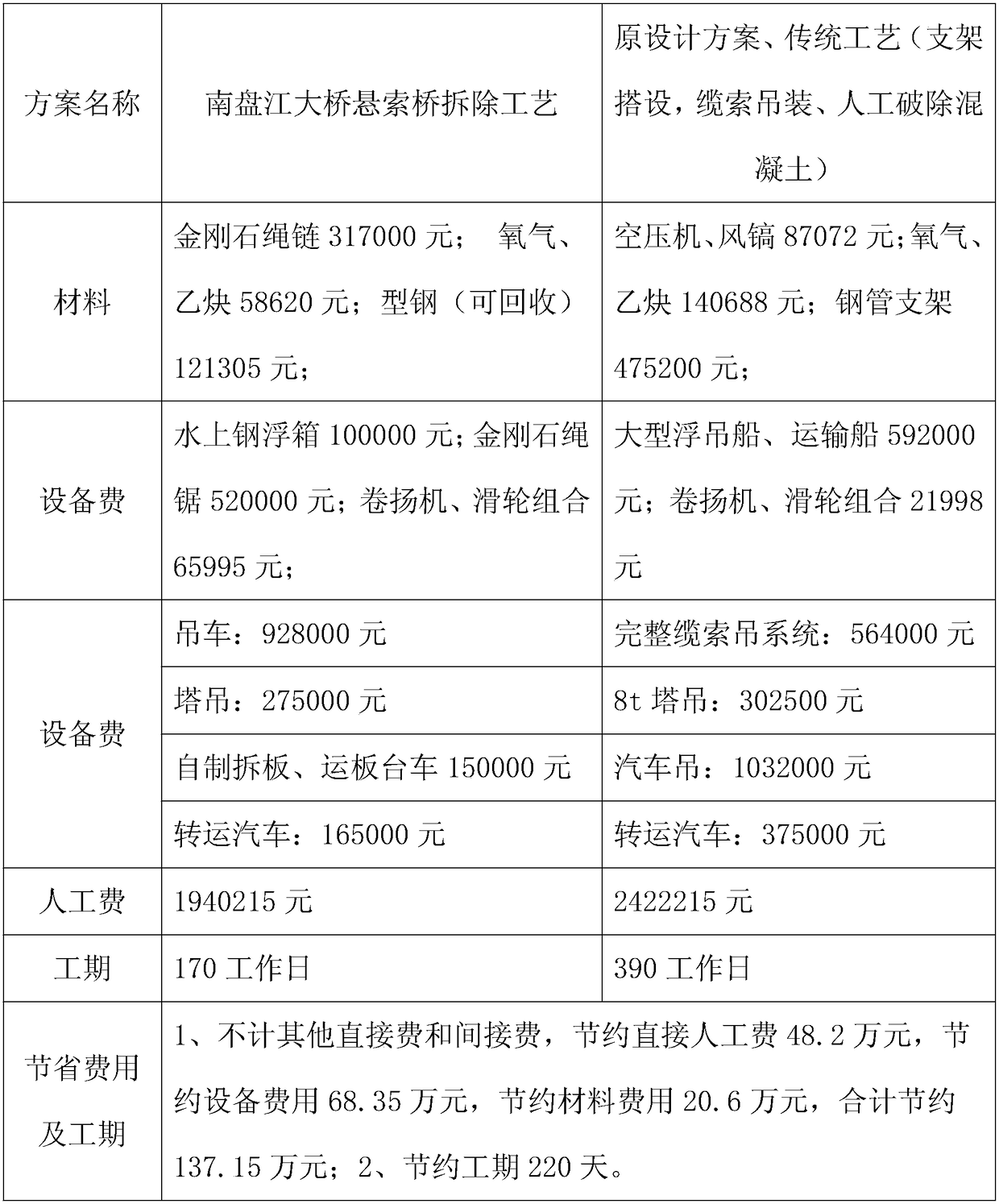

Patents

Literature

38results about How to "Reduce dismantling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

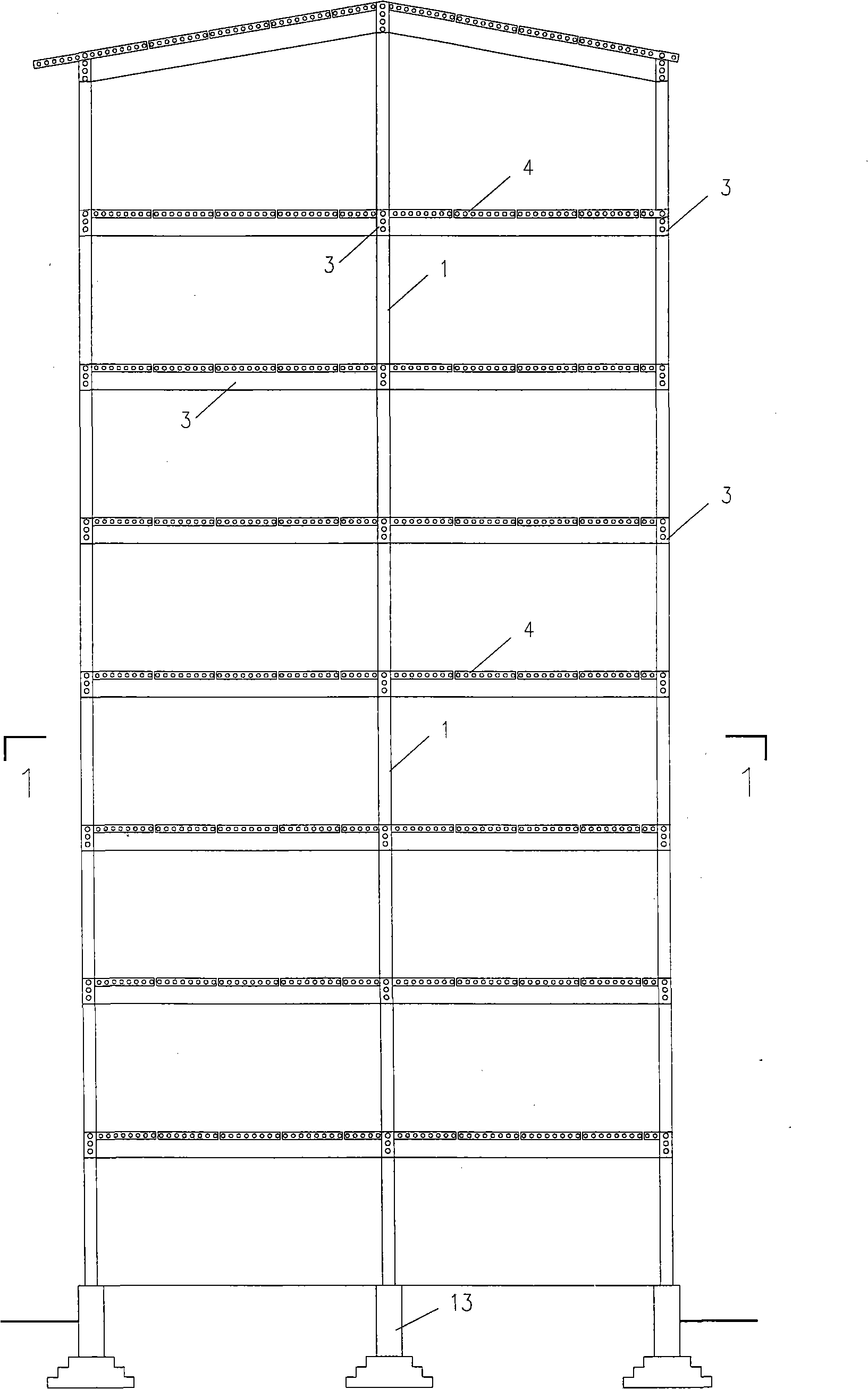

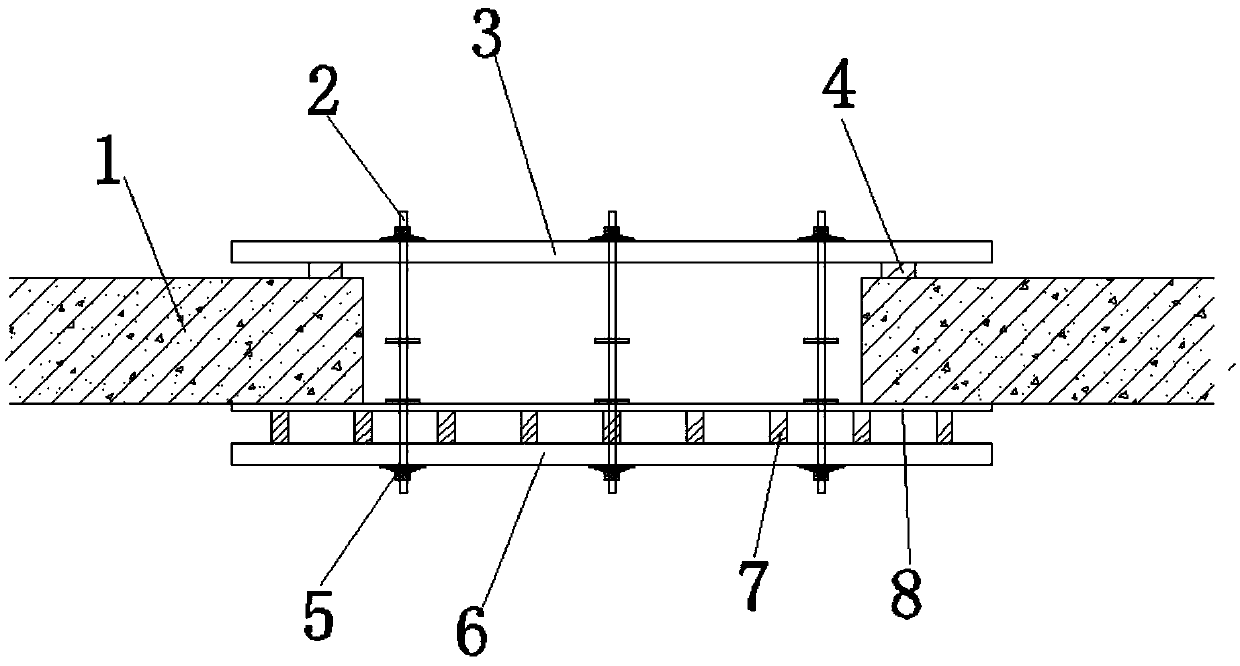

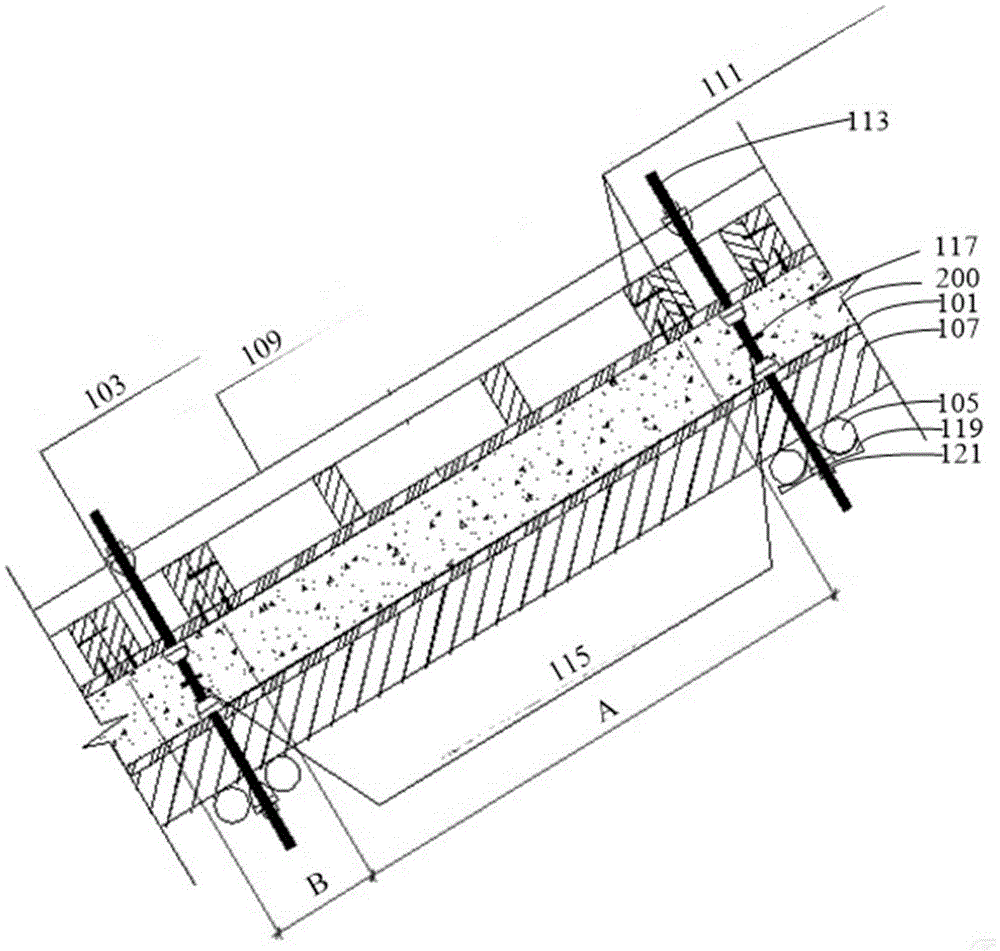

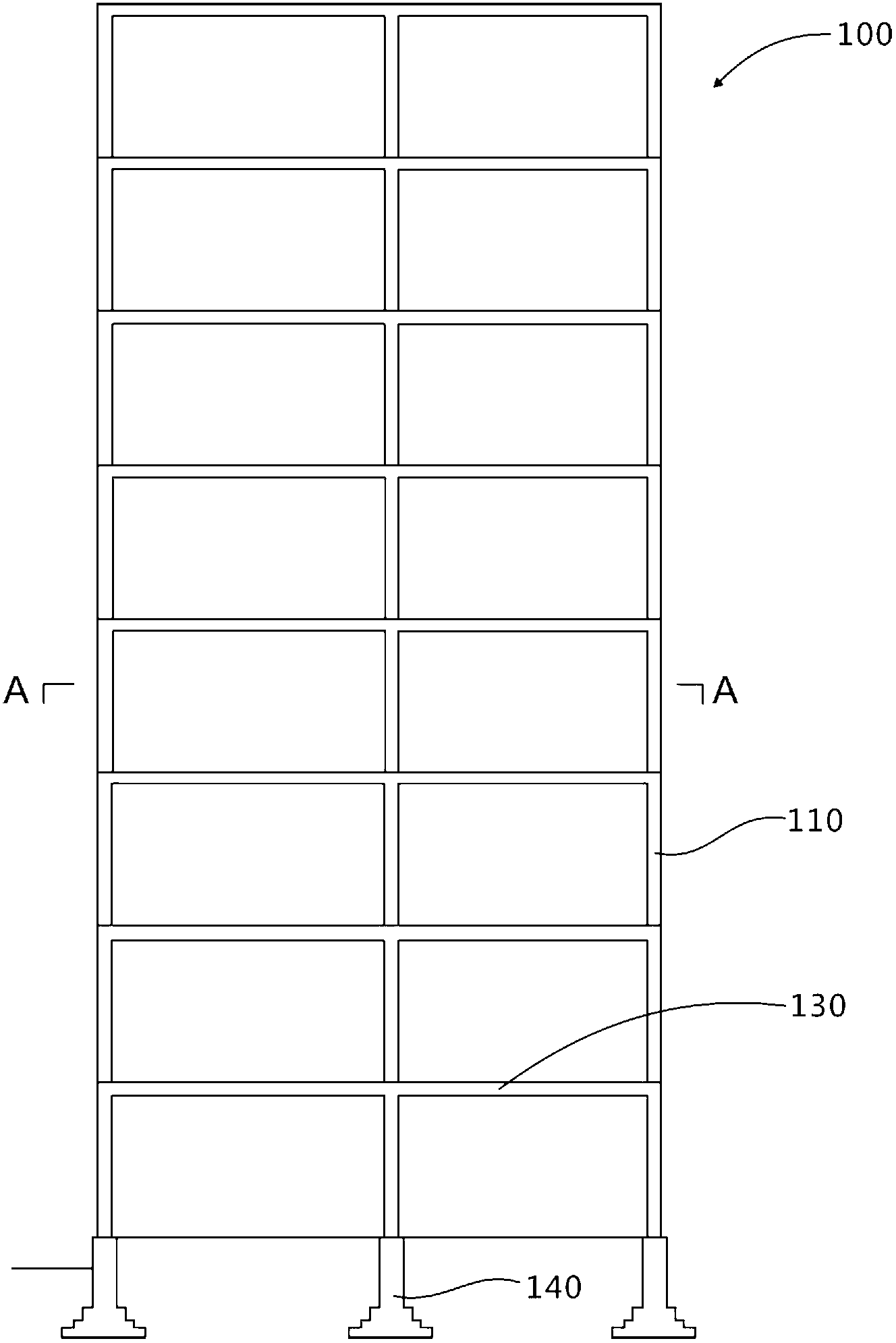

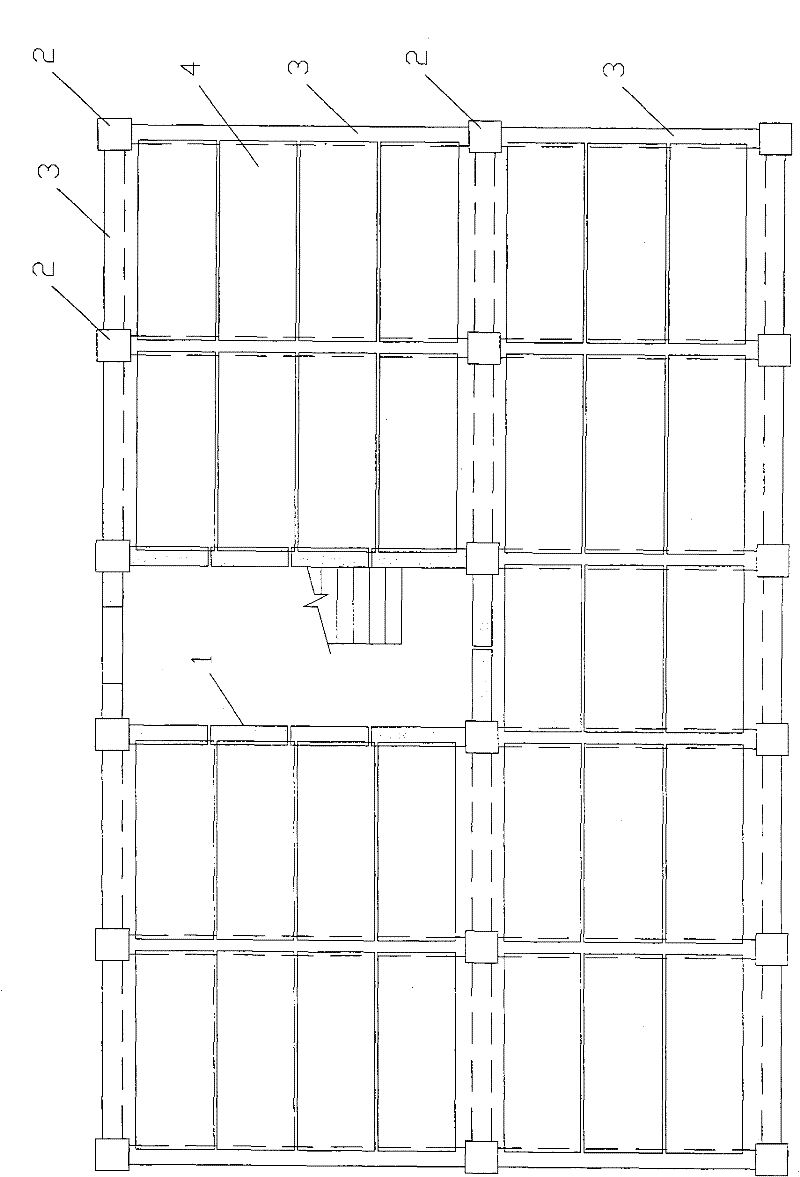

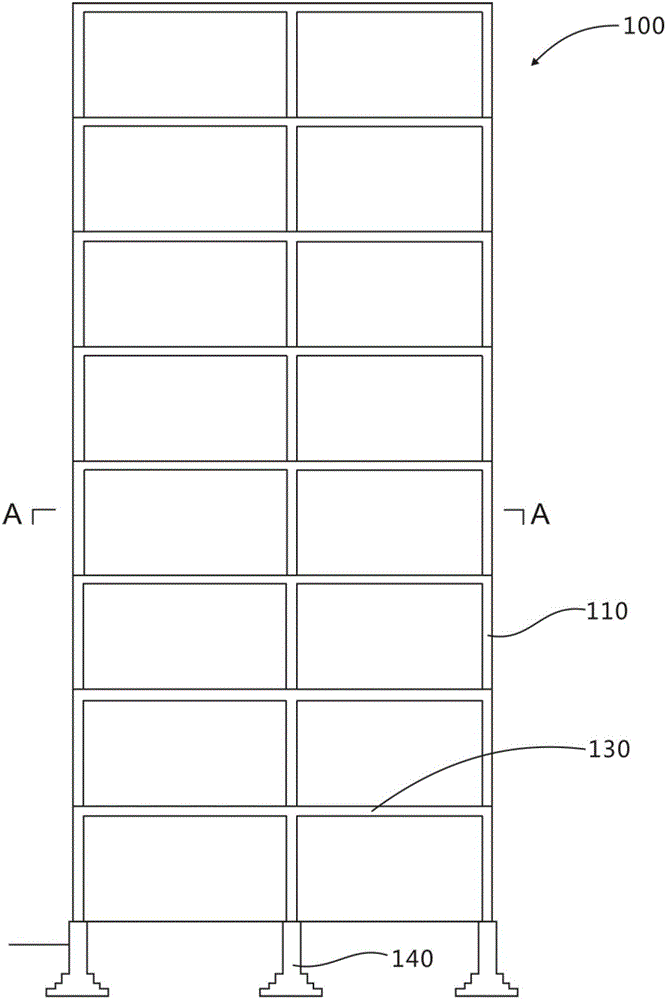

Frame-shear wall structure building of dismantling-free prefabricated reinforced concrete formwork and construction method thereof

