Construction structure for high-inclination sloping roof

A technology with sloped roofs and large slopes, applied in the field of machinery, can solve problems such as difficulty in ensuring the quality of concrete pouring, affecting the quality of sloped roofs, and increasing economic costs, and achieve good social benefits, improve work efficiency, and increase economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The application will be described in further detail below in conjunction with the accompanying drawings.

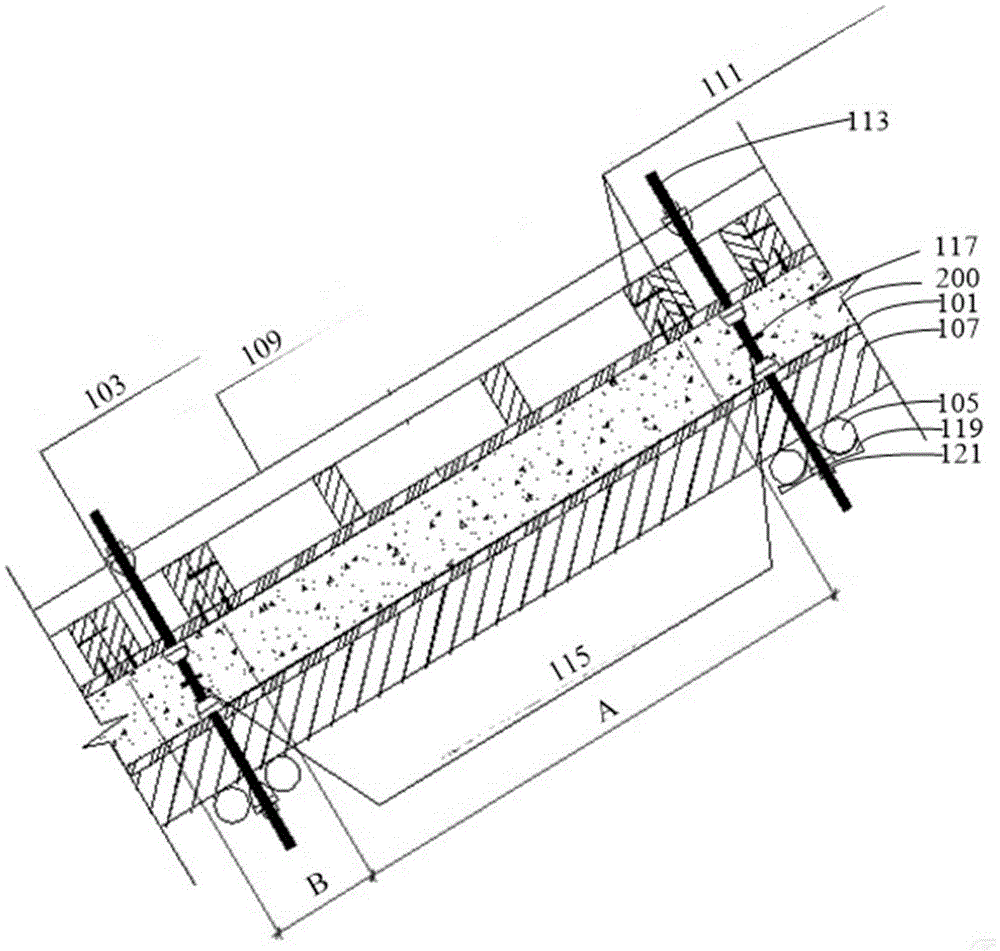

[0031] figure 1 It shows a construction structure for steep slope roofs provided according to one aspect of the present application, wherein the construction structure includes:

[0032] The bottom formwork 101 and the top formwork 103, the bottom formwork 101 is parallel to the top formwork 103 and constitutes a pouring space; wherein, the pouring space is used to pour concrete 200;

[0033] The keel is arranged on the peripheral surface of the bottom formwork 101 and the top formwork 103 to support the bottom formwork 101 and the top formwork 103;

[0034] Limiting water stop bolts are arranged along the stacking direction of the bottom formwork 101 and the top formwork 103 to fix and position the bottom formwork 101, the top formwork 103 and the keel, wherein the limit After the first-level concrete pouring, the water-stop bolts retain the upper part of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com