T-type high pier cast-in-place bent cap formwork structure and construction method

A technology of covering beams and cast-in-place, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of inconvenient installation and dismantling, low safety, and many safety threats, so as to reduce earthwork leveling, speed up construction, and avoid safety risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

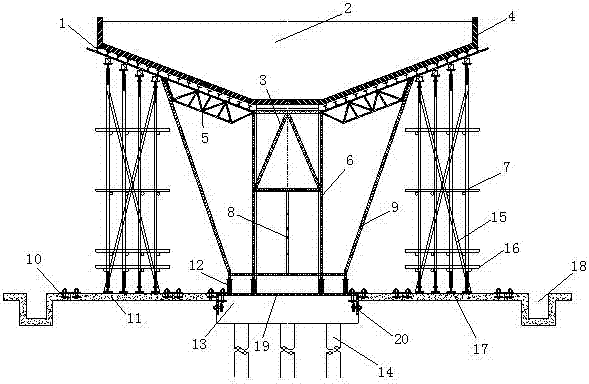

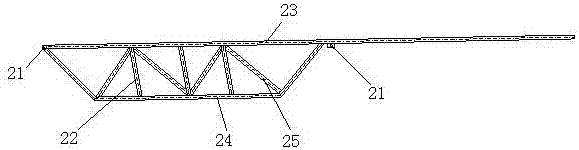

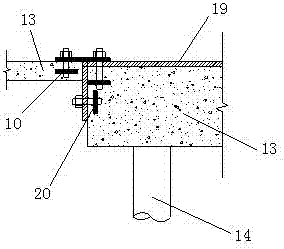

[0035] Such as Figure 1-4 As shown, a T-shaped high pier cast-in-place cover beam formwork structure and construction method, including I-shaped steel 1, cast-in-place cover beam 2, well-shaped support diagonal brace 3, shaped steel formwork 4, shaped steel frame 5, well Font bracket 6, bowl button bracket 7, adjusting bolt 8, bracket pole 9, prefabricated reinforced concrete slab embedded bolt 10, prefabricated reinforced concrete backing plate 11, jack 12, cap 13, pier pile 14, scissors support 15. Sweeping pole 16, quick assembly and disassembly joint of vertical pole 17, prefabricated reinforced concrete drainage ditch 18, steel plate frame grating 19, embedded parts of platform cap 20, bolt holes 21, shaped steel frame vertical bar 22, shaped steel frame Upper chord 23, shaped steel frame lower chord 24 and shaped steel frame inclined bar 25. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com