High pier construction method for external whole operation platform

An operating platform and construction method technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of difficulty in inspection and maintenance, difficulty in thickness control, and long time for scaffolding and dismantling, so as to facilitate quality control and inspection, The effect of reducing materials and construction time, and reducing investment in temporary facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

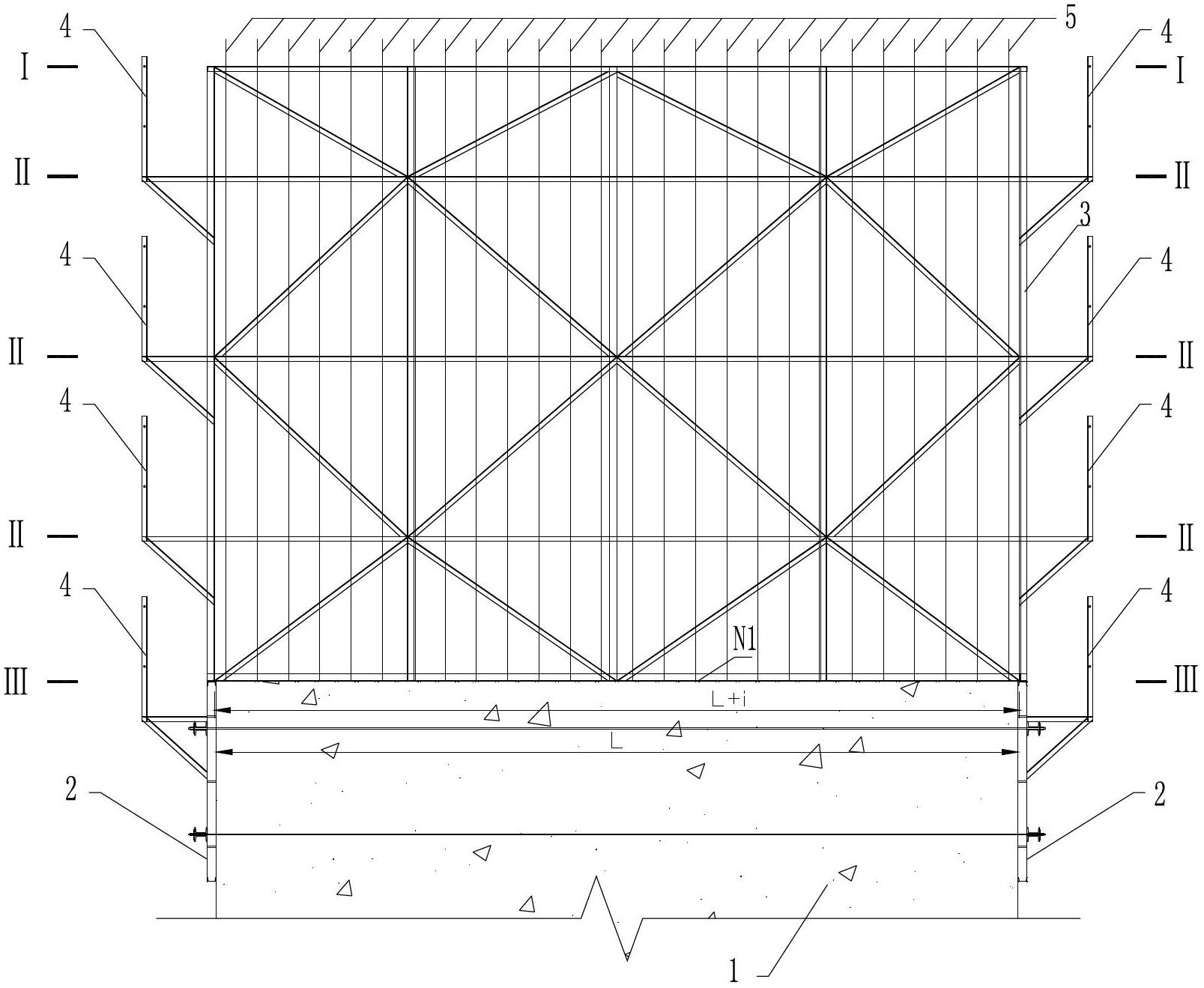

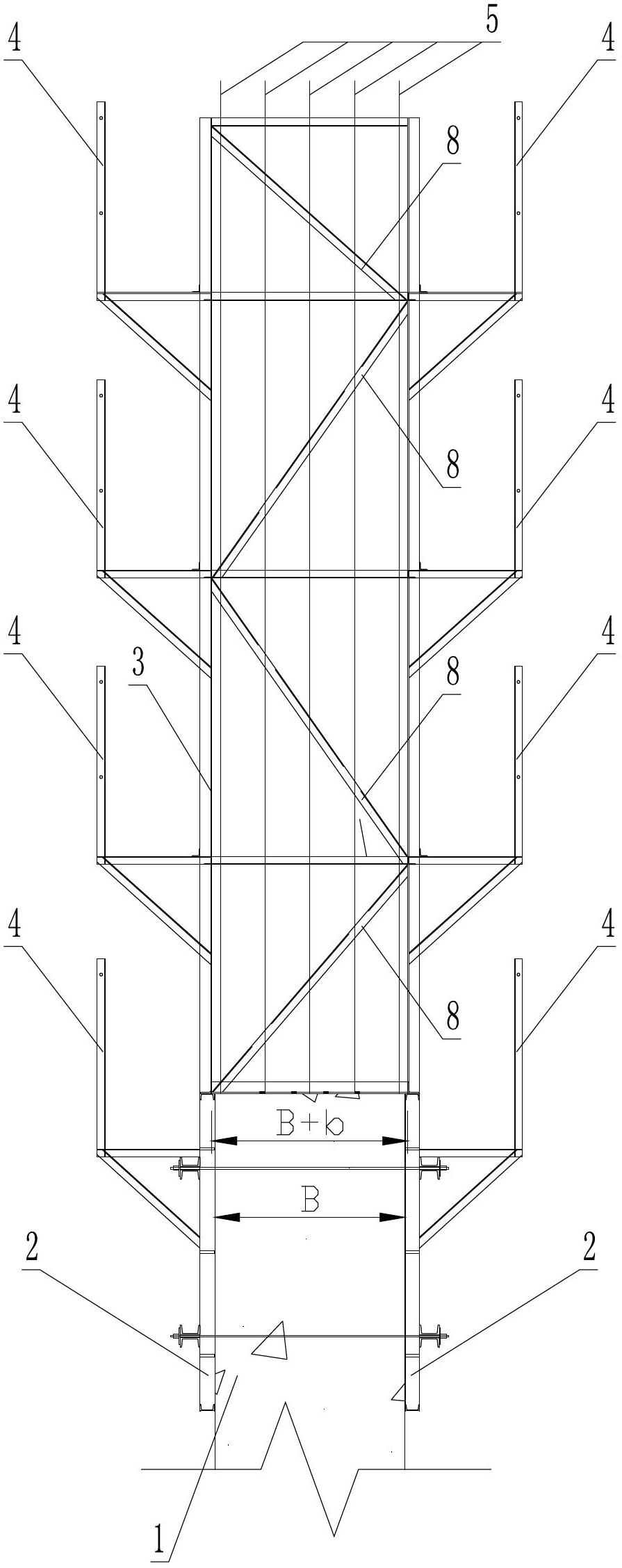

[0039] The present invention will be further described in detail below with reference to the accompanying drawings.

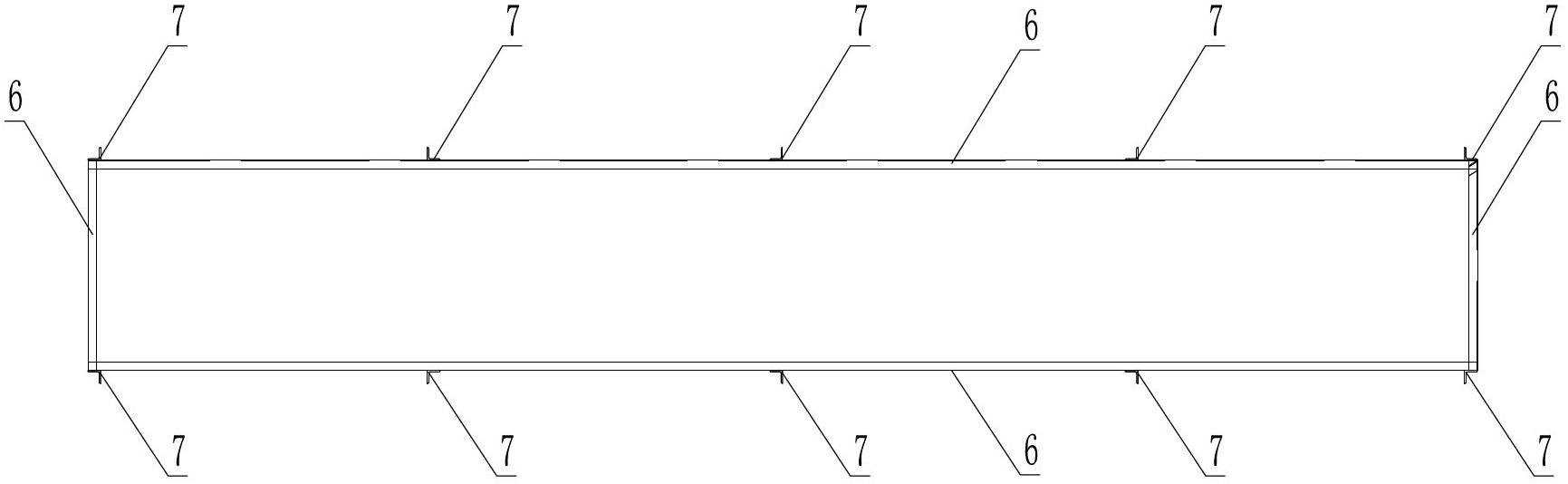

[0040] In the construction method for a high pier with an external integrated operating platform according to the present invention, firstly, the external integrated operating platform 3 is processed according to the outer contour size of the pier body;

[0041] Before the construction of the pier body, the external integral operation platform 3 is hoisted to the top of the poured pier body 1 as a whole, and is connected with the poured pier body formwork 2 on the outer surface of the poured pier body 1 by bolts;

[0042] When installing the steel bars, the personnel construct on the safe operation platform 4 of the external integrated operation platform, and use the external integrated operation platform to assist the installation and positioning of the steel bars;

[0043] After the steel bars are installed, remove the connecting bolts between the external in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com