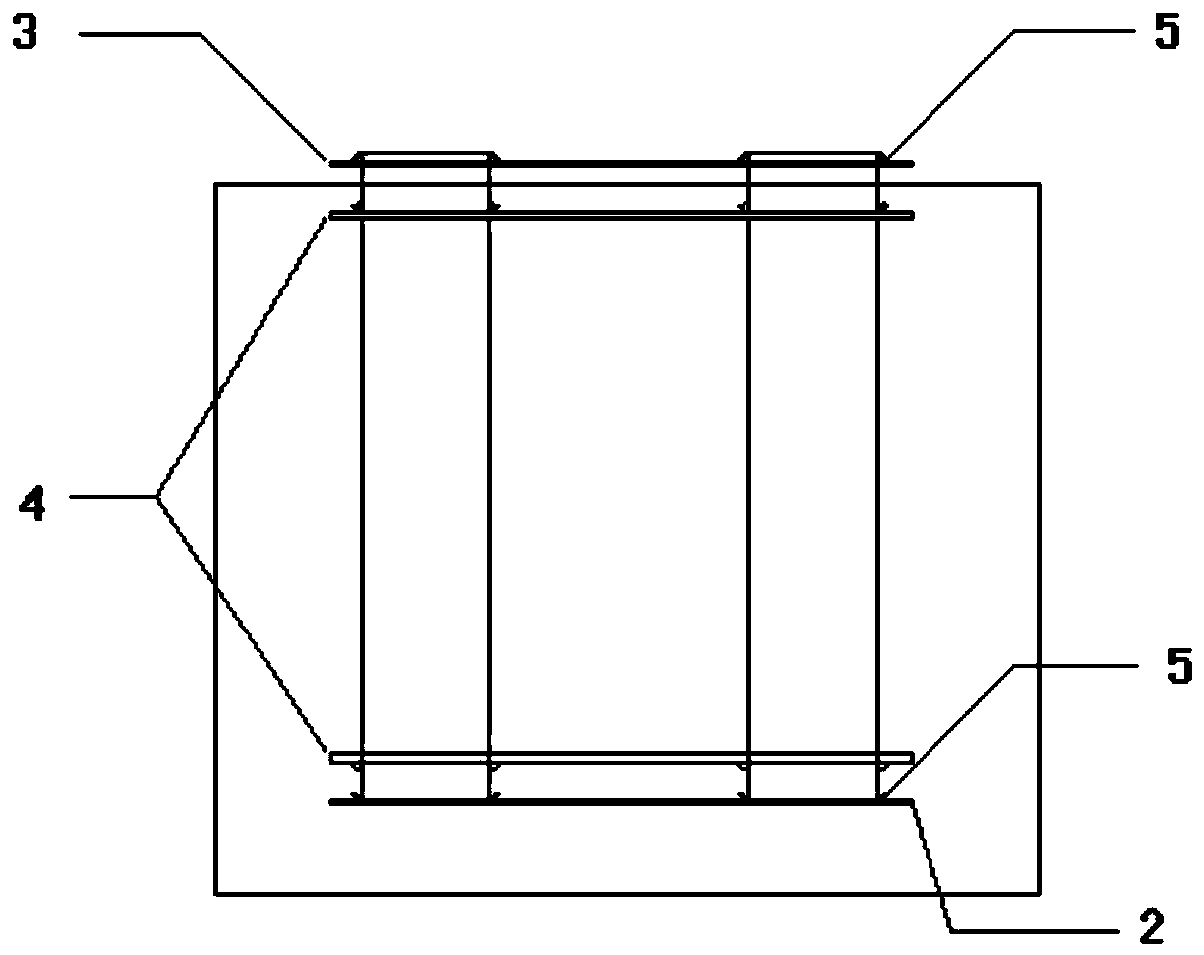

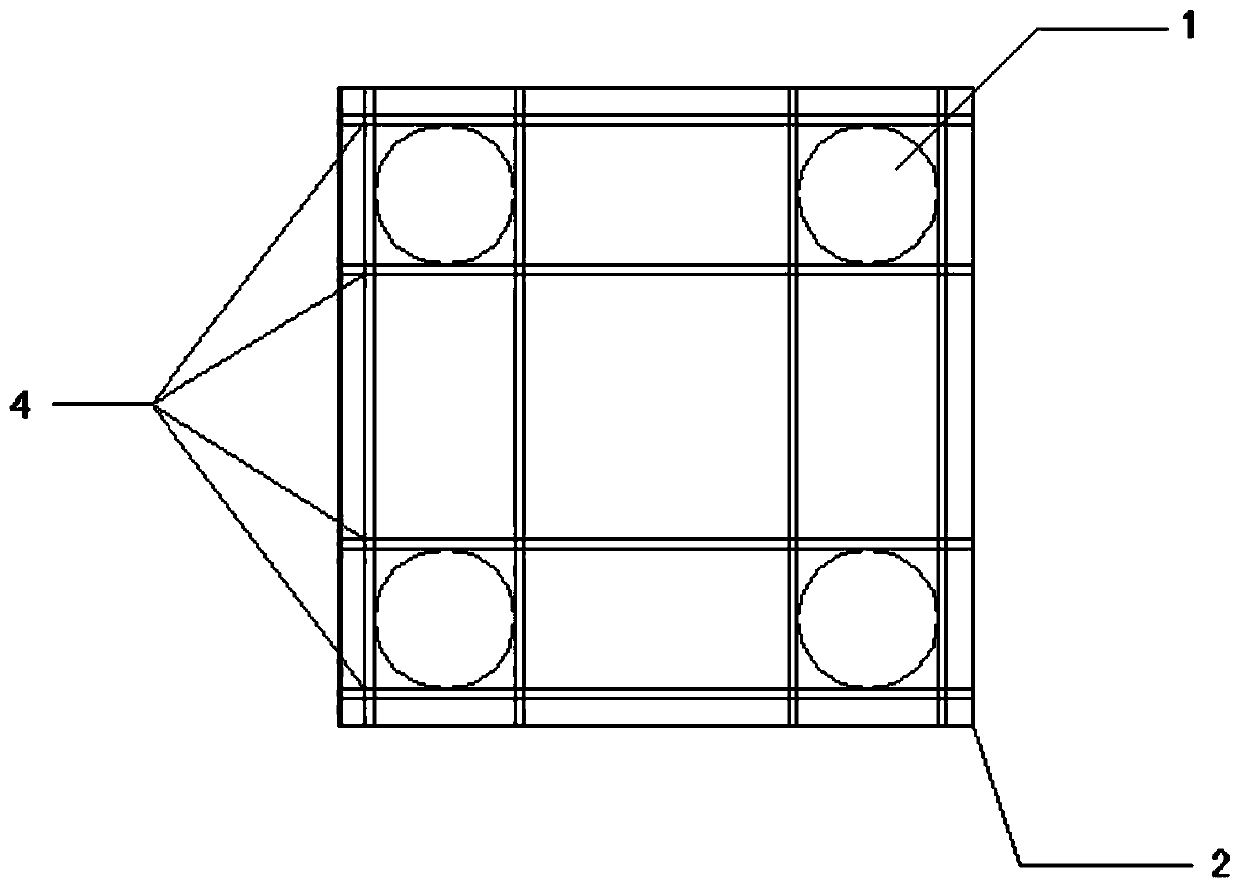

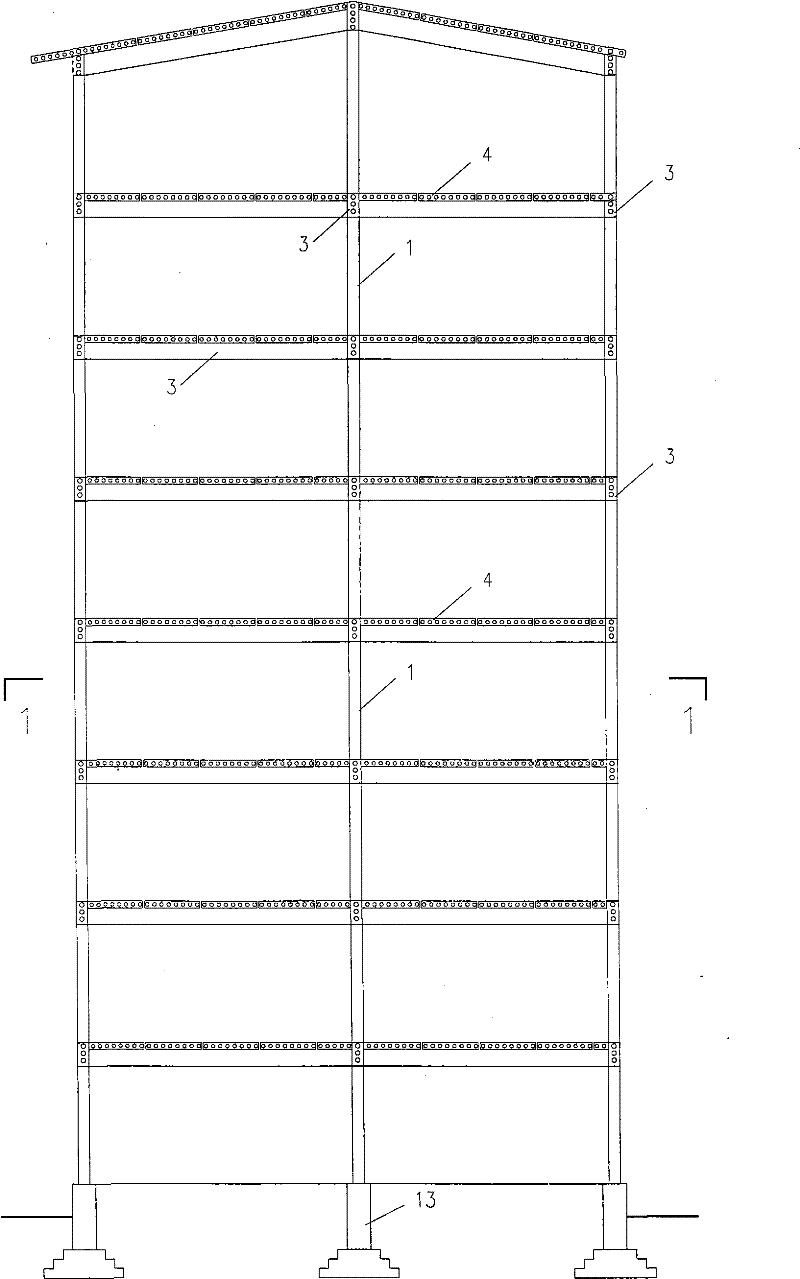

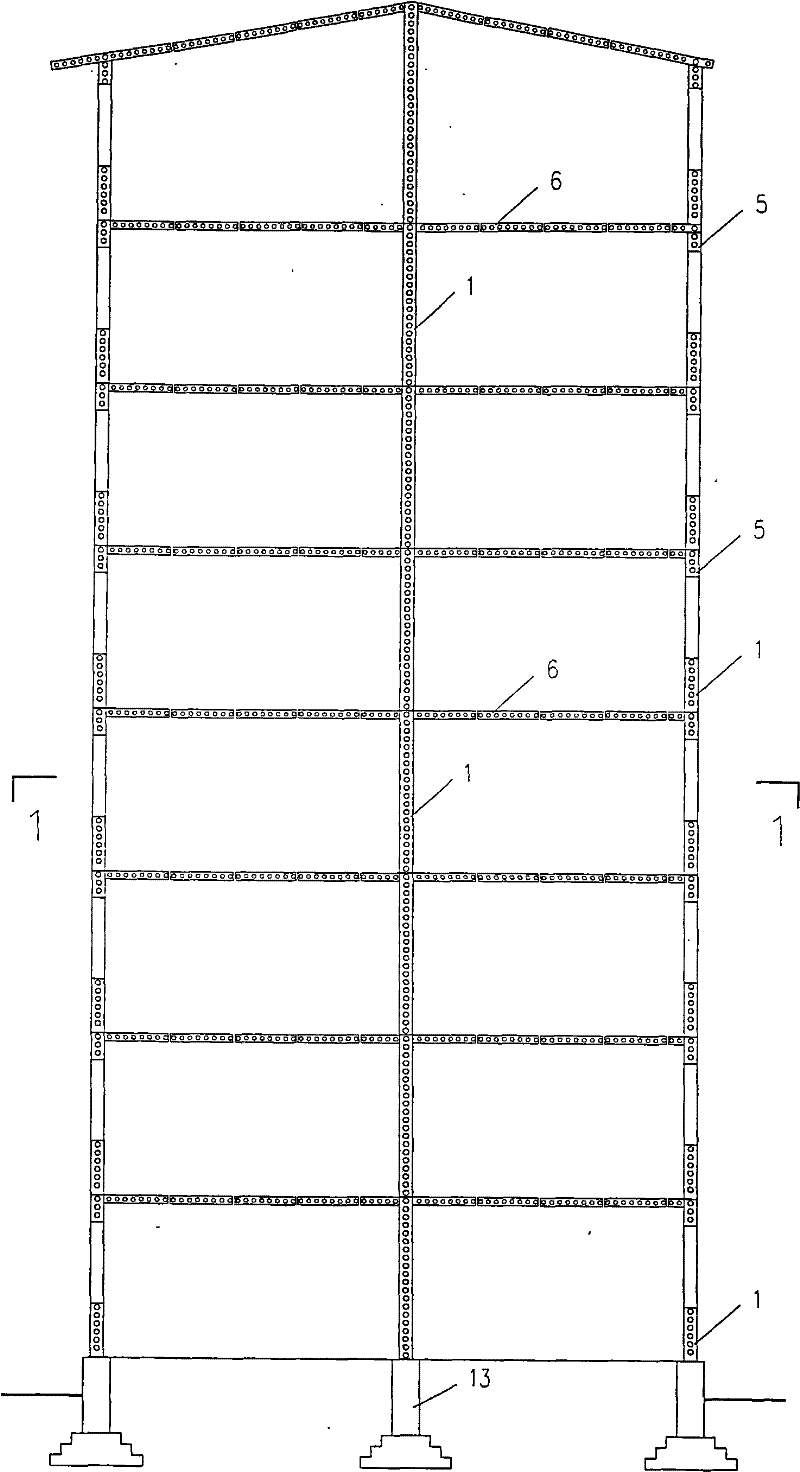

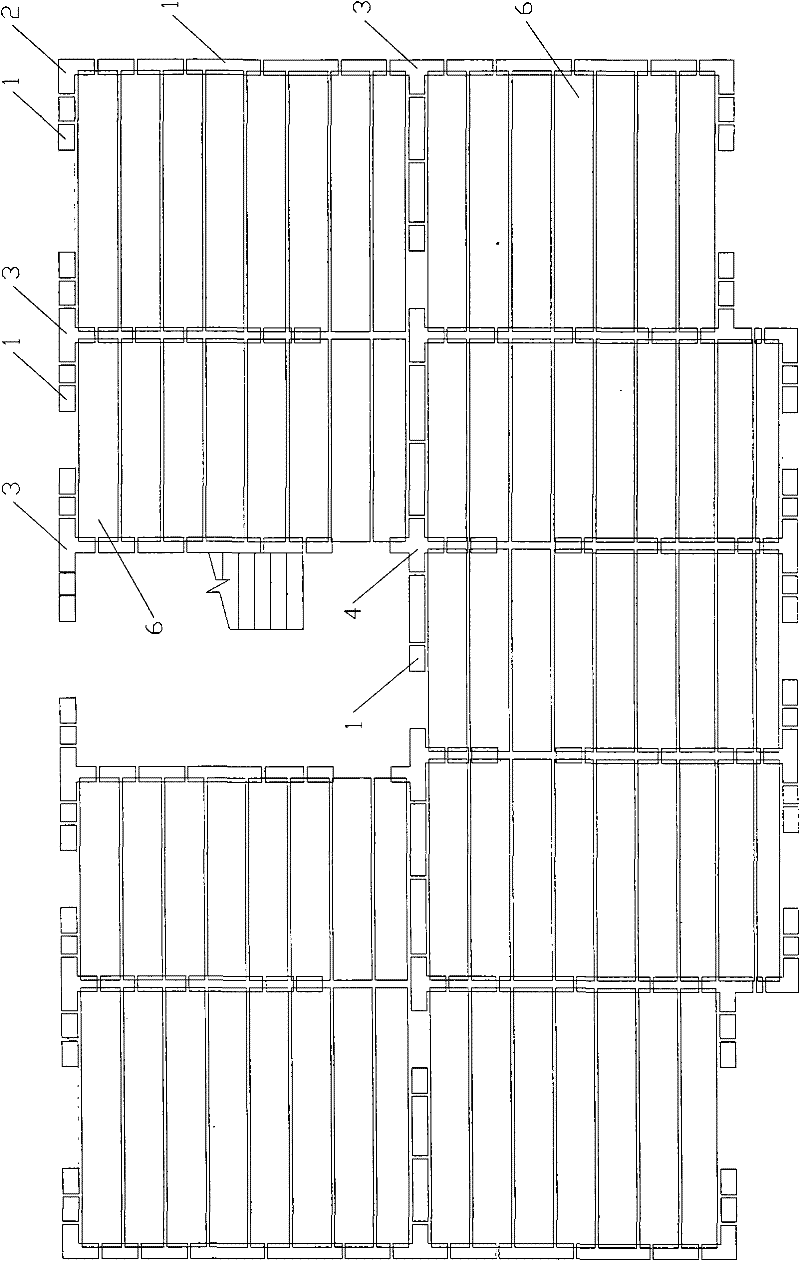

The invention relates to a frame-shear wall structure building of a dismantling-free prefabricated reinforced concrete formwork and a construction method thereof, belonging to the technical field of buildings and construction thereof. The structure is a pure frame structure building formed through connecting a dismantling-free prefabricated reinforced concrete rectangular column formwork, a beam formwork and a floor system formwork with each other by using cast-in-place concrete, or a frame-shear wall structure building formed through connecting a dismantling-free rectangular column formwork, a beam formwork, a floor system formwork and a wall formwork with each other by using cast-in-place concrete; longitudinal and transverse through holes in parallel with the surface are arranged in each formwork; one building unit of a cast-in-place concrete frame-shear wall structure is formed by alternatively arranging reinforcing steels and filling concrete in the crossed through holes; and a multistoried or high-rise cast-in-place concrete frame-shear wall structure building is formed by one building unit or more building units which are combined. The frame-shear wall structure building has the advantages of being simple for machining and less in investment of production equipment, decreasing the construction processes, accelerating the construction, saving the manpower and the like.

Owner:ZHONGQINGDA TECH HLDG CO LTD

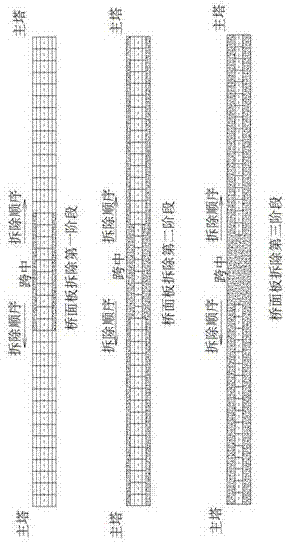

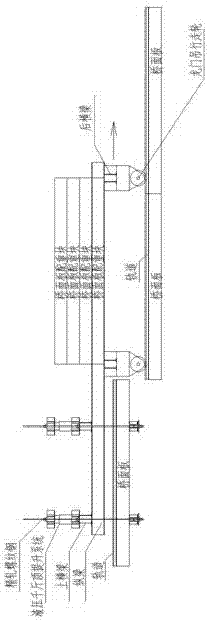

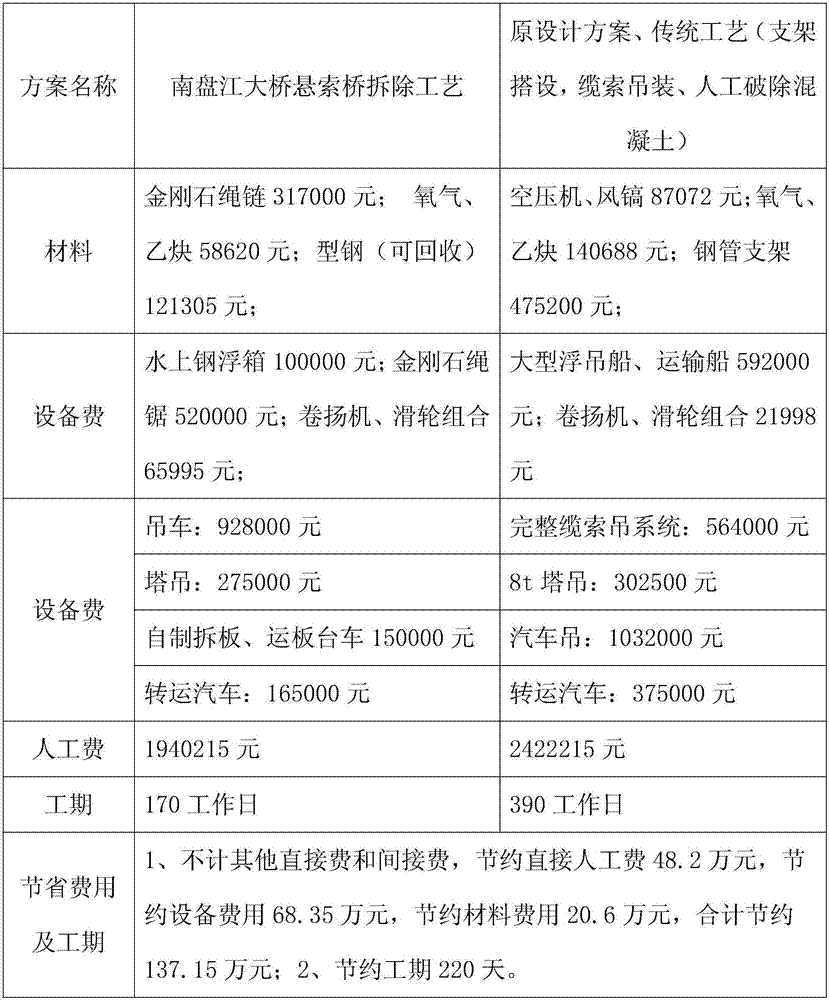

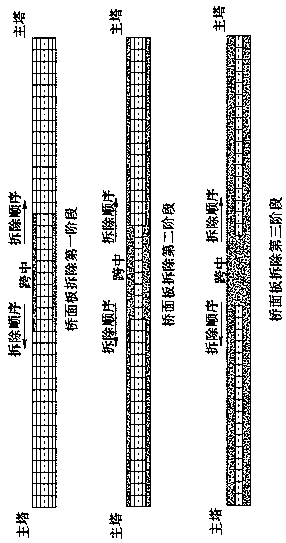

Demolition construction method for long-span highway suspension bridges

ActiveCN106978784AEnsure safetyShorten the construction periodBuilding repairsBridge strengtheningReinforced concreteDiamond wire saw

The invention discloses a demolition construction method for long-span highway suspension bridges. The construction method specifically comprises the following steps that 1, steel structure counter-force frames are installed at the top of a main tower, cable saddling and pushing are conducted, and the deflection of the main tower is corrected; 2, bridge surface plates and bridge surface paving layers are cut, and blocking and whole hoisting are conducted; 3, demolition of steel truss beams is conducted, and after the steel truss beams are cut off from the midspan, the beams are lowered in a segmental mode as a whole; 4, demolition of main cables are conducted, remaining main cable hangings and catwalks are utilized as an operation platform, the main cables are cut off in situ, and the demolition of the main cables is conducted; 5, demolition of the main tower is conducted, diamond wire saws are utilized to cut reinforced concrete with static force, upper cross beams are lowered as a whole through the adoption of a suspension system, after the main tower is cut and divided into blocks, vehicle cranes are used for hoisting, and cutting and hoisting are conducted after holes are drilled in lower cross beams. The demolition construction method for the long-span highway suspension bridges is applicable to the complex demolition of suspension bridges in geological environment, and the construction method is not only relatively little in resource waste and relatively low in economic cost, but also conductive to environmental protection.

Owner:GUIZHOU BRIDGE CONSTR GROUP

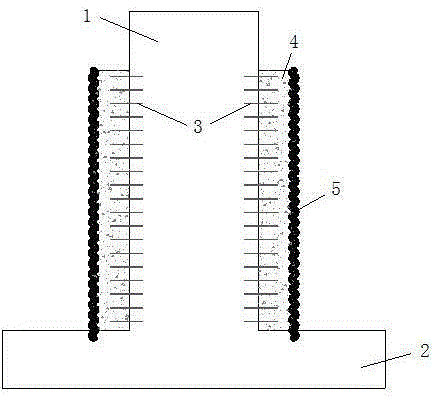

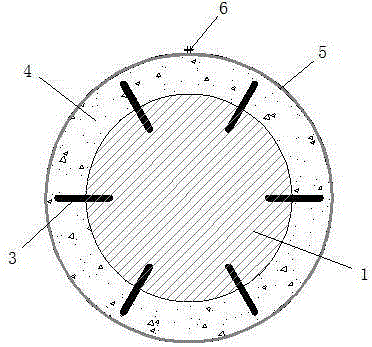

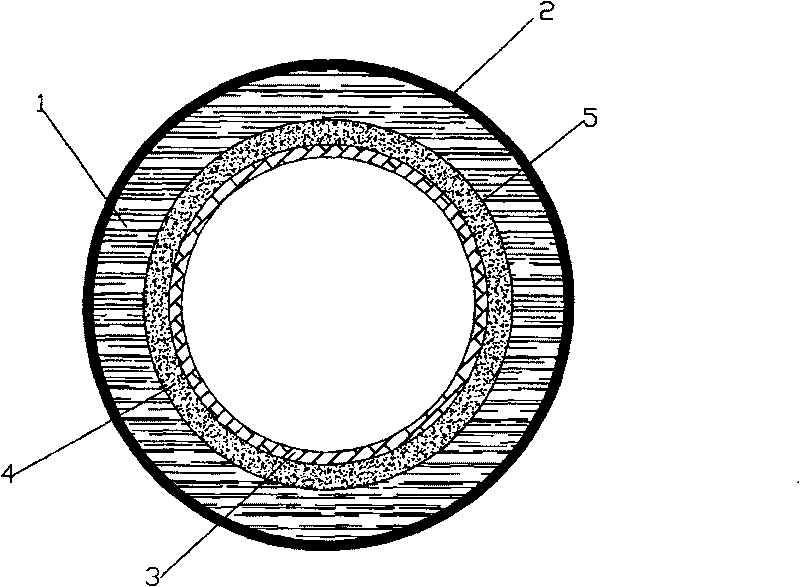

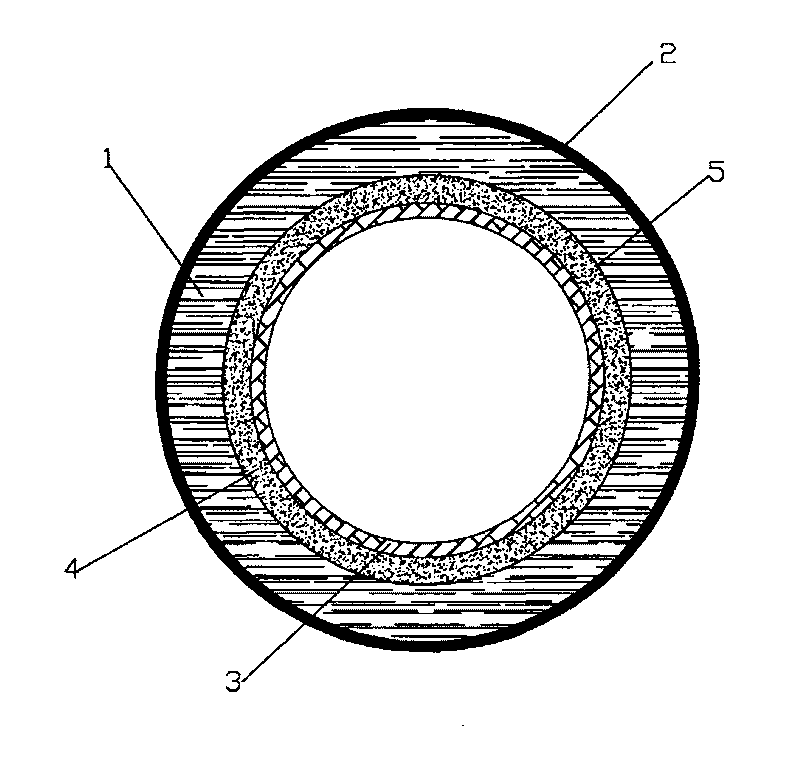

Method for reinforcing concrete pier through combination of corrugated steel pipes and fiber reinforced powder concrete

InactiveCN105178202ALow costReduce dismantling processBridge erection/assemblyBridge strengtheningSteel barShock resistance

A method for reinforcing a concrete pier through combination of corrugated steel pipes and fiber reinforced powder concrete comprises the following steps of (1) carrying out grinding and rough chiseling on the surface of a concrete pier reinforcing area; (2) determining the steel bar embedding positions on the surface of the concrete pier reinforcing area, and embedding transverse structure bars through drilling, hole clearing and gluing; (3) arranging the corrugated steel pipes embedded in a bearing platform on the outer side of the concrete pier reinforcing area; and (4) pouring the fiber reinforced powder concrete wrapping the transverse structure bars between the corrugated steel pipes and the concrete pier. By means of the method, not only can the bearing capacity and the shock resistance of the original concrete pier be improved, but also the method has the advantages that the number of construction procedures is small, the construction speed is high, and combination between new and old concrete materials is good.

