Tunnel lining construction method

A construction method and tunnel technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problem that the flatness of the concrete layer of the support structure is difficult to control, the overall durability of the lining cannot reach the design service life, and it is difficult to ensure the welding seam Quality and effect and other issues, to achieve the effect of improving sprayability, superior performance, and reducing surface shrinkage microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] A tunnel lining construction method specifically comprises the following steps:

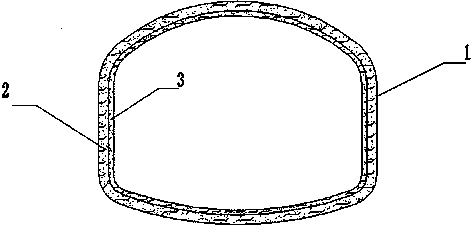

[0021] A. Excavate the cavern first, and construct full-section steel arches 1 at intervals along the excavation surface of the surrounding rock in the longitudinal direction of the tunnel in the cavern, and the distance between adjacent steel arches 1 is 750mm.

[0022] B. Stir the low-carbon fiber concrete, spray low-carbon fiber concrete with a thickness of 20mm±1mm on the excavation surface of the surrounding rock between the adjacent steel arches 1 with a wet sprayer to form the inner concrete layer 2.

[0023] The low-carbon fiber concrete of the present invention is formed by mixing fly ash and silica fume into ordinary shotcrete, and then adding steel fibers and polypropylene fibers. The prepared low-carbon fiber concrete includes per cubic meter 53.1 Kg~106.2 Kg of fly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com