Patents

Literature

81results about How to "Improve the construction work environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

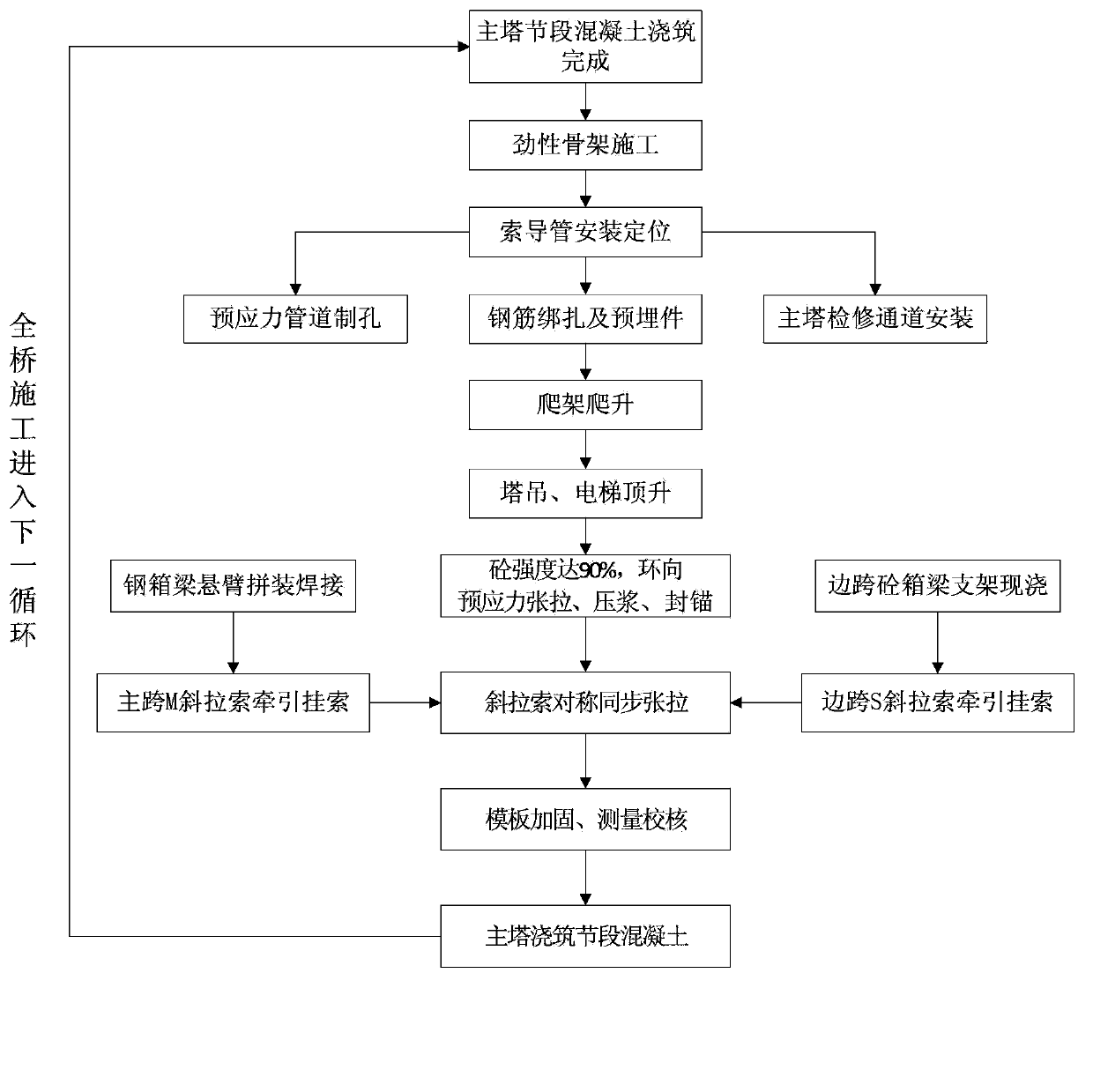

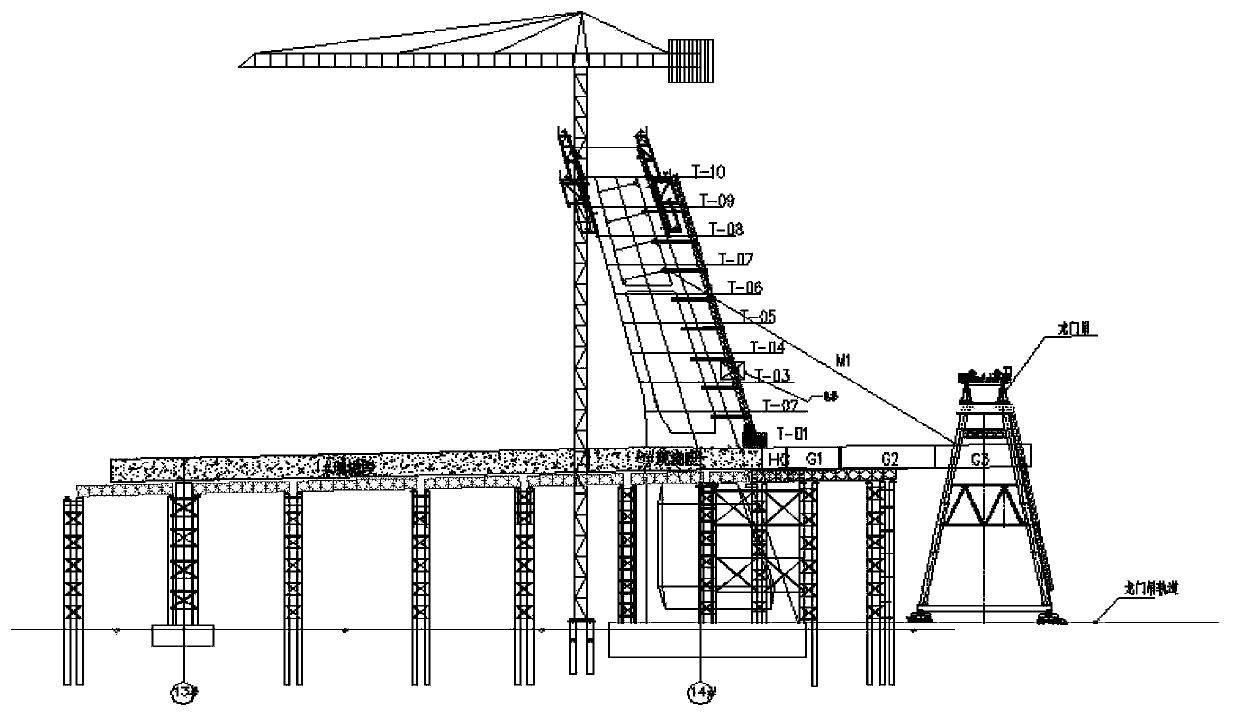

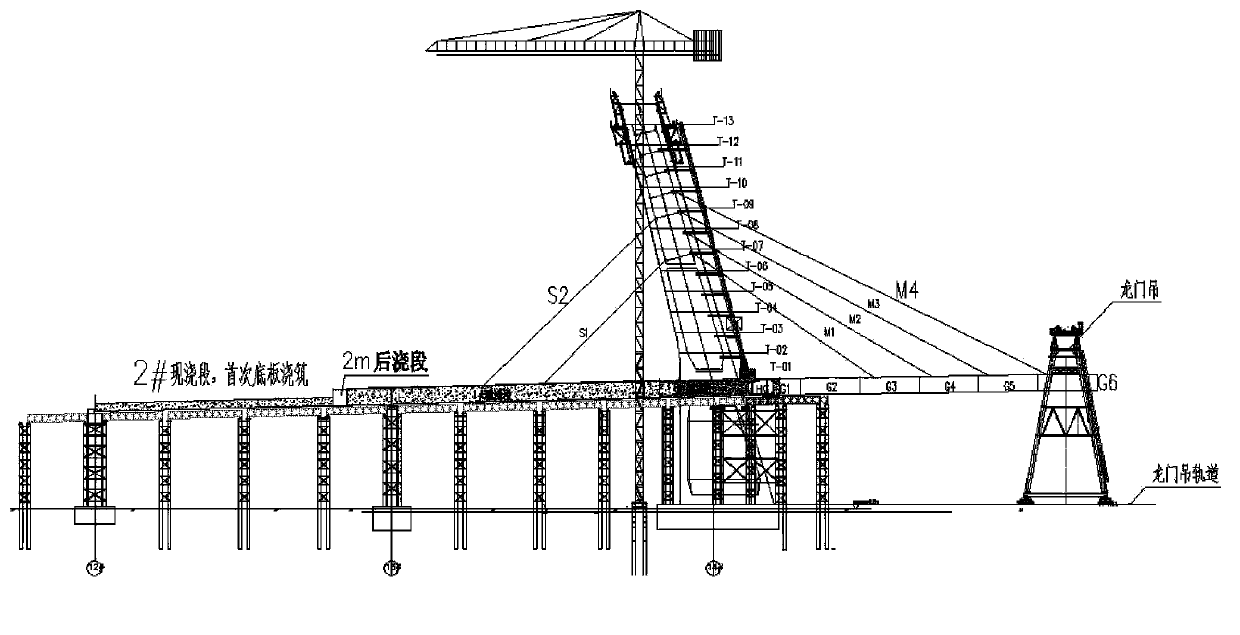

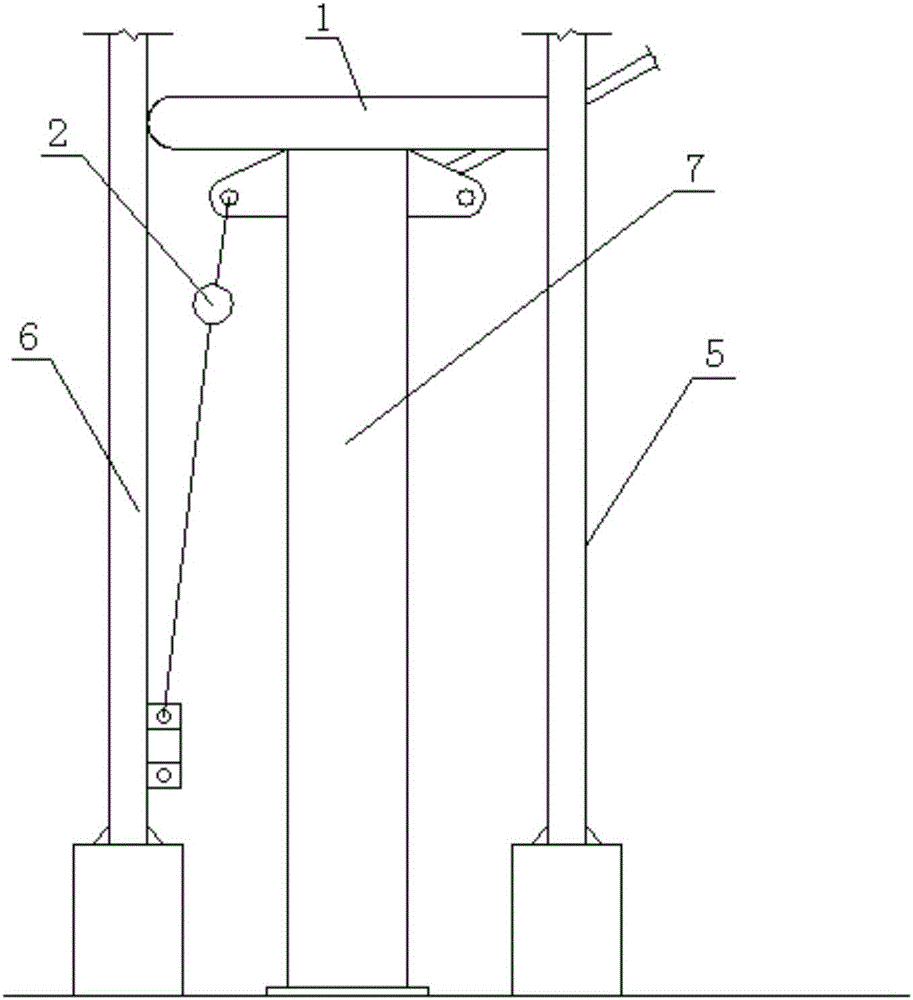

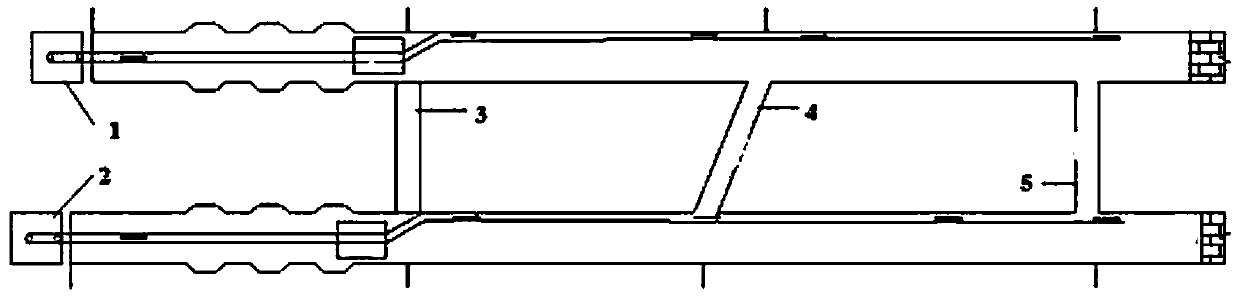

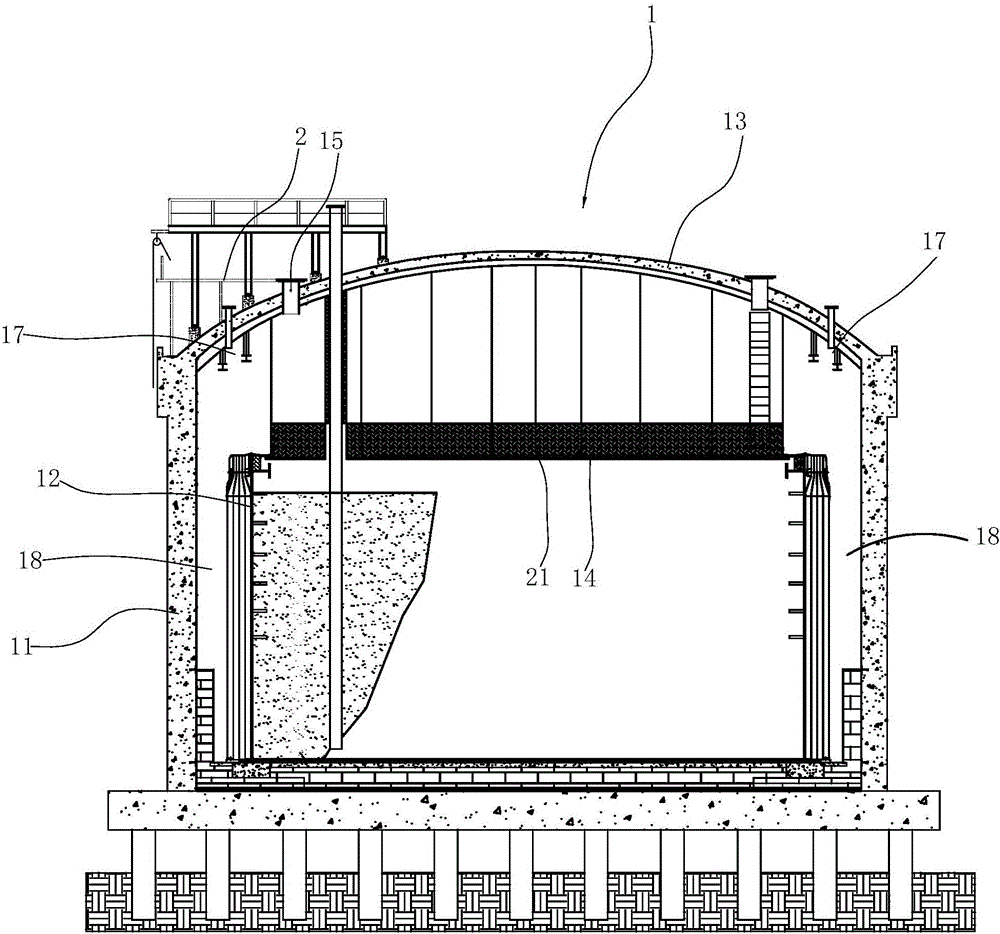

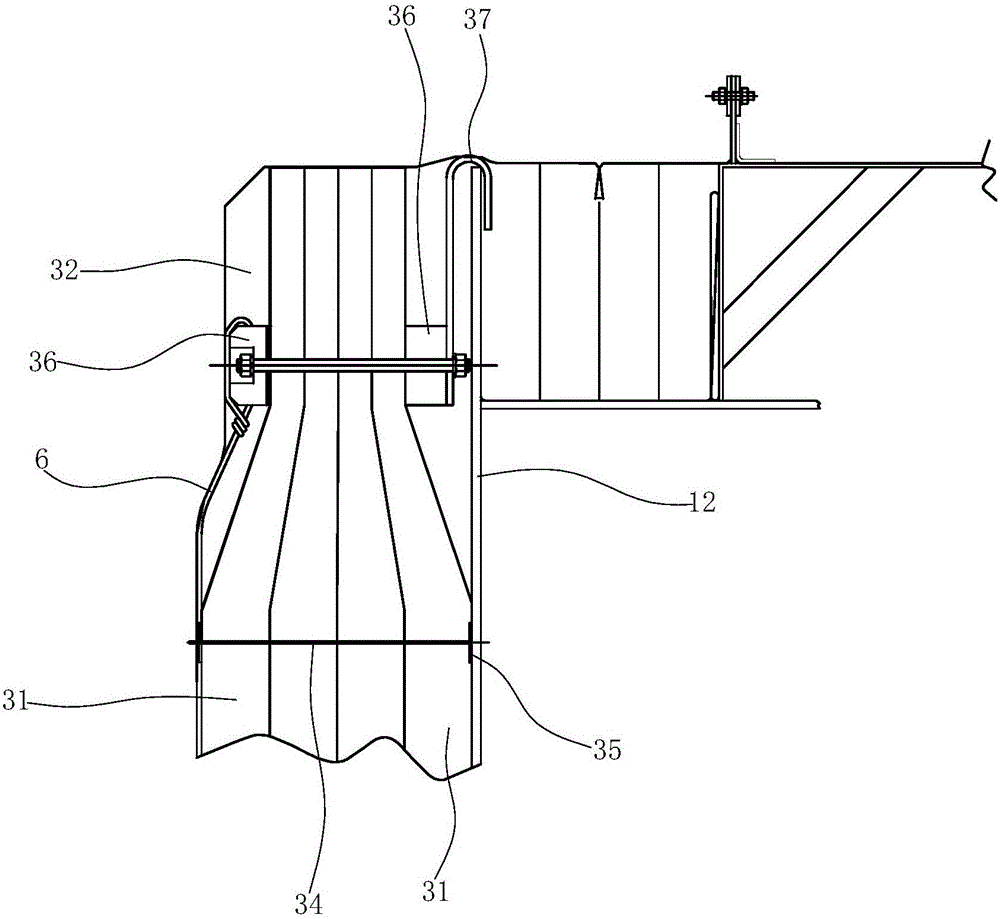

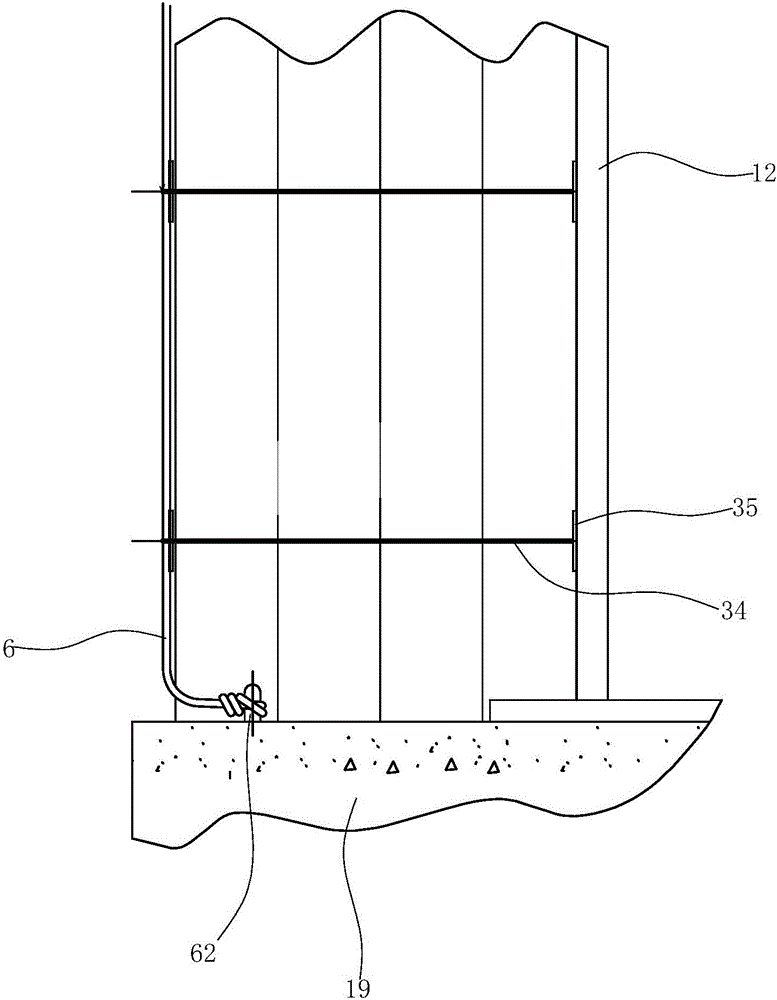

Tower, beam and cable synchronous bridge forming technology

ActiveCN103741601ASatisfied with the resultsMeet the design requirementsBridge erection/assemblyFull bridgeTower

The invention discloses a tower, beam and cable synchronous bridge forming technology. According to the technology, main tower creeping formwork construction, steel box beam cantilever assembly, side span concrete box beam cast-in-place support construction and stay cable and hung cable stretch-draw construction are conducted alternately and synchronously. The tower, beam and cable synchronous bridge forming technology achieves safe and reliable full-bridge construction.

Owner:CCCC THIRD HARBOR ENG +1

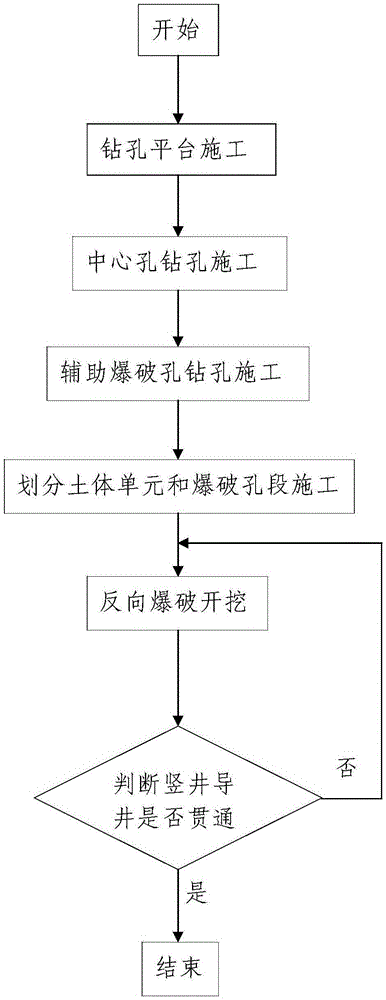

Reverse blasting excavation method of shaft and pilot shaft

The invention discloses a reverse blasting excavation method of a shaft and a pilot shaft. The method comprises the following steps that firstly, construction of a drilling platform is carried out; secondly, center hole drilling construction is carried out; thirdly, auxiliary blasting hole drilling construction is carried out; fourthly, a soil body unit and a blasting hole section are divided; fifthly, reverse blasting excavation is carried out; and sixthly, whether the shaft and the pilot shaft are connected or not is judged, and whether a to-be-excavated soil body of the shaft and the pilot shaft is totally excavated or not is checked, wherein if yes, it is proved that the shaft and the pilot shaft are connected, and excavation of the shaft and the pilot shaft is finished, and if not, excavation continues according to the manner of the fifth step. According to the reverse blasting excavation method, during blasting excavation construction, an operator does not need to enter a face for operation, potential safety hazards caused by well wall chipping, collapsing and the like are avoided, the life safety of the operator is guaranteed, and the reverse blasting excavation method is especially suitable for excavation of the shallow shaft and the shallow pilot shaft below 30 m.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

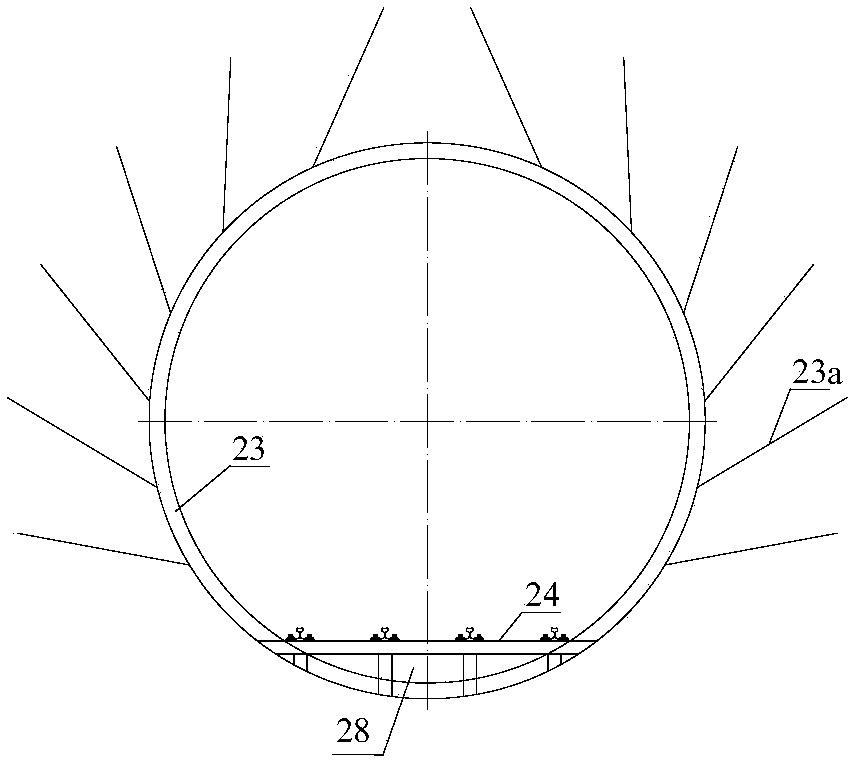

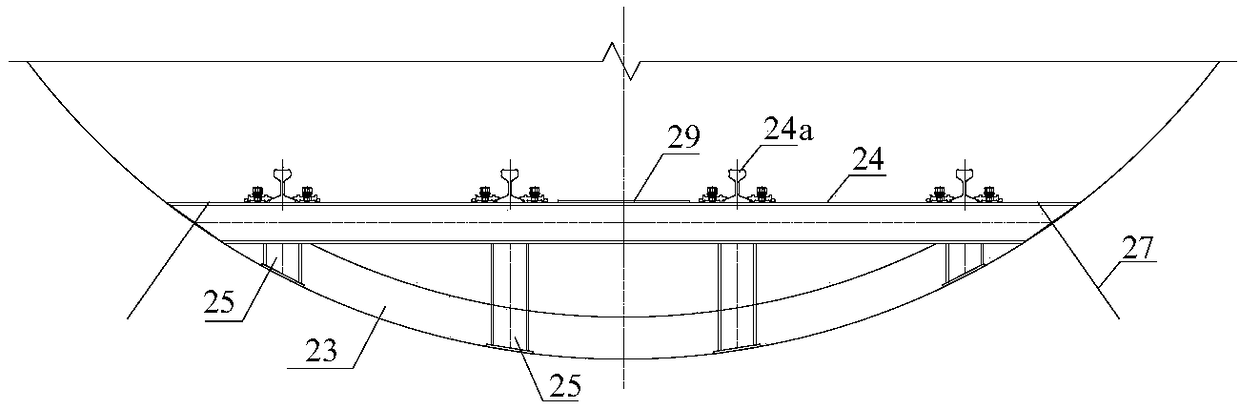

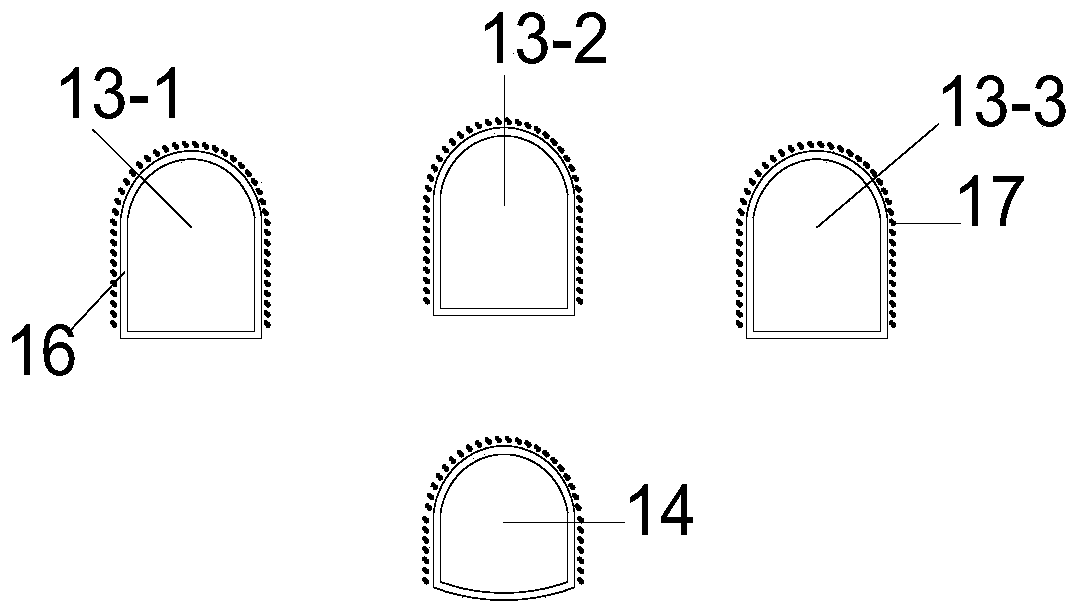