Owner:EAST CHINA JIAOTONG UNIVERSITY

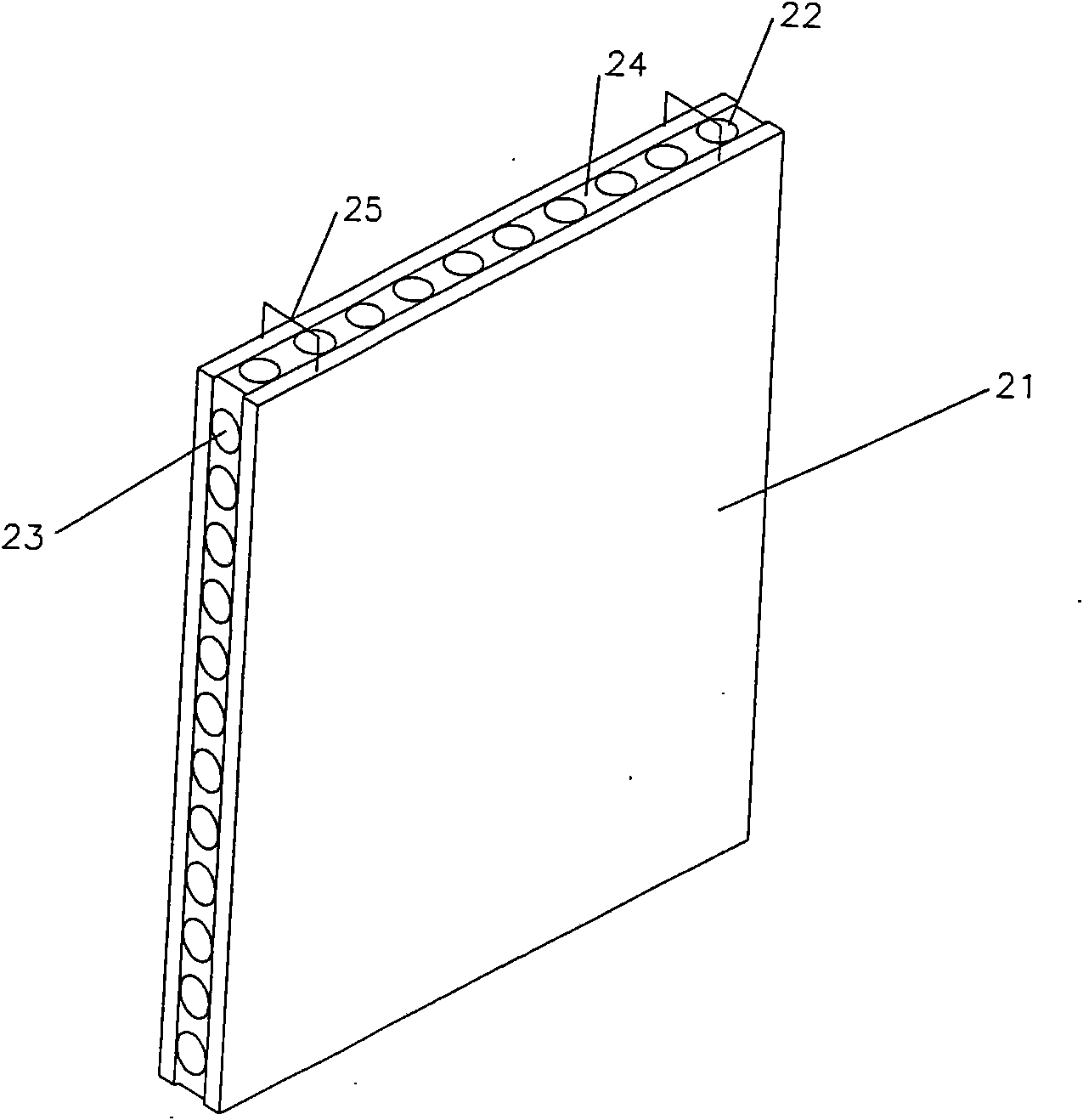

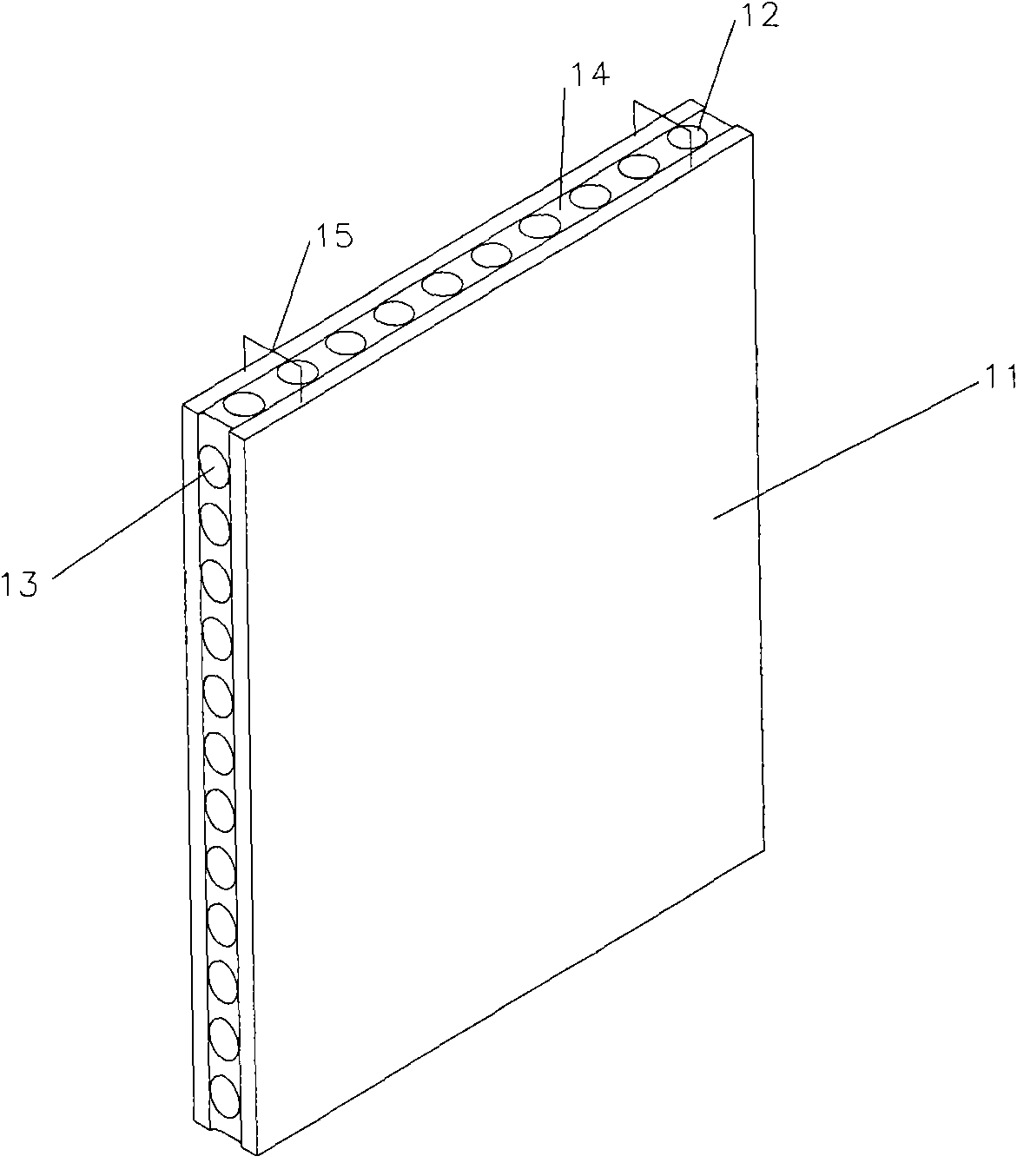

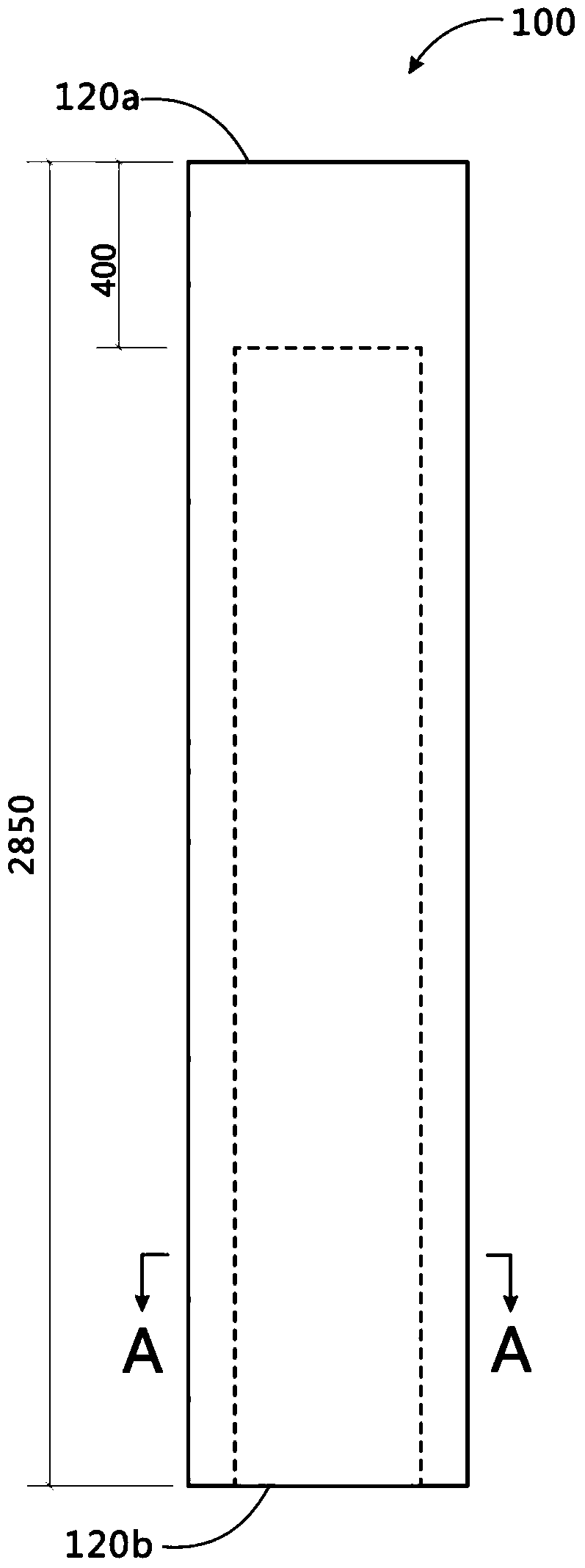

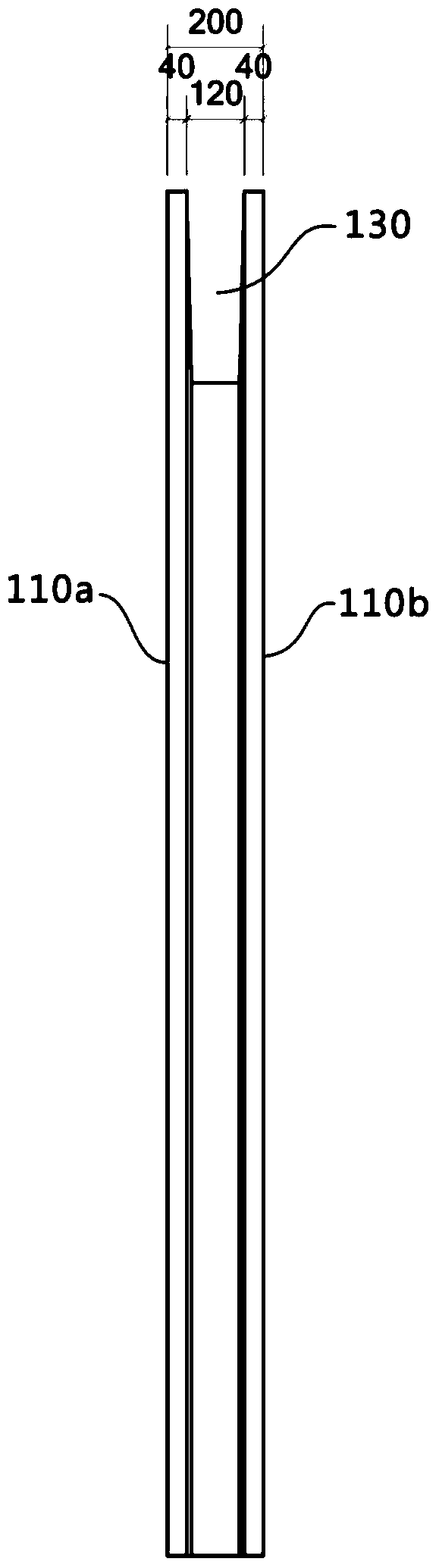

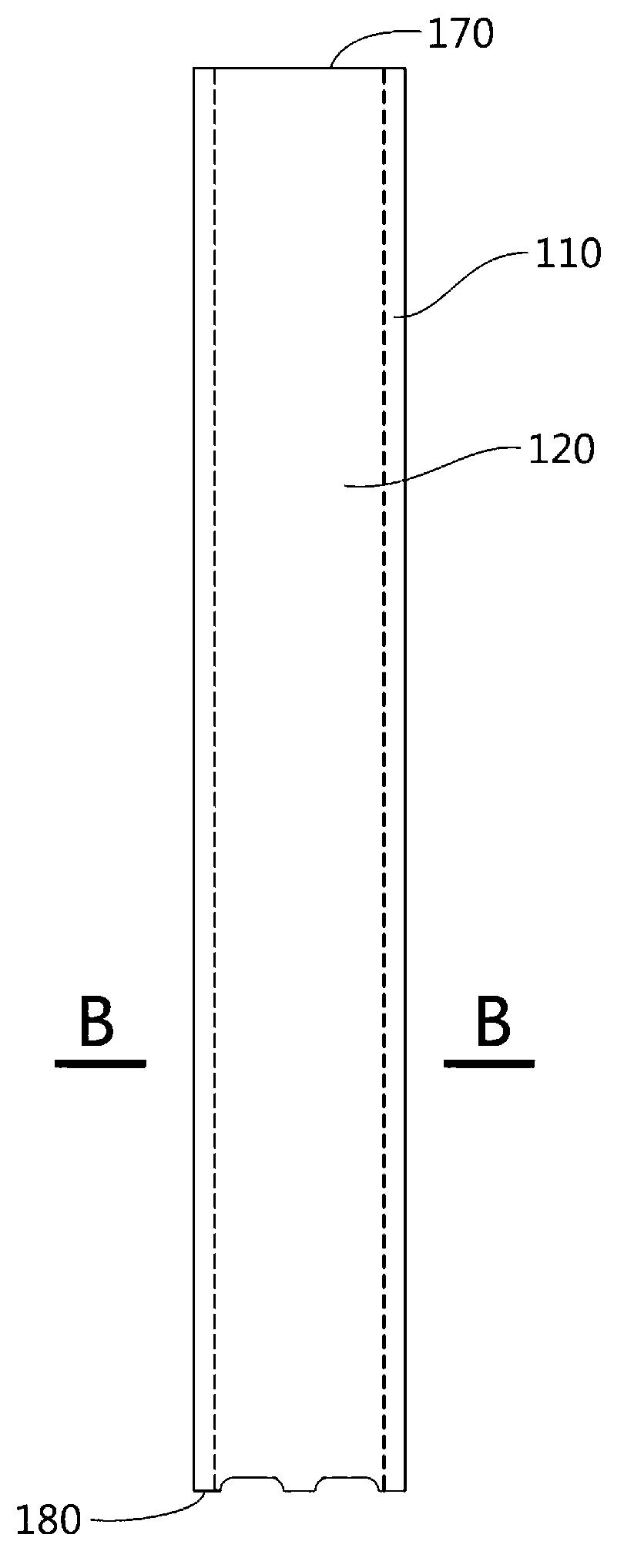

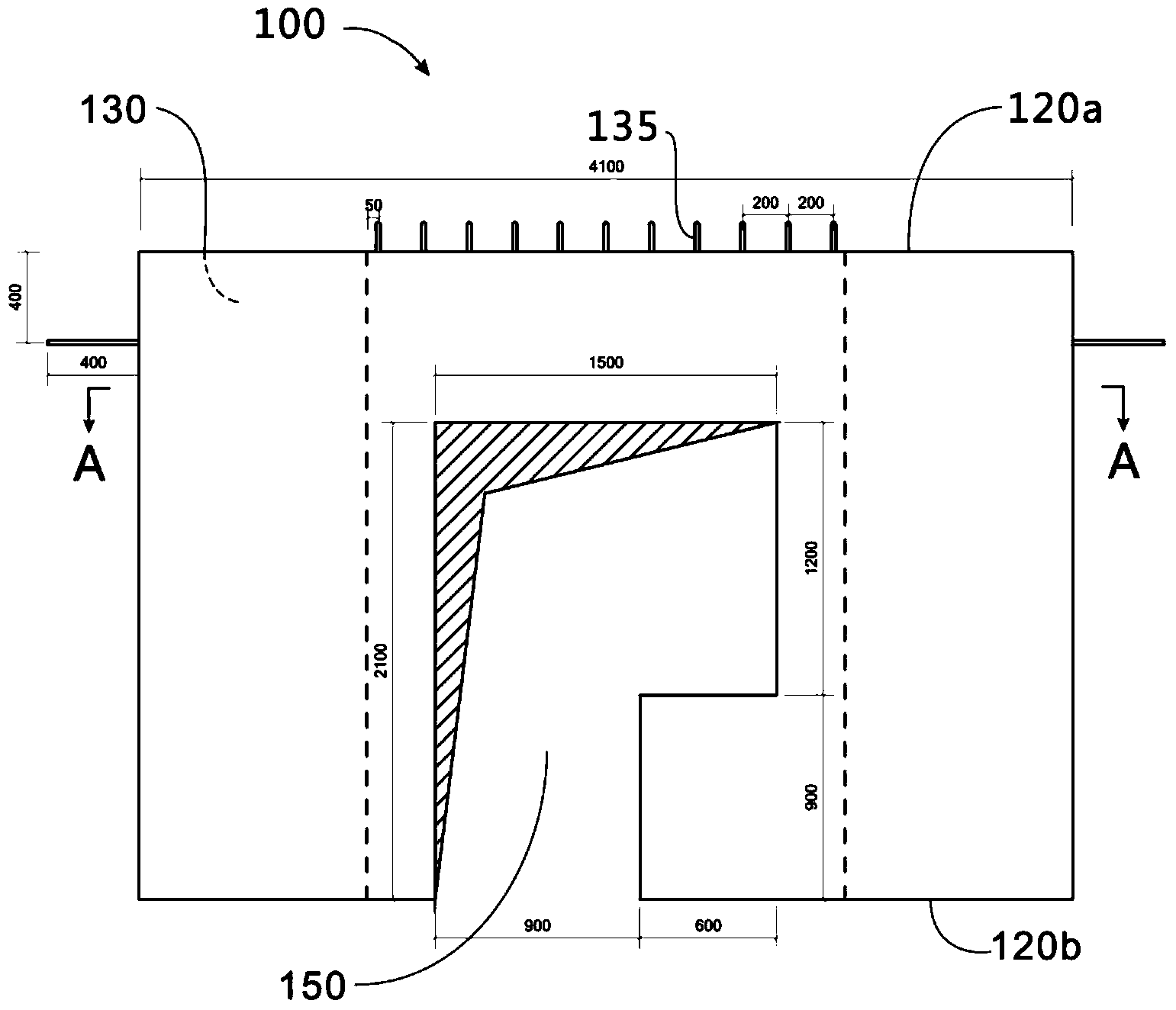

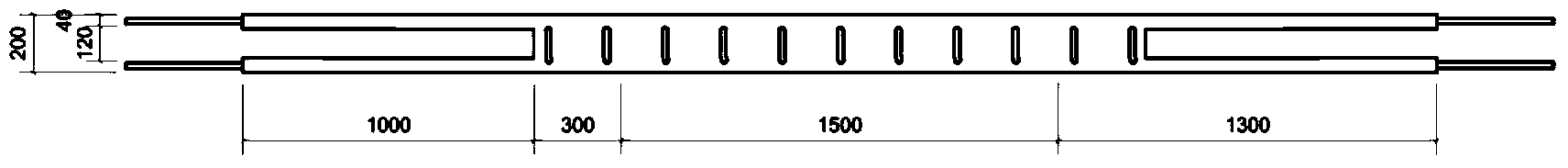

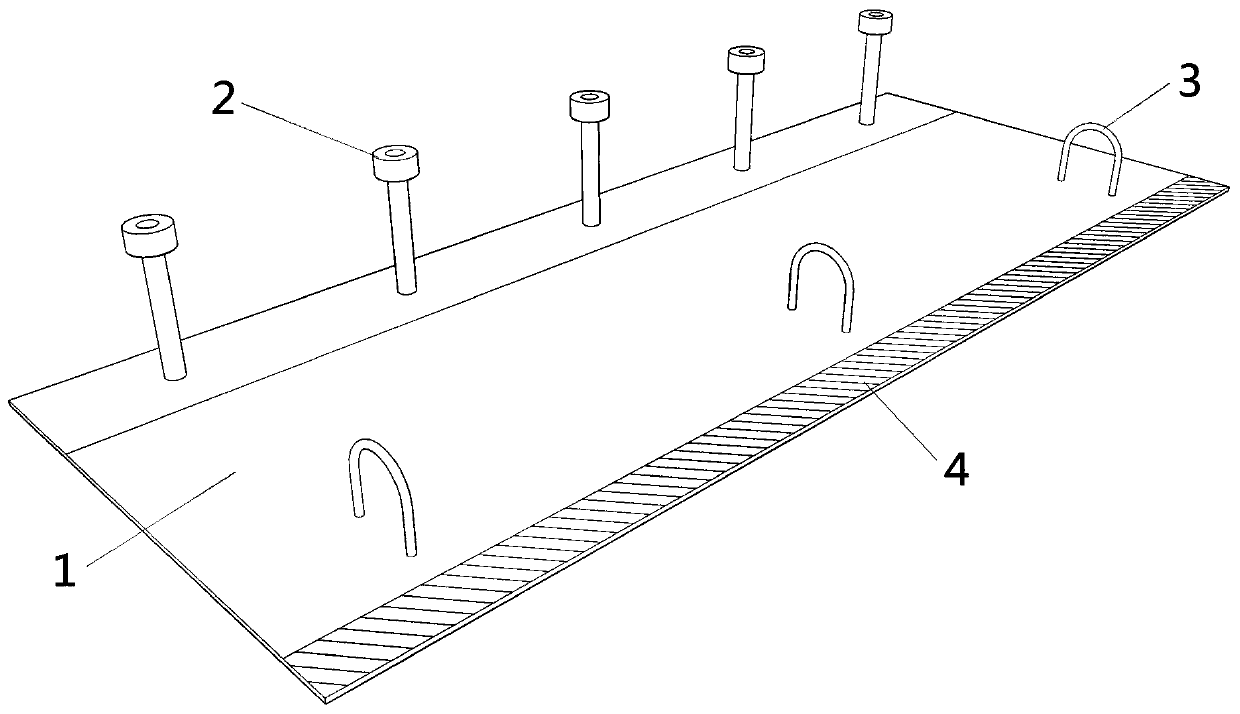

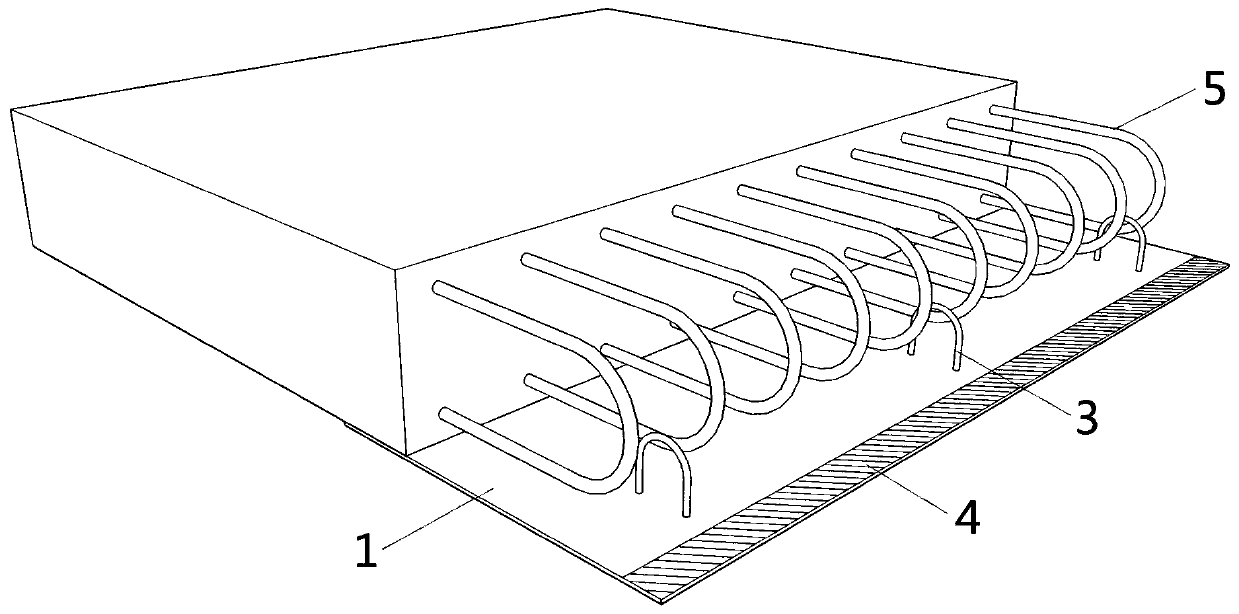

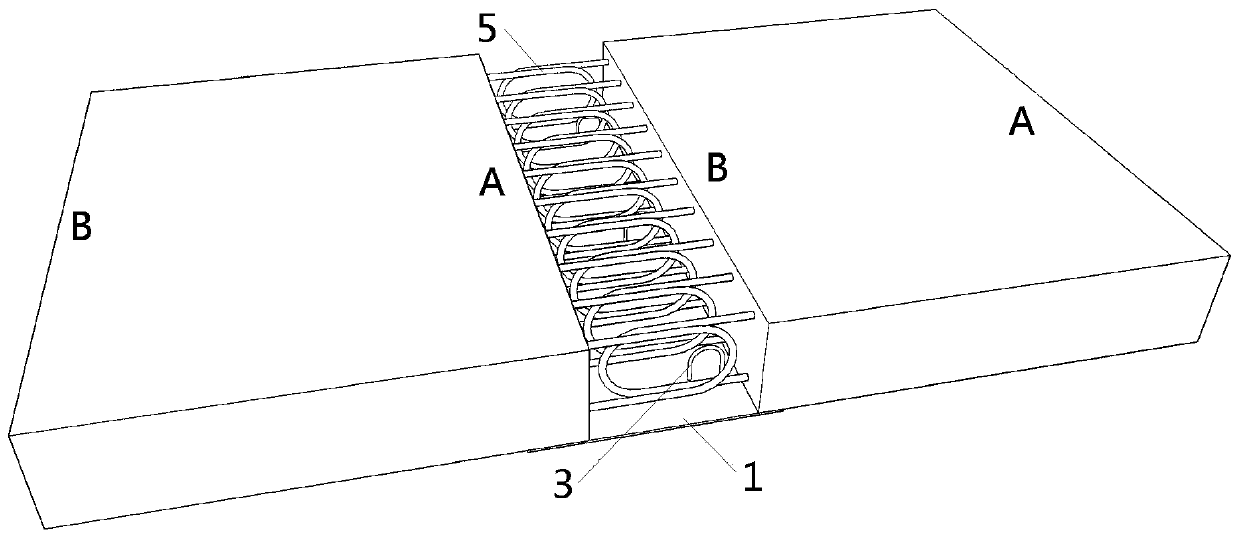

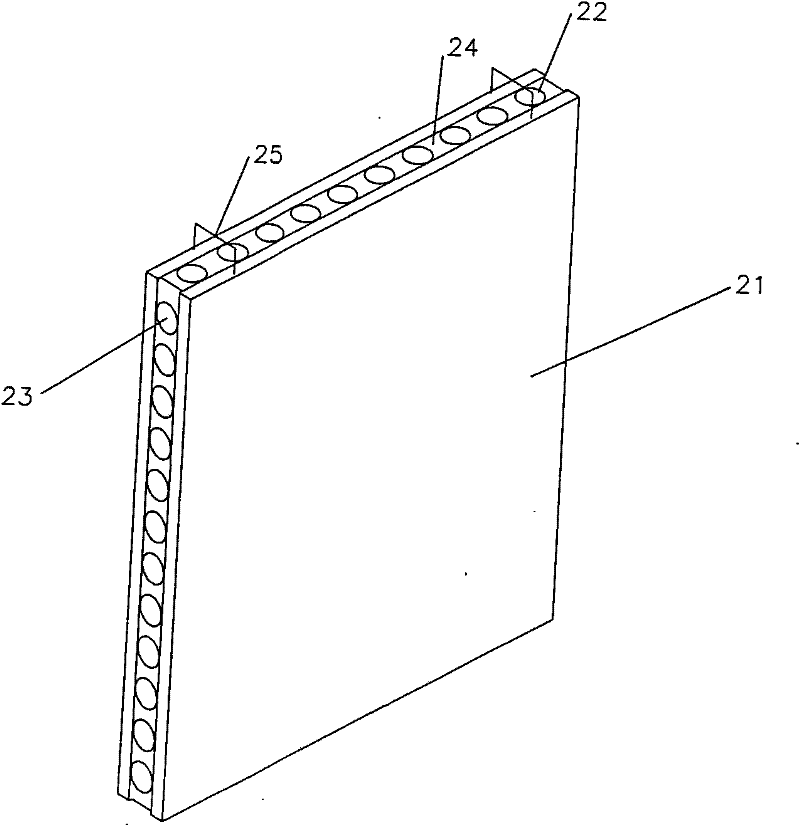

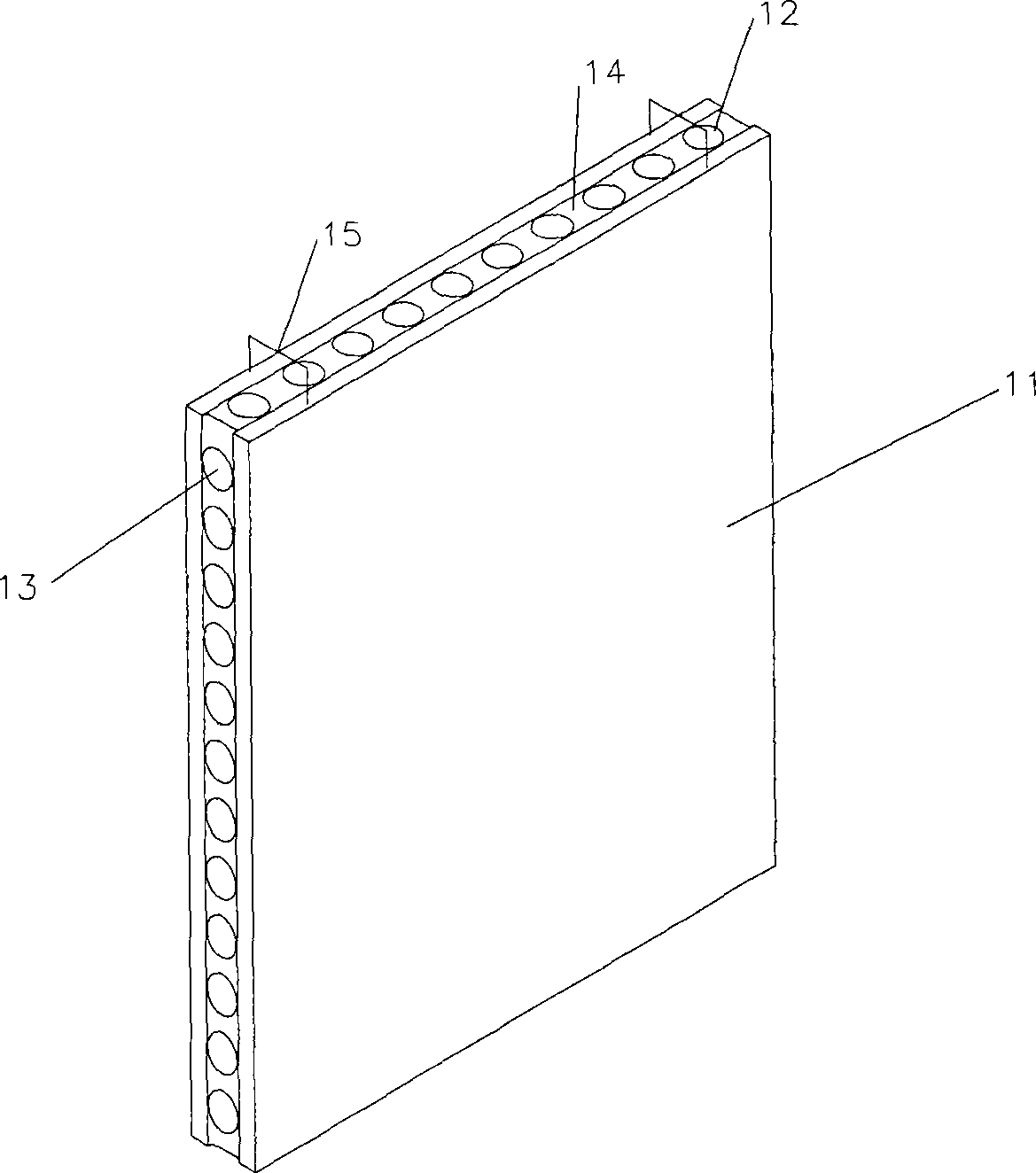

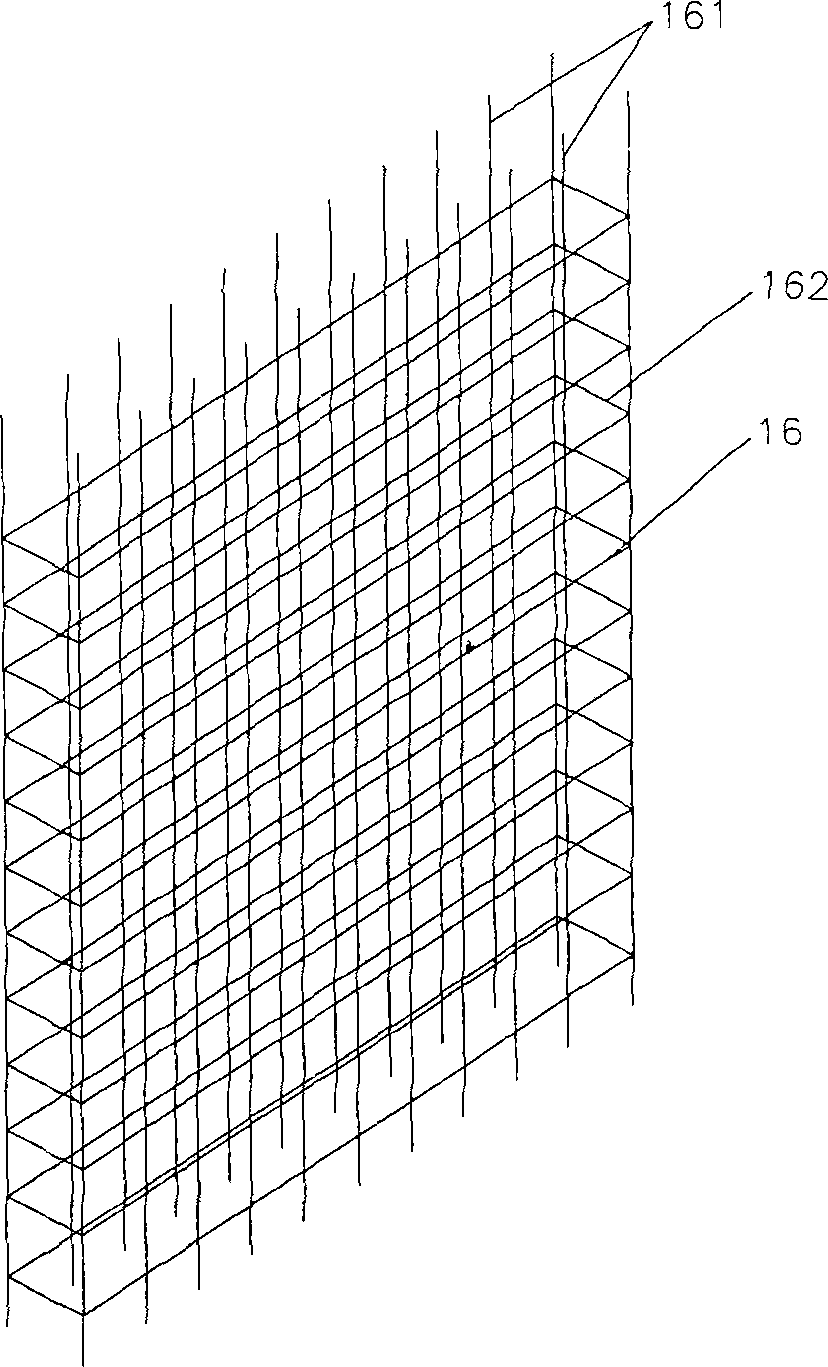

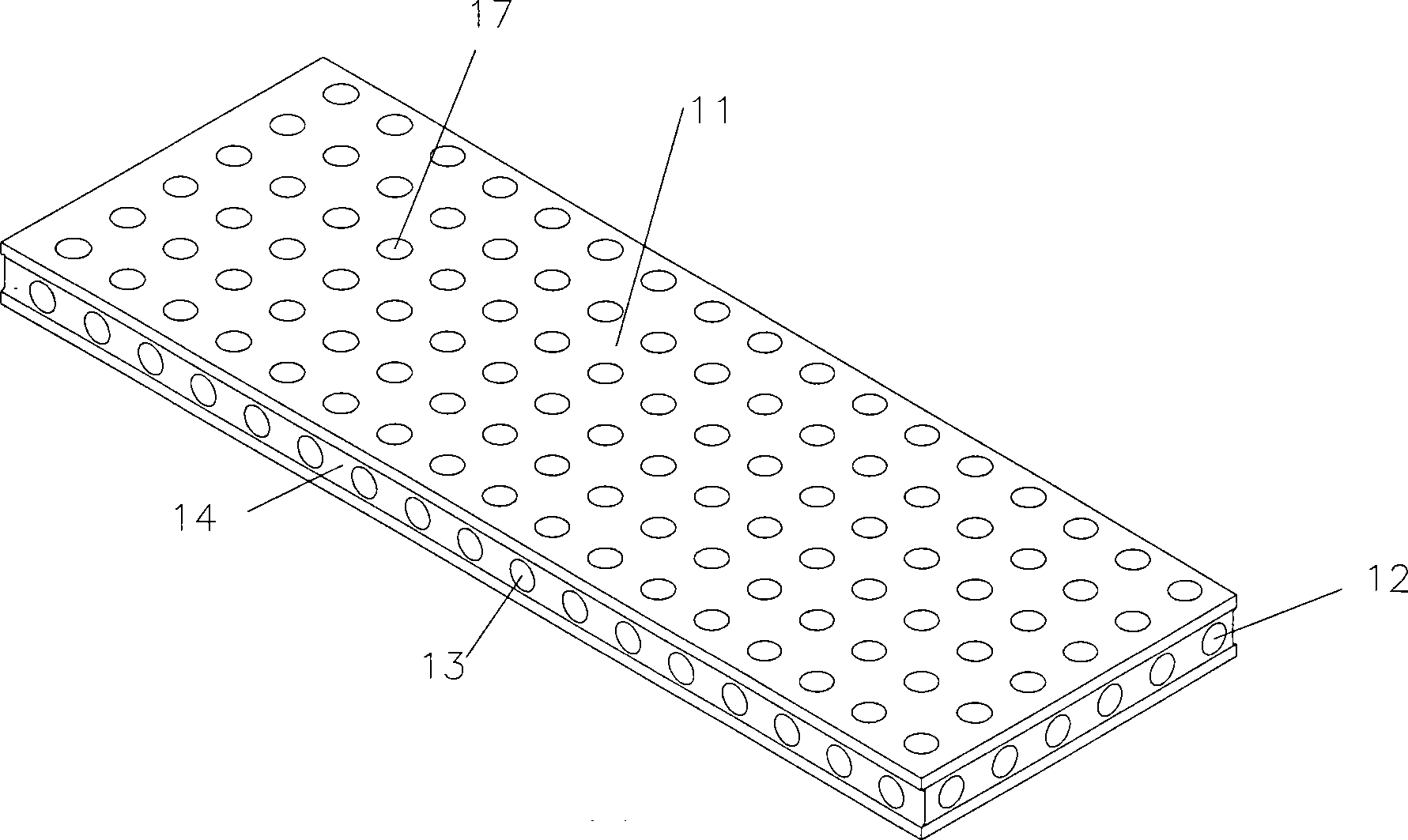

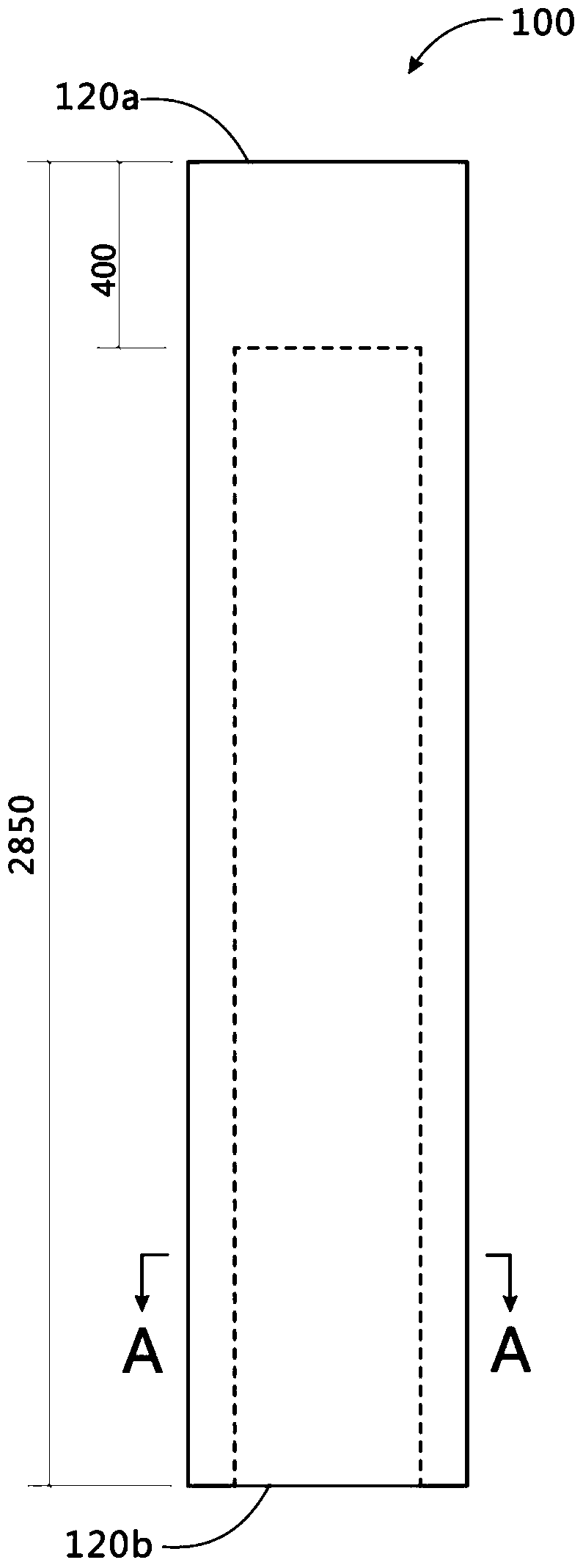

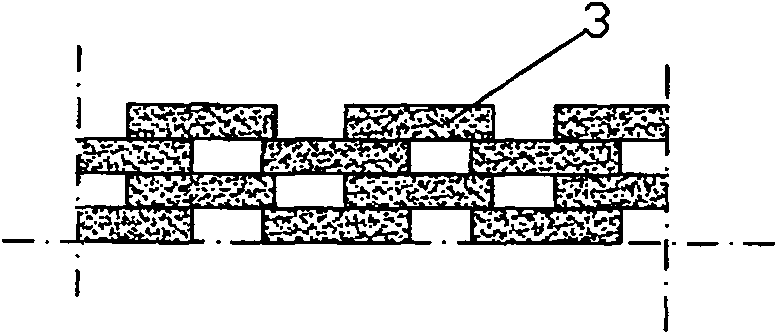

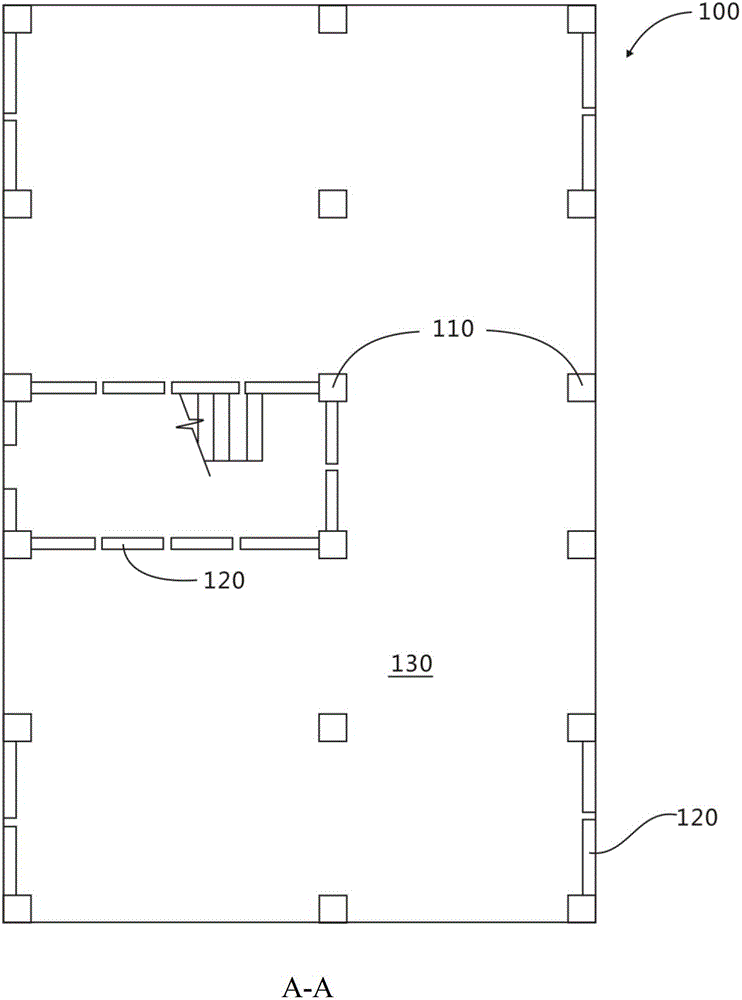

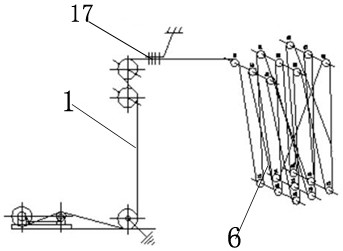

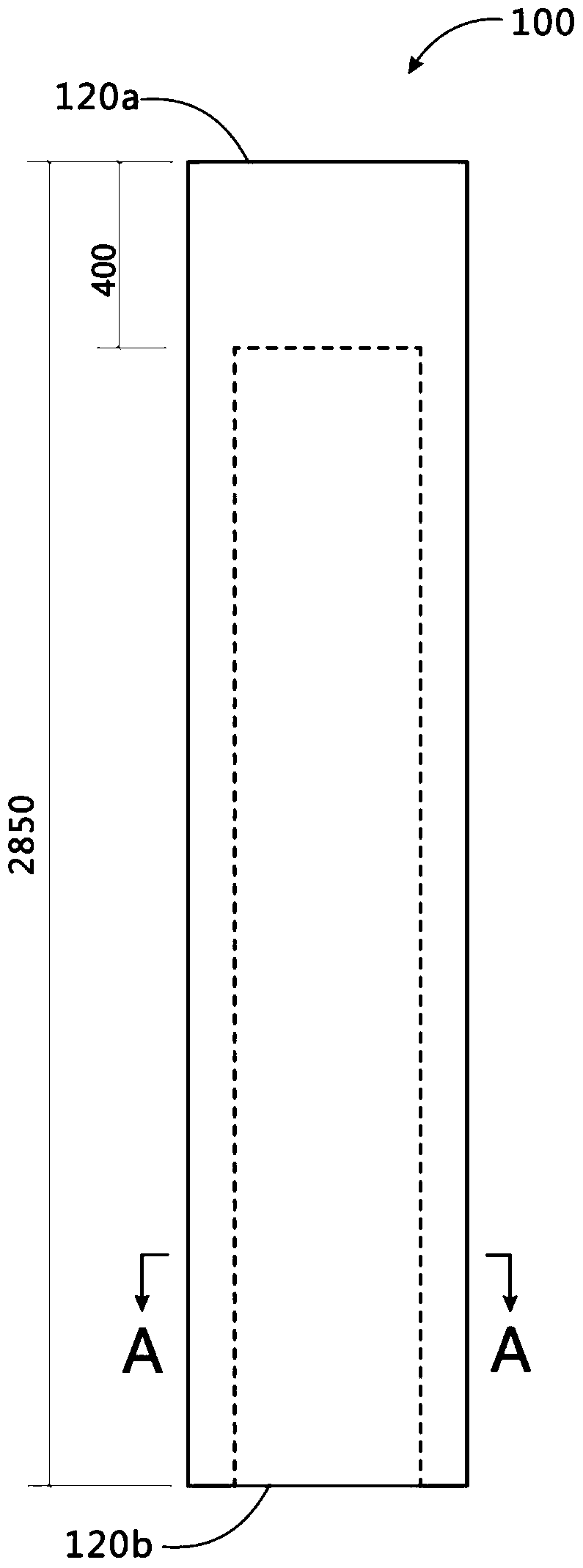

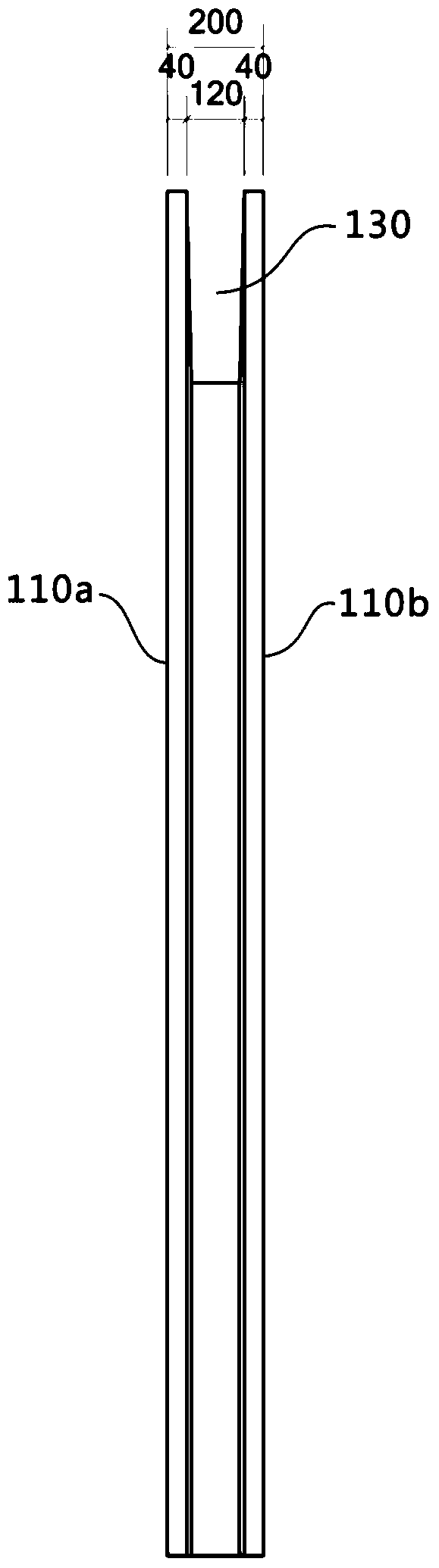

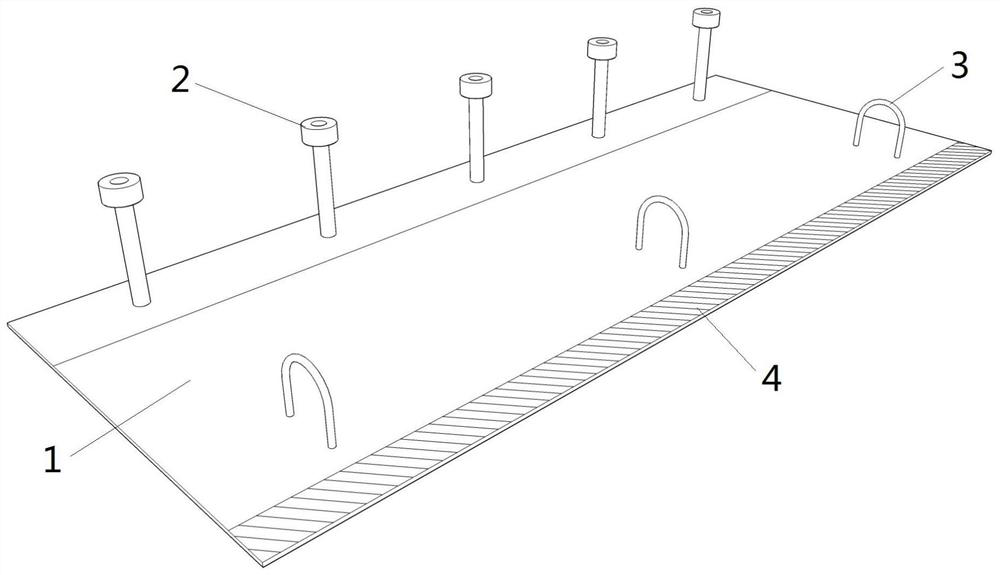

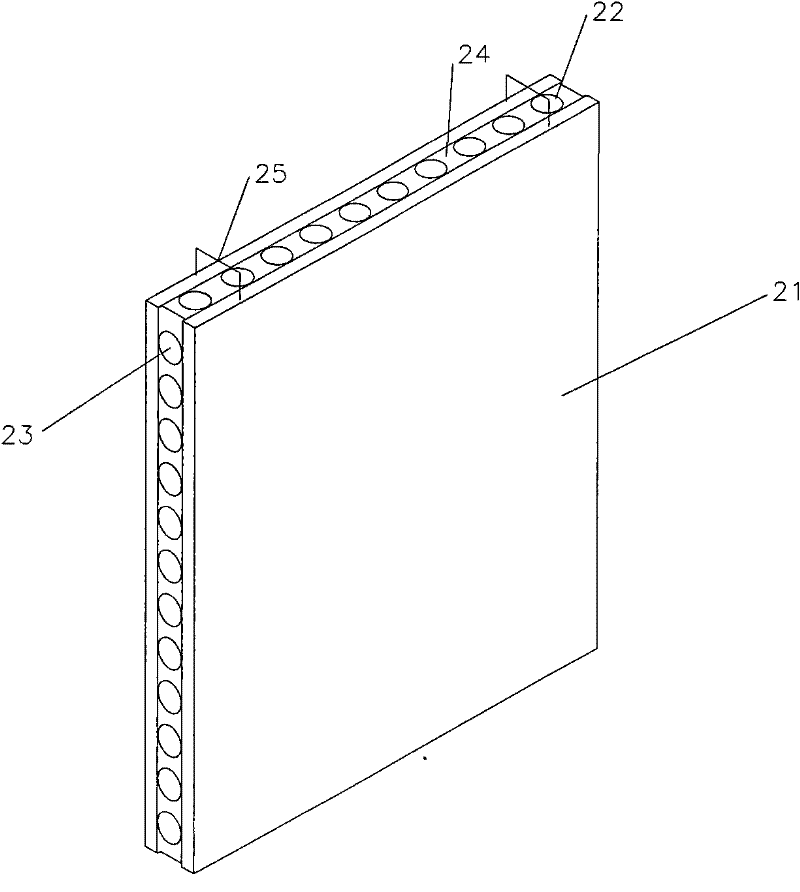

Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

ActiveCN101985856AConstruction quality is easy to guaranteeFlatness is easy to guaranteeForms/shuttering/falseworksForming/stuttering elementsEngineeringRebar

The invention relates to a removal-free prefabricated reinforced concrete template with cross holes inside. The template is a wall template, a floor template, a roof template, a T-shaped template, an L-shaped template, a cross template, a coupling beam template, a beam template or an upright template. A plurality of longitudinal through holes and a plurality of horizontal through holes parallel to the surface are arranged in the template. The plurality of longitudinal through holes and the plurality of horizontal through holes form cross channels. When the removal-free template is prefabricated in factories, 70-80% of stress reinforced concrete is prefabricated in the template, which facilitates industrialization production, transportation and hoisting, and