Prefabricated reinforced concrete hollow column template and manufacturing method thereof

A reinforced concrete and hollow column technology, applied in the direction of columns, piers, pillars, etc., can solve the problems of complex, material and labor-intensive formwork production and processing, and achieve easy assurance of construction quality, reduced workload, and reduced workload and construction. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical solutions, innovative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated and described below in conjunction with specific illustrations and through the following specific embodiments.

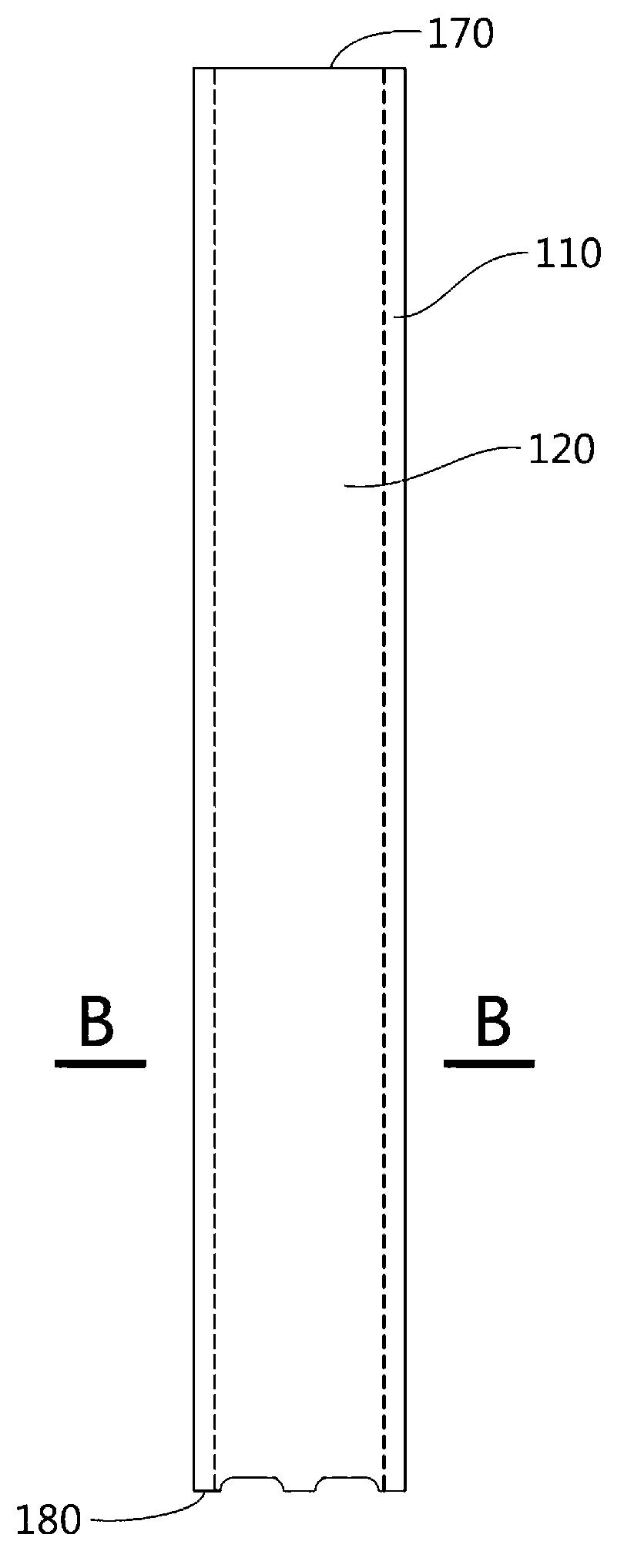

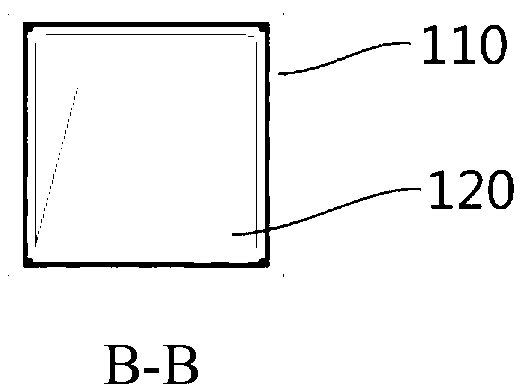