Construction organization method of complete set of tunnel mechanical equipment

ActiveCN108915696AImprove management abilityImprove the construction work environmentUnderground chambersTunnel liningArchitectural engineeringMechanical equipment

The invention discloses a complete set of tunnel mechanical equipment, which specifically refers to an excavation trolley (or an excavation gantry), a drainage and steel bar binding trolley, a liningtrolley, a spray maintenance trolley, a ditch cable trough trolley, an inverted arch self-propelled hydraulic trestle and a wet spray manipulator, referred to as five trolleys, one trestle and one wetspray machine. A construction organization method matched with the complete set of mechanical equipment comprises the following construction organization steps: S1, hole excavation; S2, initial support; S3, inverted arch lining; S4, arched wall lining; S5, ditch cable troughs and the complete set of mechanical equipment. The construction organization method is reasonable, effectively improves tunnel management effect, improves construction operation environment, ensures construction safety and quality, improves construction progress and is worthy of promotion.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

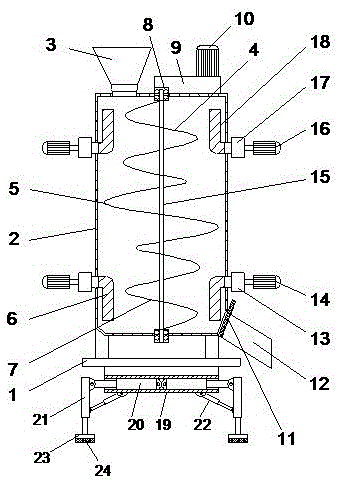

Stable supporting type building stirrer

InactiveCN105582832AImprove stabilityStir wellRotary stirring mixersTransportation and packagingHydraulic cylinderBaseboard

A stable supporting type building stirrer comprises a stirring container, a supporting frame, a feed inlet and a discharge outlet, wherein the supporting frame is fixedly installed on the bottom of the stirring container, the supporting frame is arranged on a supporting guide rail, first hydraulic cylinders are symmetrically arranged inside the supporting guide rail, the end of a piston rod of each first hydraulic cylinder is connected with one end of a corresponding second hydraulic cylinder, a third hydraulic cylinder is arranged between each second hydraulic cylinder and the supporting guide rail, and the end of a piston rod of each second hydraulic cylinder is connected with a corresponding baseboard; the feed inlet is formed in the left side of the top of the stirring container, a feed hopper is arranged above the feed inlet, the discharge outlet is formed in the right side of the bottom of the stirring container, a discharging electromagnetic valve is arranged on the discharge outlet, and a rotary shaft is installed in the middle inside the stirring container through a bearing. Stirring efficiency is high, construction cost is reduced, stirring is uniform, slipping during working of equipment is avoided, and supporting stability is high.