realizes that each layer of house wall template and the floor template are supported once, the concrete is repoured, after the current layer of concrete is poured, the next layer construction is immediately carried out, the construction period of the house is shortened, meanwhile labour is saved, the construction speed is quickened and the house cost is reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

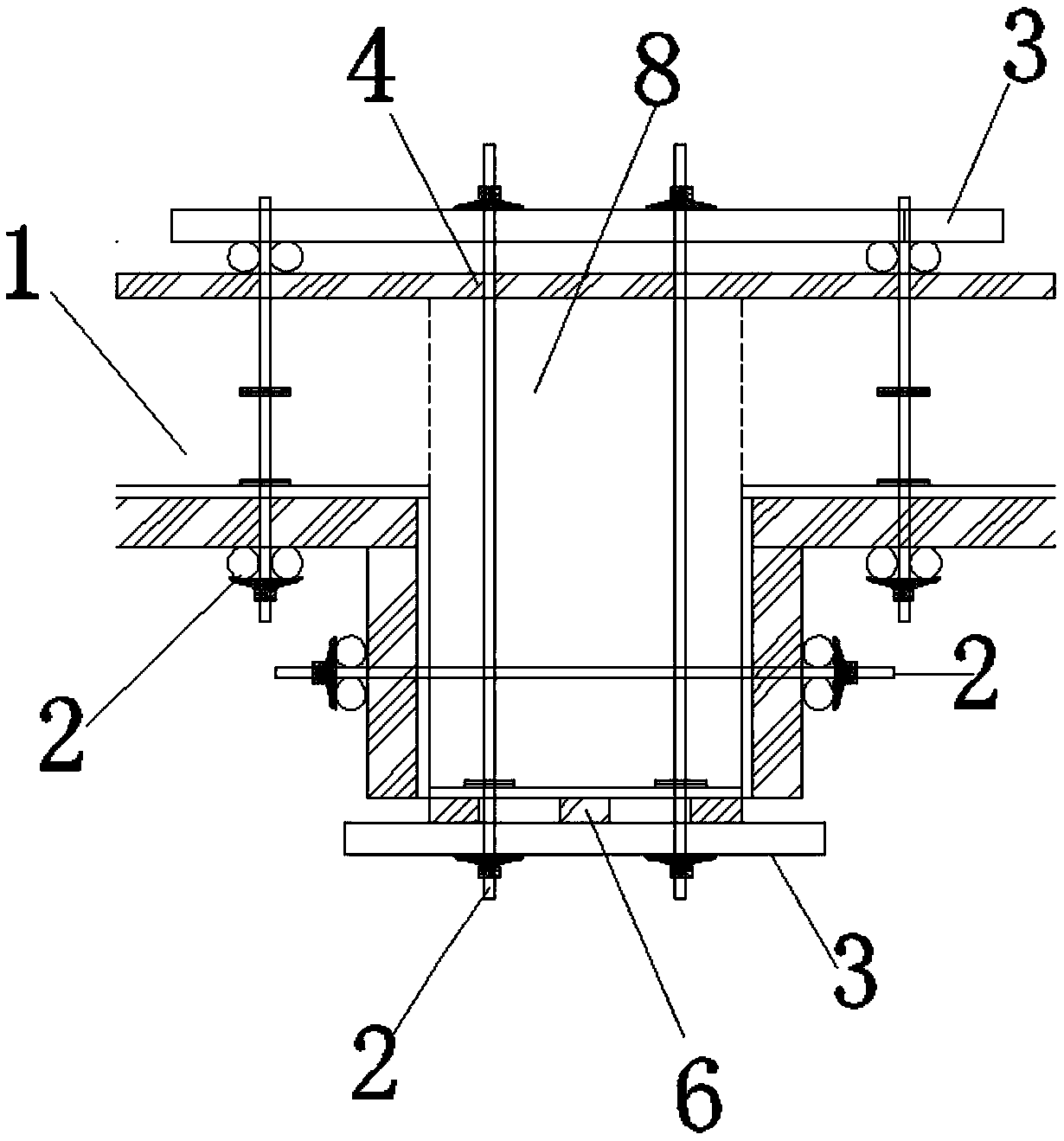

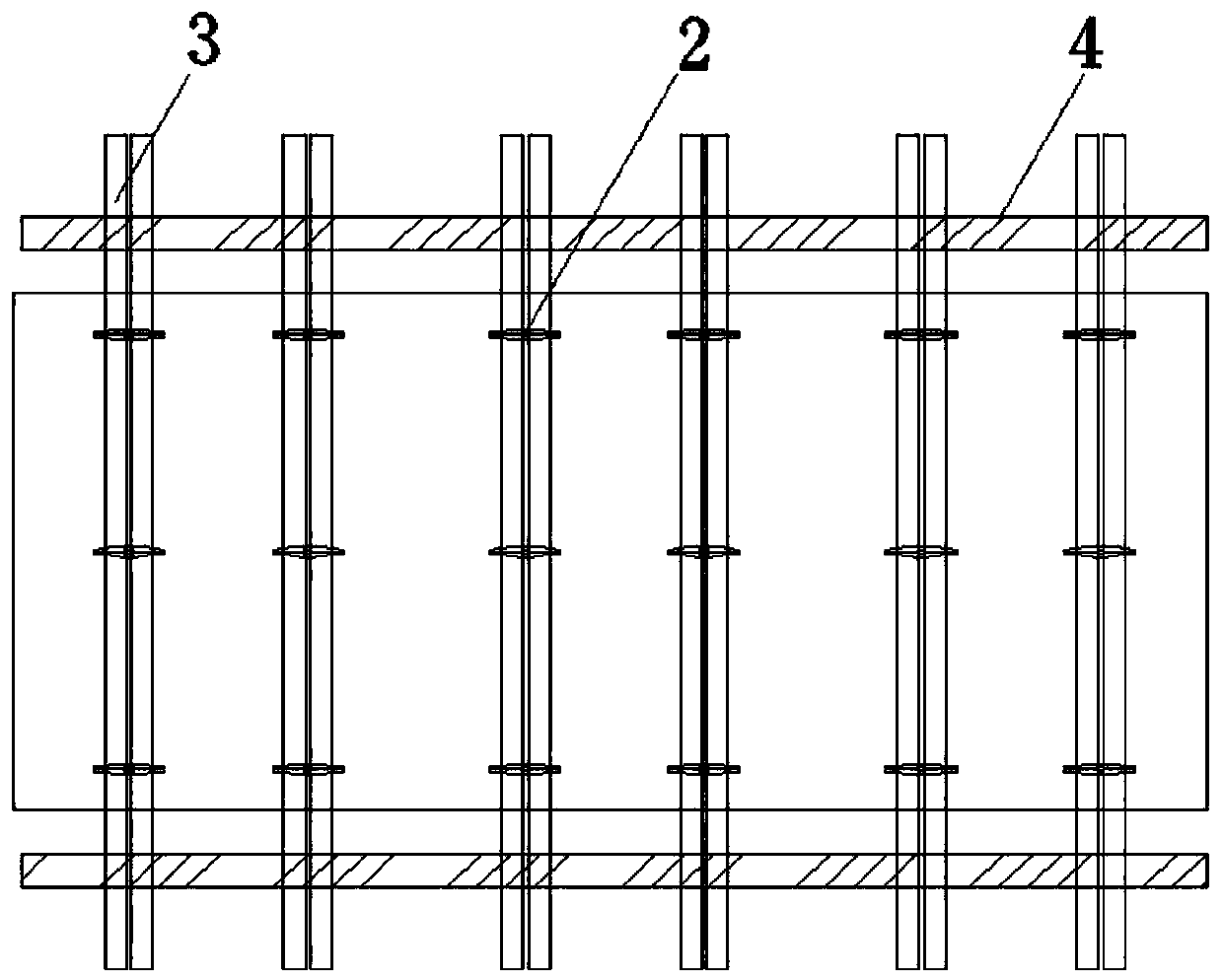

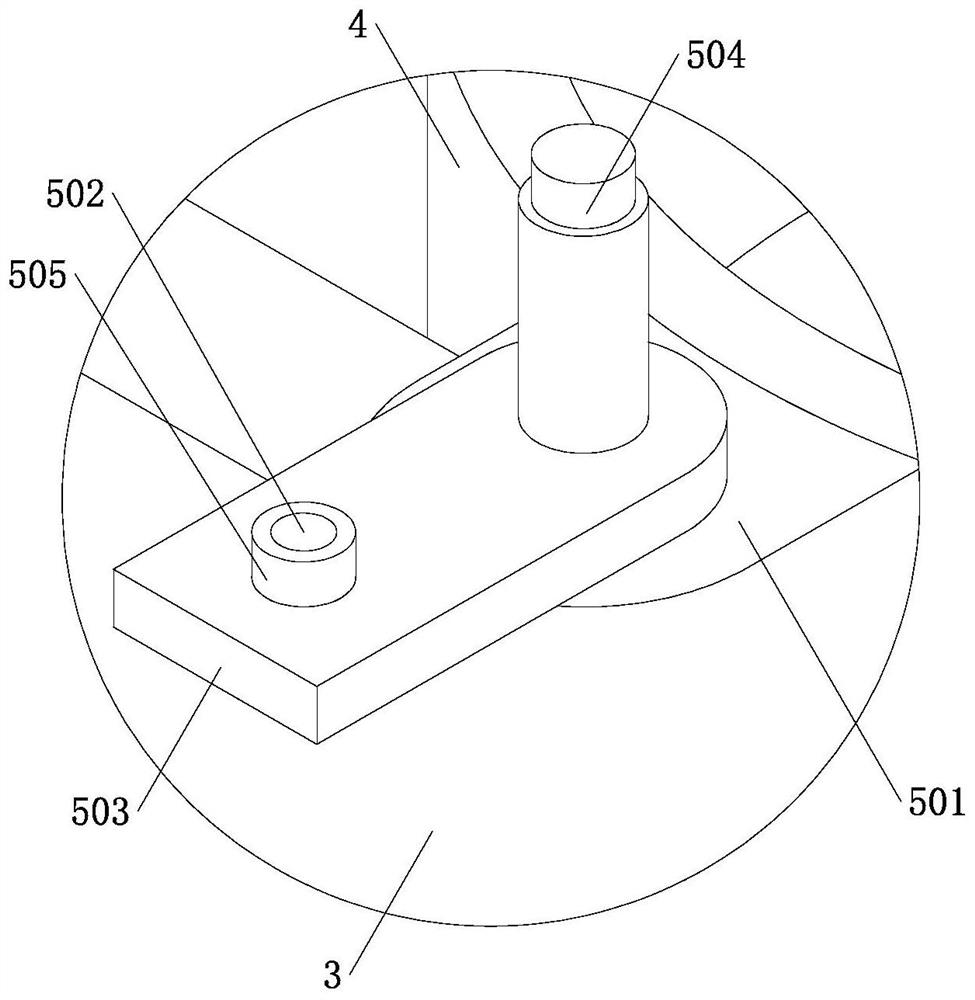

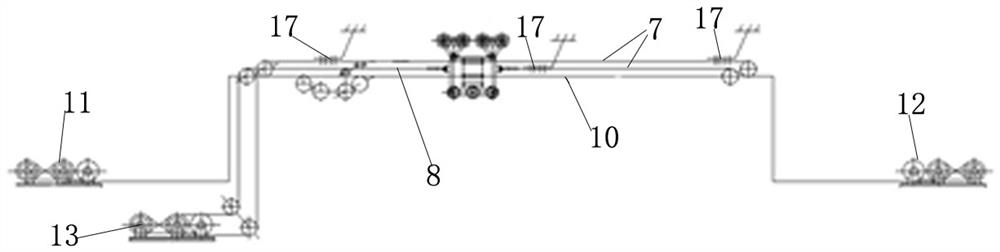

Formwork reinforcing device without top support for post-cast strip and construction method thereof

PendingCN109680931AReduce erectionReduce dismantling processForms/shuttering/falseworksSocial benefitsBasement

The invention discloses a formwork reinforcing device without top support for a post-cast strip and a construction method thereof. The formwork reinforcing device comprises basement top plates, waterstop screw rods, main rib steel pipes, timber cushion blocks, clamps, back rib timbers, formworks, a post-cast strip beam and plain concrete columns, wherein the basement top plates are respectively arranged at both ends of the post-cast strip beam; the main rib steel pipes are arranged at the upper end and lower end of each basement top plate at equal intervals along the horizontal direction; three water stop screw rods penetrate through each of the main rib steel pipes at equal intervals along the longitudinal direction; the timber cushion blocks are respectively arranged at one end of the upper end surface of each basement top plate. The formwork reinforcing device has the beneficial effects that the problem of accumulation of revolving materials such as lower steel pipes, formworks, timbers and the like at the overhanging end of the post-cast strip in the building construction project are solved, the construction cost is