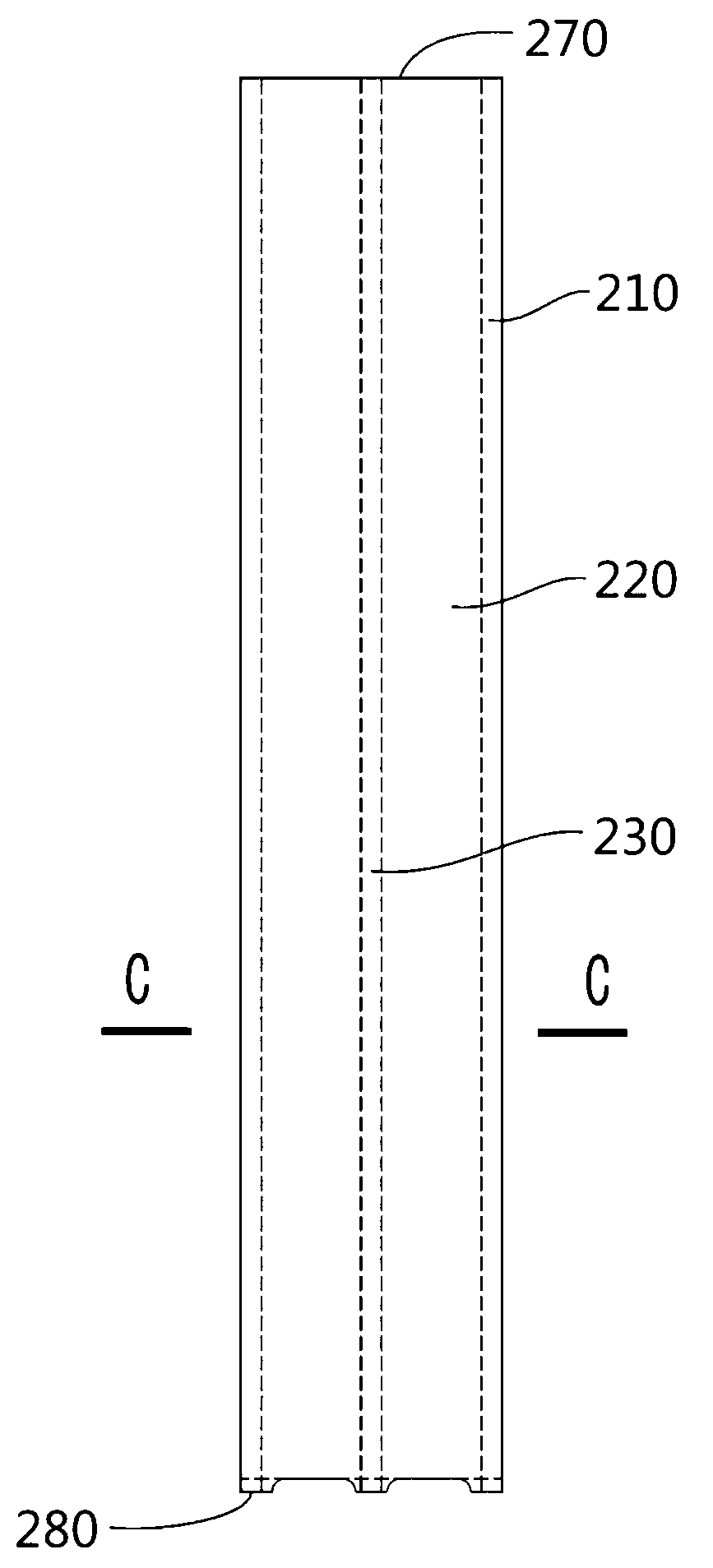

[0037] In a specific embodiment, such as Figure 1A and 1B As shown, the prefabricated reinforced concrete hollow column formwork 110 is internally provided with a hollow channel 120 penetrating along its longitudinal direction, wherein the cross-sectional shape of the outer wall surface of the hollow column formwork 110 is square, and the cross-sectional shape of the inner wall surface of the hollow channel 120 is The shape is square. The hollow channel 120 is located at the center of the hollow column template 110 , and the inner wall surface formed by the hollow channel 120 is parallel to the outer wall surface of the hollow column template 110 . In addition, the dimensions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com