A super-large-diameter overall mobile metal formwork for shafts

A super-large-diameter, overall-moving technology, applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of high labor intensity, long construction period, and large engineering volume, and achieve the effect of low labor intensity, short construction period and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

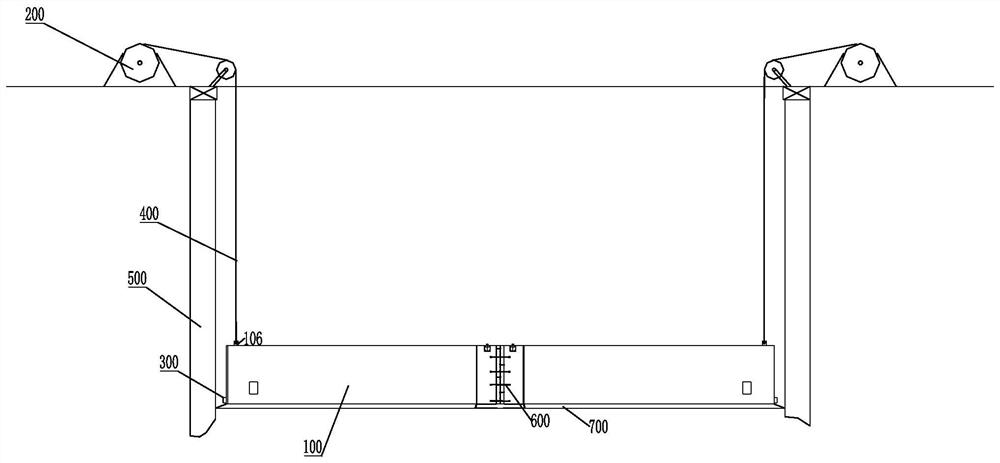

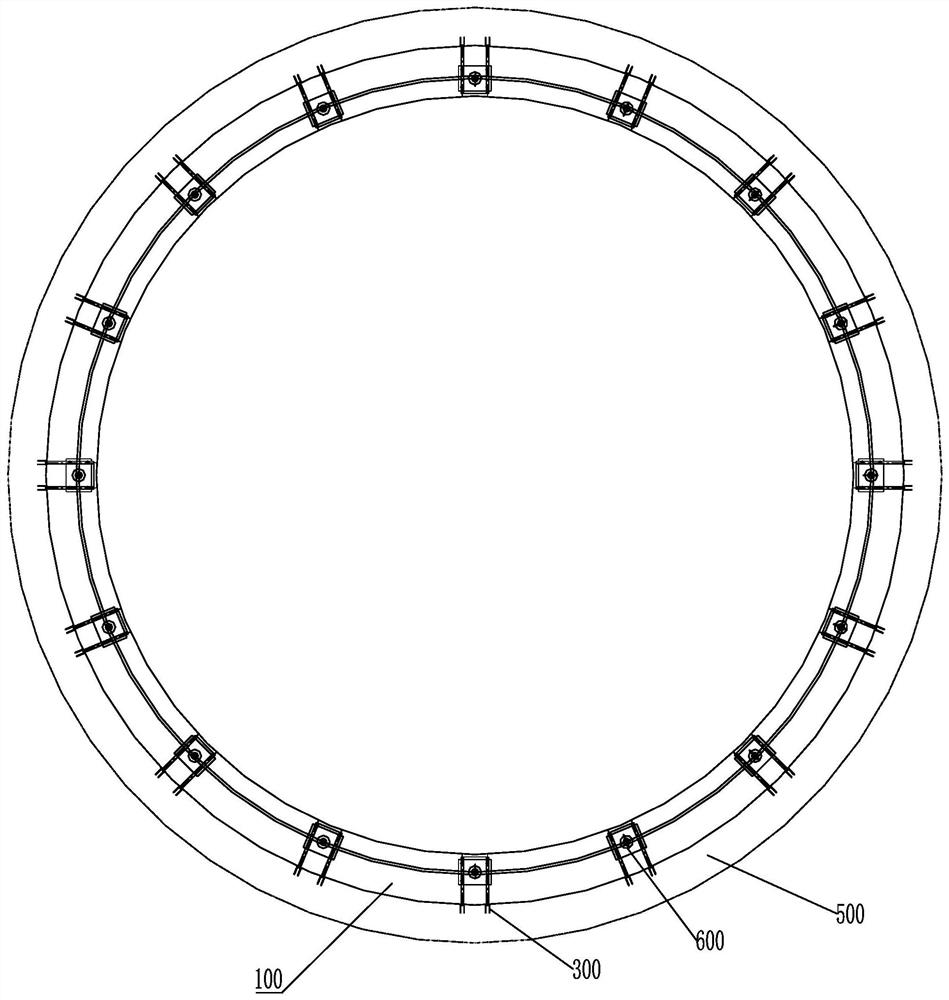

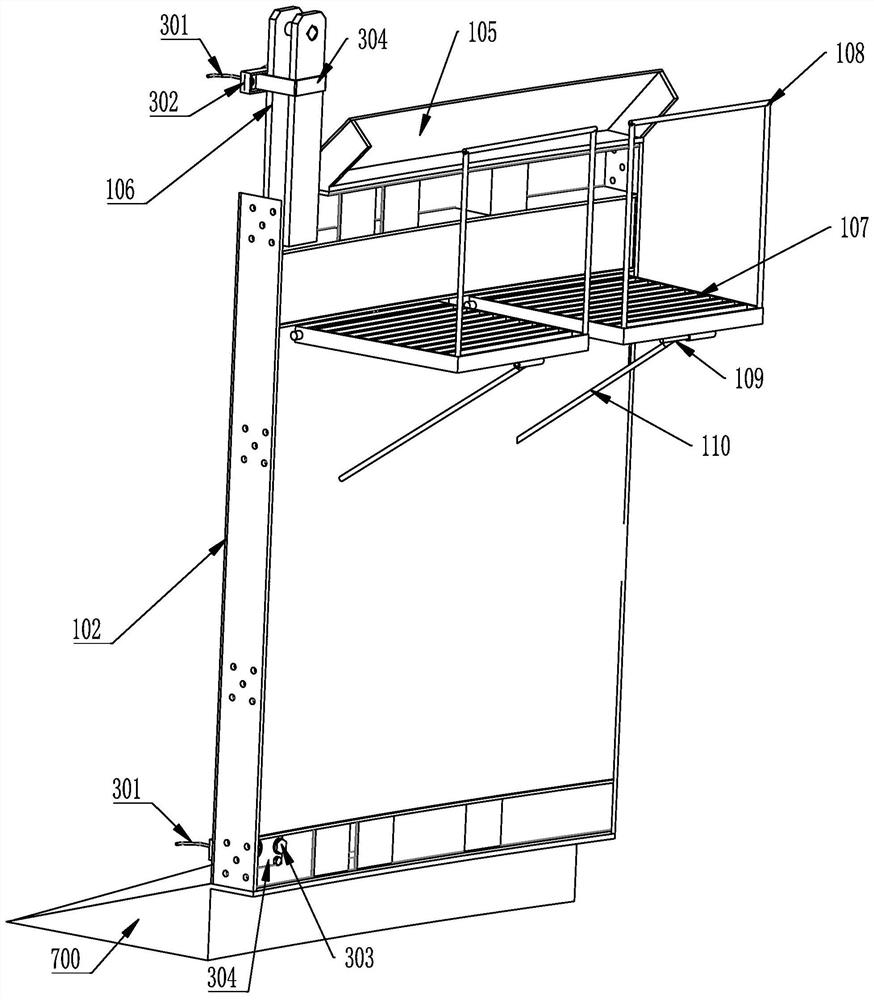

[0029] like figure 1 and figure 2 As shown, a large-diameter integral mobile metal formwork for a shaft includes a standard formwork 100, a lift drive device 200, an anti-deformation pre-embedded pressing mechanism 300 and a demolding mechanism 600. The lift drive device 200 is connected to all the The standard formwork 100 is drivingly connected, and the adjacent standard formwork 100 is detachably connected. The anti-deformation pre-embedded pressing mechanism 300 is installed on the standard formwork 100 and is pressed by the anti-deformation pre-embedded pressing mechanism 300. the suspension lugs 106 of the standard formwork 100, the demolding mechanism 600 is installed between two adjacent standard formwork 100, and the two adjacent standard formwork 100 are Under the action of the demolding mechanism 600, the die is demolded or supported. The large-diameter integral moving metal template is connected by a plurality of arc-shaped standard templates 100 to form a doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com