reduced, the load bearing function of the formwork supportingsystem can be replaced, and the project quality of the beam plate at the overhanging area of the post-cast strip is effectively guaranteed; the operation is simple, the use is convenient, the good social benefit is realized, and the formwork reinforcing device is suitable for being popularized and applied.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

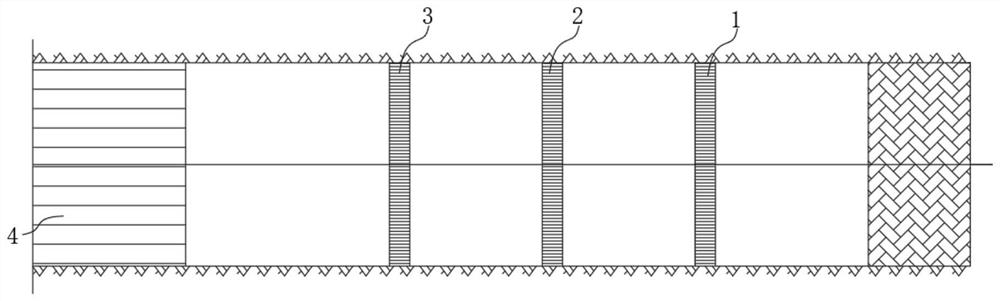

Frame-shear wall structure based on three-side-grooved strip precast concrete wallboard assembly and construction method thereof

The invention provides a frame-shear wall structure based on three-side-grooved strip precast concrete wallboard assembly and a construction method thereof. The structure comprises a cast-in-place spatial form system formed by mutually connecting strip precast concrete wallboards, wall column forms, shear walls and floor / roof forms; the strip precast concrete wallboards are precast with reinforced concrete, each wallboard is provided with end grooves and two side grooves, and the each wallboard can be provided with an insulation layer and a decorating layer as required; rebars are placed and concrete are poured between the wallboards or between the wallboards and wall columns, between the wallboards and the shear walls, including a cavity with side grooves, into space communicated through the end grooves, and onto the floor / roof forms, so that a single floor frame-shear wall structure building of a building unit is formed; a multi-floor building unit can be constructed by lap joint based on the single-floor building unit. The frame-shear wall structure and the construction method thereof have the advantages that manufacturing is simple, investment on production equipment is low, construction steps are fewer, construction speed is higher and less labor is required.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +3