Owner:黄斌

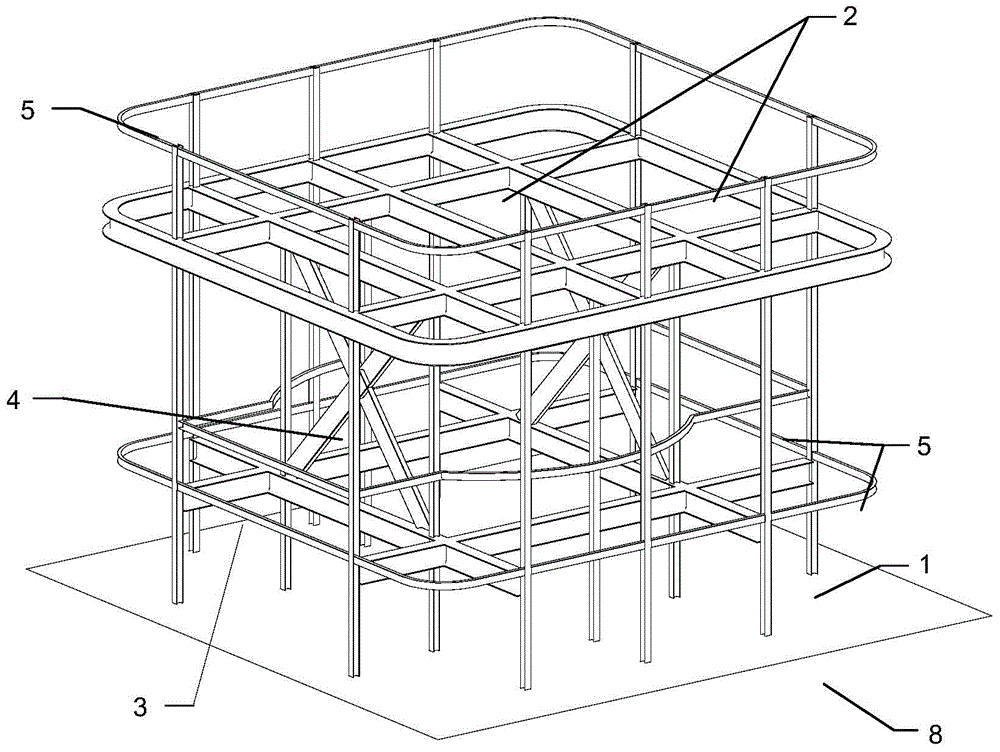

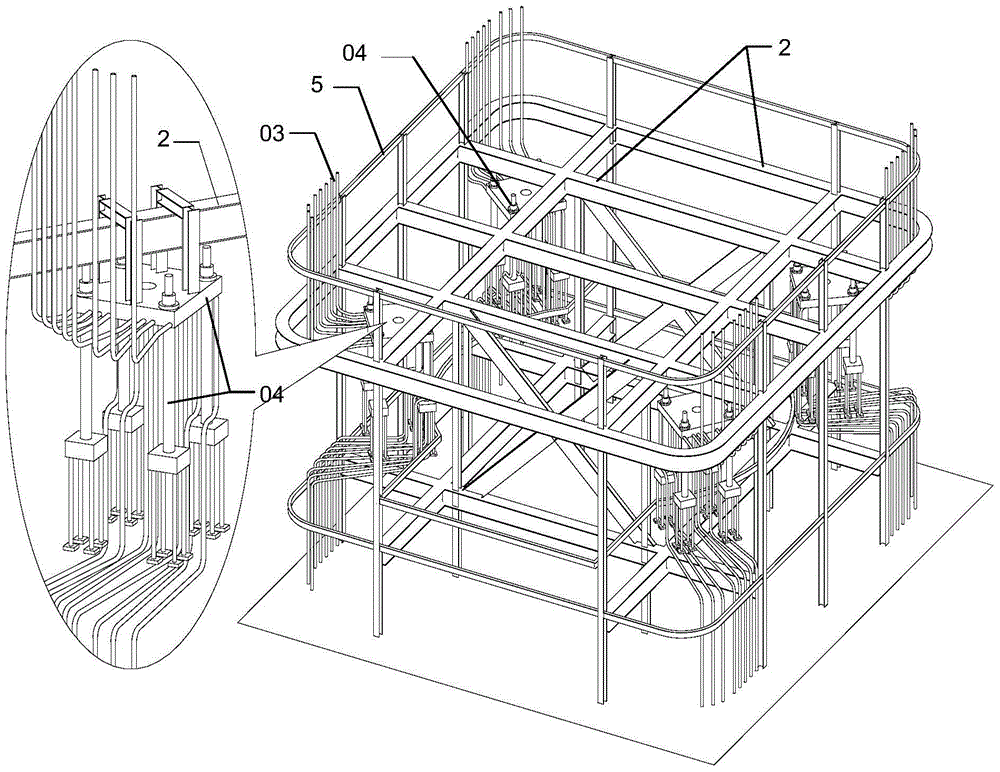

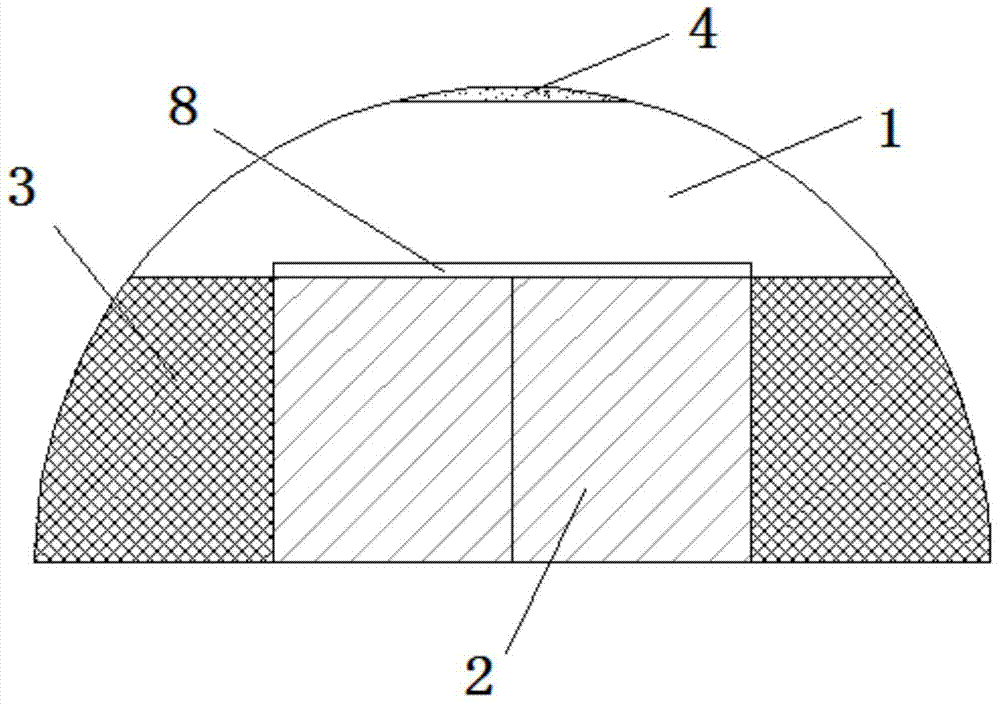

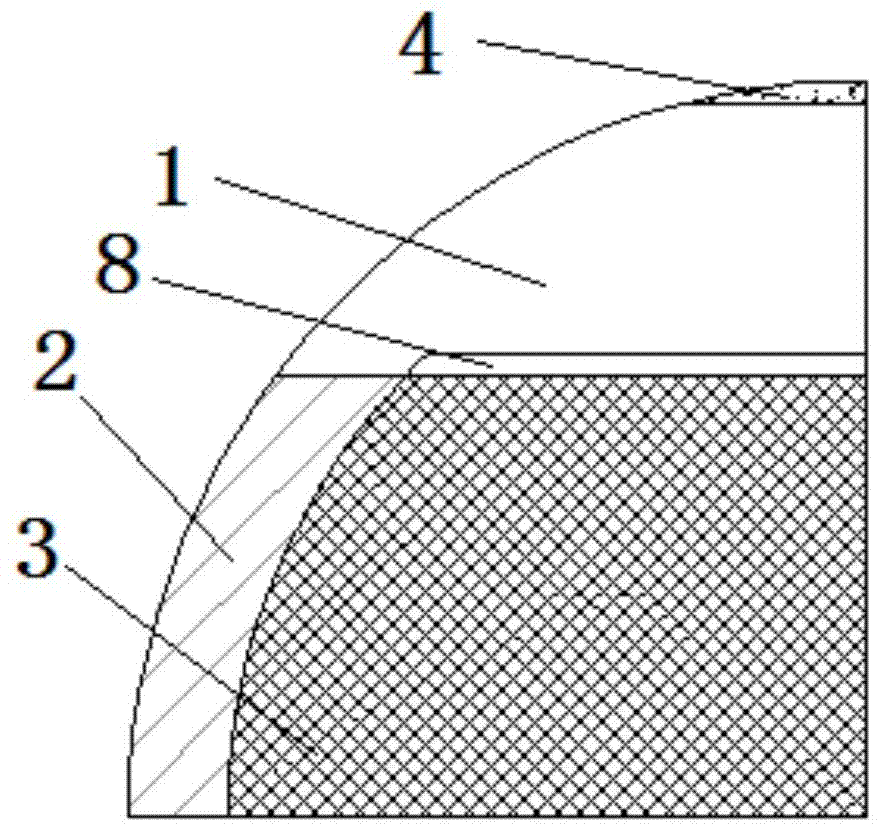

Modular construction method for high temperature gas cooled reactor nuclear power plant containment bracket section wall

ActiveCN105133881AReduce construction difficultyImprove the construction work environmentBuilding material handlingIndustrial buildingsNuclear powerCritical path method

The invention relates to a modular construction method of a high temperature gas cooled reactor nuclear power plant containment bracket section wall, and belongs to the technical field of nuclear power engineering construction. The method comprises the steps that a combined module based on a steel structure is formed by construction rebars and installation parts except wall concrete, and the combined module integrates bracket section rebars, a shielding cooling water pipeline, vapor generator bearing supporting assemblies, vapor generator adjusting line rails, a bracket side face and bottom steel cladding face into a whole structure by adopting an additional steel support structure, so that construction of the bracket section wall is fully moved out of a site for whole assembly. By means of the modular construction method of the bracket section wall, the construction difficulty of a traditional construction method is solved, and the risk of construction safety is reduced; more importantly, the construction period of a critical route is greatly shortened, and the engineering quality of a containment is guaranteed.

Owner:CHINERGY CO LTD +1

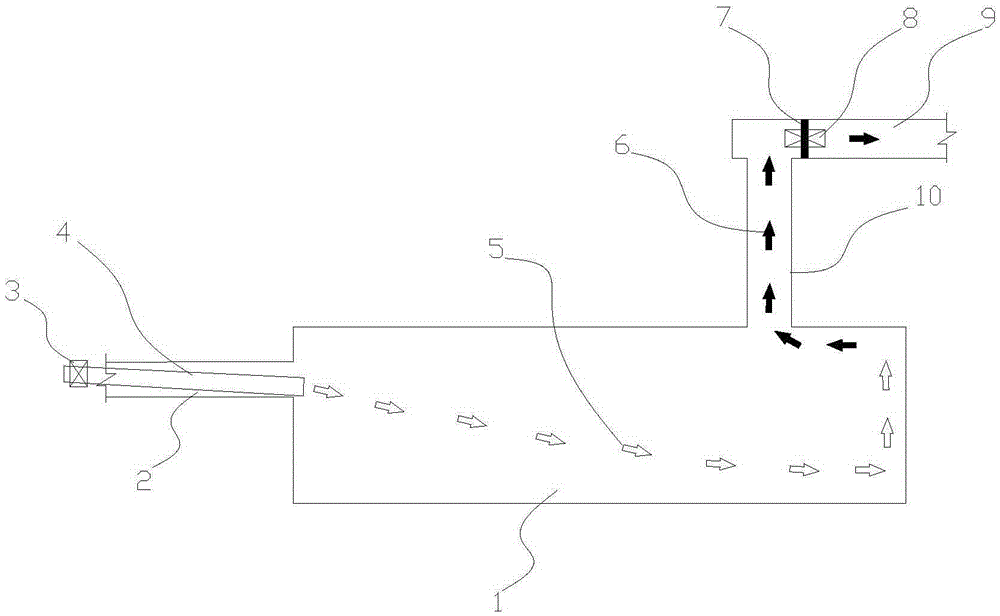

Ventilating smoke dissipating system used for underground cavern construction of large hydropower station

InactiveCN105240041ATimely exclusionImprove working environmentMining devicesWater-power plantsUnderground cavernArchitectural engineering

The invention discloses a ventilating smoke dissipating system used for underground cavern construction of a large hydropower station. The system comprises an underground cavern, wherein one end of the underground cavern is an air inlet, the other end is an air outlet, a construction adit is formed at one end of the air inlet of the underground cavern, an air inlet pipeline is laid on the top of the construction adit and is obliquely arranged in the construction adit, an air supply machine is arranged at one end of the air inlet pipeline, the air supply machine is arranged at the hole of the construction adit, an exhaust outlet is formed in the top wall of one end of the air outlet of the underground cavern, an exhaust shaft is arranged on the exhaust outlet, the upper end of the exhaust shaft is connected with an exhaust footrill, the exhaust footrill is provided with a wind stop wall and an exhaust fan at a position connected with the exhaust shaft. The system has the beneficial effects of greatly improving the air quality of a working face of each large underground cavern, creating a good construction working environment and ensuring construction quality and construction safety.

