Installation and construction method for corrugated large-inclination flange belt conveyor

A construction method and a technology with a large inclination angle, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of difficulty in laying a belt with a large inclination angle, the lack of rolling of the entire belt, and unfavorable sliding, etc., so as to improve the installation quality and work efficiency , shorten the construction period, reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

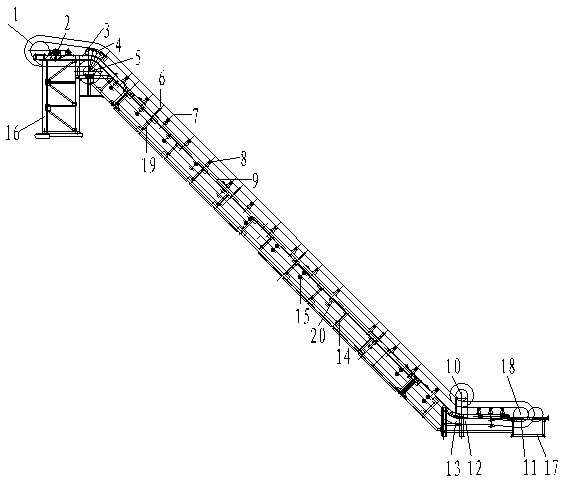

[0058] Such as figure 1 As shown, the corrugated sidewall conveyor of the present invention is divided into three parts: head, fuselage and tail.

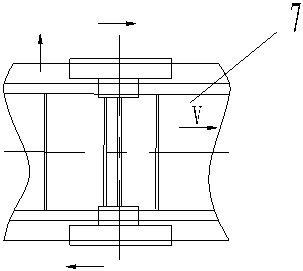

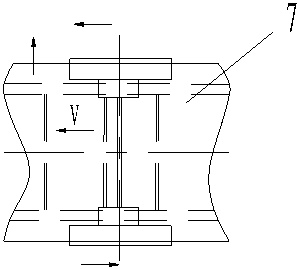

[0059] figure 1 Among them, drive drum 1 (also known as: machine head drum); cleaner 2; convex arc intermediate frame 3; convex arc idler roller 4; convex arc pressure pulley 5; Name: conveyor belt); upper flat roller 8; intermediate frame 9; concave arc pressure pulley 10; tensioning device 11; concave arc intermediate frame 12; concave arc idler roller 13; intermediate frame leg 14; return idler 15 ; Headstock 16; Tailstock 17;

[0060] Such as Figure 13 Shown is the construction process flow chart of the present invention.

[0061] The installation method is:

[0062] According to the analysis of the equipment structure and the actual situation on site, the machine head is first aligned and fixed, and the fuselage and tail are not installed temporarily; then the corrugated sidewall conveyor belt 7 is laid, and then the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com