Demolition construction method for long-span highway suspension bridges

A construction method and large-span technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of technical difficulty and high risk of construction, and achieve the effect of shortening the demolition period, controllable safety risks, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

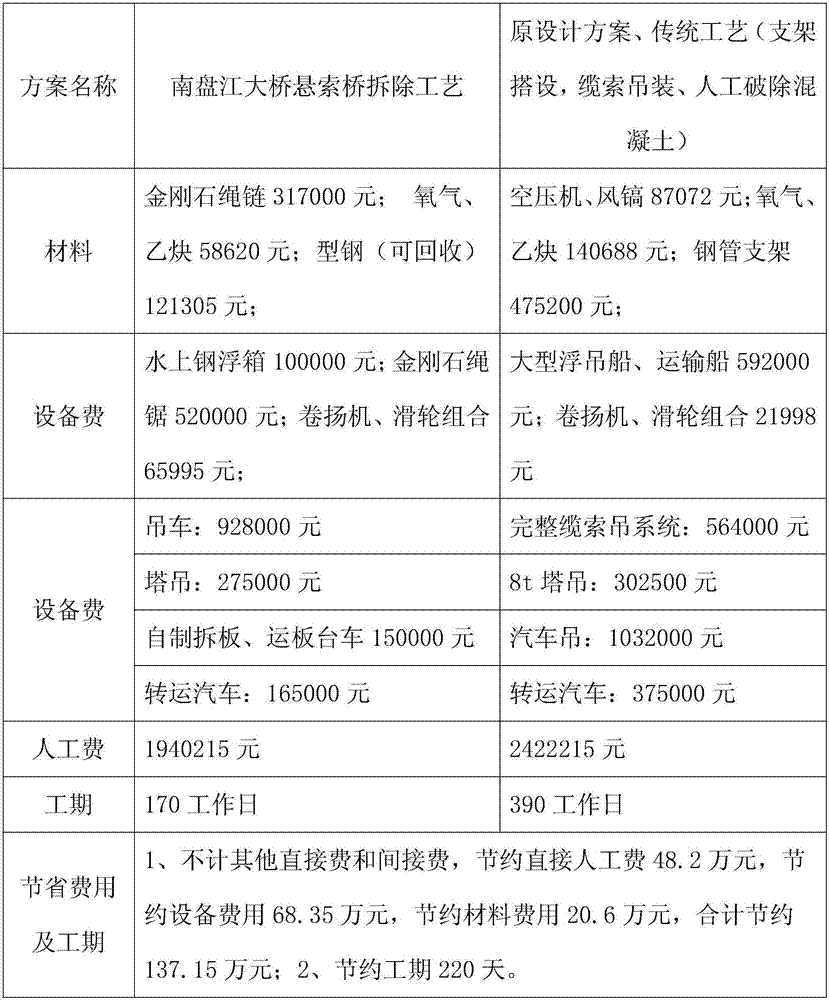

[0035] The embodiment of the present invention: a construction method for dismantling a large-span highway suspension bridge, the construction method specifically includes the following steps:

[0036] A. The steel structure reaction frame is installed on the top of the main tower, and the cable saddle is pushed to correct the deviation of the main tower;

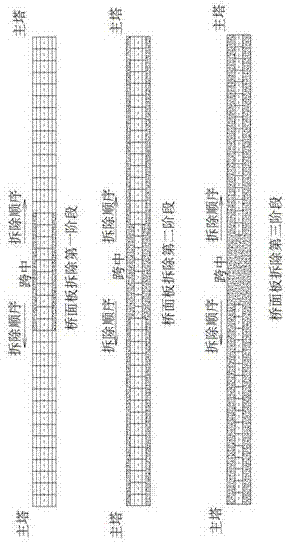

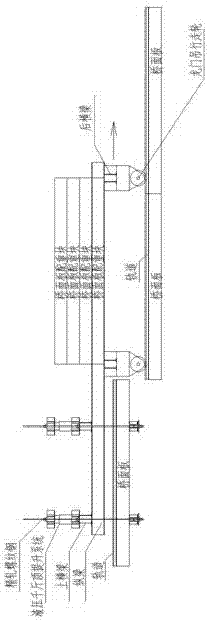

[0037] B. Cut the bridge deck and the bridge deck paving layer, and hoist it in blocks;

[0038] C. Removal of steel truss beam: After cutting the steel truss beam from the middle of the span, it is lowered into sections as a whole;

[0039] D. Demolition of the main cable: use the remaining main cable suspension and catwalk as the operating platform to cut and remove it on the spot;

[0040] E. Demolition of the main tower: use a diamond wire saw to cut reinforced c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com