Owner:CHINA THREE GORGES CORPORATION

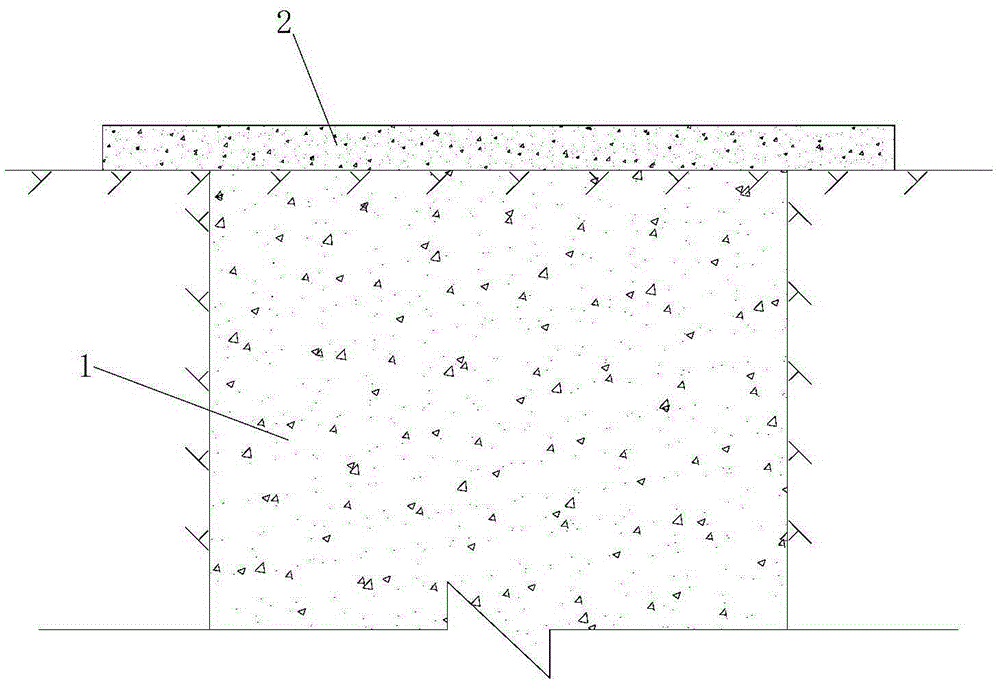

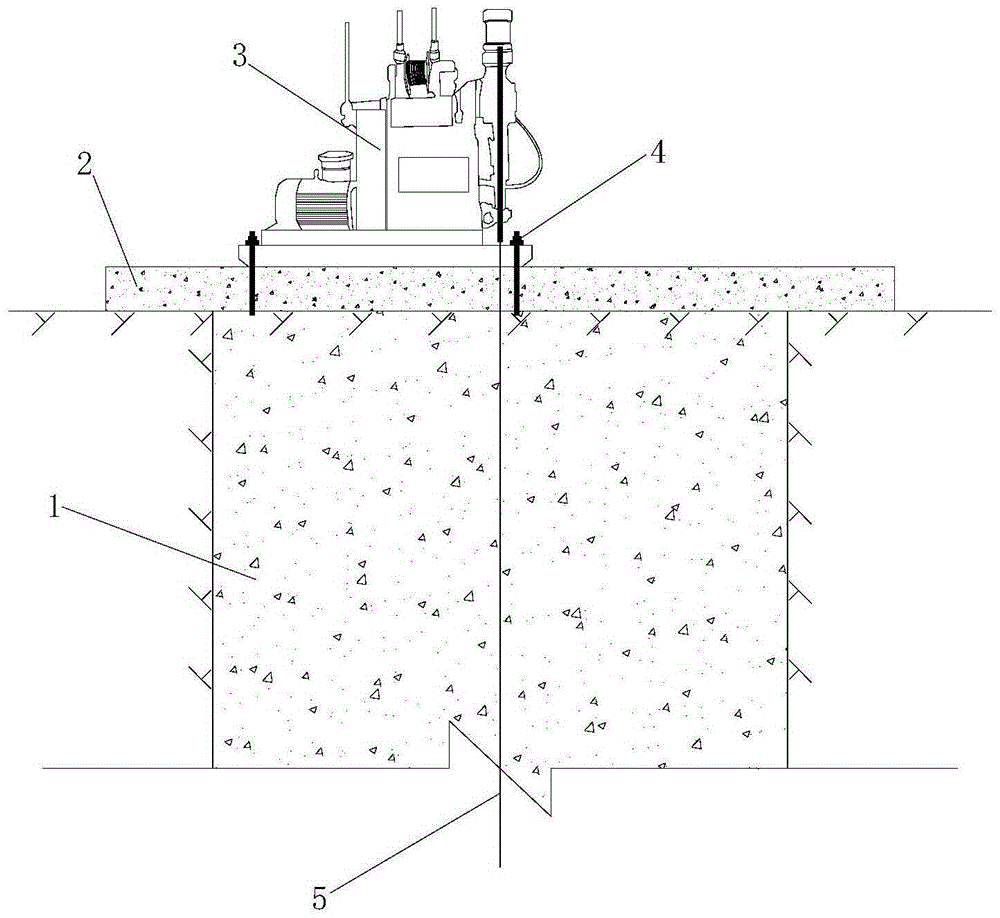

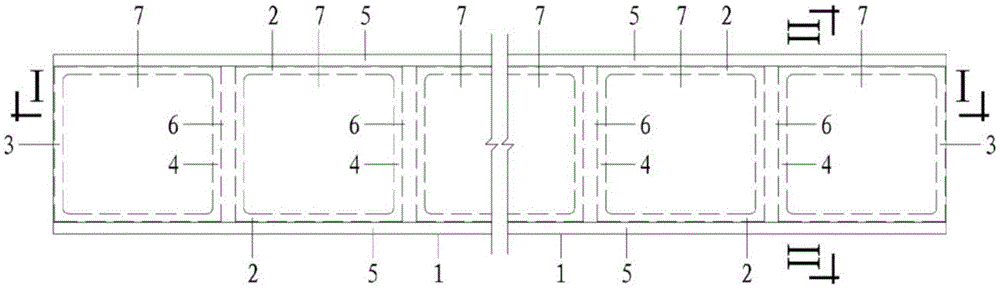

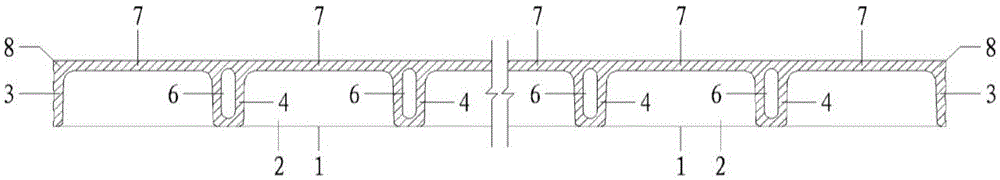

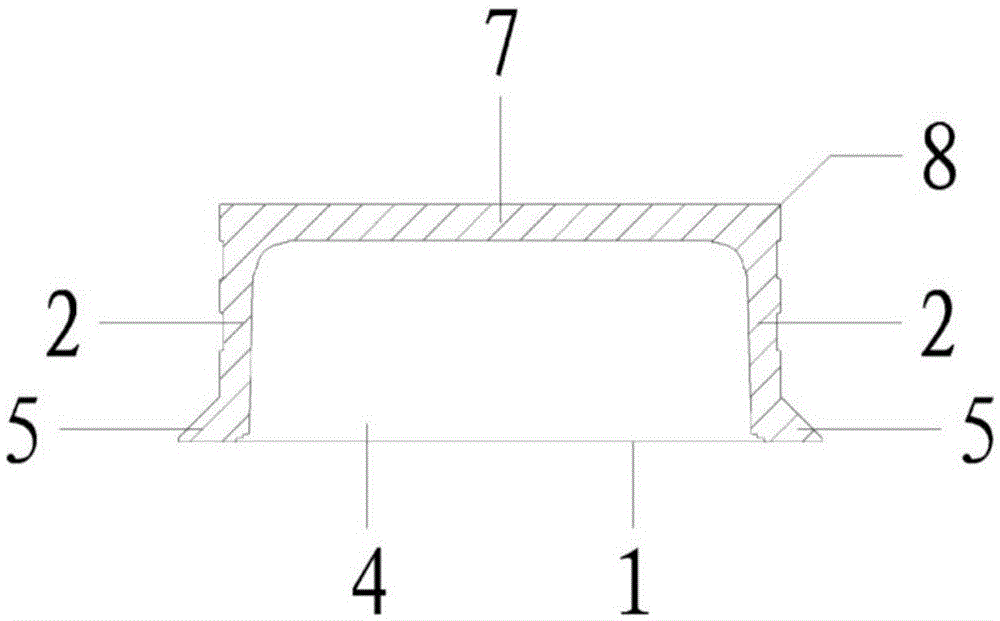

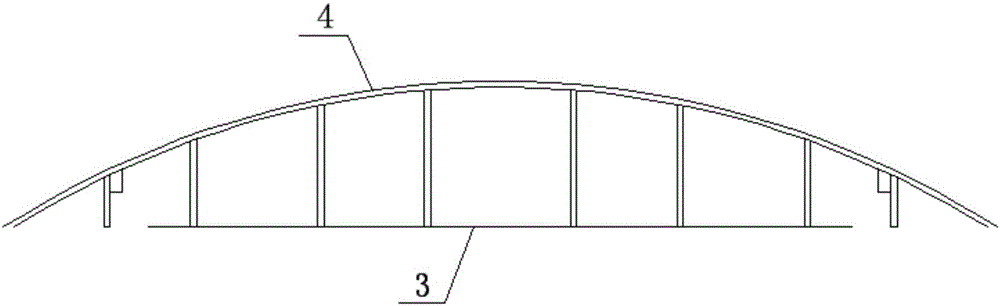

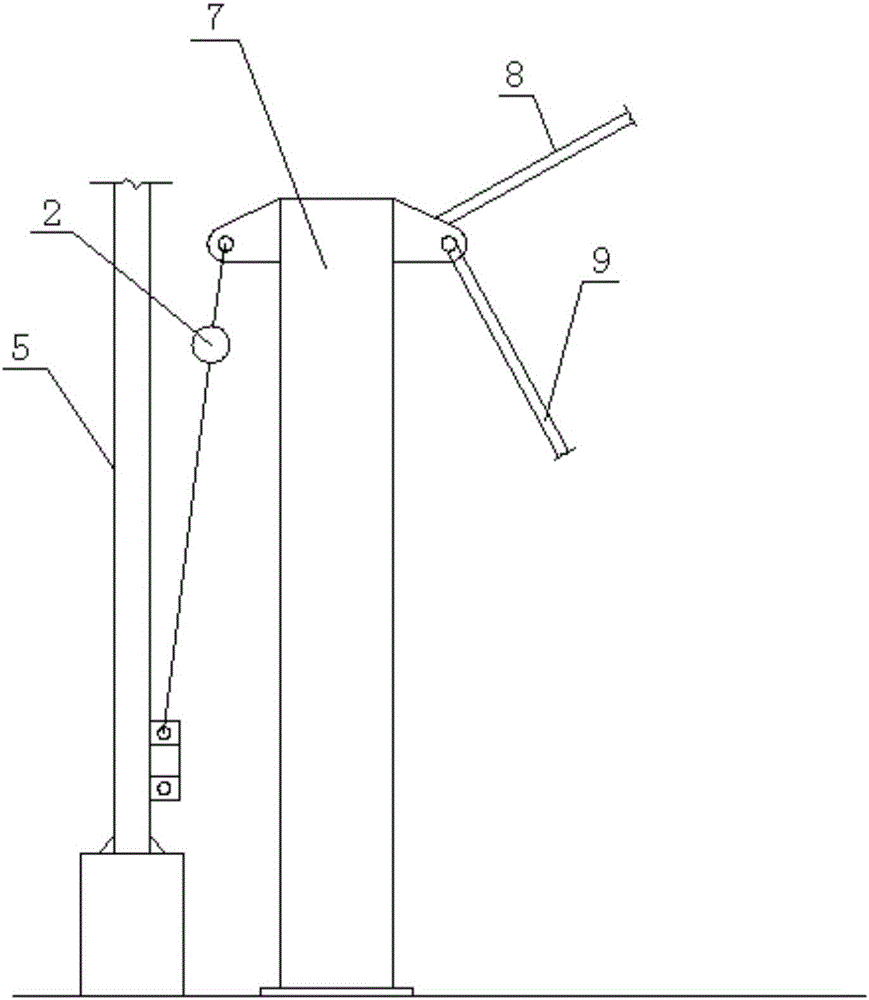

Assembly type concrete bidirectional ribbed floor and construction method therefor

ActiveCN105484403AReduce binding workloadBinding quality is easy to guaranteeFloorsWorking environmentEngineering

An assembly type concrete bidirectional ribbed floor and a construction method therefore belong to the technical field of building engineering. The assembly type concrete bidirectional ribbed floor includes a concrete bar-shaped channel board, a prefabricated concrete bar-shaped hollow board, prefabricated concrete groove-shaped blocks, and prefabricated concrete hollow blocks. The construction method relates to four types of design, member prefabrication and installation construction in sum. The production technology and devices are simple. The hoisting and installation are convenient. Formwork engineering and plastering are avoided, and construction processes are reduced. The steel bar binding workload is low, and the steel bar binding quality is easy to guarantee. The construction efficiency is improved, the appearance quality is good, and the appearance is flat and clean. The construction work environment is improved. The engineering construction cost is obviously reduced. The prefabricated concrete bar-shaped channel board and the prefabricated concrete bar-shaped hollow board have a bearing function during the construction period, so that arrangement of supports is not needed. Although the prefabricated concrete groove-shaped blocks and the prefabricated concrete hollow blocks need support, the needed support is less.

Owner:新疆冶金建设(集团)有限责任公司

Construction method for double layer storage tank with flat suspended roof as inner tank roof

ActiveCN105952228AIncrease the depth of prefabricationImprove the quality of protectionBulk storage containerThermal insulationArchitectural engineering

The invention discloses a construction method for a double layer storage tank with a flat suspended ceiling as an inner tank roof. The method comprises following steps: installation of an inner tank top ring wallboard, a flat suspended ceiling and an outer tank dome; simultaneously upside down lifting of the inner tank flat suspended ceiling, inner tank top ring wallboard and the outer tank dome; after the installation of the inner tank wallboard is finished, the outer tank wallboard is inversely mounted in order; after the construction of a thermal insulation layer between the inner tank base plate and the outer tank base plate is finished, an inner tank base plate is paved. By means of the construction method, the construction efficiency is effectively increased, the construction period is shortened, the difficulty for dumping and transferring the material in the inner tank is reduced, and construction cost is reduced.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

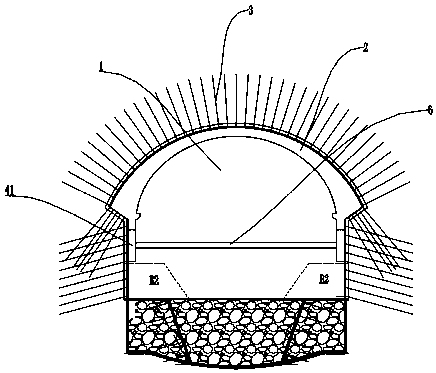

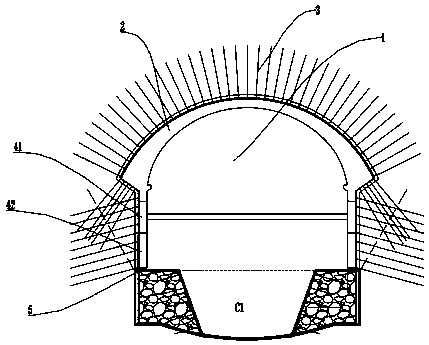

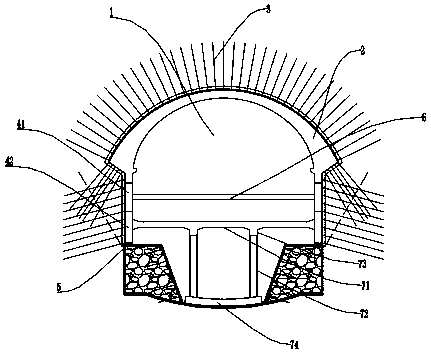

In-tunnel reverse construction method for mined metro station with oversized cross section based on arch cover method in soft rock area

ActiveCN110735656AImprove the construction work environmentImprove bearing capacityUnderground chambersDrainageMetro stationThree-dimensional space

The invention provides an in-tunnel reverse construction method for a mined metro station with an oversized cross section based on an arch cover method in a soft rock area. The method comprises the following steps of S1, excavating excavated areas in a top layer and a middle layer and excavating a slot jumping area in the middle of a bottom layer; S2, carrying out construction of a local invertedarch, a second section side wall and a negative second floor driving plate structure of the station; and S3, finishing full-cross section excavation and constructing a second liner to line residual parts and the negative second floor driving plate structure of the station. The arch cover method is applied to the soft rock area effectively by means of a supporting measure combining permanent and temporary structures and a reinforcing measure of a special part and combining the in-tunnel reverse construction method of the mined tunnel. Excavation on the lower part in the cross section of the tunnel is carried out by middle broaching, and separated areas on two sides are excavated, so that construction organization in an in-tunnel three-dimensional space is achieved. Compared with a conventional tunnel face-based excavation mode, a sufficient operating space is provided for construction.

Owner:JIESHUN RAIL TRAFFIC TECH CHONGQING

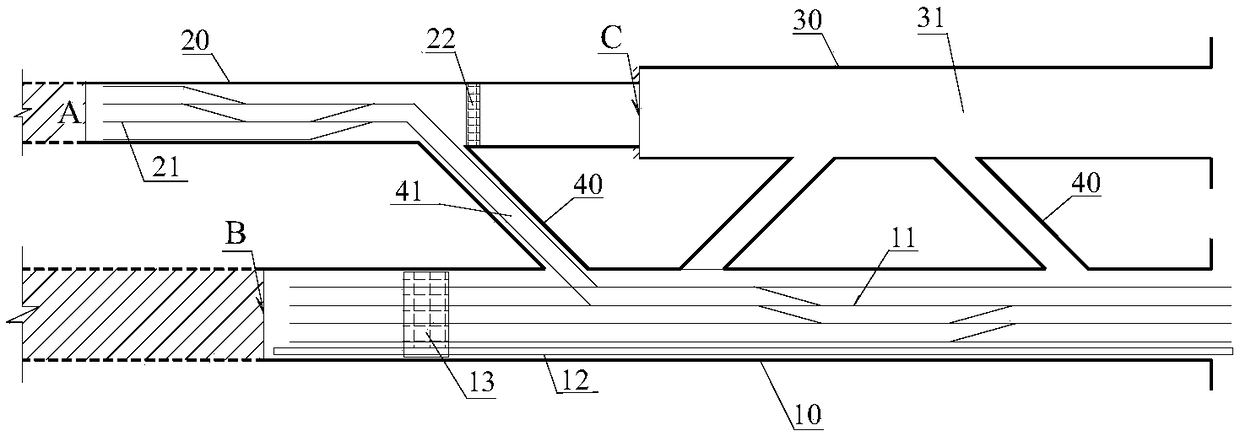

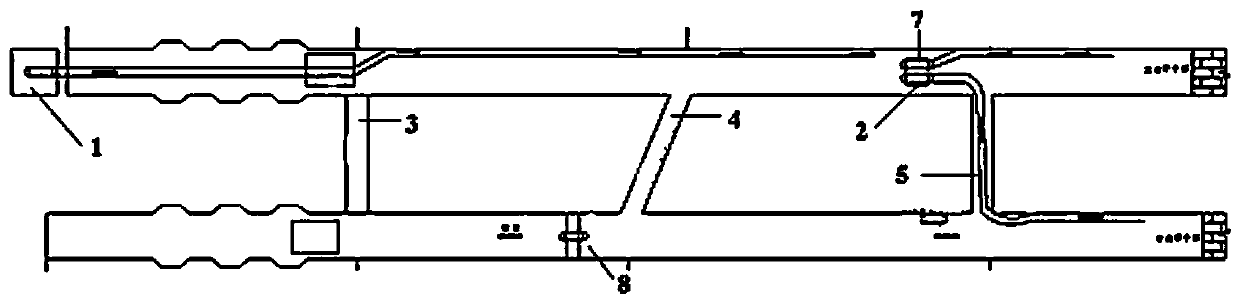

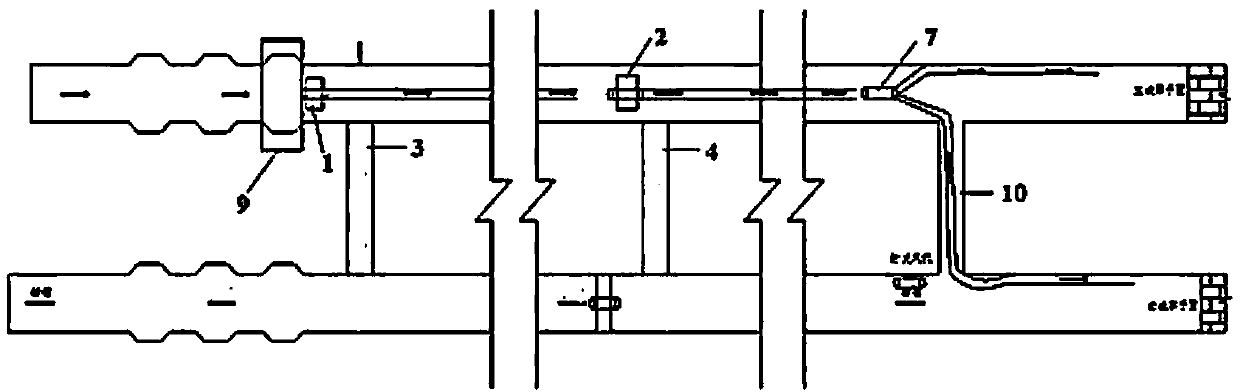

Construction method for simultaneous extension of parallel guide pits into double-line tunnel for TBM tunneling construction

PendingCN109403986AShorten the construction periodLow costTunnel/mines ventillationTunnelsArchitectural engineeringTunnel construction

The invention relates to a construction method for simultaneous extension of parallel guide pits into a double-line tunnel for TBM tunneling construction and aims to guarantee simultaneous construction of the double-line tunnel and an I-line tunnel, put into operation at the same time and realize effective shortening of the total construction period of the tunnel and great reduction of the construction cost. The method comprises steps that small-diameter open TBM is utilized for full-section excavation in-advance construction of the parallel guide pits; after lagging behind the tunneling surface of the parallel guide pits about 800m, large-diameter TBM full-section tunneling construction of the I I-line is utilized at the left or right side of the parallel guide pits at 30-50m, and a transverse passage between the parallel guide pits and the I-line tunnel is constructed along the extension direction of the line at intervals; after lagging behind the TBM tunneling surface of the I-linetunnel about 1200 meters, extension construction of the parallel guide pits is carried out, that is, when the parallel guide pits are continuously tunneled without interruption by the small TBM ahead,the borehole-blasting method is utilized to carry out simultaneous digging extension of the constructed parallel guide pits at about 2km lagging behind the tunneling surface of the parallel guide pits, and the double-line tunnel is formed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Long-distance tunnel relay ventilation method

ActiveCN109667614AGuaranteed ventilation effectImprove the construction work environmentTunnel/mines ventillationWorking environmentBreathing

The invention discloses a long-distance tunnel relay ventilation method, and relates to the technical field of tunnel construction, mainly aiming at solving the problem that the tunnel construction ispoor in ventilation effect. The method comprises the following steps: S1, adopting an ordinary tunnel press-in ventilation way before a tunnel is tunneled to 1200 meters; S2, adopting a roadway ventilation way after the tunnel is tunneled to 1200 meters; S3, when the tunnel is excavated to 2500 meters, adopting tunnel face ventilation through a left line hole and a right line hole, and moving a fan arranged outside the left line hole inwards to the front of a third fan section for ventilation; S4, continuing to tunnel forward along with a tunnel face. The fan arranged outside the left line hole, a fan arranged outside the right line hole, a first fan, a second fan and fan sections are cooperatively used, so that the ventilation effect of the tunnel construction is fully guaranteed, the work environment of construction in the tunnel is improved, and the phenomenon that the health of workers is affected by excessive dust, impurities and the like is effectively avoided.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

