Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

A process method and technology of cable-mounted cranes, which are applied in the directions of suspension bridges, cable cranes, load hanging components, etc., can solve the problems of heavy steel truss girder, difficult to solve problems, high construction cost, and achieve large free space and hoisting moving speed. Fast, guarantee the effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

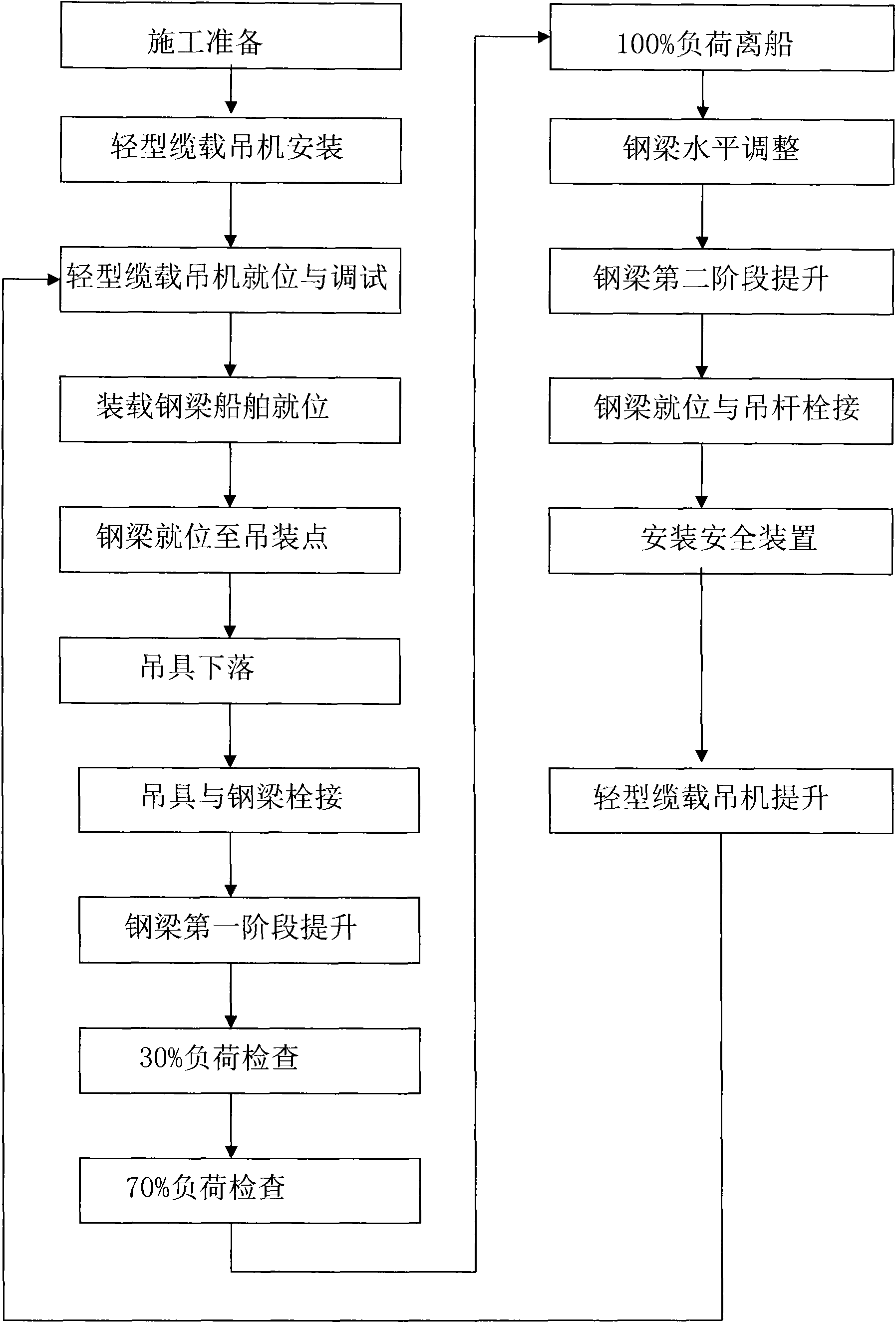

[0047] The construction process of the steel suspension bridge is as follows:

[0048] 1. Construction preparation

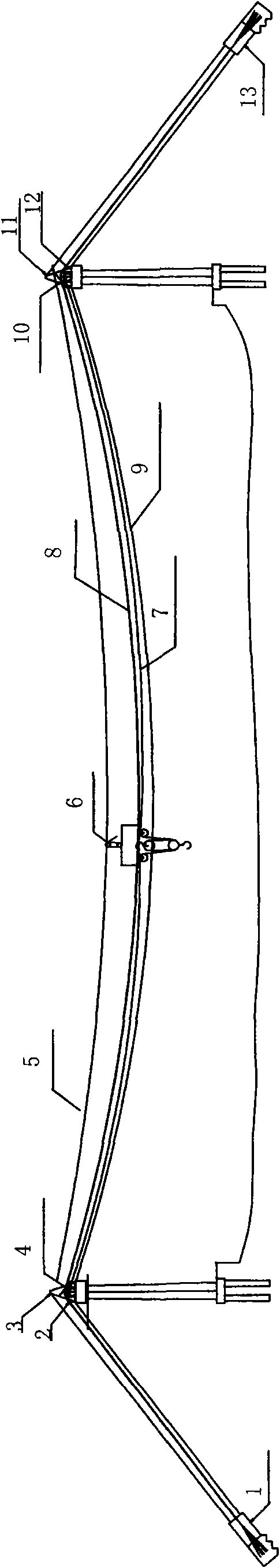

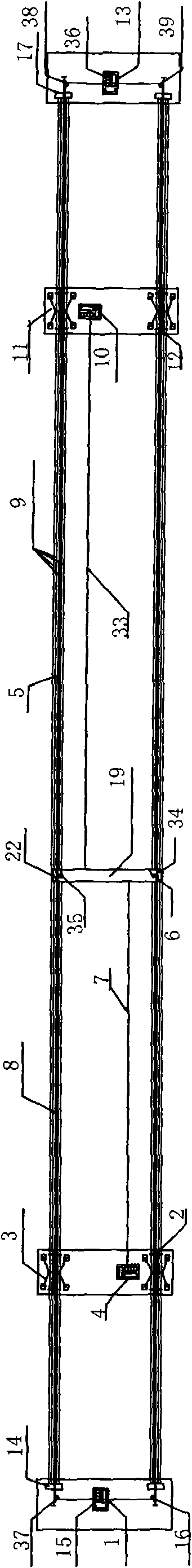

[0049] Before the steel beam hoisting construction, it is necessary to complete the construction of the anchor pier, the installation of the left saddle 2 and the right saddle 12, the erection of the catwalk, the installation of the front main cable 8 and the rear main cable 32, the installation of the cable clamp and the boom, etc.

[0050] 1. Construction of the anchor piers: the anchor piers are arranged respectively under the left scatter pier 14 and the right scatter pier 17 of the left anchorage 1 and the right anchorage 13, and each anchorage is provided with two anchor piers. The anchorage pier is a reinforced concrete structure, and 4 anchor rings are pre-embedded on the front of each anchorage pier, which are used to anchor the catwalk steel wire rope and the circulating traction cable 5. At the same time, two steel plates are pre-embedded on its top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com