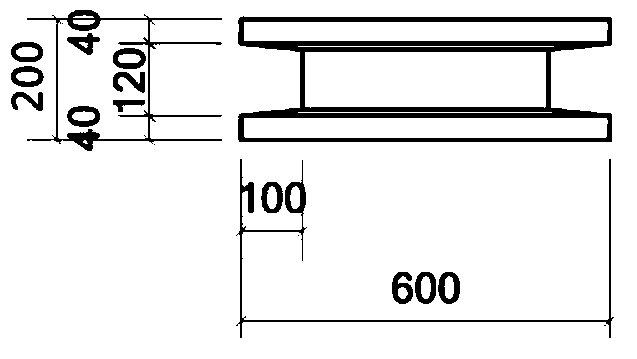

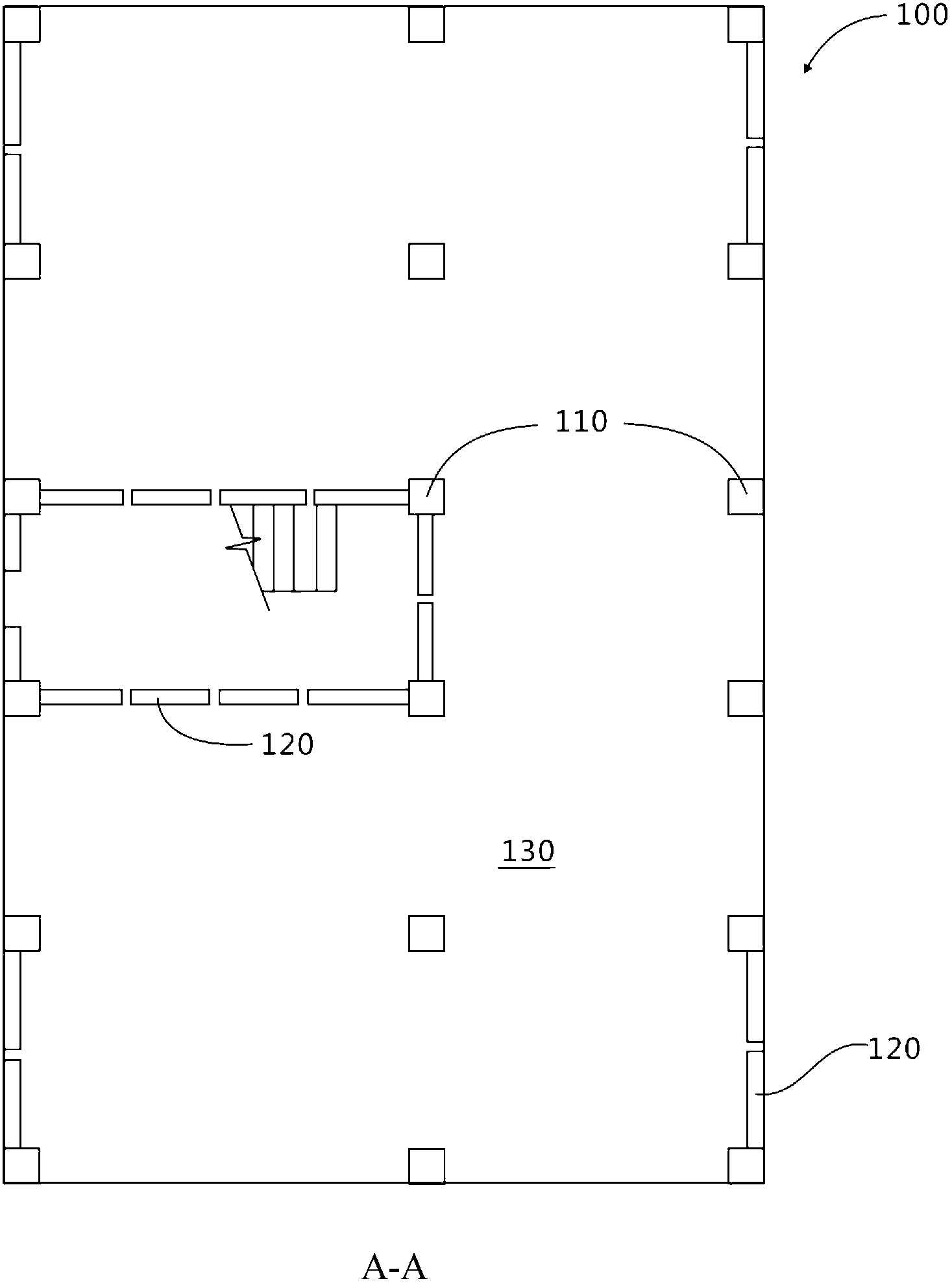

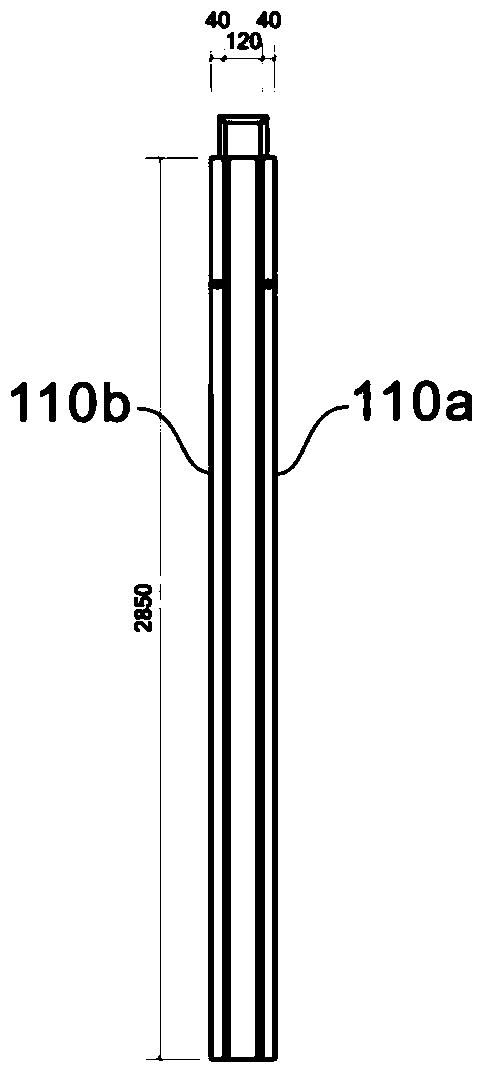

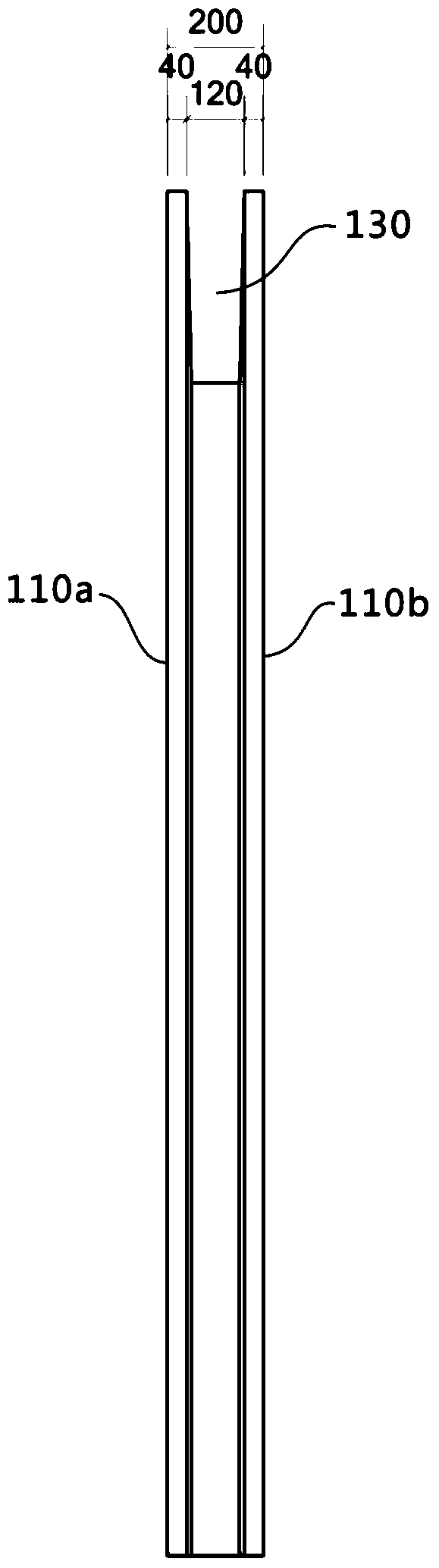

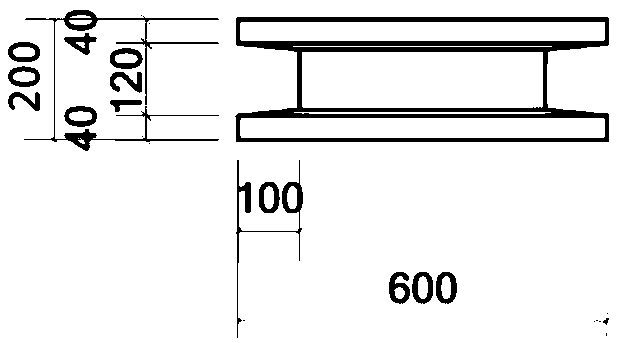

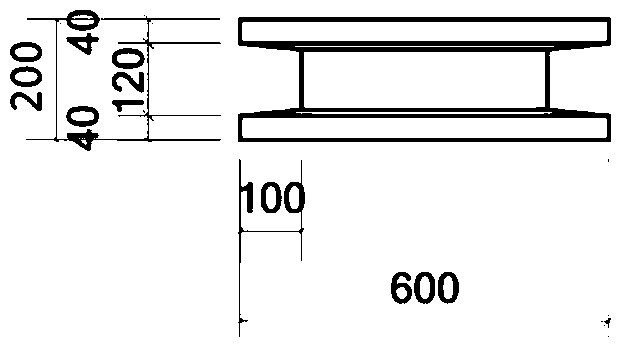

Prefabricated reinforced concrete hollow column template and manufacturing method thereof

InactiveCN102995833AEasy to prepareConstruction quality is easy to guaranteeStrutsCeramic shaping apparatusReinforced concreteRebar

The invention provides a prefabricated reinforced concrete hollow column template which is internally embedded with reinforcing steel bars and is provided with one or a plurality of hollow hole duct(s) which is / are penetrated longitudinally; and the cross section shape of the outer wall surface of a column body of a hollow column die as well as the cross section shape of the inner wall surface of the hollow hole duct are square. The invention also provides a manufacturing method of the prefabricated reinforced concrete hollow column template by adopting a die. The hollow column template provided by the invention has the advantages of simplicity in machining, simplicity and convenience in construction and the like, and can be widely applied to various building constructions.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

Construction structure for high-inclination sloping roof

InactiveCN105298115AReduce lossGuarantee molding qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksKeelBuilding construction

The invention provides a construction structure for a high-inclination sloping roof. The construction structure comprises a lower layer formwork, an upper layer formwork, keels and limiting waterproof bolts; the lower layer formwork is parallel to the upper layer formwork, and a pouring space is formed by the lower layer formwork and the upper layer formwork; the keels are arranged on the peripheral faces of the lower layer formwork and the upper layer formwork to support the lower layer formwork and the upper layer formwork; the limiting waterproof bolts are arranged in the overlapped direction of the lower layer formwork and the upper layer formwork and used for fixing and locating the lower layer formwork, the upper layer formwork and the keels, wherein the portions, above concrete, of the limiting waterproof bolts are reserved after first-stage concrete pouring is completed and are used for fixing roof tiles. By means of the construction structure for the high-inclination sloping roof, the concrete pouring quality can be improved, and the engineering cost can be reduced.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

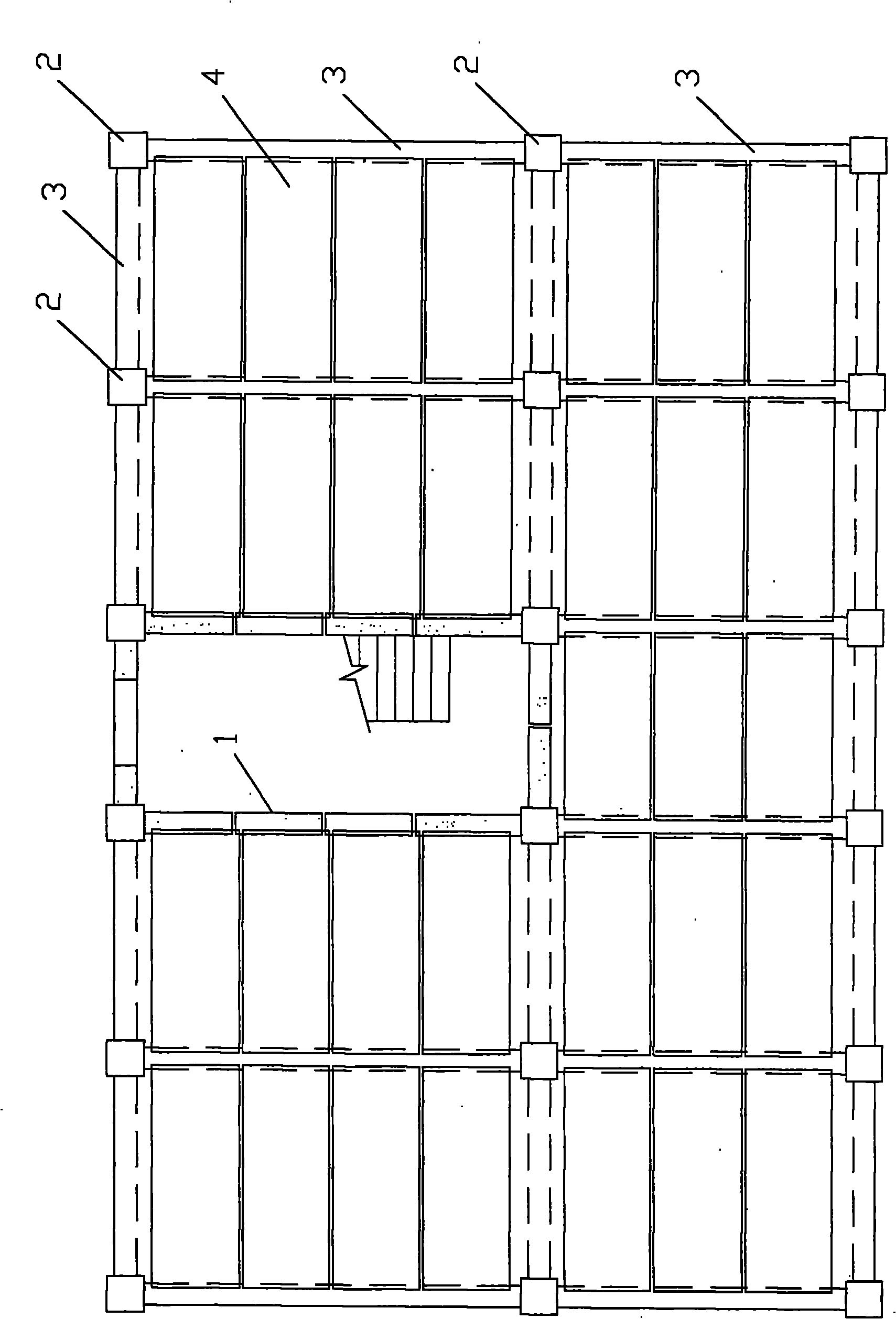

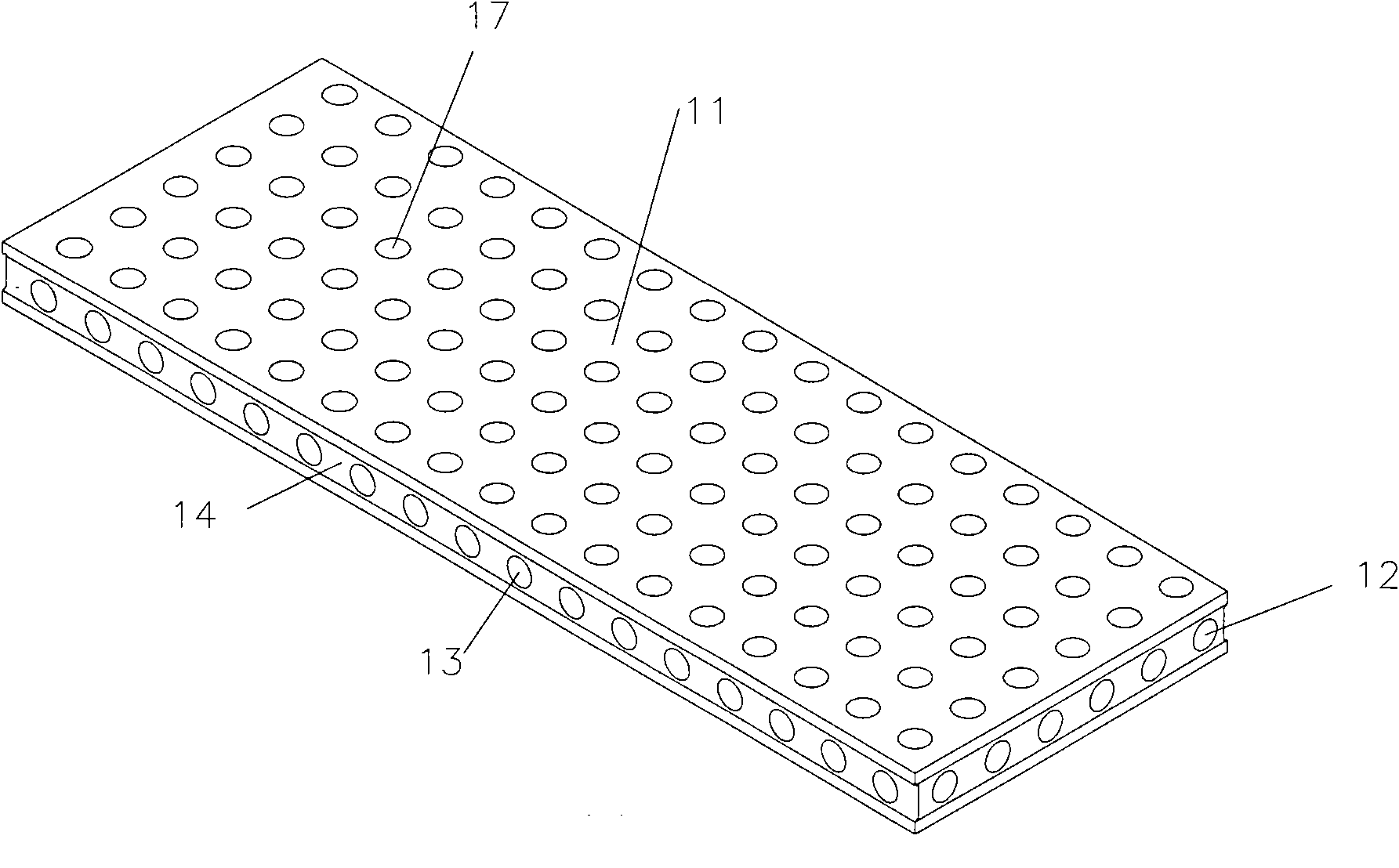

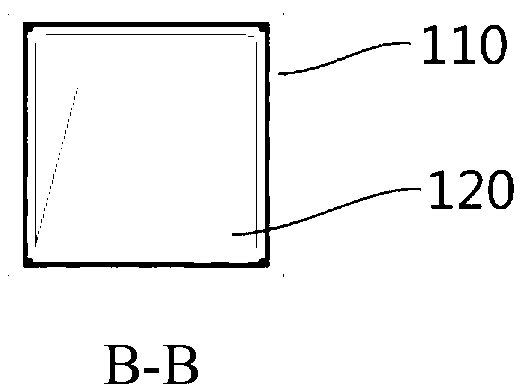

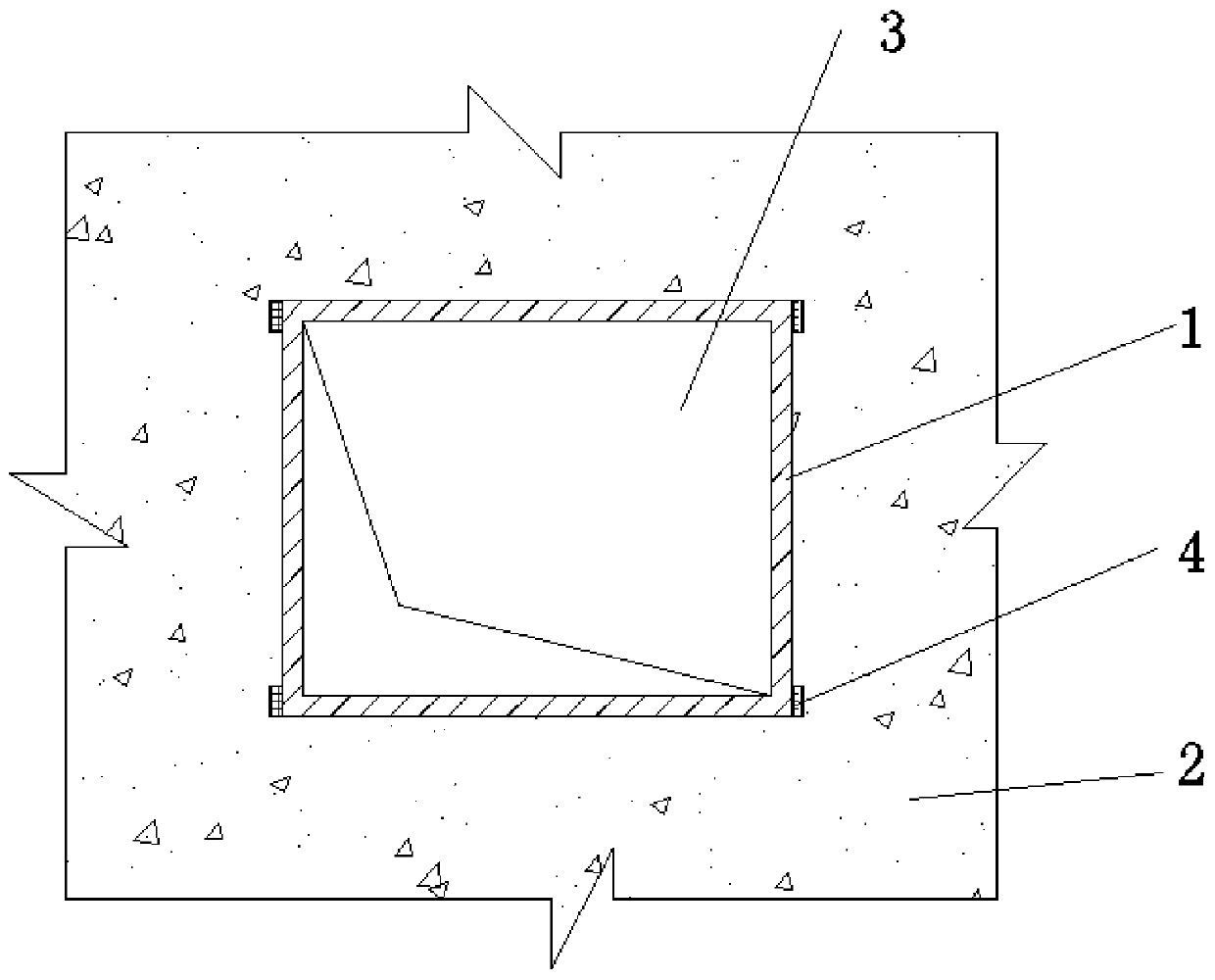

Slab column-shear wall structure building based on precast reinforced concrete hollow formworks and construction method thereof

ActiveCN103015704ASimple processingLess investment in production equipmentForms/shuttering/falseworksBuilding material handlingRebarHollow core

The invention provides a slab column-shear wall structure building based on precast reinforced concrete hollow formworks and a construction method thereof. The building comprises a cast-in-place space formwork system which is formed through the interconnection of hollow column formworks, wall formworks and floor / roof formworks, wherein each hollow column formwork is made of reinforced concrete in a precasting way and provided with at least one longitudinally-penetrating hollow channel; through the interspersion of reinforcements and the filling of concrete in the intercommunicated hollow channels of the hollow column formworks and the wall formworks and the laying of the reinforcements and the pouring of the concrete onto each floor / roof formwork, a single storey slab column-shear wall structure building which can be a one-storey building unit or a single-storey building is formed; and next, based on the one-storey building unit, a multistorey building unit can be formed in a lap joint way. The slab column-shear wall structure building based on the precast reinforced concrete hollow formworks and the construction method thereof provided by the invention have the advantages of simplicity in workpiece processing, low production equipment investment, fewer installation procedures, high construction speed, lower labor cost and the like.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

Short-leg shear wall structure assembled on basis of large hidden-beam prefabricated concrete wallboards with grooves on two sides and construction method of short-leg shear wall structure

ActiveCN103883024AConstruction quality is easy to guaranteeReduce dismantling processWallsInsulation layerBuilding unit

The invention provides a short-leg shear wall structure assembled on the basis of large hidden-beam prefabricated concrete wallboards with grooves on two sides and a construction method of the short-leg shear wall structure. The short-leg shear wall structure comprises a cast-in-situ spatial formwork system composed of the large hidden-beam prefabricated concrete wallboards, wall pillar formworks and a floor / house roof formwork, which are mutually connected. The large hidden-beam prefabricated concrete wallboards are prefabricated by concrete and provided with holes and two side grooves and can be provided with heat insulation layers and decorating layers according to needs. Cavities of the side grooves are formed between large wallboards and the wall pillar formworks, rebars are disposed on the floor / house roof formwork and concrete are cast on the same to form a short-leg shear wall structure building with a building unit. Multiple building units can be formed by overlapping on the basis of the building unit. The short-leg shear wall structure building and the construction method thereof have the advantages of simplicity in processing, low investment in production equipment, fewer construction procedures, higher construction speed, labor reduction and the like.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +3

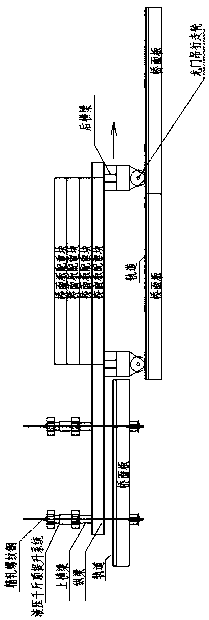

Construction process of wet joint connecting structure of prefabricated bridge deck slab

ActiveCN111305081AReduce installationReduce dismantling processBridge structural detailsBridge erection/assemblyEpoxyArchitectural engineering

The invention discloses a construction process of a wet joint connecting structure of a prefabricated bridge deck slab. The construction process is characterized in that firstly, a welding nail, a steel plate and a steel bar lifting ring are combined into an integral structure, the welding nail is connected with the bridge deck slab, a welding nail side of the steel plate is attached to a bottom surface of a concrete plate, epoxy mortar is laid on the other side of the steel plate, the steel plate is attached to a bottom surface of the other bridge deck slab, and finally, the overall structureis connected with the embedded steel bars exposed out of ends of bridge decks on two sides through steel bars in a welding or binding mode, the two adjacent bridge deck slabs and the prefabricated bridge deck wet joint connecting structure are combined into a whole, and the bottom of a wet joint between the two adjacent bridge deck slabs is completely sealed by the steel plate. Compared with theprior art, the construction process is advantaged in that procedures of mounting and dismounting the formwork during wet joint construction of a traditional prefabricated bridge deck slab on site arereduced, the construction speed is increased, the connection quality of the wet joint is guaranteed, the bearing capacity of the structure at the wet joint is improved, and the safety reserve of the structure is increased.