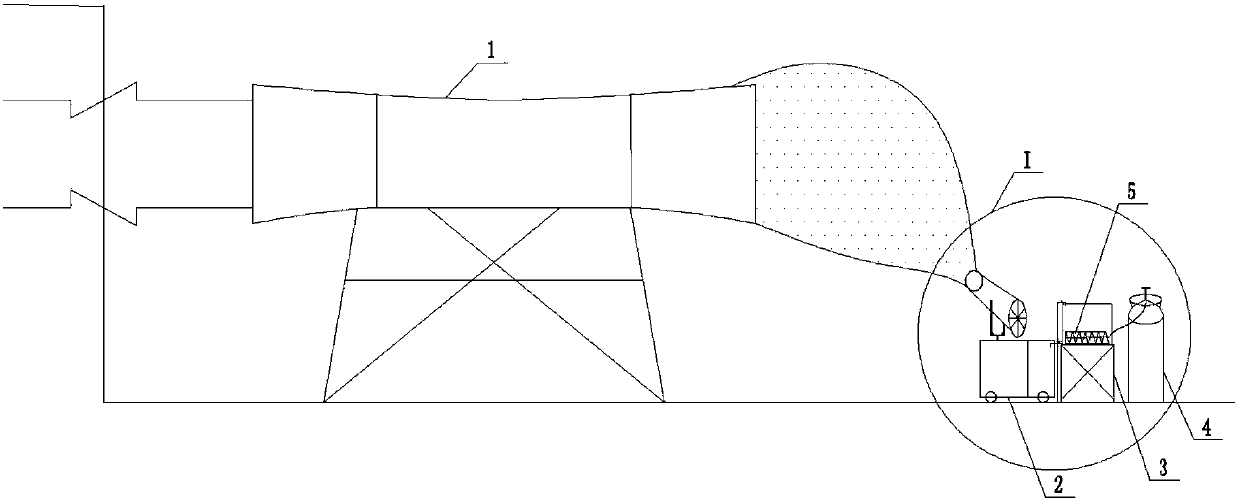

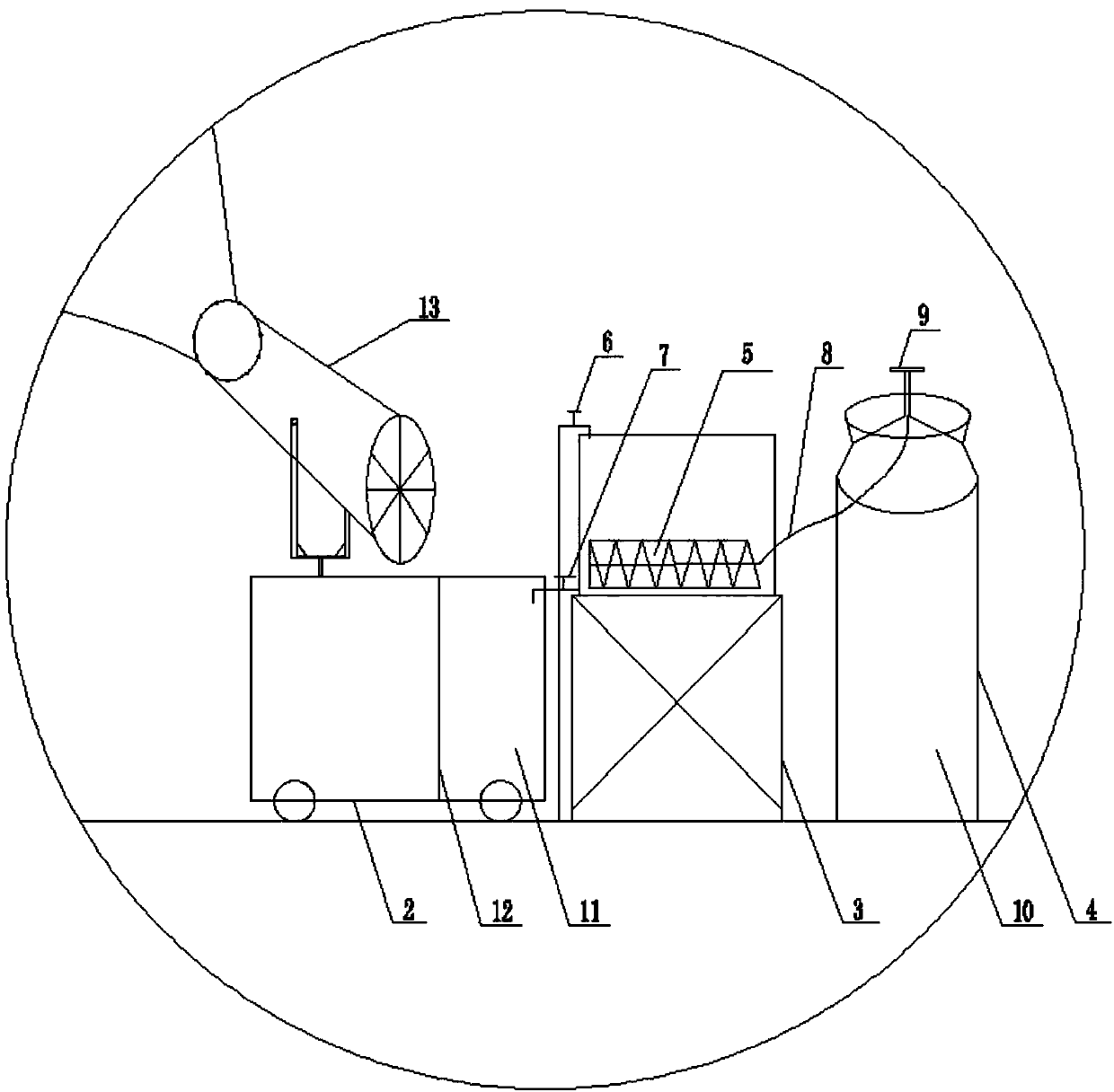

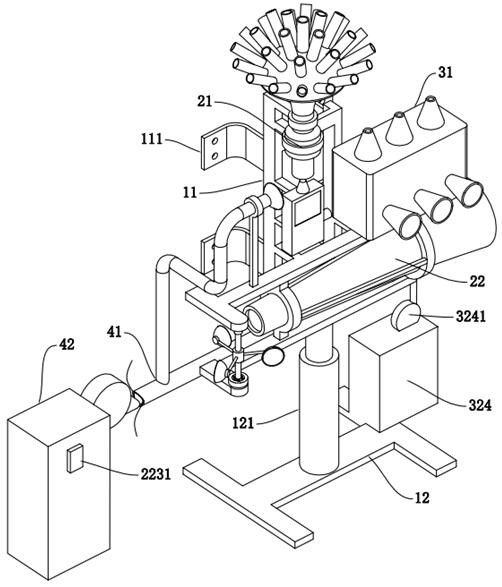

Tunnel construction cooling device and method

PendingCN107795332AReduce the temperatureImprove the construction work environmentLighting and heating apparatusTunnel/mines ventillationCold airEngineering

The invention discloses a tunnel construction cooling device and method. The tunnel construction cooling device includes a press-in type fan, a fog gun machine, a heat insulation water tank and a cooling device body. The cooling device body is installed in the heat insulation water tank. The output end of the heat insulation water tank communicates with the input end of the fog gun machine. The output end of the fog gun machine and the input end of the press-in type fan are arranged oppositely. The cooling method of the tunnel construction cooling device includes the following steps that 1, the heat insulation water tank is filled with sufficient water; 2, low-temperature liquid is led into the cooling device body; 3, the cooled water in the heat insulation water tank is led into the fog gun machine and is atomized and sprayed out by the fog gun machine; and 4, the press-in type fan sucks cold air from a spray-out area of the fog gun machine and sends wind to a construction section ina tunnel. According to the tunnel construction cooling device and method, the temperature of the construction position in the tunnel can be reduced, the life safety of workers is ensured so that the workers can be able to work normally, the cost is saved, manpower is saved, and the construction environment is kept good.

Owner:GUIZHOU BRIDGE CONSTR GROUP

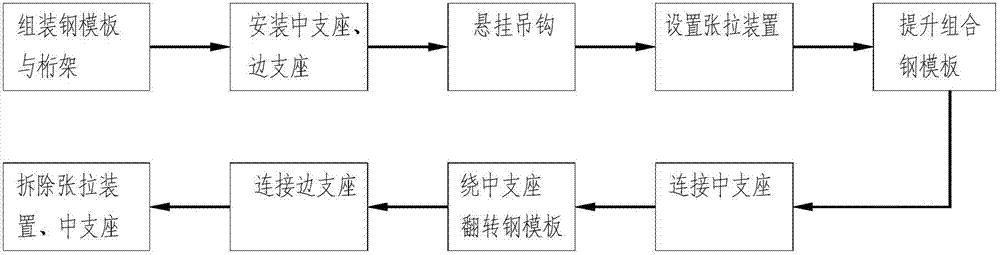

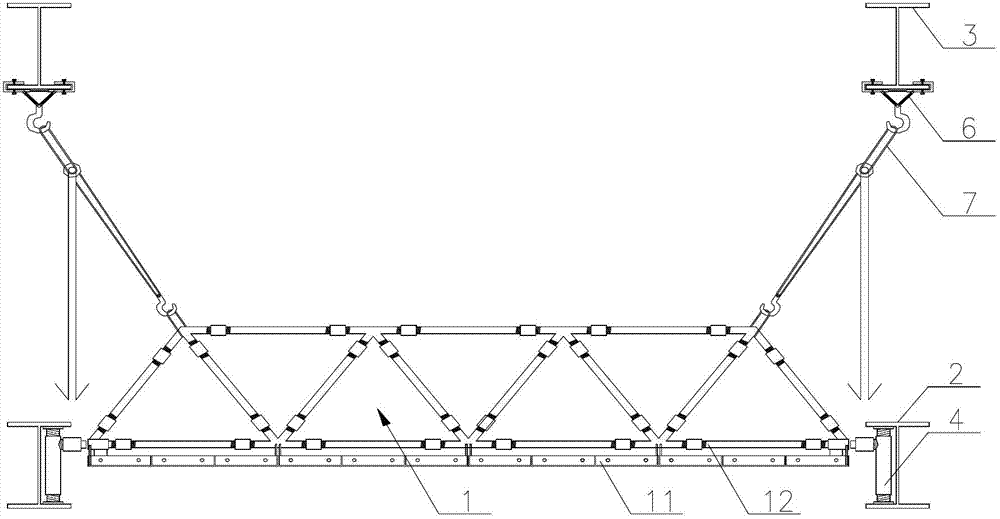

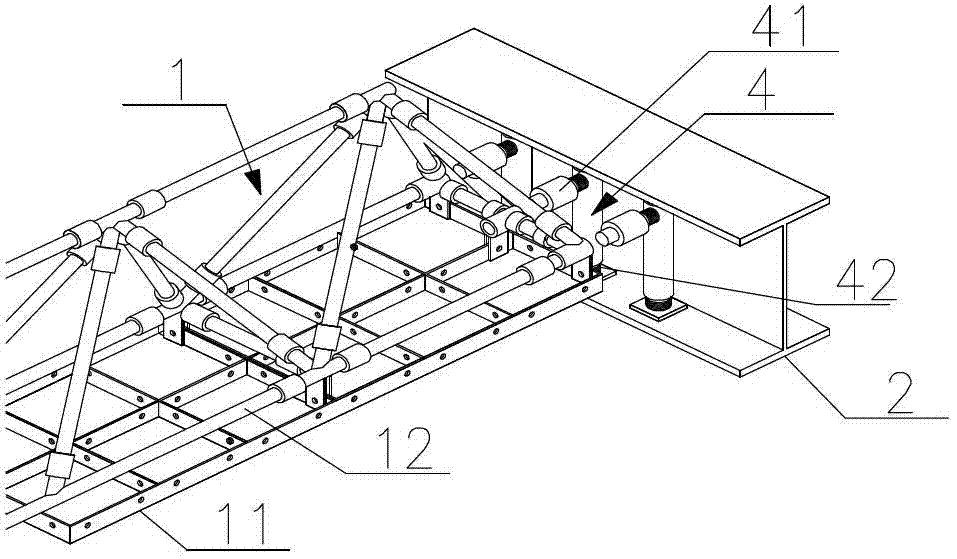

Self-supporting combined steel template construction method

ActiveCN102787717AReduce construction costsFast constructionForms/shuttering/falseworksFalseworkSystem construction

The invention relates to a multi-story and high-rise mixed structure building system construction technology, and aims to provide a self-supporting combined steel template construction method. The method comprises the following steps of: integrally and inversely assembling a self-supporting combined steel template on the ground surface or a platform, and lifting the inverse self-supporting combined steel template to a specified position through a tensioning device; connecting the inverse self-supporting combined steel template with a middle supporting seat though a horizontal connecting rod, and integrally overturning the inverse self-supporting combined steel template into place around a middle supporting seat horizontal connecting rod under the action of self-gravity; realizing connection through a side supporting seat horizontal connecting rod; and during construction of a self-supporting combined steel template of a next independent unit, circularly performing the construction steps. Compared with a construction method for erecting full framing scaffolding, the method has the advantages that the template construction cost is lowered greatly, the construction speed is increased greatly, and the site construction environment is improved remarkably.

Owner:HANGZHOU HENGDA STEEL STRUCTURE

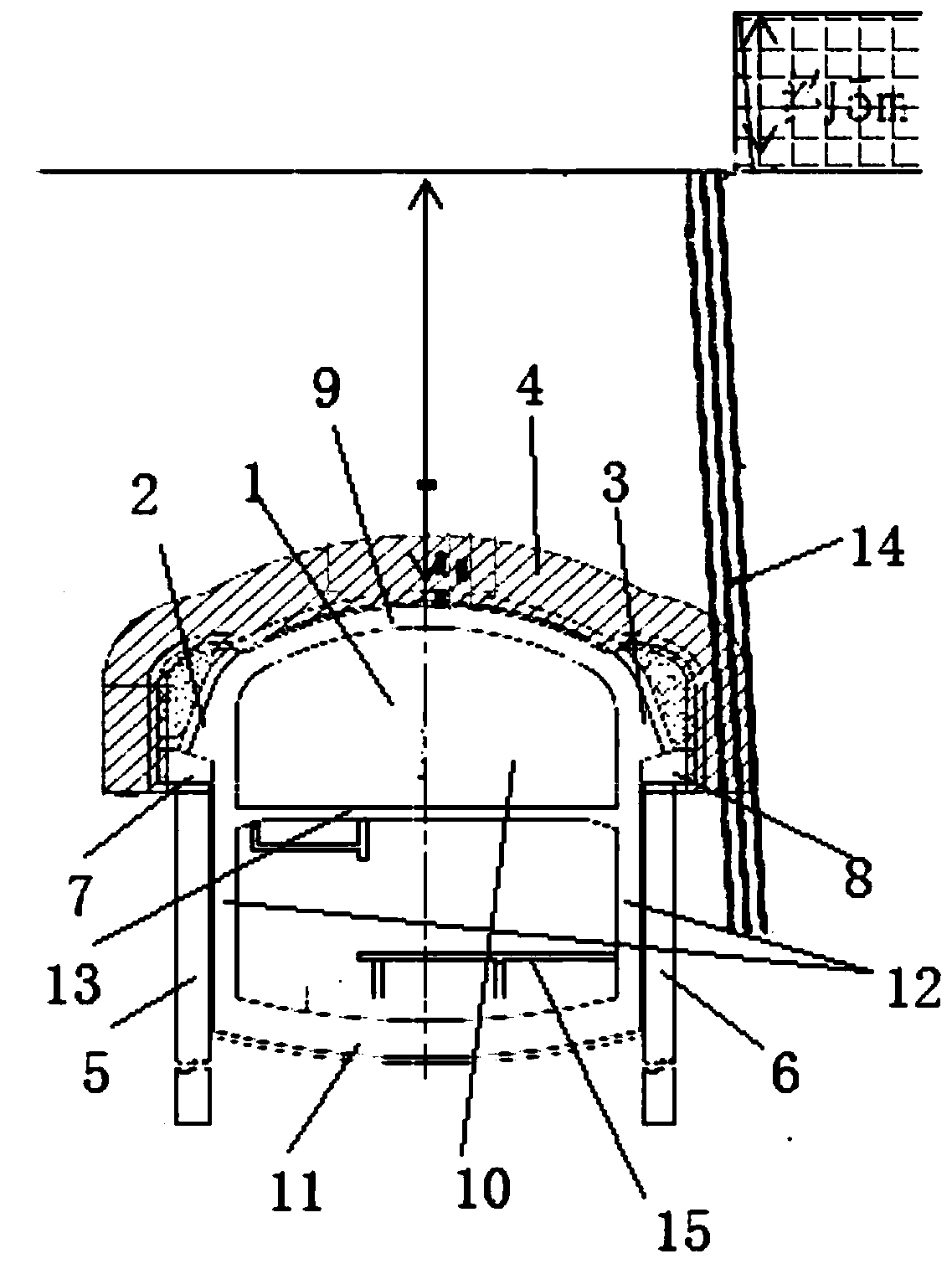

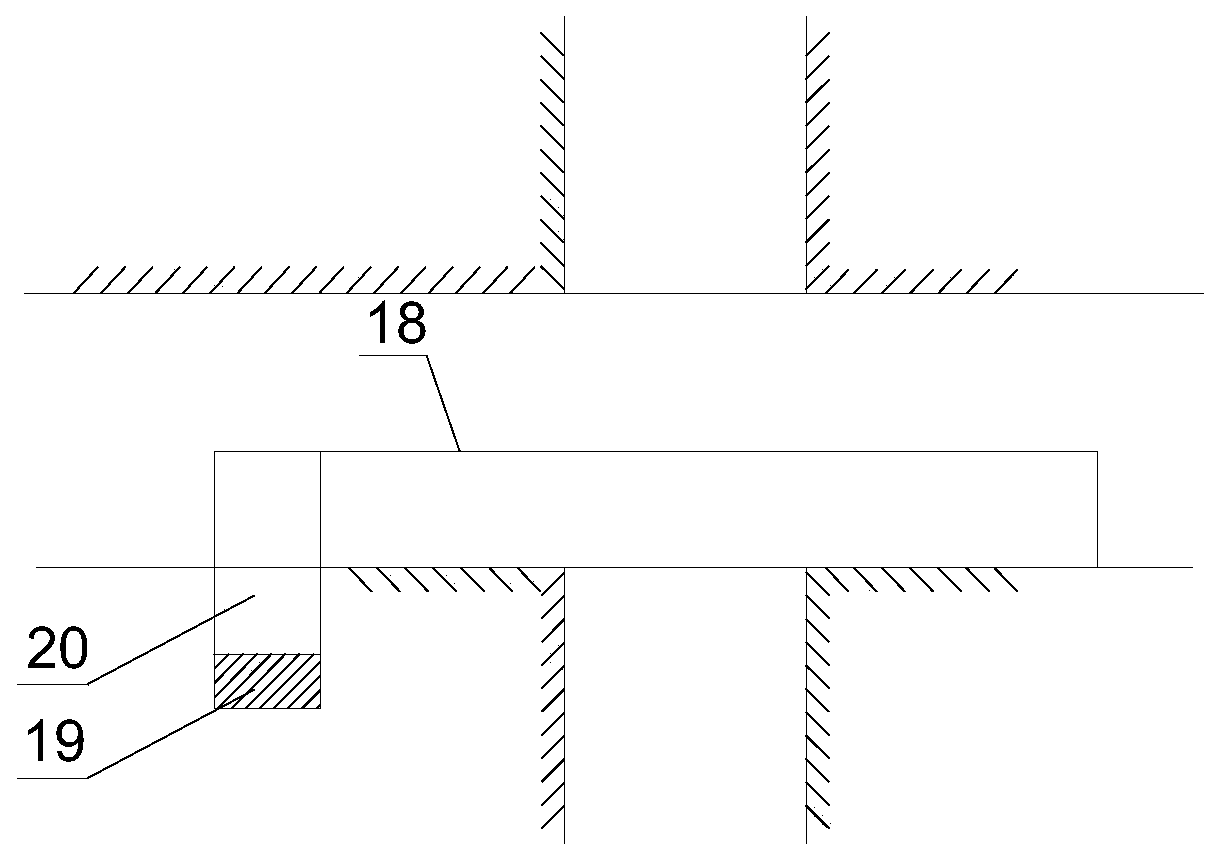

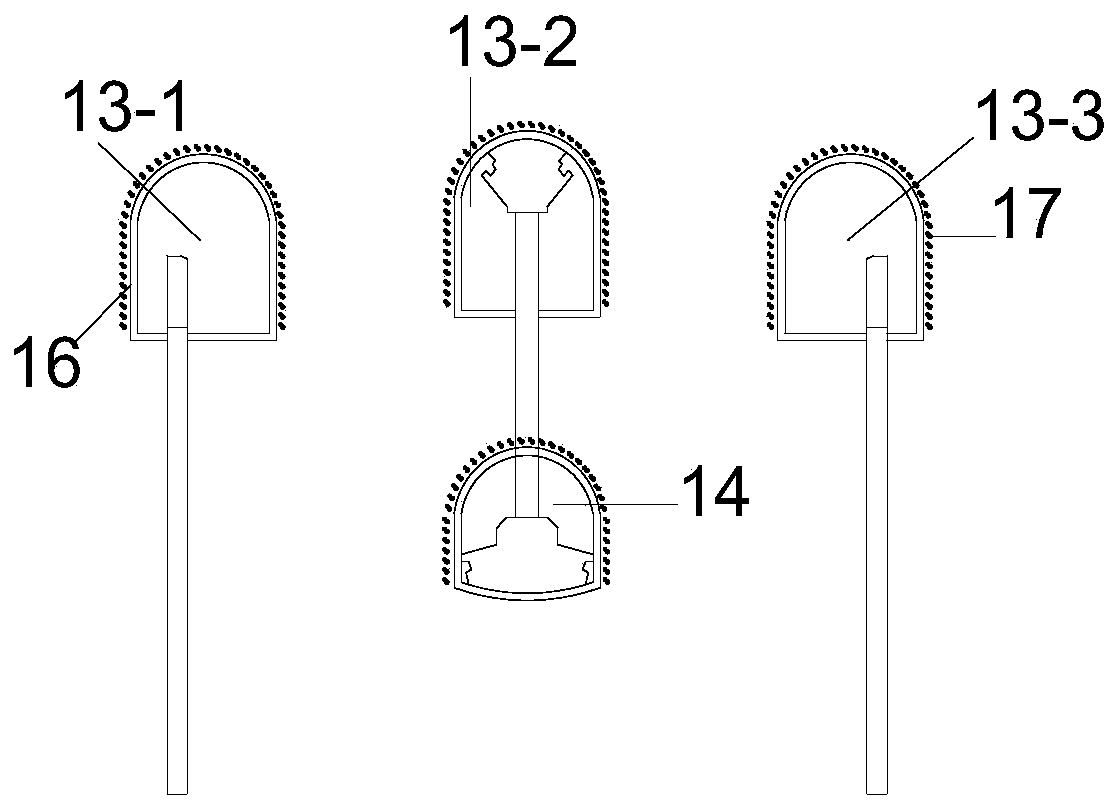

Design method of deeply-buried PBA subway station section

ActiveCN110566223ASolve comprehensive technical problemsSolving the challenges of groundwater treatmentUnderground chambersTunnel liningAccessory structureSubway station

The invention relates to a design method of a deeply-buried PBA subway station section. The design method includes the following steps that a, a void is detected; b, a composite anchor rod pile (14) is driven on the ground; c, a large pipe shed (4) is applied; d, small pilot tunnels (2 and 3) are constructed; e, grille arch centers for the small pilot tunnels (2 and 3) are erected; f, initial supporting is conducted on the inner parts of the small pilot tunnels (2 and 3), and then side piles (5 and 6) are applied in the small pilot tunnels (2 and 3) correspondingly; g, a main body arch part (1) is excavated, initial supporting is conducted, and a secondary lining structure (9) is poured by concrete; h, a soil mass of a lower main body center (10) is excavated; i, a bottom plate (11), a side wall (12) and a middle plate (13) of a lower secondary lining structure of the lower main body center (10) are constructed; and j, an accessory structure is applied, and a complete station structureis formed. According to the method, the construction safety, the construction quality and the construction period can be ensured, the cost can be saved, and the construction efficiency can be improved; and section structure design is reasonable, the overall structure is stable, construction is easy and convenient, and the use effect is good.

