of damaging the hardened soil body structure is achieved; then, the fragments or the slurry is pumped out through the mud discharge pipe by means of the air pressure structure, pertinence to riverbed geology with the clay property is higher, iron-manganese nodules mixed in a clay layer can also be cleaned away and discharged, mud suction efficiency is improved, and meanwhile construction cost is controlled.

Owner:CHINA RAILWAY SIXTH GROUP +1

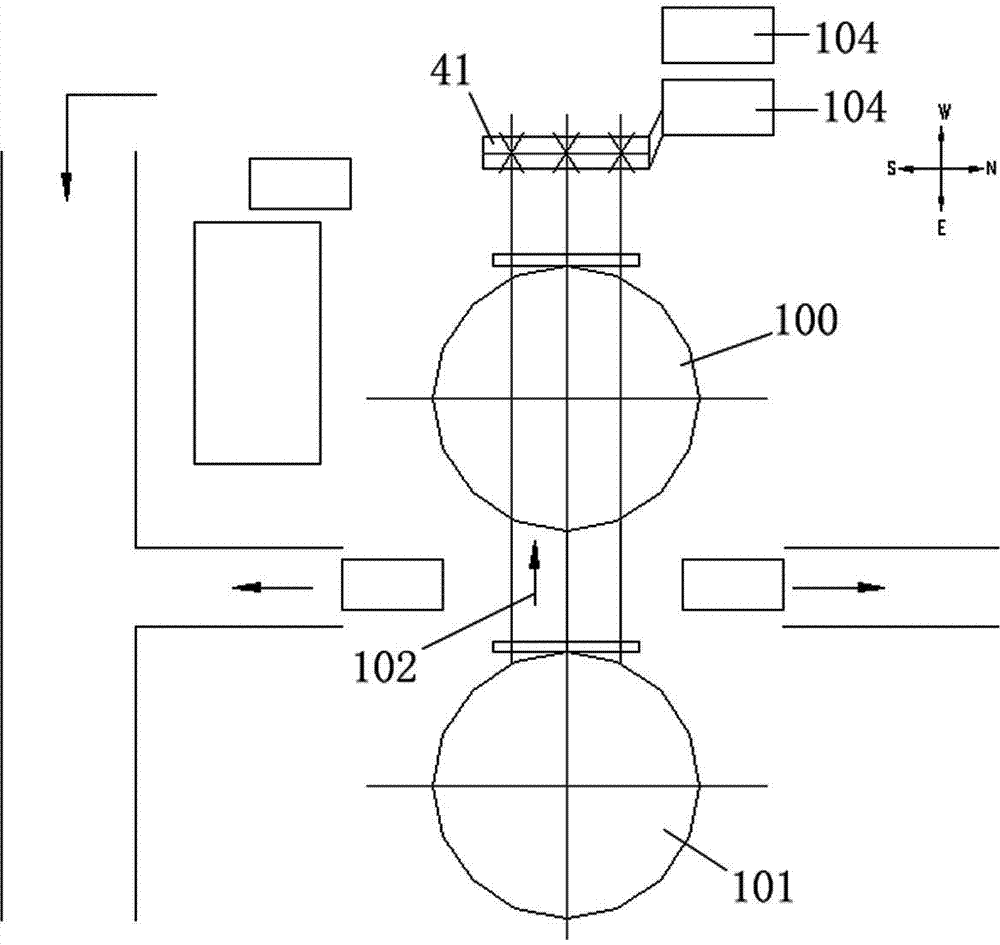

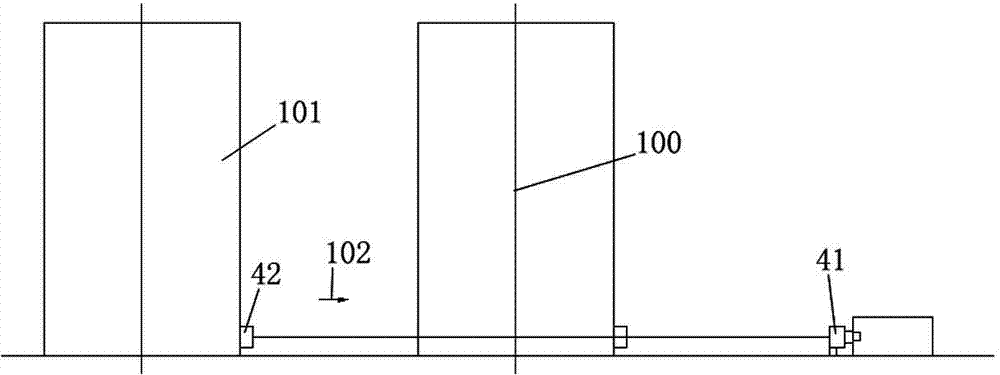

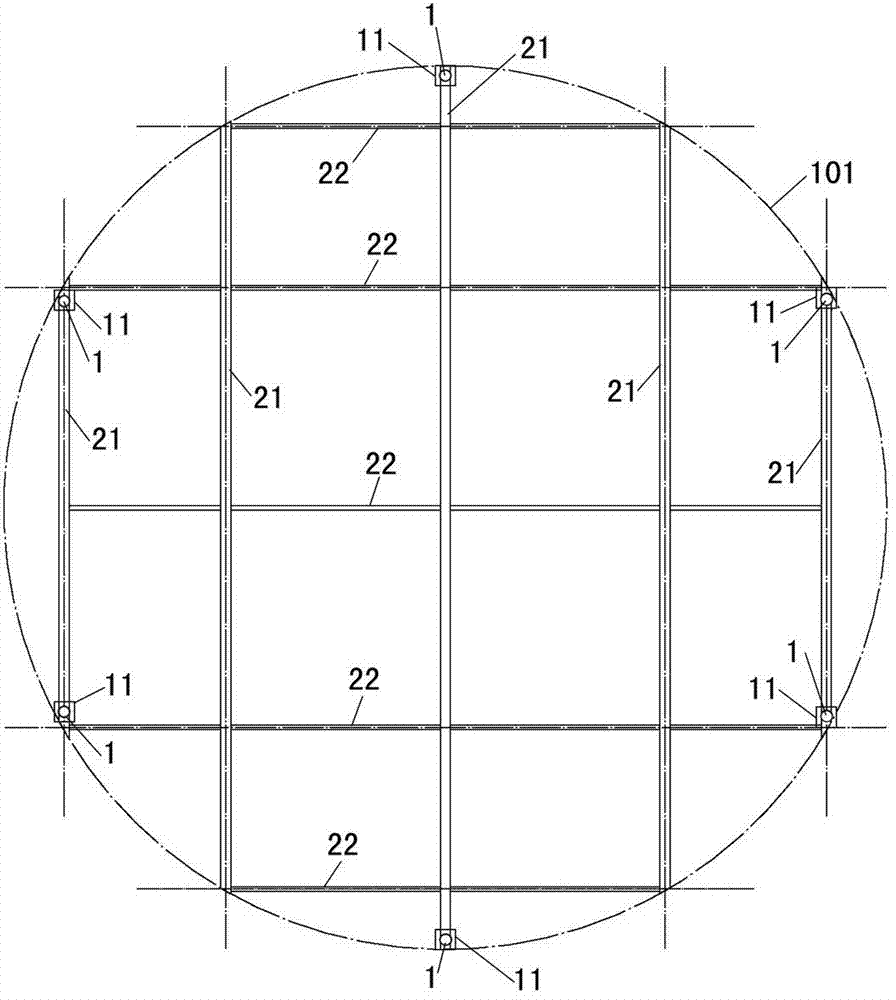

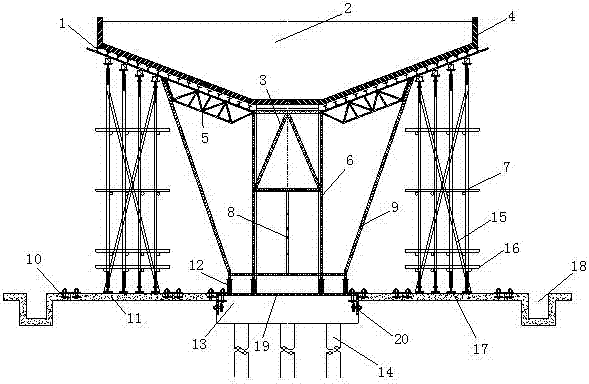

Absorbing tower horizontal moving device and construction method thereof

The invention discloses an absorbing tower horizontal moving device and a construction method thereof. The absorbing tower horizontal moving device is used for horizontally moving a new absorbing tower to the original position of an old absorbing tower and comprises a jacking component, a frame component, a horizontal moving sliding component and a track forwarding component, wherein the jacking component comprises a plurality of hydraulic jacks; the frame component comprises a plurality of longitudinal support beams and a plurality of transverse supports; the longitudinal support beams are welded and fixed on a wall plate of the new absorbing tower; the transverse supports are connected among the longitudinal support beams; the length extension directions of thelongitudinal support beams are all parallel to the moving direction of the new absorbing tower; thehydraulic jacks are arranged below the ends of thelongitudinal support beams; the horizontal moving sliding component comprises a channel steel track and a heavy article displacer. Through the adoption of the absorbing tower horizontal moving device, the construction cost such as the mechanical cost, the security investment and relevant measure expense can be comprehensively reduced, and meanwhile the overall construction field arrangement and the resource allocation are comprehensively reduced.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

T-type high pier cast-in-place bent cap formwork structure and construction method

InactiveCN107100083AReduce earthwork levelingSave on machinery costsBridge erection/assemblyBridge materialsRebarSteel plates

