Slab column-shear wall structure building based on precast reinforced concrete hollow formworks and construction method thereof

A technology of hollow columns and shear walls, which is applied in the direction of building construction, construction, and building material processing, etc., can solve the problems of many on-site labor and long construction periods, and achieve the effects of simple processing, reduced labor intensity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical solutions, innovative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated and described below in conjunction with specific illustrations and through the following specific embodiments.

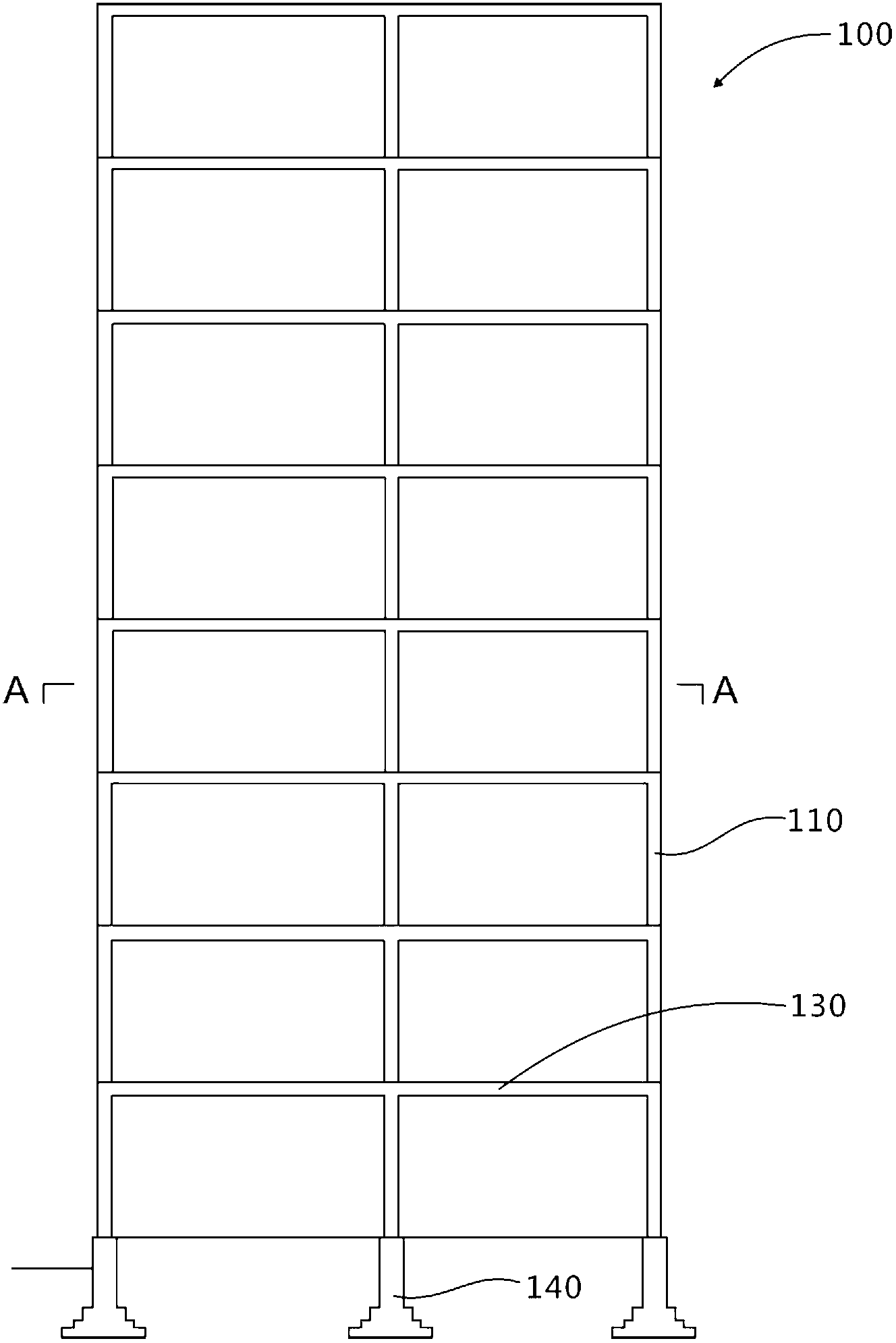

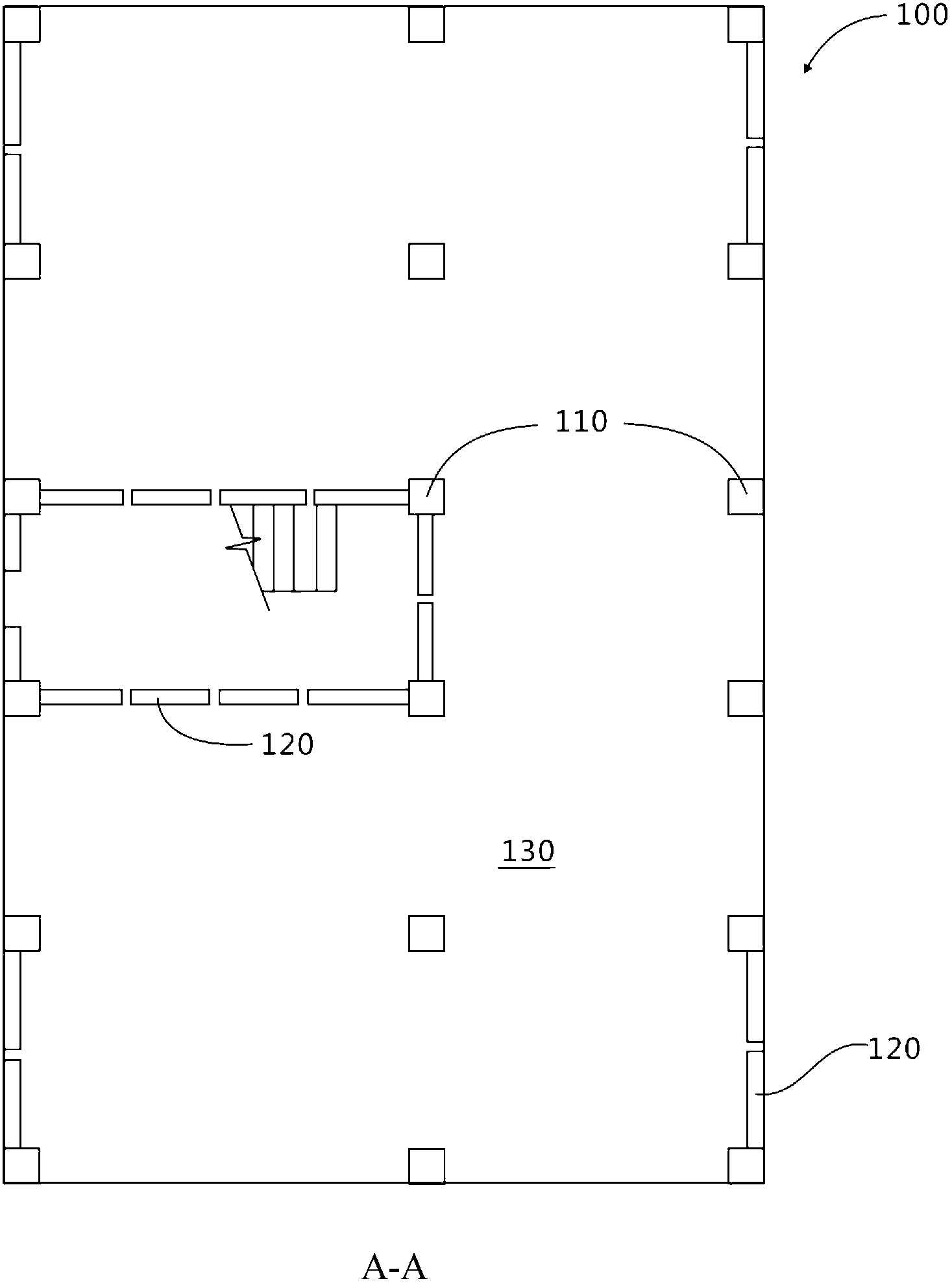

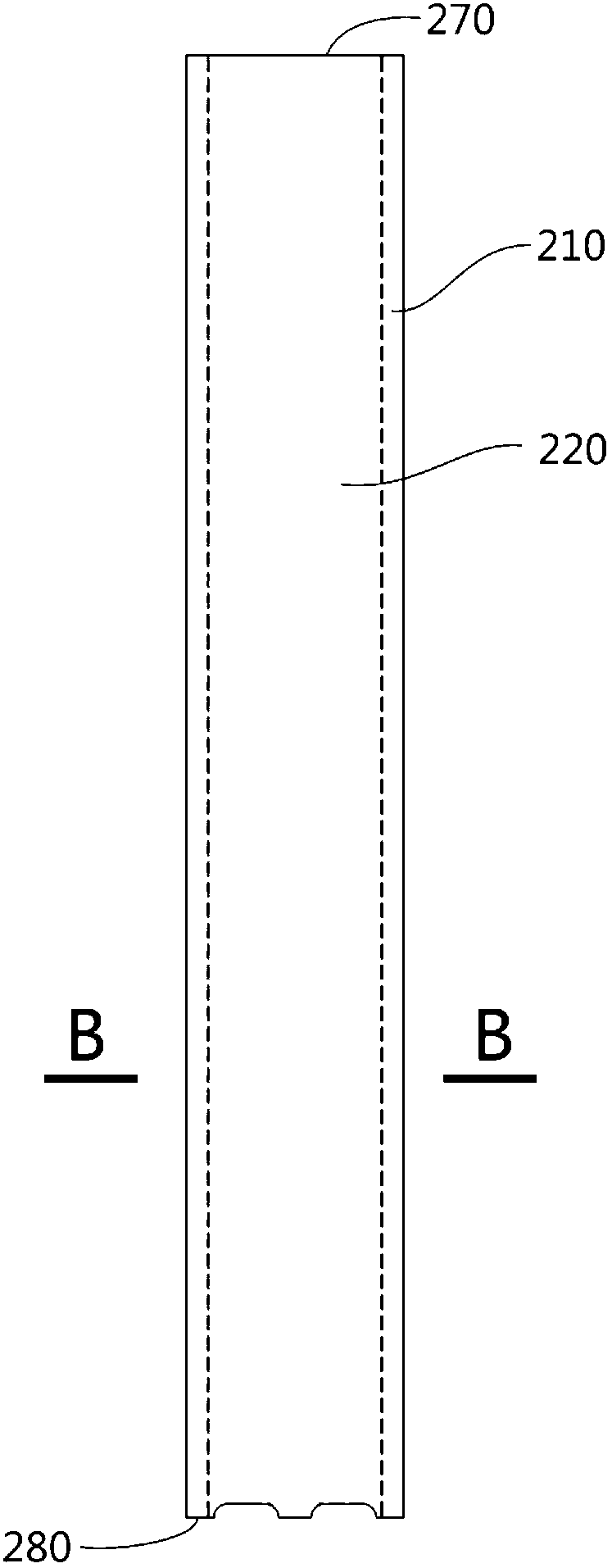

[0038] Figure 1A with 1B Schematically depicts a hollow column formwork 110, a wall formwork 120 and a floor / roof formwork 130 in the foundation / The base surface 140 is connected to form a space formwork system. It shows the spatial arrangement relationship of the hollow column formwork 110, the wall formwork 120 and the building / roof formwork 130.

[0039] In one embodiment, the hollow column formwork 110 is prefabricated with reinforced concrete, and is vertically fixed on the foundation / base surface 140, each along the longitudinal direction of the column and one or more wall formworks perpendicular to the base surface 140 120 is connected and fixed, and the building / roof for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com