Owner:BEIJING NO 4 MUNICIPAL CONSTR ENG +1

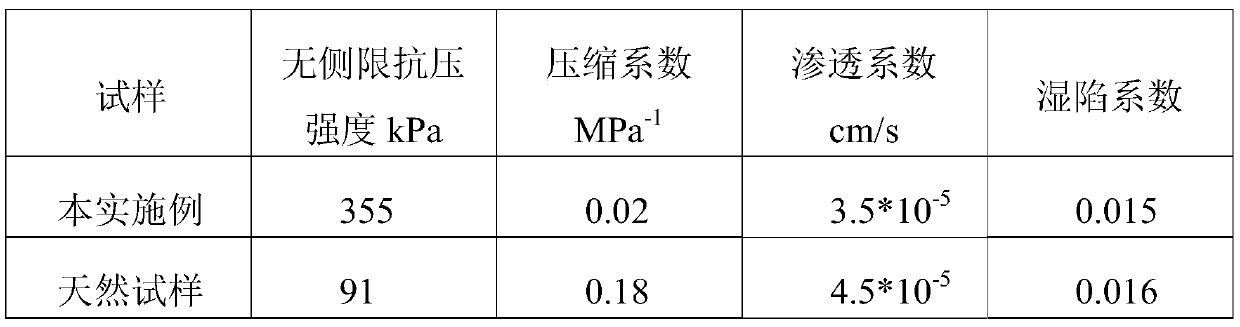

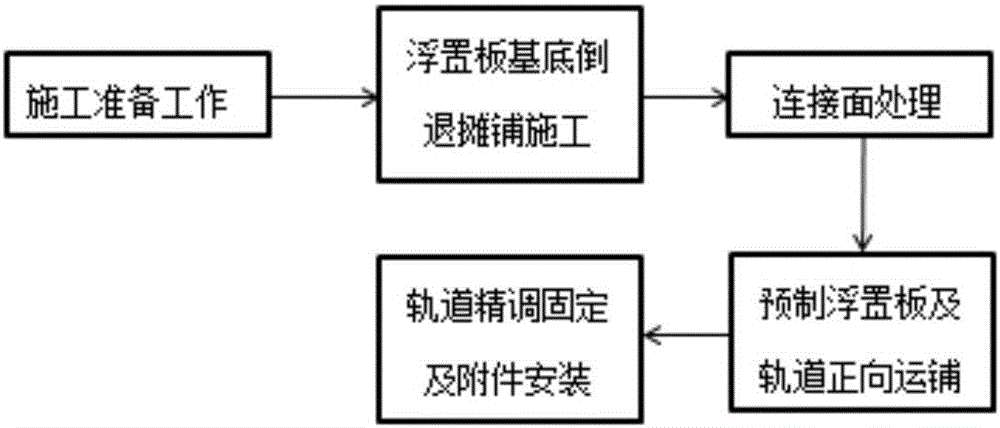

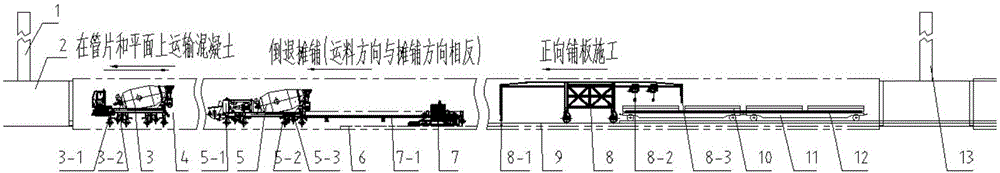

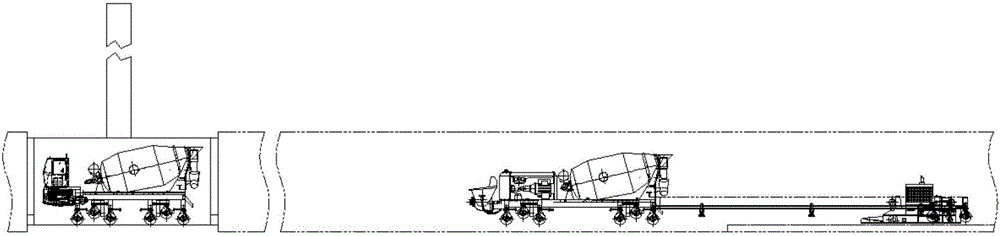

Construction method for plate ballast bed of metro

ActiveCN106758555AGuarantee the construction qualityReduce pouring work on siteBallastwayTruckMaterial storage

The invention relates to a construction method for a plate ballast bed of a metro. The method comprises the steps of a basement backward paving construction step, in which a truck mixer transports concrete from a front material feeding well segment to a material storage truck to and fro via a pump or a belt conveyer in a backward moving manner, the material storage truck moves backward to an area to be paved and discharges concrete, and a paver paves; and a plate pathway conveying and paving steps, in which a back pathway and floating plates are transported to a construction area by using a flatcar, a plate paver is used for sequentially discharging the floating plates from the flatcar and paving the same to a predetermined area; and then the pathway is discharged from the flatcar and paved on the floating plates. According to the method provided by the invention, building of a temporary pathway is not needed, the damage to tunnel segments caused by the temporary pathway when the temporary pathway is supported and fixed is reduced, and the construction speed is rapid; in a tunnel, both the truck mixer and the material storage truck can move on a plane as well as a hook face for conveying the concrete, so that the concrete transportation cost is low, and the adaptability is good; the backward paving construction can be operated with subsequent construction in parallel, so that the construction efficiency is high.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD +1