The invention discloses a T-type high pier cast-in-place bent cap formwork structure. The T-type high pier cast-in-place bent cap formwork structure comprises a cushion cap, a steel plate frame latticed panel is arranged at the top of the cushion cap, prefabricated reinforced concrete base plates are fixedly connected to the two ends, a groined support is arranged on the upper portion of the steel plate frame latticed panel, a shaped steel formwork is arranged on the upper portion of the groined support, and support vertical rods are connected to the two ends of the groined support; a shaped steel frame is arranged between the top of the groined support and the tops of the support vertical rods and is fixedly connected with the groined support and the support vertical rods, and joist steel is arranged between the shaped steel frame and the shaped steel formwork; upside down bowl-type brackets are arranged on the upper portion of the prefabricated reinforced concrete base plates. The T-type high pier cast-in-place bent cap formwork structure has the advantages that the existing cushion cap and prefabricated reinforced concrete plate concrete are used as bearing bases, the work of earthwork flattening and foundation hardening is reduced, foundation processing mechanical cost, concrete material cost and labor cost are saved, and the engineering period is shortened.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Kerb transfer tool for municipal road engineering and kerb mounting method

InactiveCN109162179AReduce installation deviationImprove installation qualityRoads maintainenceRoad engineeringArchitectural engineering

The invention relates to a kerb transfer tool for municipal road engineering and a kerb mounting method. The kerb transfer tool comprises a horizontal support beam, wherein rubber wheels are arrangedat two ends of the horizontal support beam respectively; a vertical support beam is vertically arranged in the middle of the horizontal support beam; a horizontal beam is arranged at the top end of the vertical support beam; a V-shaped fixed pulley is arranged at the front end of the horizontal beam; a main rope is arranged on the V-shaped fixed pulley; the lower end of the main rope is connectedwith a lower rope; the lower rope is connected with a kerb clamp; a left clamp plate and a right clamp plate are connected through a hinge pin; parallel jaws for clamping a kerb are formed by a vertical section of the left clamp plate and a vertical section of the right clamp plate. The kerb transfer tool for municipal road engineering is convenient to use and simple to operate, and a large amountof labor and mechanical cost is saved; mounting error of the kerb is reduced, and kerb mounting quality is improved; construction efficiency is improved substantially, and influence of kerb mountingon next procedure is reduced.

Owner:CHINA 22MCC GROUP CORP

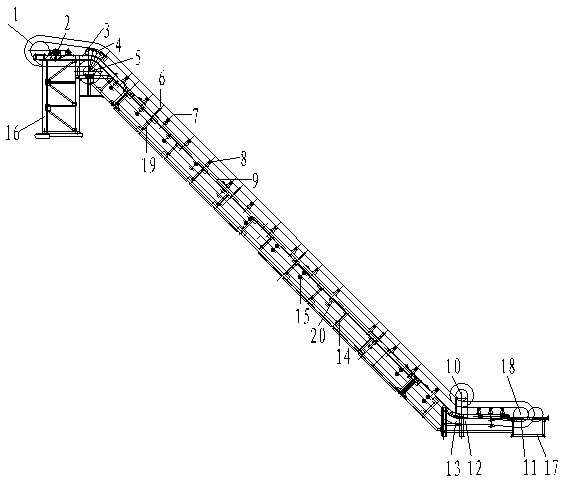

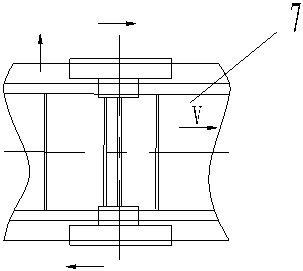

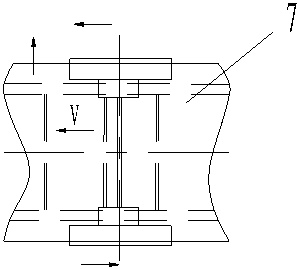

Installation and construction method for corrugated large-inclination flange belt conveyor

ActiveCN102030171AImprove quality and efficiencyImprove work efficiencyConveyorsHeadframeShop drawing

The invention discloses an installation and construction method for a corrugated large-inclination flange belt conveyor, which comprises the following steps of: 1, finding out a centre line of the complete machine and a cross line of centre lines of a head pulley and a tail pulley according to a working drawing; 2, installing a head frame, a driving device, a convex arc-shaped middle frame and a convex arc-shaped pinch roller according to a centre line of a complete-machine frame and a cross line of the head pulley; 3, laying an annular flange conveyer belt 7; 4, taking the centre lines of the head frame and a tail frame as references, installing a middle frame support, a middle frame and the tail frame in turn from the machine head; 5, installing a return roller without installing other carrier rollers or rollers, and loosening a chain to make the annular flange conveyer belt fall onto the frame; 6, installing an upper flat carrier roller and a tension roller, and adjusting a tension device to the loosest position in the process of installing the tension roller; 7, installing a concave arc-shaped pinch roller, a concave arc-shaped carrier roller, a convex arc-shaped carrier roller and upper and lower blocking rollers; and 8, installing a sweeper and other accessories and getting ready for debugging.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com