Owner:JIANGXI PROVINCIAL EXPRESSWAY INVESTMENT GRP CO LTD

Urban ecological river channel underwater environment-friendly cutter suction type dredging device and construction method thereof

InactiveCN111894069AImprove collection efficiencyEasy to removeMechanical machines/dredgersUnderwaterEnvironmental engineering

The invention discloses a river channel dredging device and a construction method using the device. The device comprises a ship body and a water suction pipe, a connecting piece is fixedly arranged atthe top of one side of the ship body, the top end of the water suction pipe communicates with a connecting pipe, and the connecting pipe and the connecting piece are connected through a limiting mechanism. According to the device, the water suction pipe, an external underwater pipeline, a water pipeline and a land pipeline are matched, cut water grass, duckweed and the like are discharged to theoutside, the water is filtered and then conveyed to the original position, and the collection efficiency of the cut water grass and the duckweed is improved through a fishing net. Through the device,dredging is achieved, the water grass, the duckweed and the like can also be removed, the utilization rate of resources is improved, and practicability is enhanced.

Owner:中建新疆建工集团第五建筑工程有限公司

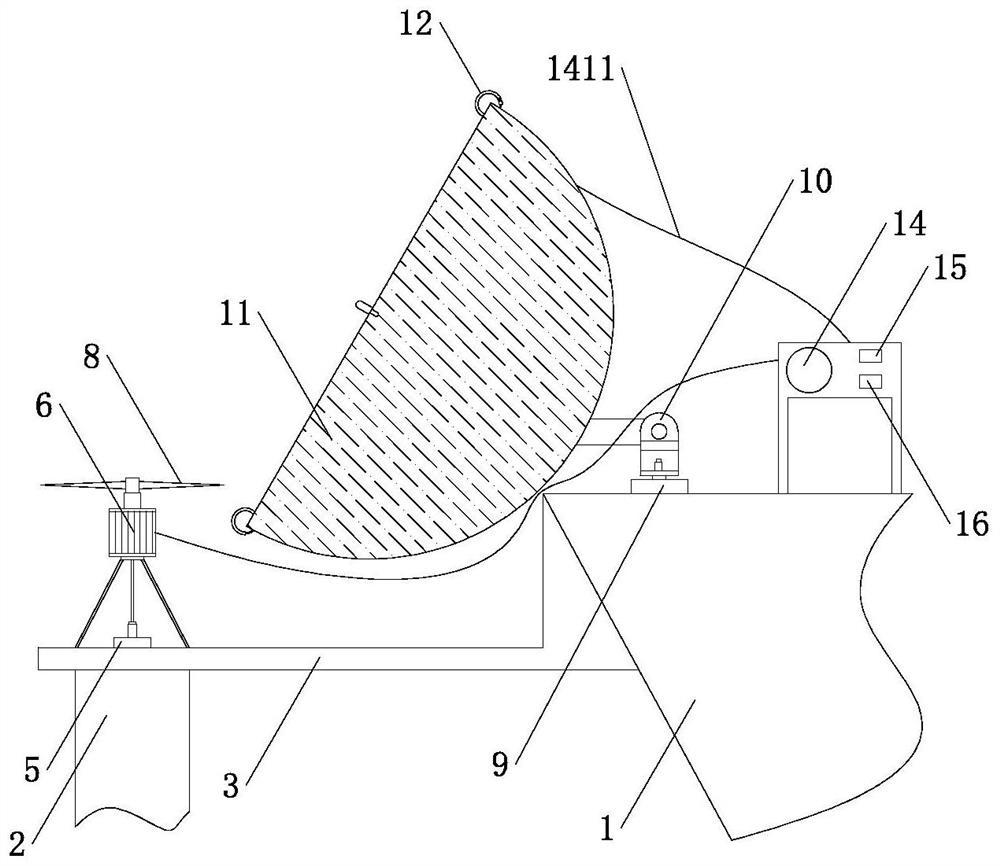

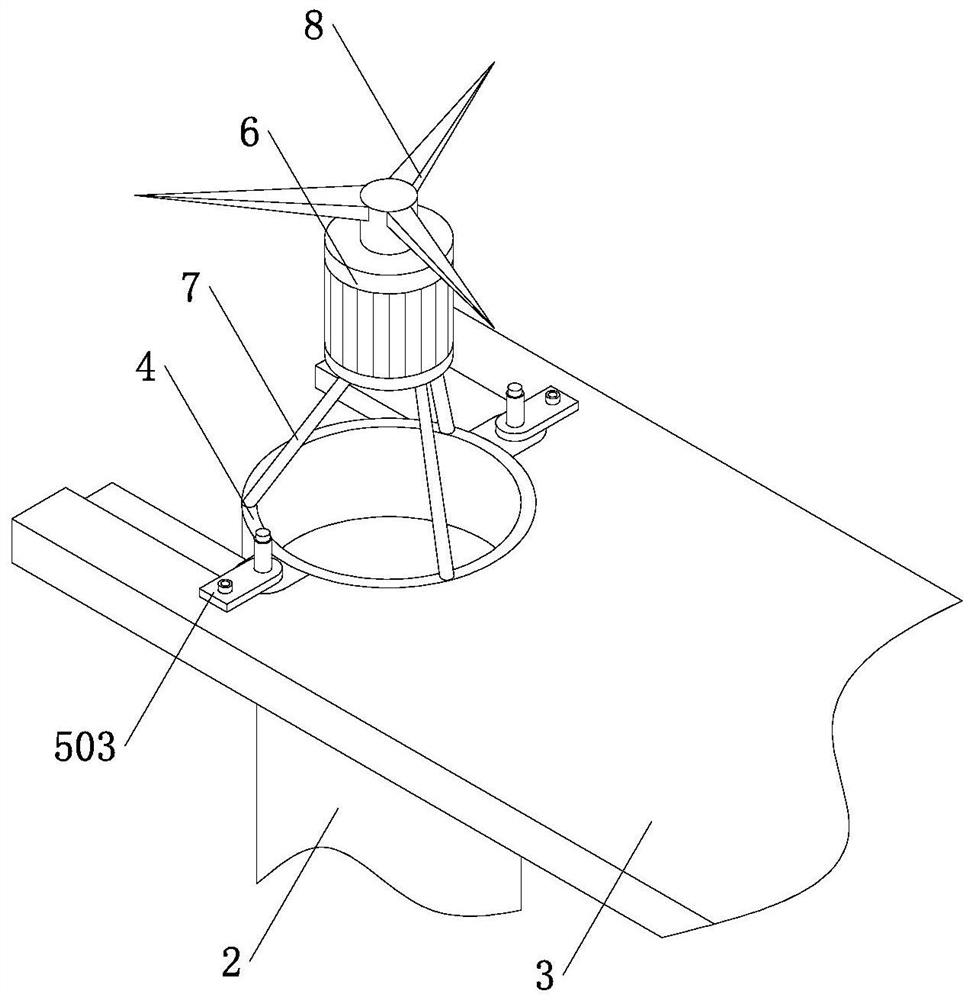

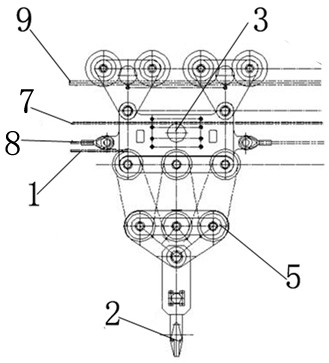

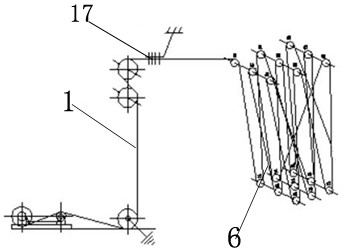

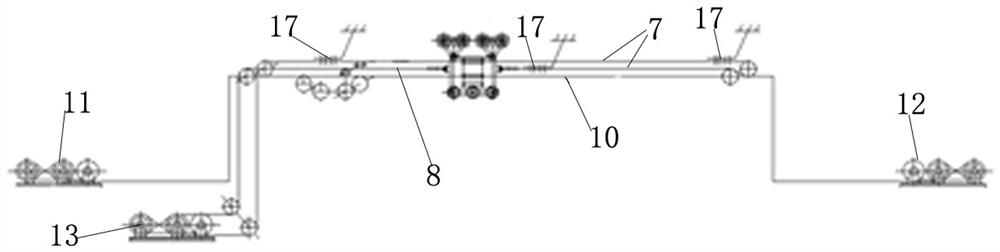

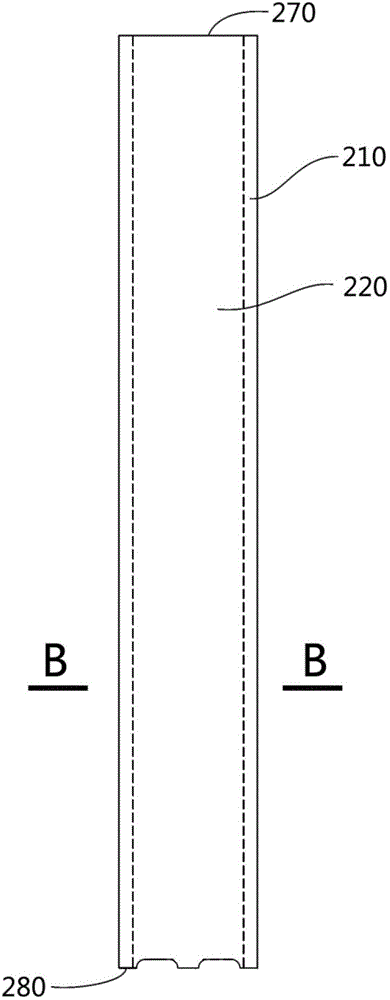

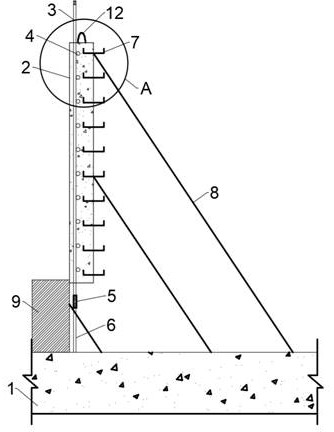

Demolition construction method for large-span cable crane adjacent to railway business line

ActiveCN111762697AAvoid damageReduce difficultyWinding mechanismsCable carsArchitectural engineeringWorking environment

The invention belongs to a demolition construction method of cable cranes, in particular to a demolition construction method for a large-span cable crane adjacent to a railway business line, and solves the technical problem in the background art. The method comprises the following steps: firstly, a hoisting rope 1, a traction rope, a bearing cable 9 and a working rope 10 are demolished stepwise, and then parts above 100 m of a super high-rise tower are disassembled by a shaking derrick mast 14; the 80-100 m part is disassembled by a jib of a truck crane 15; and the part below 80 m is demolished as a whole by a main jib of the truck crane 15. The construction method is special for demolition of large-span cable cranes on the railway business lines with short demolition period and poor working environment, the super-high-rise tower system is divided into three parts to be demolished, the three parts are demolished in different means, demolition of conventional single-layer loose parts isadjusted to be demolition of whole demolition stepwise, so that working efficiency is improved, a large number of high-altitude operations are switched to ground work, safety risks are reduced to thegreatest extent, railway blockade points are reduced, and safety of railway business lines is ensured.

Owner:CHINA RAILWAY SIXTH GROUP +1

Support-free formwork for reserved bolt holes of roughing mill body and construction method

PendingCN111042188AIncrease stiffnessQuality assuranceFoundation engineeringArchitectural engineeringPipe

Owner:MCC TIANGONG GROUP

Frame-shear wall structure building of dismantling-free prefabricated reinforced concrete formwork and construction method thereof

Owner:ZHONGQINGDA TECH HLDG CO LTD

A construction method for the demolition of a long-span highway suspension bridge

ActiveCN106978784BEnsure safetyShorten the construction periodBuilding repairsBridge strengtheningReinforced concreteDiamond wire saw

The invention discloses a demolition construction method for long-span highway suspension bridges. The construction method specifically comprises the following steps that 1, steel structure counter-force frames are installed at the top of a main tower, cable saddling and pushing are conducted, and the deflection of the main tower is corrected; 2, bridge surface plates and bridge surface paving layers are cut, and blocking and whole hoisting are conducted; 3, demolition of steel truss beams is conducted, and after the steel truss beams are cut off from the midspan, the beams are lowered in a segmental mode as a whole; 4, demolition of main cables are conducted, remaining main cable hangings and catwalks are utilized as an operation platform, the main cables are cut off in situ, and the demolition of the main cables is conducted; 5, demolition of the main tower is conducted, diamond wire saws are utilized to cut reinforced concrete with static force, upper cross beams are lowered as a whole through the adoption of a suspension system, after the main tower is cut and divided into blocks, vehicle cranes are used for hoisting, and cutting and hoisting are conducted after holes are drilled in lower cross beams. The demolition construction method for the long-span highway suspension bridges is applicable to the complex demolition of suspension bridges in geological environment, and the construction method is not only relatively little in resource waste and relatively low in economic cost, but also conductive to environmental protection.

Owner:GUIZHOU BRIDGE CONSTR GROUP

Removal-free prefabricated reinforced concrete template with cross holes inside and manufacturing method thereof

ActiveCN101985856BConstruction quality is easy to guaranteeFlatness is easy to guaranteeForms/shuttering/falseworksForming/stuttering elementsRebarCoupling beam

The invention relates to a removal-free prefabricated reinforced concrete template with cross holes inside. The template is a wall template, a floor template, a roof template, a T-shaped template, an L-shaped template, a cross template, a coupling beam template, a beam template or an upright template. A plurality of longitudinal through holes and a plurality of horizontal through holes parallel to the surface are arranged in the template. The plurality of longitudinal through holes and the plurality of horizontal through holes form cross channels. When the removal-free template is prefabricated in factories, 70-80% of stress reinforced concrete is prefabricated in the template, which facilitates industrialization production, transportation and hoisting, and realizes that each layer of house wall template and the floor template are supported once, the concrete is repoured, after the current layer of concrete is poured, the next layer construction is immediately carried out, the construction period of the house is shortened, meanwhile labour is saved, the construction speed is quickened and the house cost is reduced.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

Frame-shear wall structure and its construction method based on the assembly of strip prefabricated concrete wall panels with grooves on three sides

ActiveCN103882976BConstruction quality is easy to guaranteeReduce dismantling processWallsFloorsInsulation layerReinforced concrete

The invention provides a frame-shear wall structure based on three-side-grooved strip precast concrete wallboard assembly and a construction method thereof. The structure comprises a cast-in-place spatial form system formed by mutually connecting strip precast concrete wallboards, wall column forms, shear walls and floor / roof forms; the strip precast concrete wallboards are precast with reinforced concrete, each wallboard is provided with end grooves and two side grooves, and the each wallboard can be provided with an insulation layer and a decorating layer as required; rebars are placed and concrete are poured between the wallboards or between the wallboards and wall columns, between the wallboards and the shear walls, including a cavity with side grooves, into space communicated through the end grooves, and onto the floor / roof forms, so that a single floor frame-shear wall structure building of a building unit is formed; a multi-floor building unit can be constructed by lap joint based on the single-floor building unit. The frame-shear wall structure and the construction method thereof have the advantages that manufacturing is simple, investment on production equipment is low, construction steps are fewer, construction speed is higher and less labor is required.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +3

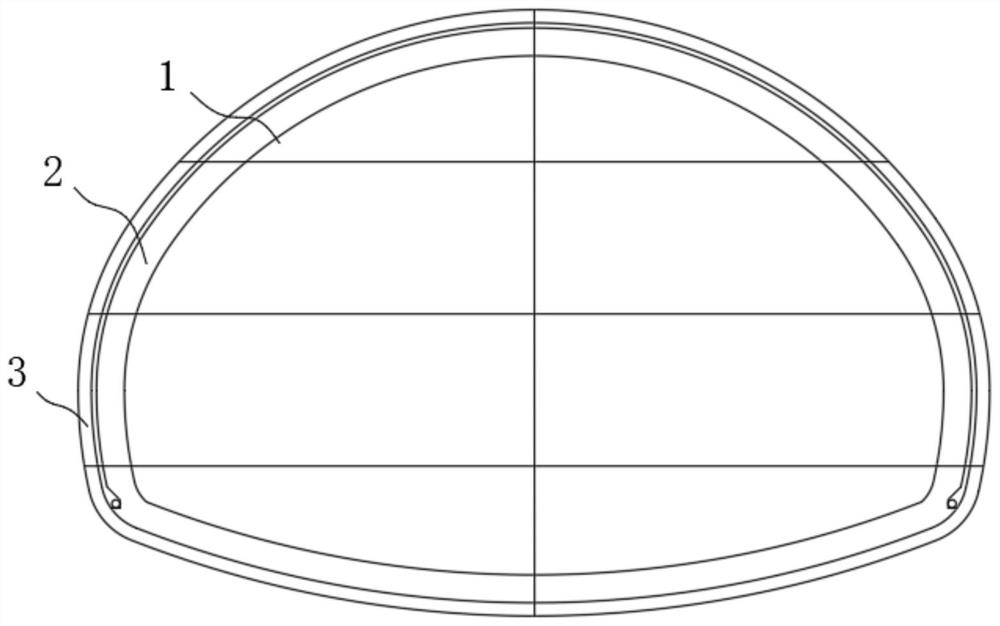

Construction method of steel reinforced concrete chimney

ActiveCN101225718BIncrease temperatureDoes not affect strengthForms/shuttering/falseworksTowersSocial benefitsReinforced concrete

The invention discloses a construction method for reinforced concrete chimney, which comprises a foundation construction and a chimney cylinder construction; wherein the chimney cylinder construction comprises the steps: the steel bars are arranged on the cylinder wall along the direction of the chimney cylinder body; the firebrick lining is built along the inner circumference of the chimney; a displacement formwork is arranged at the outer circumference of the chimney cylinder body; the concrete is poured between the firebrick lining and the displacement formwork; when the intensity of the concrete is over 1.2N / mm<2>, the displacement formwork can be removed; the removable displacement formwork is displaced upwards; the steps are repeated until the chimney reaches the design height; the construction method for reinforced concrete chimney has the advantages that: the construction cost is low; the construction measure cost can be reduced greatly; an installation and removal procedure of the inner chimney formwork is reduced; the construction difficulty is reduced; the construction speed is improved and the construction cost is lowered; the construction period for displacement formwork construction is shortened by 30 percent than that of the slip-form construction in the same project, and the construction cost is reduced by 60 percent; thereby the construction method for reinforced concrete chimney has significant integrated technical economic and social benefits.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Large-span small-clear-distance shallow-buried tunnel excavation construction method

PendingCN114233297AImprove construction efficiencyAccelerate the progress of excavationUnderground chambersTunnel liningTunnel constructionLong span

The invention belongs to the field of tunnel construction, and particularly discloses a large-span small-clear-distance shallow-buried tunnel excavation construction method which comprises the following steps: determining basic mechanical parameters of surrounding rocks: testing the basic mechanical parameters of the surrounding rocks of a current construction section by carrying out an indoor test on a rock sample taken on site; after testing, according to the determined basic mechanical parameters of the surrounding rock, carrying out surrounding rock partition evolution analysis and excavation method judgment on the currently constructed section; tunnel arch advanced grouting reinforcement is carried out on the currently constructed large-span small-clear-distance segment; excavating an upper step and primarily supporting; excavating a middle step and carrying out primary support; excavating a lower step and primarily supporting; an inverted arch is excavated, and an inverted arch steel frame is installed and backfilled; and laying a waterproof plate, and completing construction after quality inspection. According to the method, an IV-level surrounding rock three-step four-step excavation mode and a V-level surrounding rock lining mode are adopted, namely, rapid excavation, strong supporting and frequent measurement are achieved, and tunnel construction safety is ensured.

Owner:SOUTHERN CONSTR CO LTD OF CHINA CONSTR EIGHTH ENG DIV

Slab column-shear wall structure building and construction method based on prefabricated reinforced concrete hollow formwork

ActiveCN103015704BConstruction quality is easy to guaranteeReduce weightForms/shuttering/falseworksBuilding material handlingEngineeringInterconnection

The invention provides a slab column-shear wall structure building based on precast reinforced concrete hollow formworks and a construction method thereof. The building comprises a cast-in-place space formwork system which is formed through the interconnection of hollow column formworks, wall formworks and floor / roof formworks, wherein each hollow column formwork is made of reinforced concrete in a precasting way and provided with at least one longitudinally-penetrating hollow channel; through the interspersion of reinforcements and the filling of concrete in the intercommunicated hollow channels of the hollow column formworks and the wall formworks and the laying of the reinforcements and the pouring of the concrete onto each floor / roof formwork, a single storey slab column-shear wall structure building which can be a one-storey building unit or a single-storey building is formed; and next, based on the one-storey building unit, a multistorey building unit can be formed in a lap joint way. The slab column-shear wall structure building based on the precast reinforced concrete hollow formworks and the construction method thereof provided by the invention have the advantages of simplicity in workpiece processing, low production equipment investment, fewer installation procedures, high construction speed, lower labor cost and the like.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

A large-span cable crane demolition construction method adjacent to the railway business line

ActiveCN111762697BAvoid damageReduce difficultyWinding mechanismsCable carsArchitectural engineeringLong span

The present invention relates to a construction method for dismantling a cable crane, specifically a construction method for dismantling a large-span cable crane adjacent to a railway business line, which solves the technical problems in the background technology. The working rope 10 is dismantled step by step, and then the part above 100m of the super high-rise tower is dismantled by the shaking head 14; The whole floor is demolished. The present invention is specially aimed at dismantling large-span cable cranes on railway business lines with tight construction schedule and poor working environment. The super high-rise tower system is divided into three parts for dismantling. The demolition of parts is gradually adjusted to the demolition of the whole floor, which improves work efficiency and transfers a large number of high-altitude operations to the ground, which minimizes safety risks, reduces railway blockade points, and ensures the safety of railway operation lines.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

A construction structure and construction method for building an empty box structure of a ship lock

ActiveCN113356172BReduce the cost of setting upAvoid instabilityDry-docksClimate change adaptationStress concentrationArchitectural engineering

The invention relates to a construction structure and a construction method for building an empty box structure of a ship lock. The construction structure and the method not only greatly reduce the cost of erecting the bracket formwork in the empty box structure, but also improve the construction efficiency, and the prefabricated concrete formwork is used as the main structure for pouring Part of it, eliminating most of the demolition workload and material waste, saving construction costs. In addition, the side wall formwork and the pre-embedded steel bars adopt a dislocation connection structure, so that the stress of the main reinforcement and the pre-embedded steel bars in the side wall formwork is dispersed, and the stress concentration at the same height is avoided, causing the main structure of the concrete to be unstable. This structure can replace the role of the traditional formwork, and also It can be combined with the pouring main body to form a permanent structure, and the formwork is used as a part of the permanent structure, which greatly speeds up the construction progress and saves construction costs.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

Frame structure and its construction method based on the assembly of strip-shaped prefabricated concrete wall panels with grooves on three sides

ActiveCN103882977BConstruction quality is easy to guaranteeReduce dismantling processWallsBuilding material handlingReinforced concreteInsulation layer

The invention provides a frame structure based on three-side-grooved strip precast concrete wallboard assembly and a construction method thereof. The frame structure comprises a cast-in-place spatial form system formed by mutually connecting strip precast concrete wallboards, wall column forms and floor / roof forms; the strip precast concrete wallboards are precast with reinforced concrete, each wallboard is provided with end grooves and two side grooves, and each wallboard can be provided with an insulation layer and a decorating layer as required; rebars are placed and concrete is poured between the wallboards or between the wallboards and wall columns, including a cavity with side groove, into space communicated through the end grooves, and onto the floor / roof forms, so that a single-floor frame structure building of a building unit is formed; a multi-floor building unit can be constructed by lap joint based on the single-floor building unit. The frame structure and the construction method thereof have the advantages that manufacturing is simple, investment on production equipment is low, construction steps are fewer, construction speed is higher and less labor is required.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +3

