Compartment funnel slipping mounting method and slipping mounting mechanism

A technology of small grid funnel and installation method, which is applied in hoisting devices, transportation and packaging, portable lifting devices, etc., can solve the problems of high mechanical cost, low work efficiency, hidden safety hazards, etc., and achieve labor saving, convenient implementation, Avoid the effect of crooked pulling and slanting hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

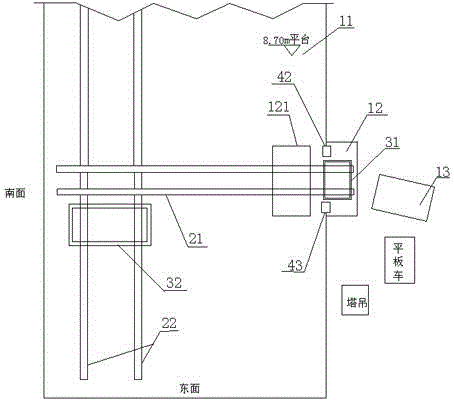

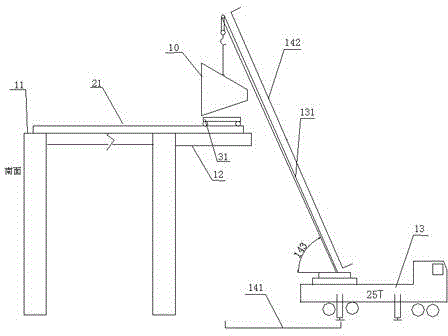

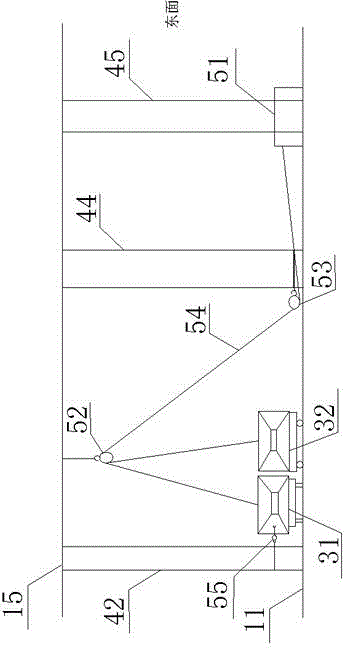

[0030] A sliding installation method for a small grid funnel disclosed by the invention, the specific steps are as follows: figure 1 , figure 2 , image 3 , Figure 4 shown in the following:

[0031]Including the following steps, the lifting and transfer steps of the small grid funnel, the small grid funnel 10 to be installed is hoisted to the horizontal transfer trolley 31 at the hoisting hole platform 12 with a lifting device, and the horizontal transfer trolley 31 is transferred to the horizontal transfer rail 21 and The transfer place of the vertical transfer track 22; use the hoist 51 and the wire rope 54 to cooperate with the first pulley 52 and the second pulley 53 to lift the small grid funnel 10, and transfer the small grid funnel 10 from the horizontal transfer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com