Hydroelectric barrage building machine

A hydropower and weir technology, applied in construction, water conservancy projects, barrage/weir, etc., can solve problems such as trouble, downstream channel obstruction, manual cleaning of the channel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

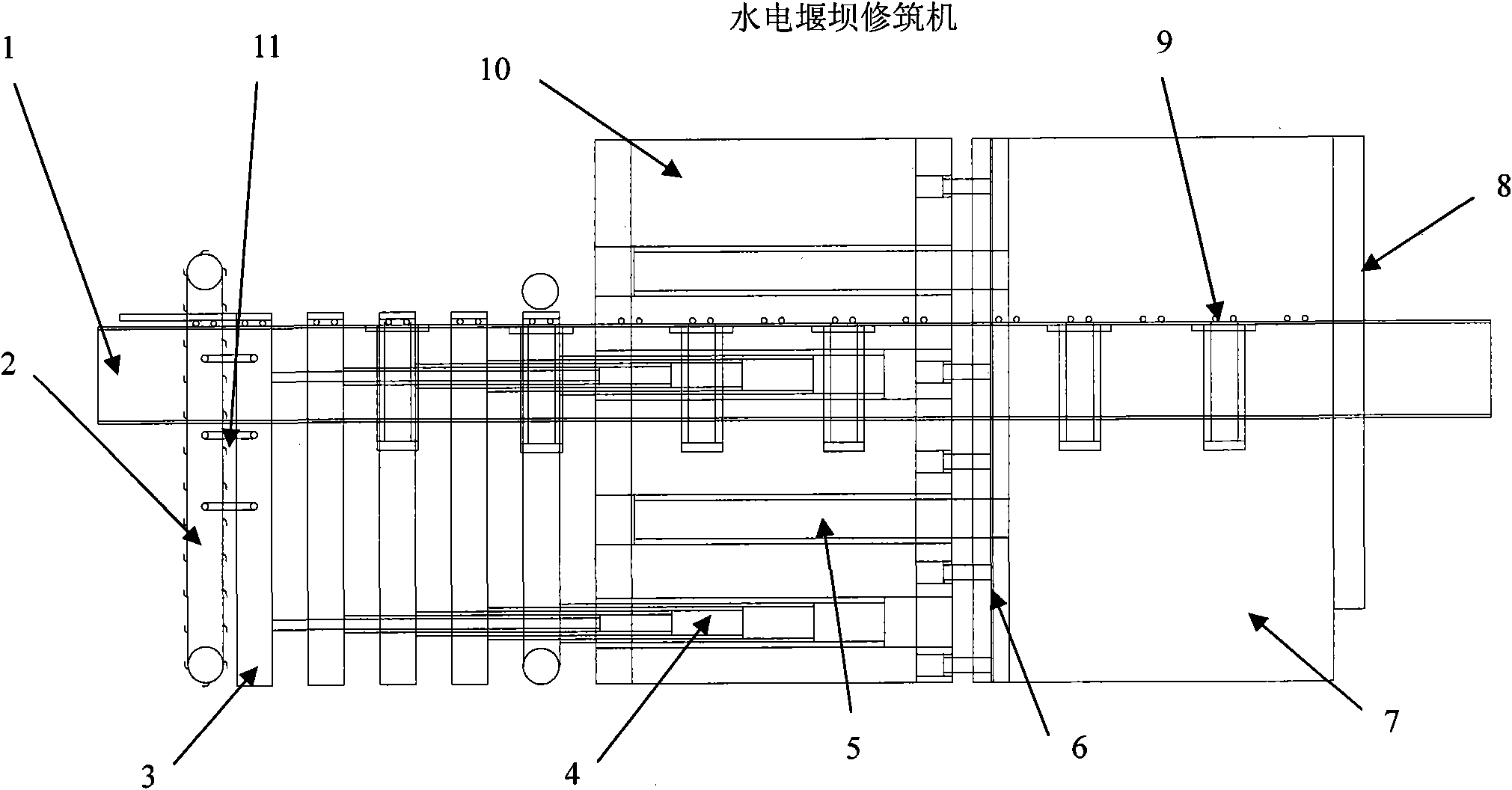

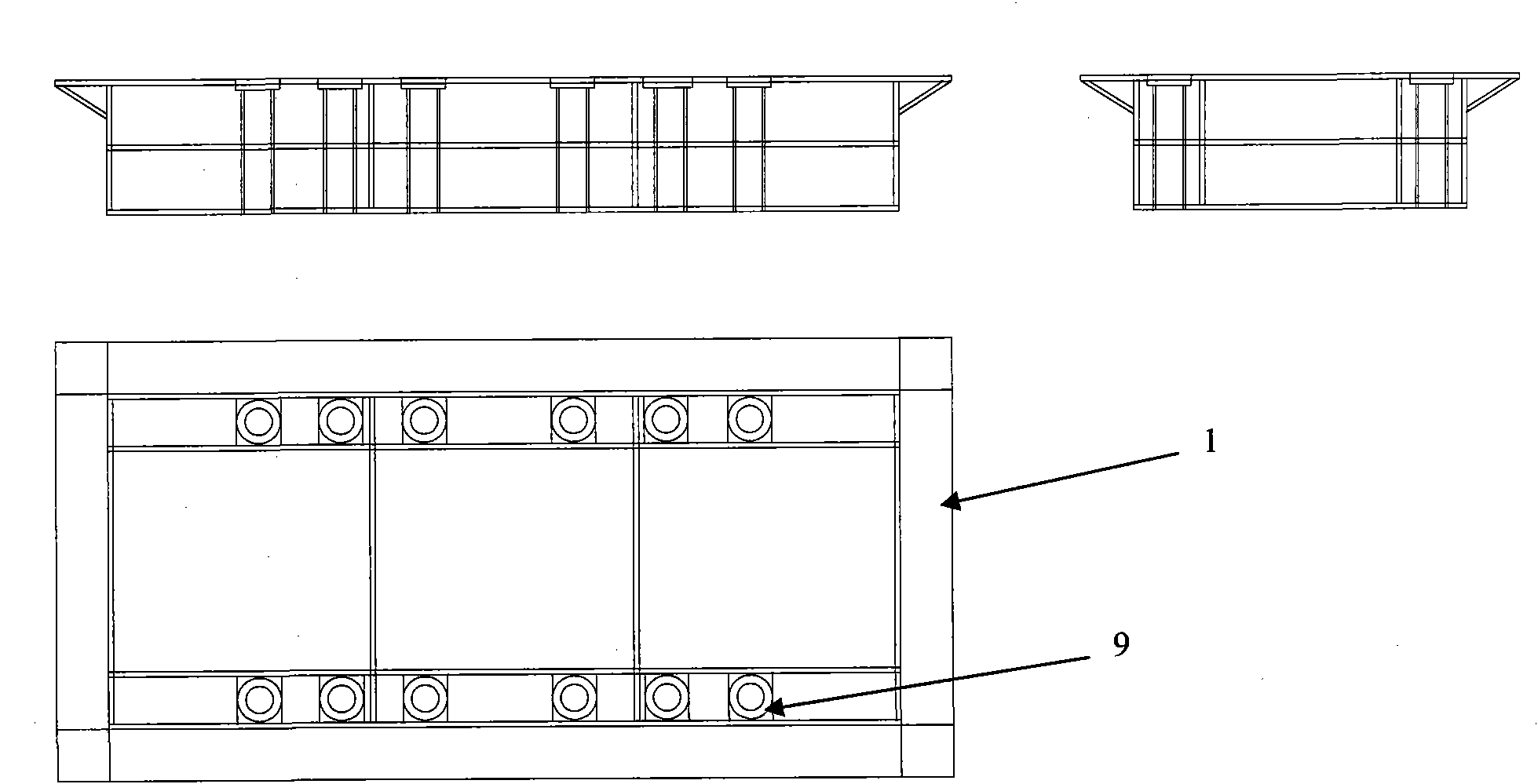

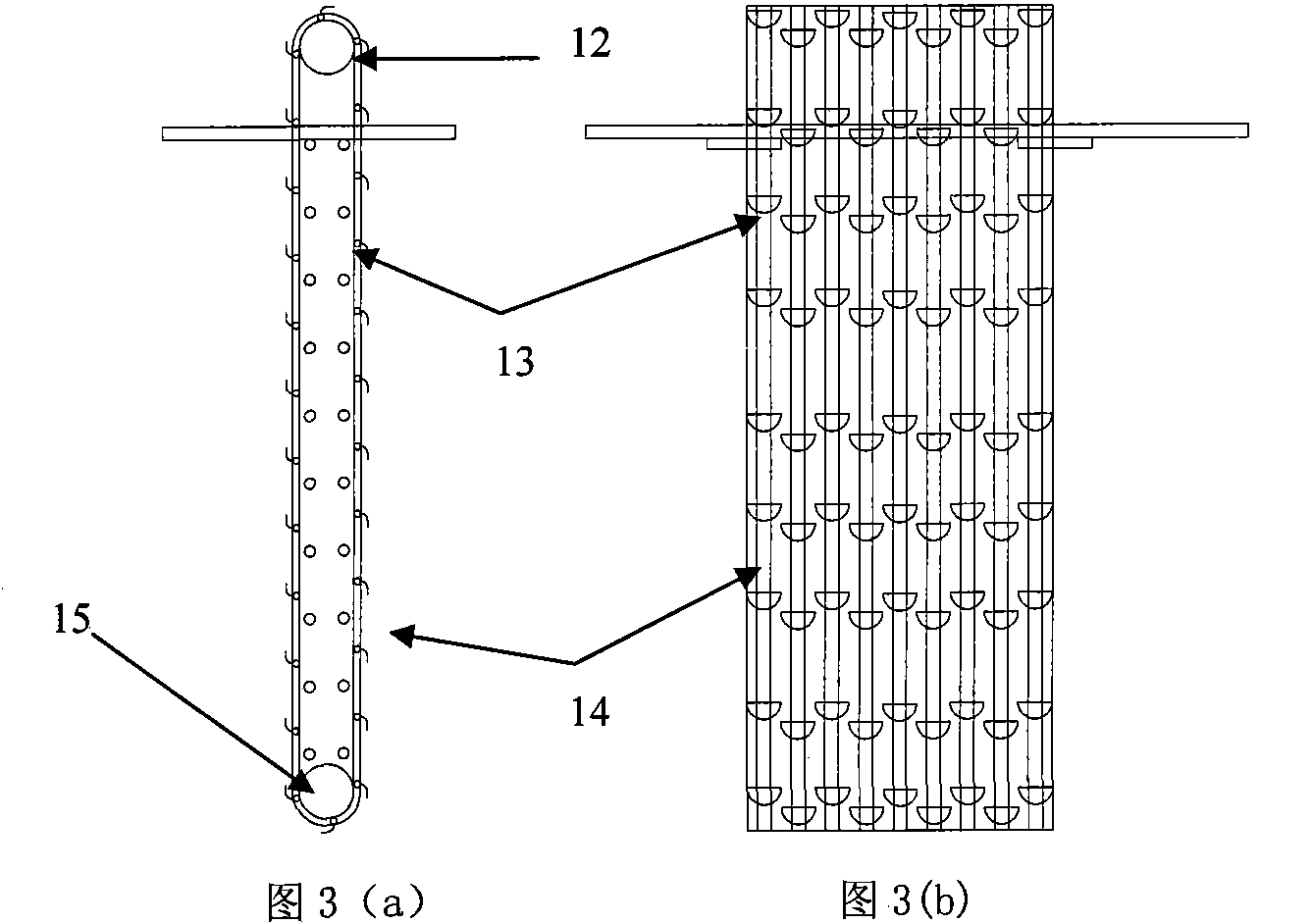

[0010] Firstly, on the bank of the river section to be intercepted or constructed, a site that can accommodate the unit and the overhead crane is roughly leveled out, and a square frame that is shaped like a "well" and whose height is weaker than the dimension between the short axes of each well frame is made of section steel. (like figure 2 ) is used as the horizontal reference frame of the unit, facing the opposite bank as the front direction, using brackets or other materials to raise the height of one rack floor and placing it on the site. The well in front of the horizontal reference frame is the digging well, and the chain bucket excavator and the Shrink frame with support plate; the middle well position of the horizontal reference frame is a hydraulic well, and the hydraulic propulsion system frame with support plates on both sides is placed; the azimuth well behind the horizontal reference frame is a pouring well, and a support plate and a pouring concrete formwork mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com