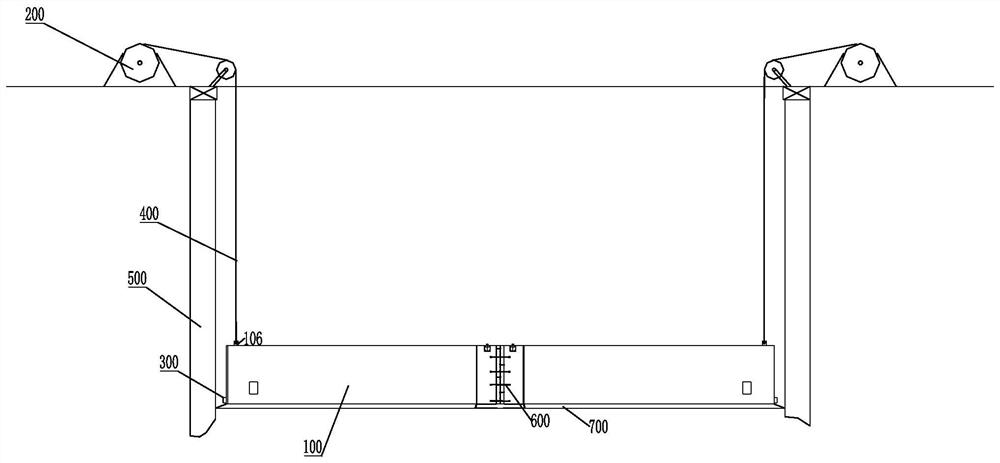

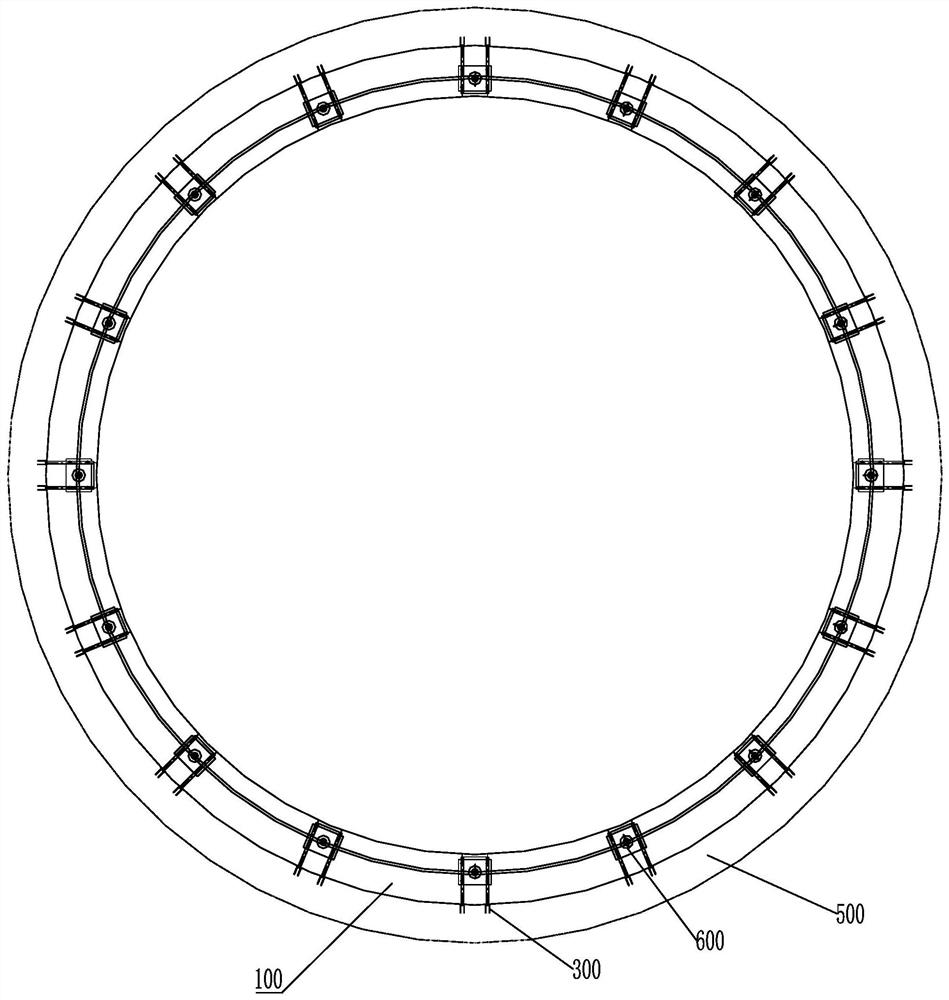

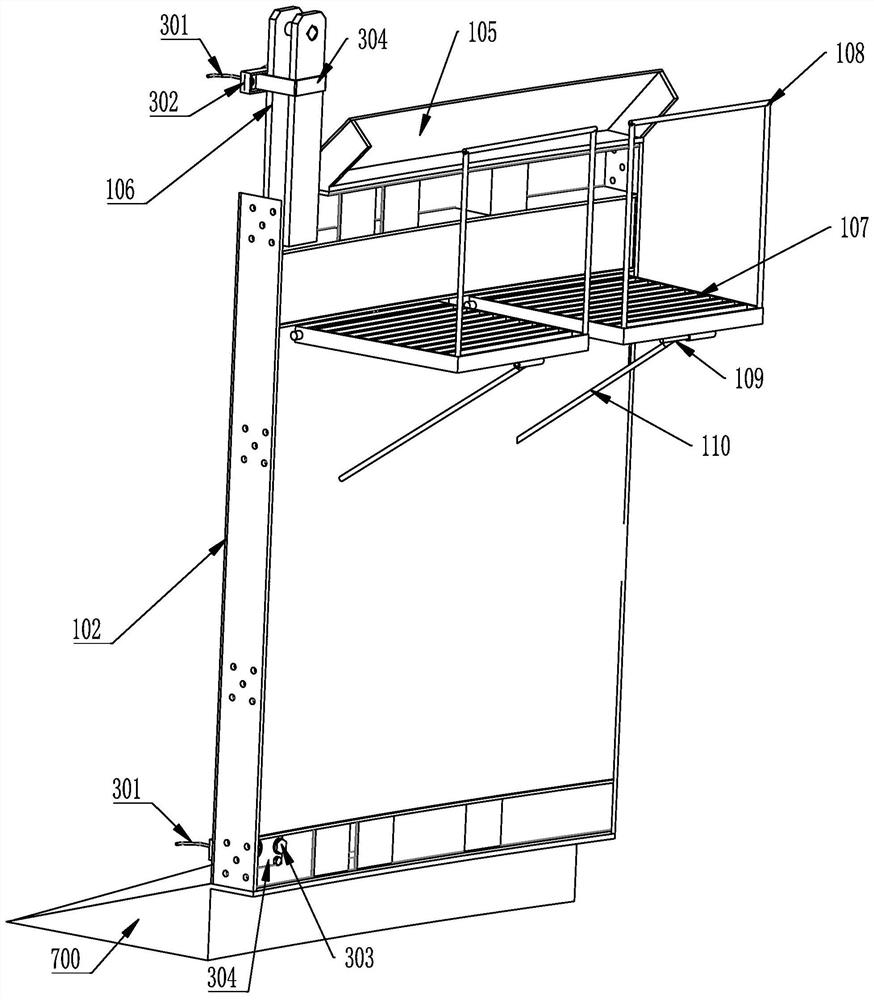

A super-large-diameter overall mobile metal formwork for shafts

ActiveCN111608662BIncrease stiffnessImprove the immunityShaft liningHydraulic cylinderClassical mechanics

Owner:BEIJING CHINA COAL MINE ENG CO LTD

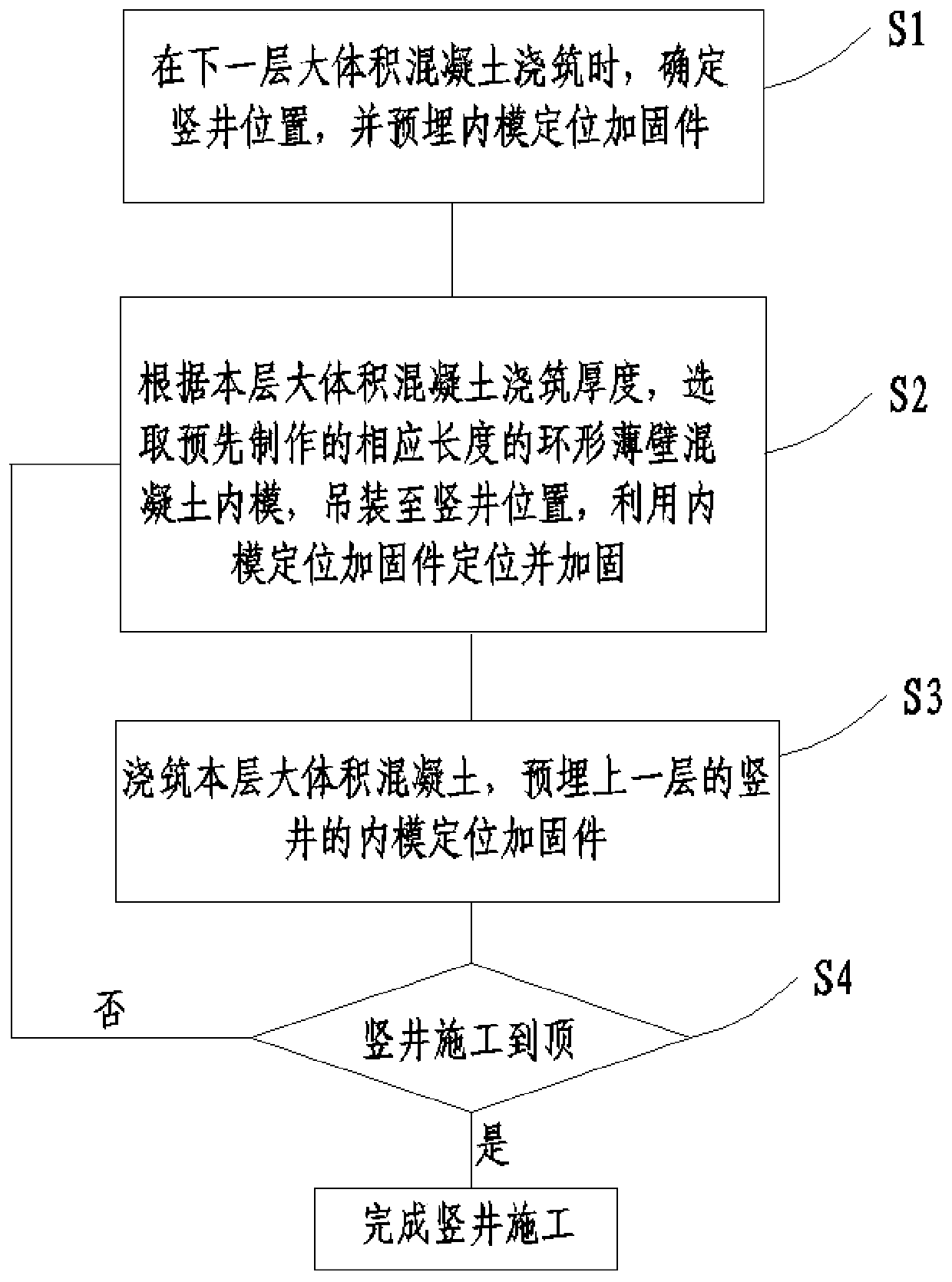

A construction method for small-section shafts without removing formwork

ActiveCN109057245BReduce dismantling processReduce security risksVertical ductsArchitectural engineeringMold removal

Owner:SINOHYDRO BUREAU 8 CO LTD

A construction organization method for complete sets of mechanical equipment for tunnels

ActiveCN108915696BImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningRobot handArchitectural engineering

The invention discloses a complete set of mechanical equipment for tunnels, specifically referring to excavation trolley (or excavation platform), waterproof and drainage and steel bar binding trolley, lining trolley, spraying maintenance trolley, ditch cable trough trolley , Inverted arch self-propelled hydraulic trestle, wet spray manipulator, referred to as five vehicles, one trestle, and one wet spray machine; the construction organization method adopted with the complete set of mechanical equipment includes the following construction organization methods: S1: cave body excavation; S2: Primary support; S3: Inverted arch lining; S4: Arch wall lining; S5: Ditch cable trough; the complete set of mechanical equipment. The construction organization method of the present invention is reasonable, effectively improves the tunnel management effect, improves the construction operation environment, ensures the construction safety and quality, and improves the construction progress; it is worthy of vigorous promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

A Construction Technology of Wet Joint Connection Structure of Prefabricated Bridge Deck

ActiveCN111305081BReduce installationReduce dismantling processBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a construction process of a prefabricated bridge deck wet joint connection structure. Firstly, welding studs, steel plates and reinforcement rings are combined into an integral structure, and then the welding studs are connected with a bridge deck, so that the steel plate has the welding stud side and the steel bar suspension ring. The bottom surface of the concrete slab is attached, epoxy mortar is laid on the other side of the steel plate, the steel plate is attached to the bottom surface of the other bridge deck, and finally the overall structure is exposed through the steel bars and the ends of the bridge deck on both sides by welding or binding. The pre-embedded steel bars are connected to combine the two adjacent bridge decks with the wet joint connection structure of the prefabricated bridge decks into a whole, and the bottom of the wet joint between the two adjacent bridge decks is completely sealed by the steel plate. Compared with the prior art, the present invention reduces the process of formwork installation and removal during the wet joint construction of the traditional prefabricated bridge deck on site, speeds up the construction speed, ensures the connection quality of the wet joint, and improves the quality of the wet joint. The bearing capacity of the structure increases the safety reserve of the structure.

Owner:JIANGXI PROVINCIAL EXPRESSWAY INVESTMENT GRP CO LTD

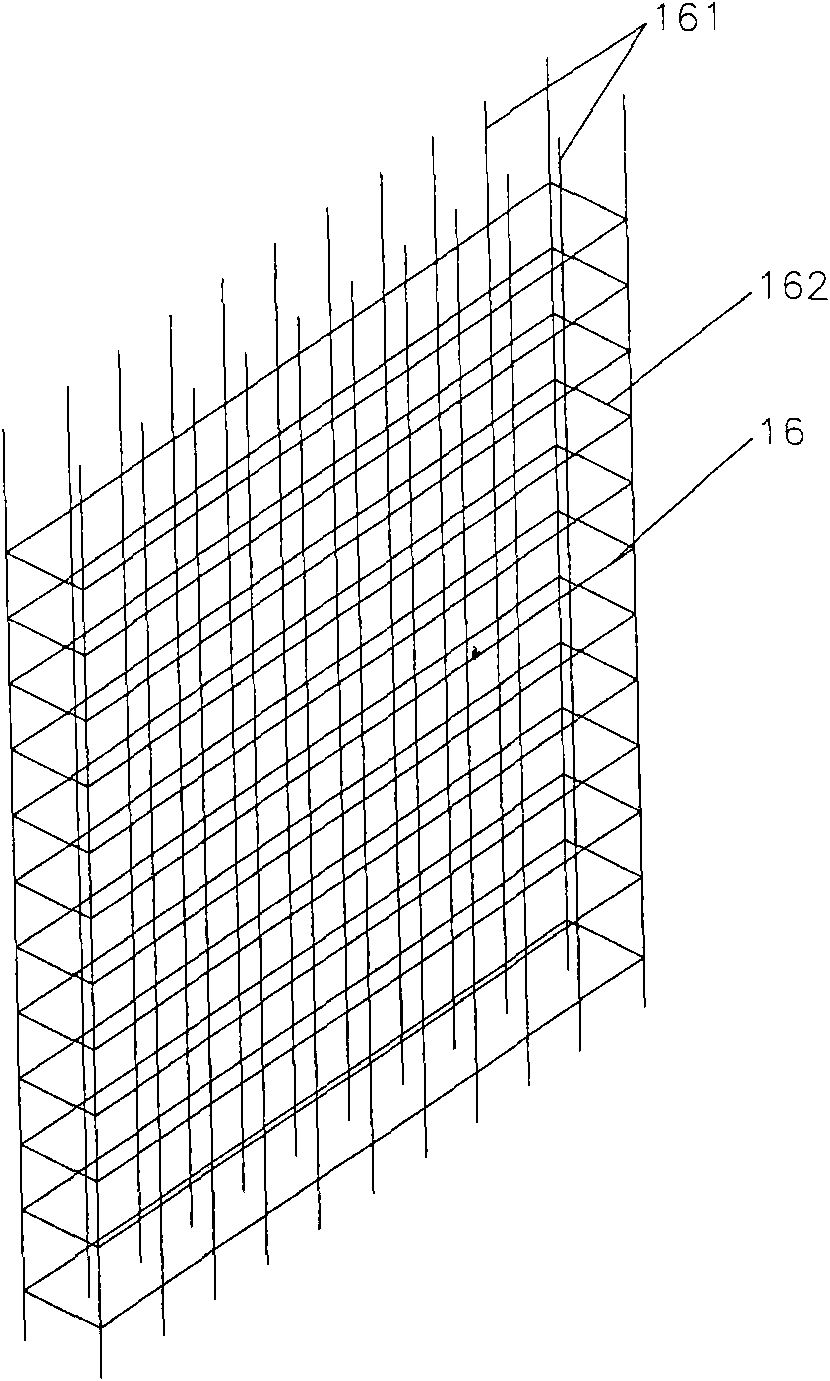

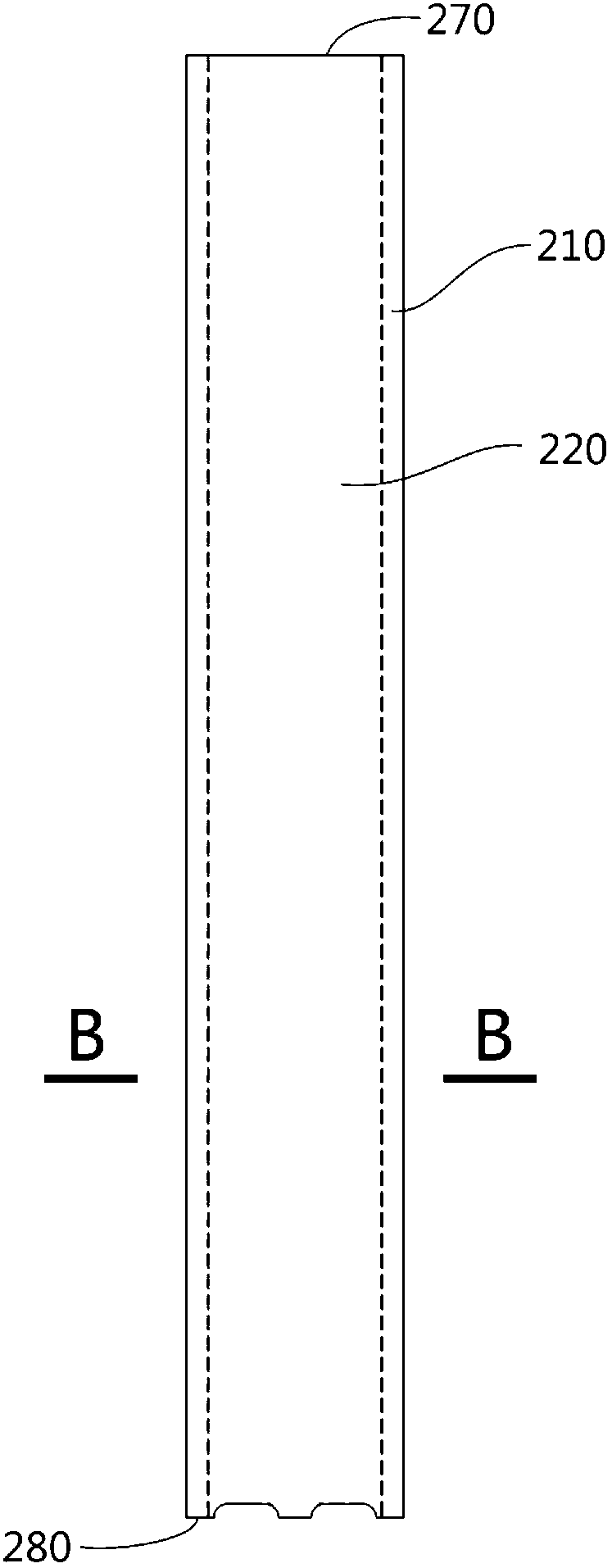

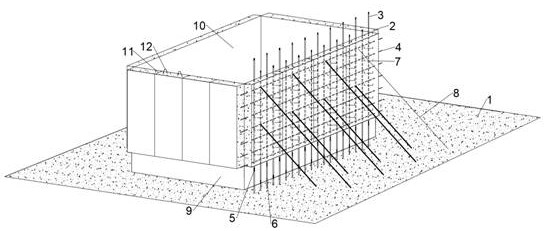

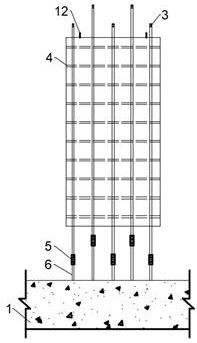

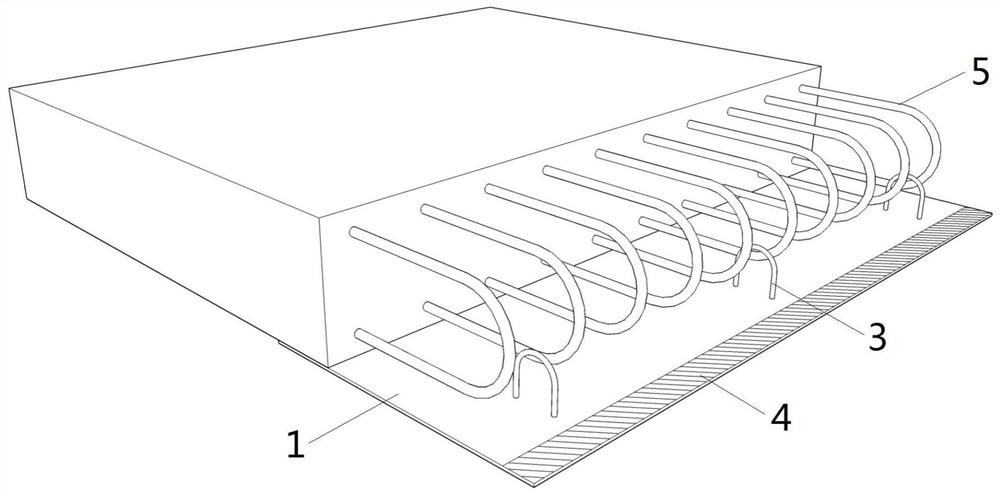

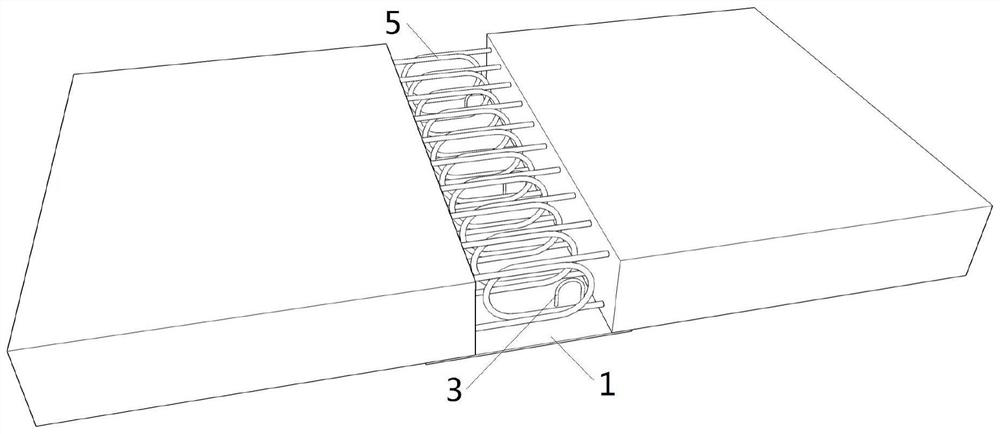

Shear wall structure building based on cross-hole prefabricated reinforced concrete template and construction method thereof

ActiveCN102061803BFlatness is easy to guaranteeReduce weightWallsBuilding reinforcementsEngineeringRebar

The invention relates to a shear wall structure building based on a cross-hole prefabricated reinforced concrete template and a construction method thereof, belonging to the technical field of buildings and construction thereof. In the building, a wall template, an L-shaped column template, a T-shaped column template, a rectangular column template, a cruciform column template, a coupling beam template and a superstructure template which are free of removal are mutually connected to form a polyhedral space template system; all templates are the cross-hole prefabricated reinforced concrete templates; a longitudinal through hole and a lateral through hole, which are parallel to the surface, are arranged in the templates to form hollow hole paths in all directions; reinforcing steel bars and filling concrete are alternately inserted in the hollow hole paths to form a one-layer building unit or a single-layer building with the cast-in-place concrete shear wall structure; and multiple-layerbuilding units are lapped and combined to form the multiple-layer building with the cast-in-place concrete shear wall structure. The shear wall structure building disclosed by the invention has the advantages of simpleness of processing, low production equipment investment, reduced construction working procedures, quickened construction speed, labor saving and the like.

Owner:ZHONGQINGDA TECH HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com