Support-free formwork for reserved bolt holes of roughing mill body and construction method

A construction method and bolt hole technology are applied in the field of supporting free formwork and construction with reserved bolt holes in the body of the roughing mill, which can solve the problem of time-consuming and labor-intensive installation and dismantling of formwork, time-consuming and labor-consuming installation and dismantling of formwork, and low lateral rigidity of wooden formwork, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

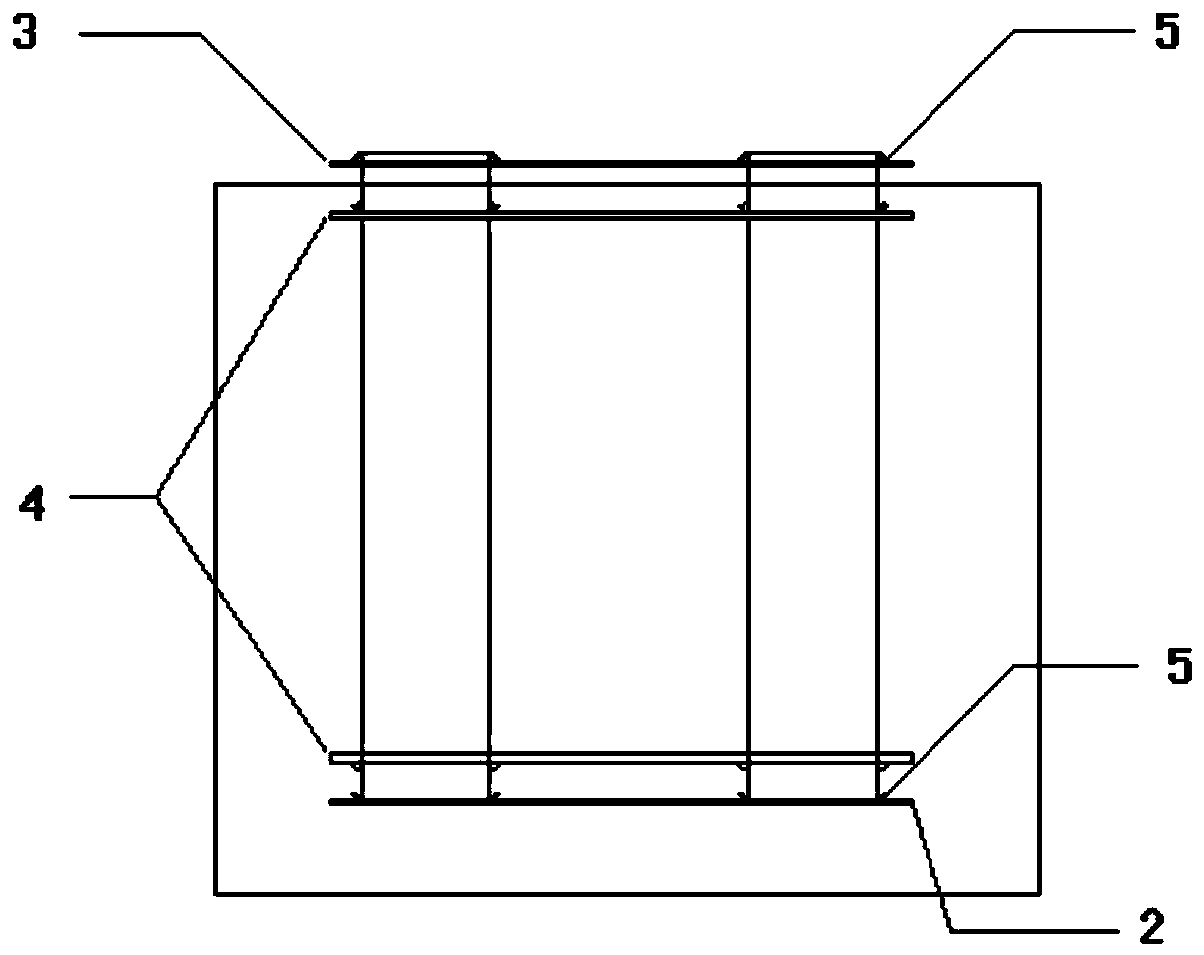

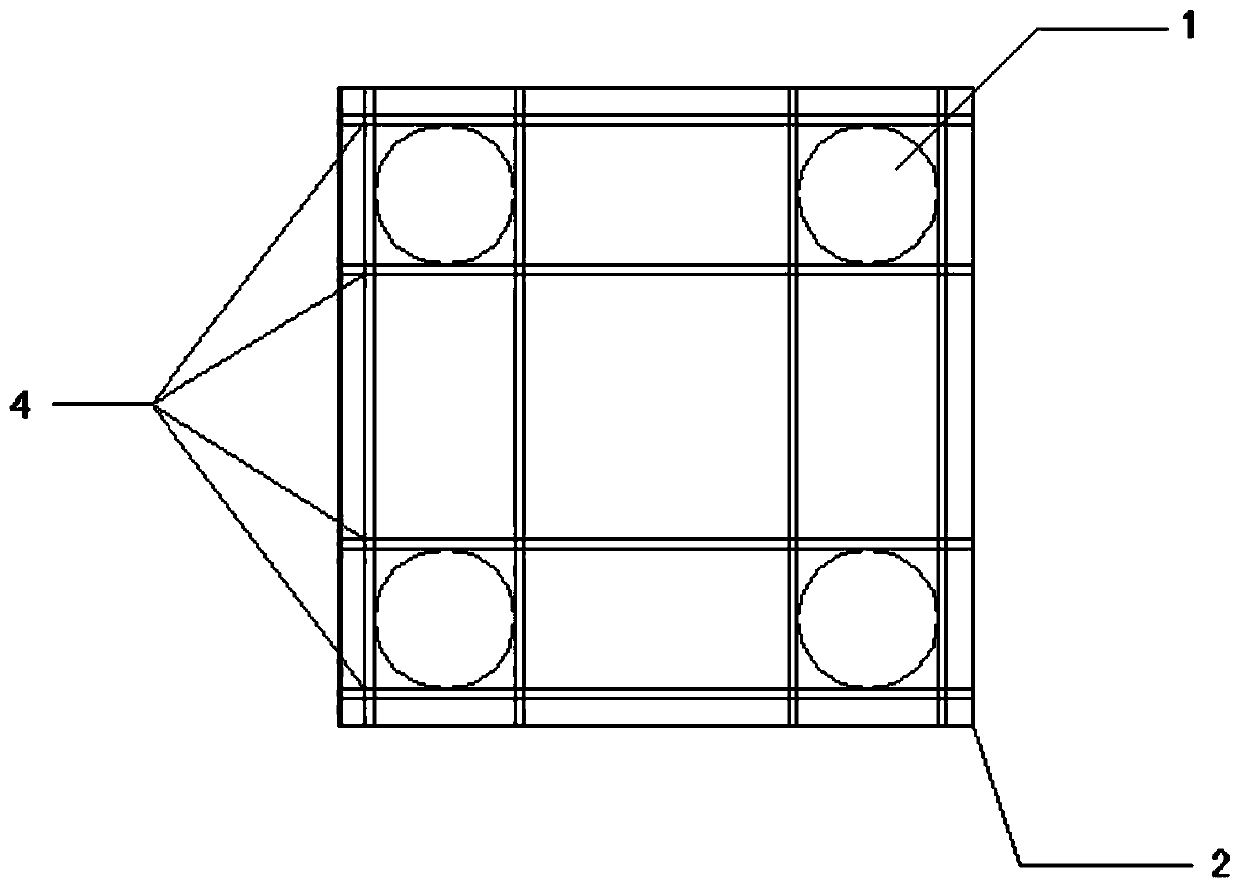

[0030] In order to solve the problems of mold expansion, difficult demolition, and poor perception quality in the construction of reserved bolt holes, a formwork structure for pre-embedded bolt holes for reserved equipment foundations in cast-in-place concrete was studied, including bottom sealing plates, A reserved hole box formed by fixed connection of threaded steel pipe and top sealing plate (reusable). The reserved hole box is fixedly set in the concrete foundation for pouring internal concrete and fixing anchor bolts. This construction method makes full use of the advantages of high rigidity of the threaded pipe, high friction on the corrugated surface, and uniform force, effectively solving the problems of mold expansion, difficulty in dismantling, and poor appearance quality, and greatly improving the construction quality, accuracy and quality of the reserved bolt holes. Efficiency, cost savings, and high promotion value for the entire construction industry.

[0031] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com