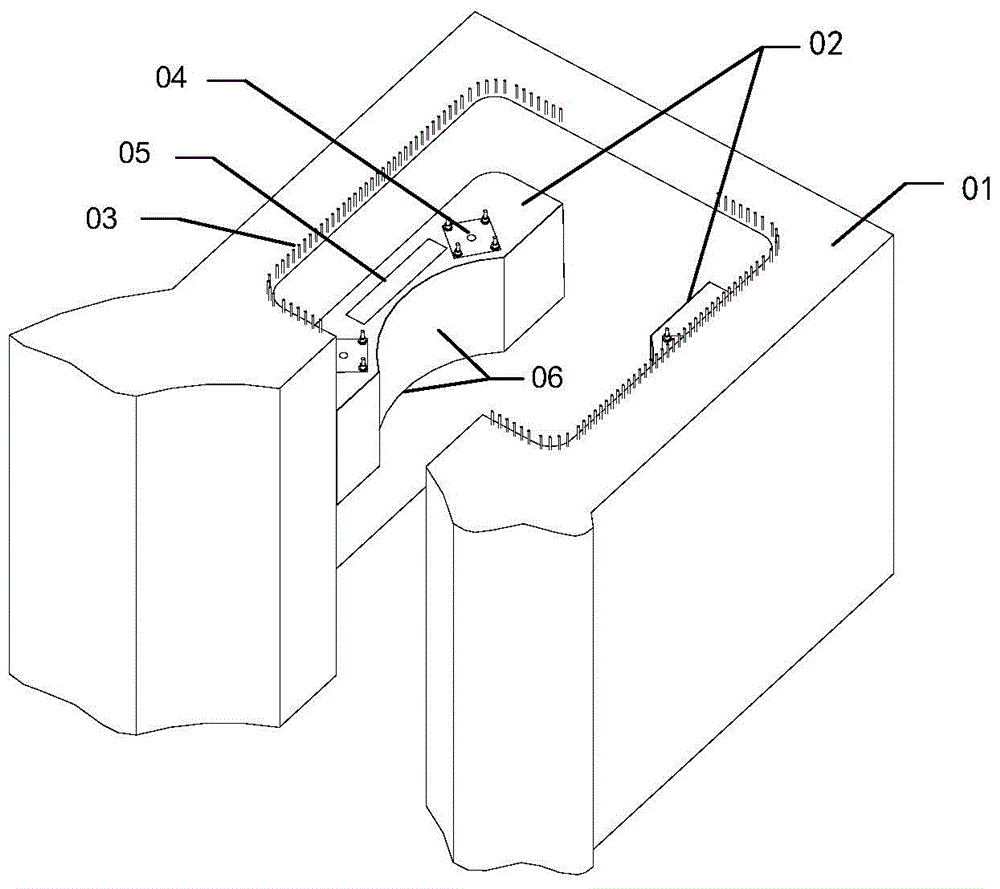

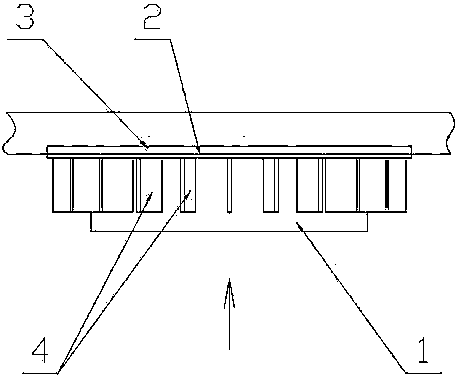

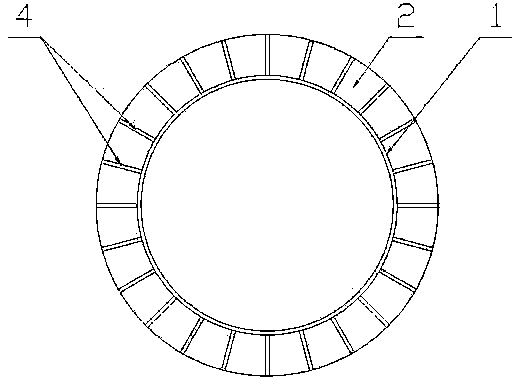

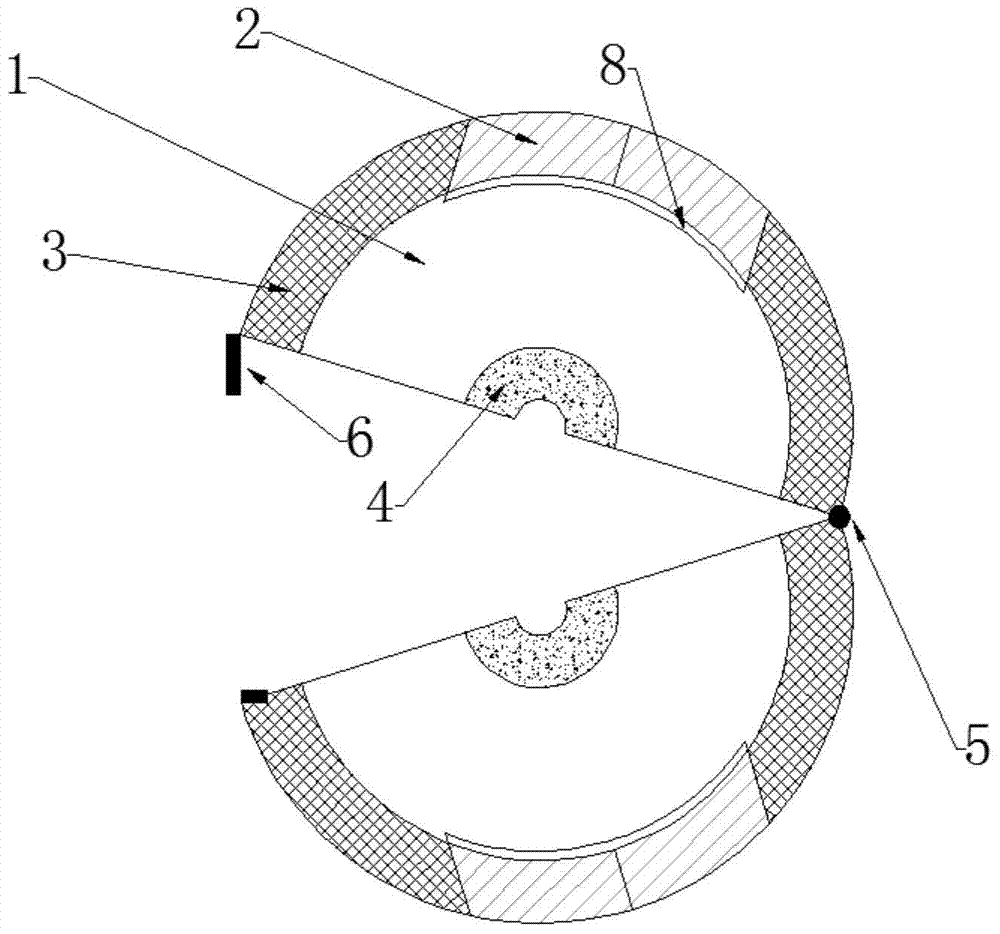

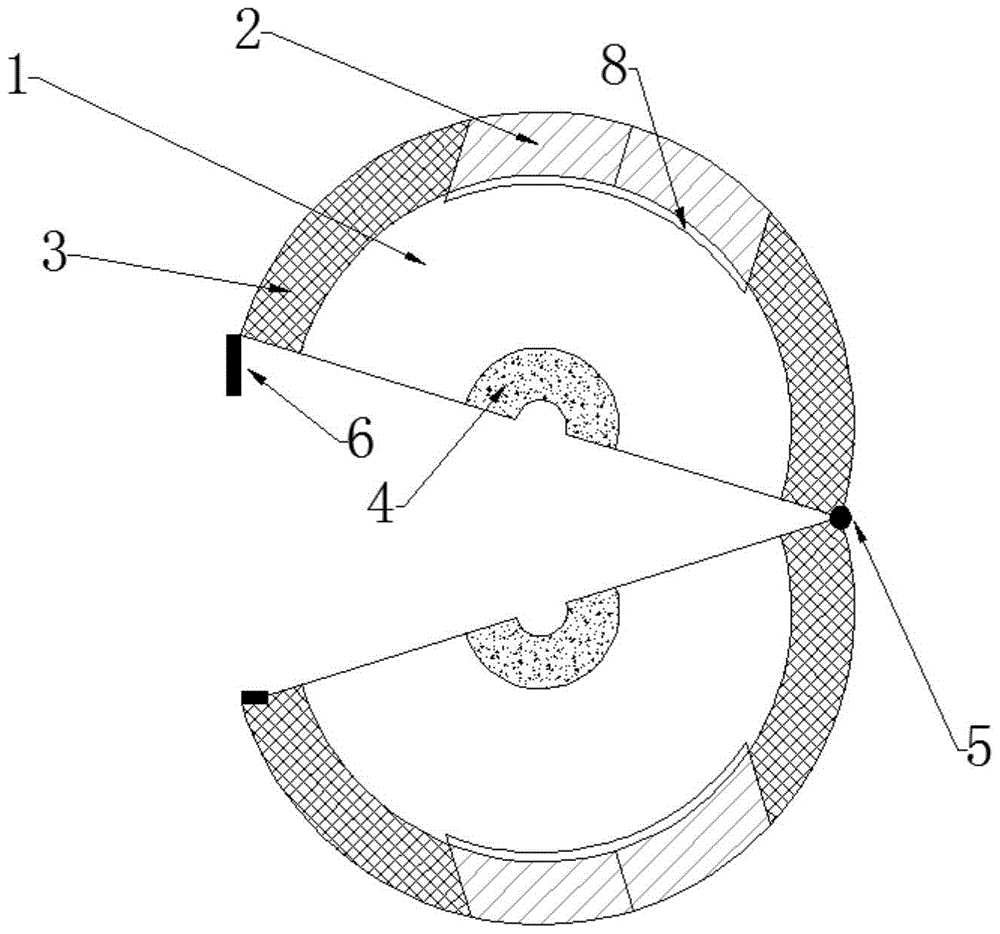

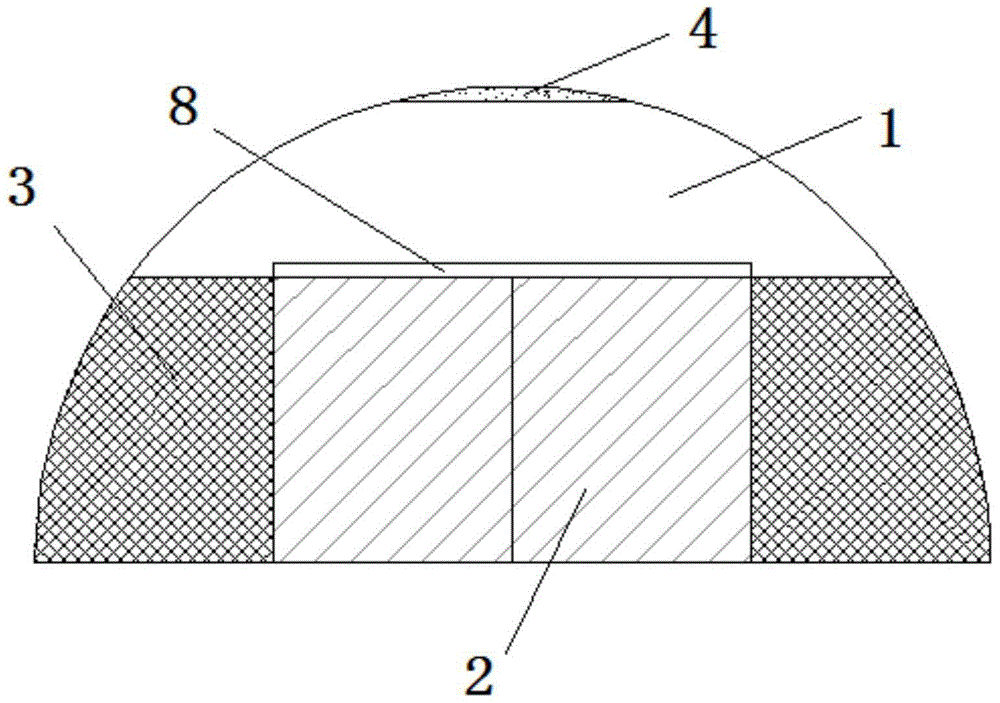

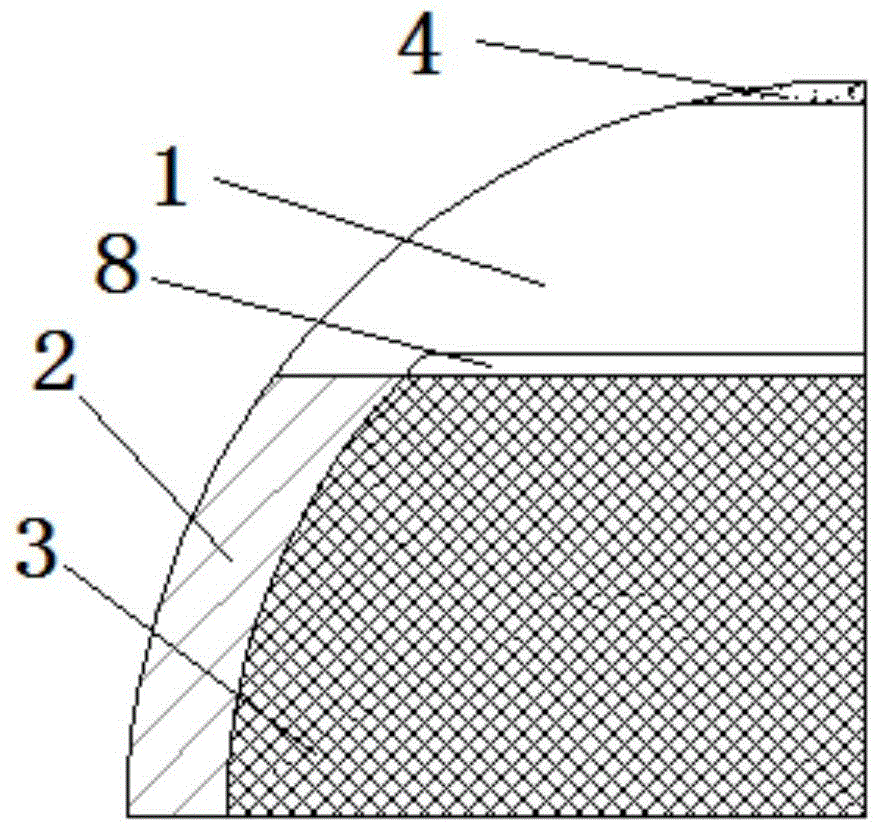

Shield starting tunnel portal extension steel ring

The invention discloses a shield starting tunnel portal extension steel ring. The shield starting tunnel portal extension steel ring is characterized in that the steel ring comprises a steel ring body (1) with the width of at least 45mm, one end of the steel ring body (1) is connected with a first ring plate (2), the internal diameter of the first ring plate (2) is equal to that of the steel ring body (1), the external diameter of the first ring plate (2) is larger than the diameter of the steel ring body (1), and a second ring plate (3) is fixedly connected with the first ring plate (2), twice as thick as the first ring plate (2) and embedded in the wall of a tunnel portal. The shield starting tunnel portal extension steel ring is simple in structure and skillful in design, avoids dust pollution caused by manual pile breaking and can improve working efficiency of a shield machine.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

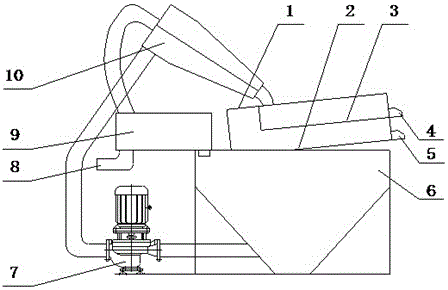

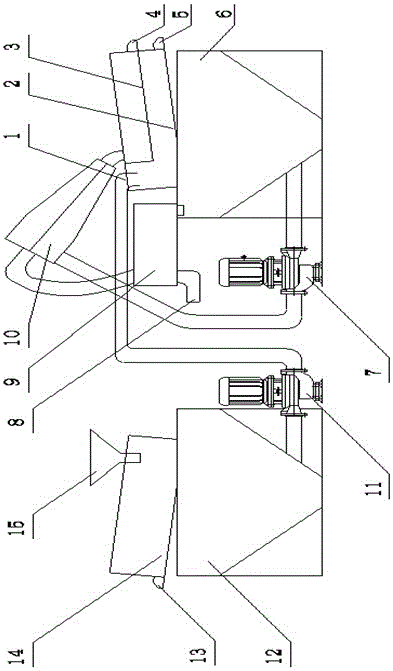

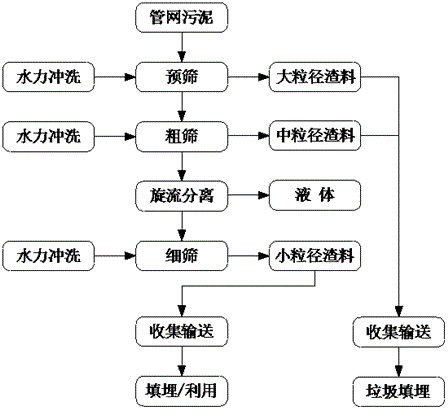

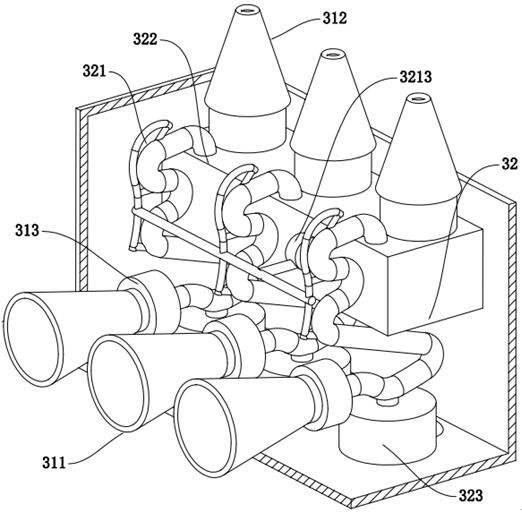

Sludge reduction treatment device and treatment method for city pipe network

PendingCN106830609AFully automated processingExtended service lifeSludge treatment by de-watering/drying/thickeningSewer systemsReduction treatmentSludge

The invention discloses a sludge reduction treatment device and treatment method for a city pipe network. According to the sludge reduction treatment device for the city pipe network, a fine material separation screen is located at the upper part of a coarse material separation screen; the fine material separation screen and the coarse material separation screen are overlapped up and down; the coarse material separation screen is provided with a mud inlet and a coarse material outlet and a slurry storage tank is arranged at the lower part of the coarse material separation screen; the slurry storage tank communicates with a cyclone separator through a high-pressure suction pump; the cyclone separator is arranged at the upper part of the fine material separation screen, the separated liquid enters a middle storage tank and the separated solid falls into the fine material separation screen from the bottom of the cyclone separator; a fine material outlet is arranged in the fine material separation screen; a water liquid passing through the fine material separation screen falls into the coarse material separation screen at the lower part and enters the slurry storage tank again; a liquid outlet is arranged in the middle storage tank; and the middle storage tank communicates with the slurry storage tank through a floating ball liquid switch. The sludge reduction treatment device is compact in structure and high in treatment flow efficiency according to the treatment principle of solid-liquid separation from coarse to fine; and full-automatic treatment of the sludge of the city pipe network is achieved.

Owner:ANHUI JIAMING ENVIRONMENTAL PROTECTION TECHCO

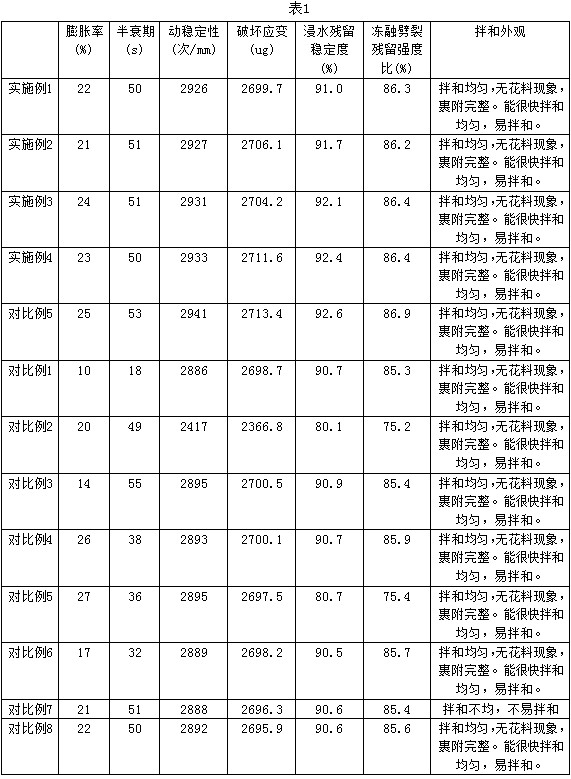

Foamed asphalt warm-mixing mixture and preparation method thereof

ActiveCN111960730ASave resourcesImprove dispersion uniformitySolid waste managementFoaming agentAsphalt pavement

The invention discloses a foamed asphalt warm-mixing mixture and a preparation method thereof, and belongs to the field of asphalt mixtures. The preparation method comprises the following steps: heating 1-6 parts of matrix asphalt to 140-160 DEG C, and adding water which is 0.8-1.5% of the mass of the asphalt and contains a foaming agent and a stabilizer to obtain foamed asphalt; b, mixing 10-40 parts of waste cement concrete recycled aggregate and 20-80 parts of an old asphalt pavement material and stirring for 40-90 s at the temperature of 95-130 DEG C; then adding the foamed asphalt, and stirring for 40 to 90s at 130 to 140 DEG C; and finally, adding 2-20 parts of mineral powder, and mixing for 40-90 s at the temperature of 95-130 DEG C. According to the invention, the discharge amountof harmful gas and dust can be greatly reduced, the energy consumption in the production process can be reduced, the aging of the asphalt cement in the production process can be reduced, and the pavement performance of the mixture can be improved.

Owner:THE 5TH CONSTR COMPANY LTD OF CHINA RAILWAY 15TH BUREAU GRP

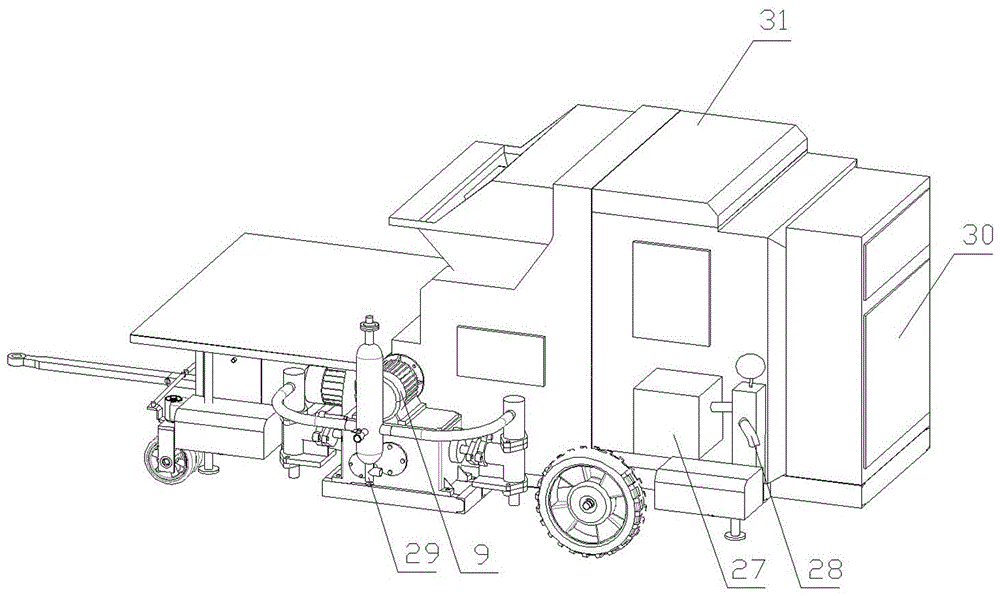

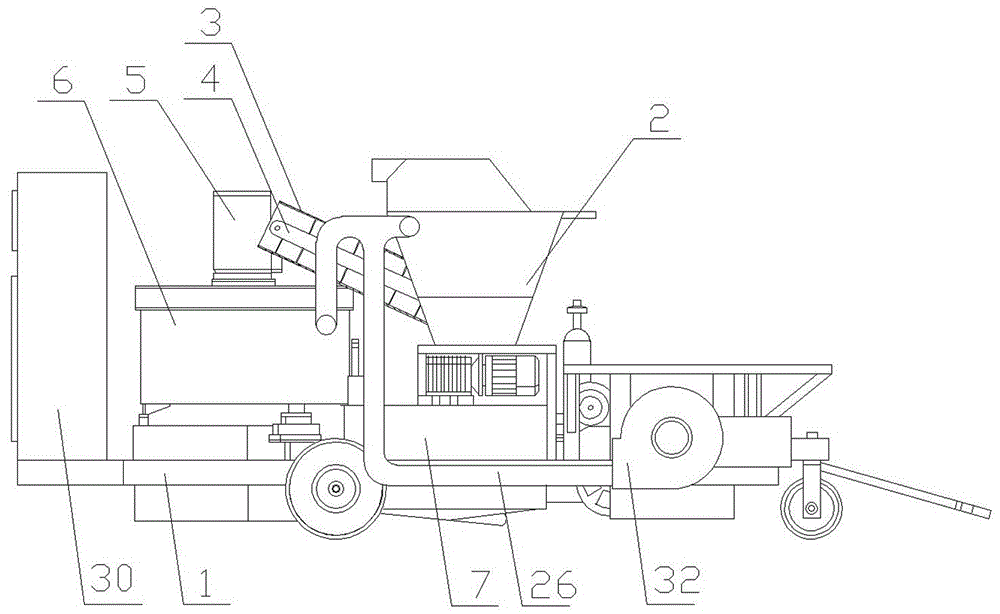

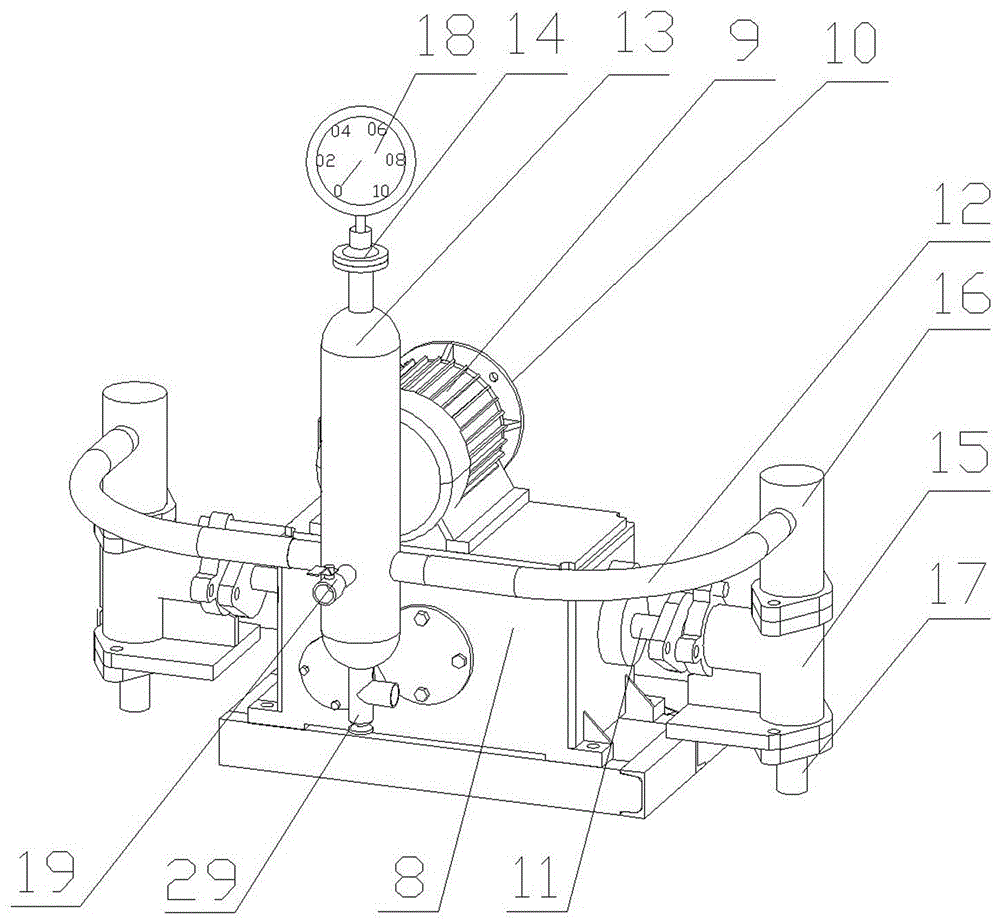

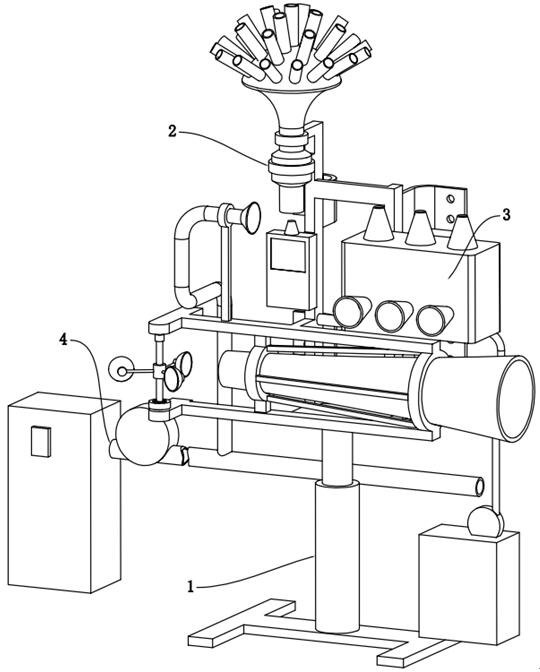

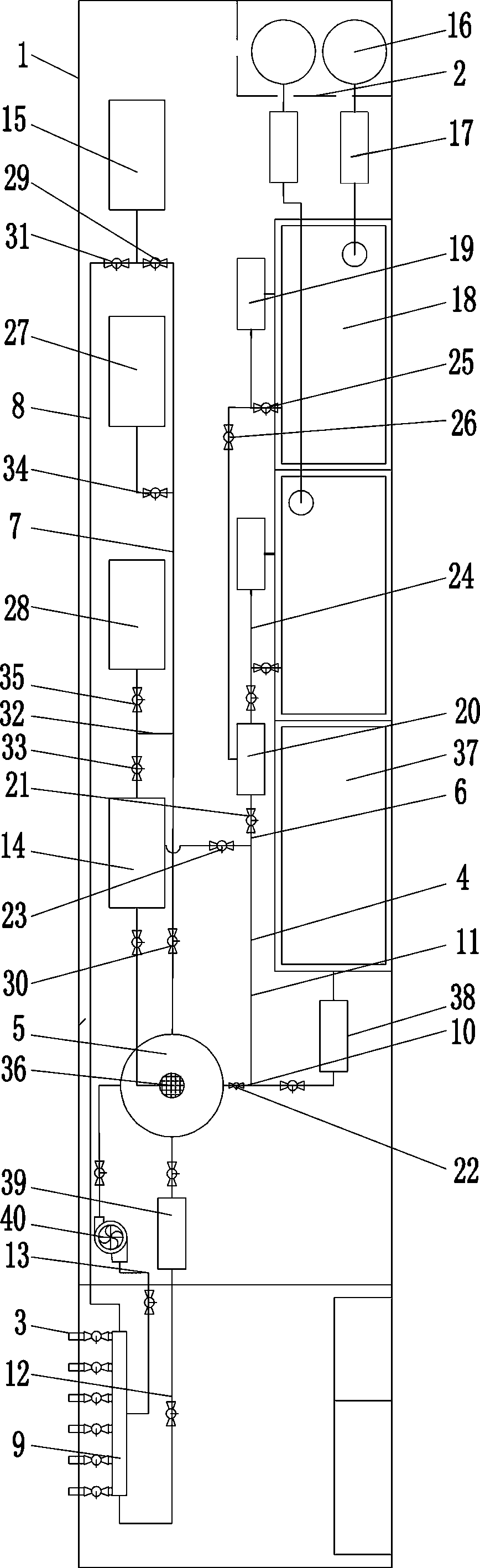

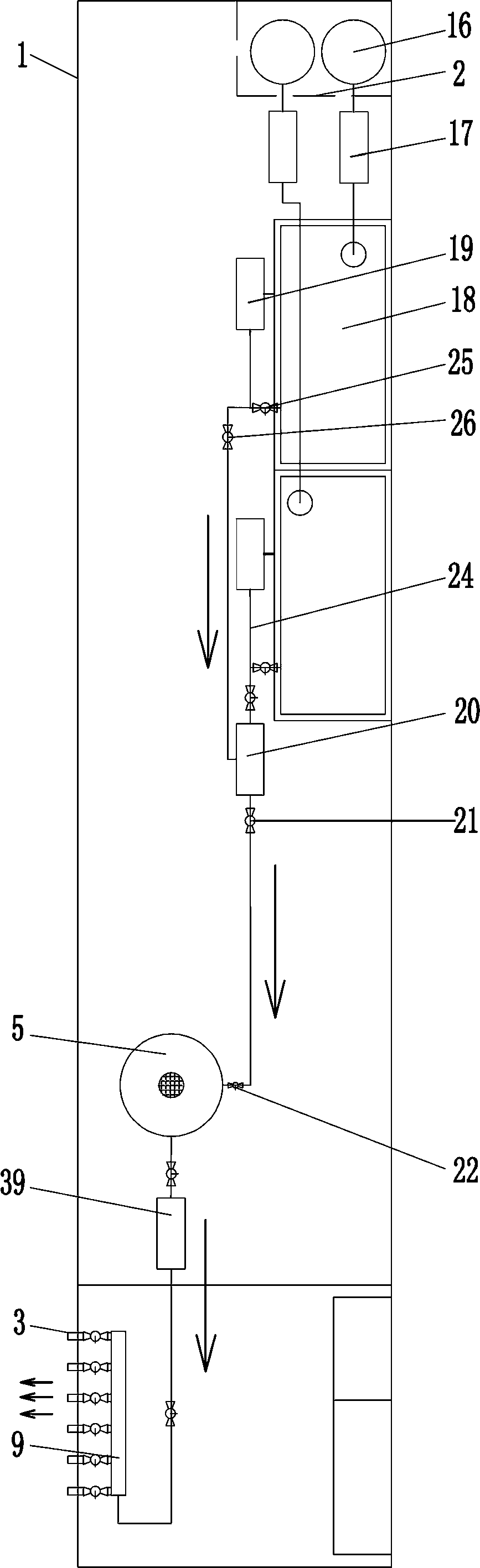

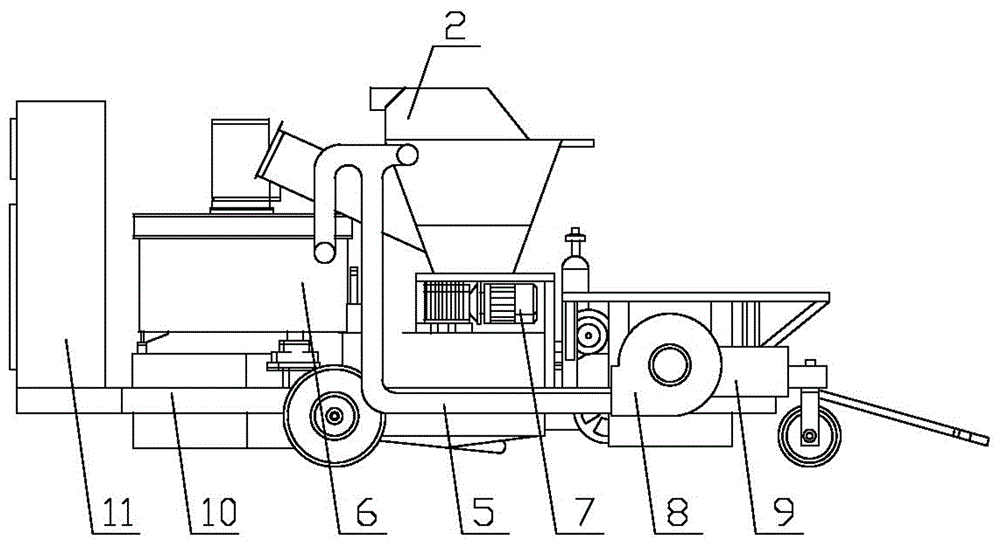

Auxiliary vacuumizing and automatic mud jacking integrated machine for railways

ActiveCN106436582AEasy to operateHigh degree of controlBridge erection/assemblyAutomatic controlLow speed

The invention discloses an auxiliary vacuumizing and automatic mud jacking integrated machine for railways. The auxiliary vacuumizing and automatic mud jacking integrated machine for railways comprises a rack, an automatic mud jacking system and a vacuumizing system, wherein the automatic mud jacking system and the vacuumizing system are arranged on the rack. The automatic mud jacking system comprises a feeding system, a high-speed and low-speed stirring system, a static weighing system, a mud jacking and pressure stabilizing system, an environmental protection dust removal system, an automatic control system, a data storage and transmission system, an equipment self-inspection system, a cleaning system and an alarm system. By means of the novel vacuumizing and automatic mud jacking integrated machine, the purpose of conducting vacuumizing and mud jacking work at the same end of a pipeline is achieved, one-key operation of the work is achieved by adopting the uniform central control system, operation control is simplified, the automatic operation and control degree of the vacuumizing and mud jacking work are improved, accurate feeding and weighing, stable and continuous mud jacking and controllable flow are achieved, plumpness of mud in the pipeline can be guaranteed, and the whole construction process is environmentally friendly and free of pollution.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

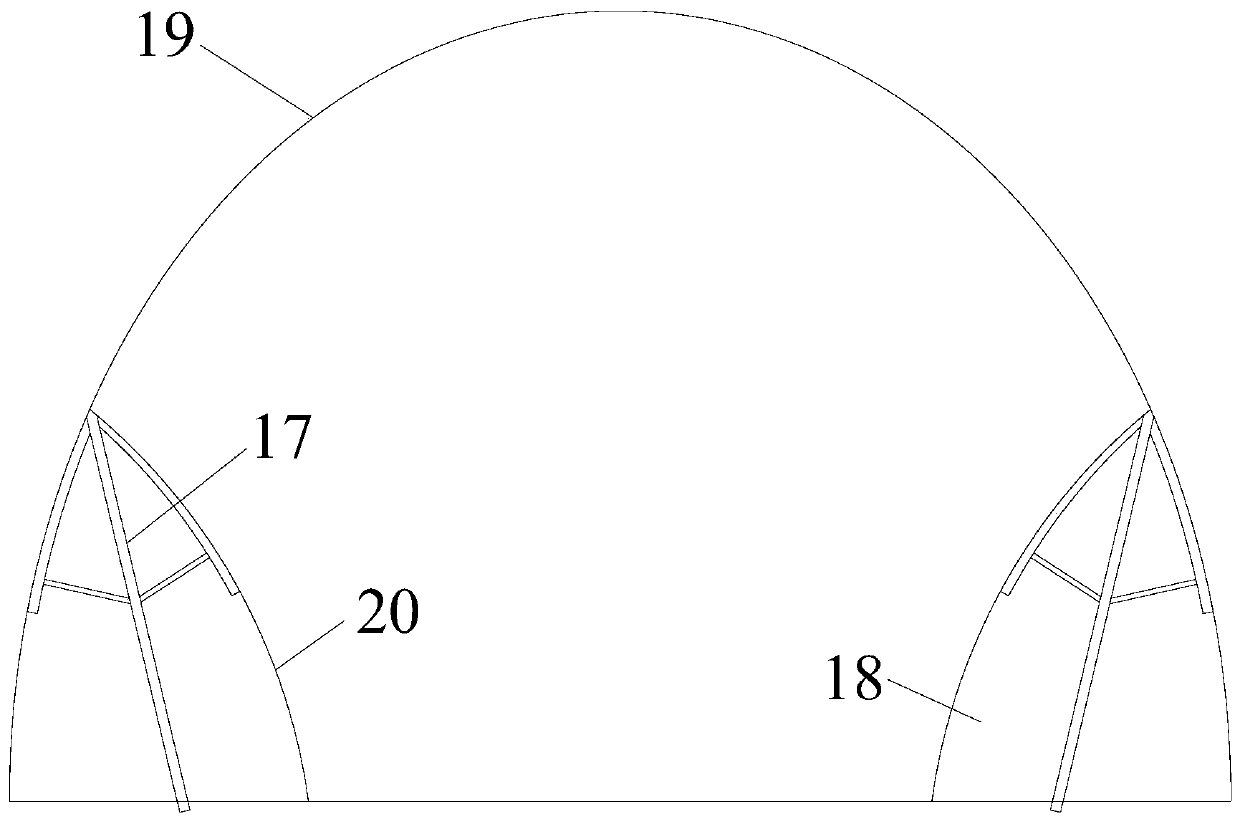

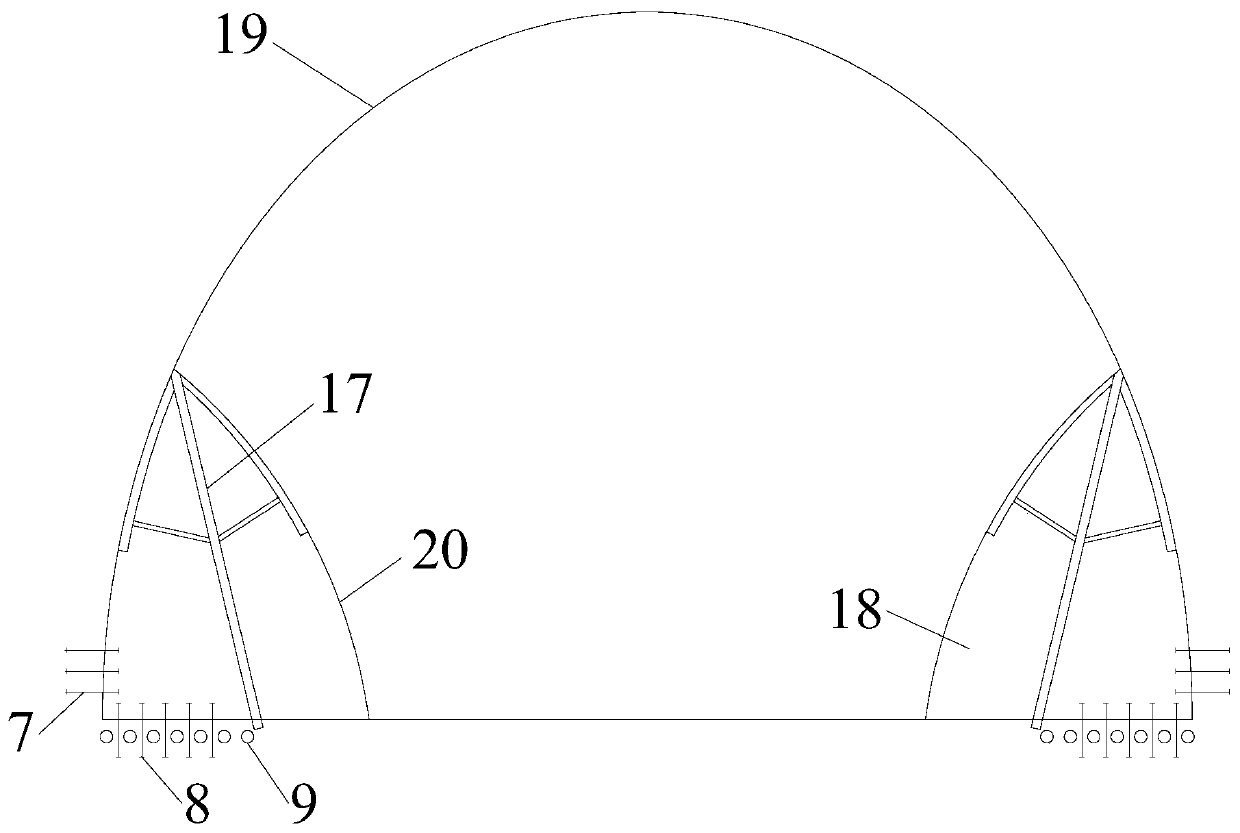

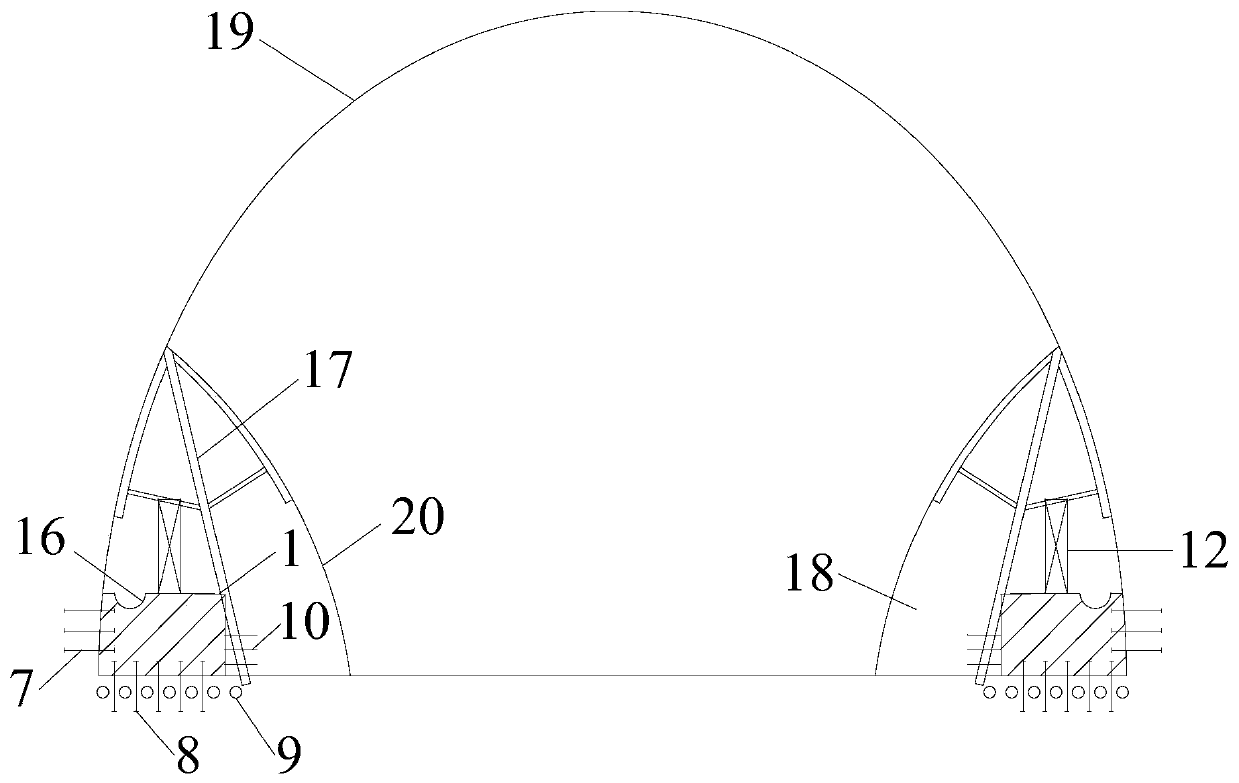

Novel tunnel initial support structure and construction method

ActiveCN111119928AGuaranteed stabilitySimple structureUnderground chambersDrainageReinforced concreteArchitectural engineering

The invention relates to a novel tunnel initial support structure. The novel tunnel initial support structure includes a support foundation, a connecting type steel column, a steel arch, a steel plate, micro-expansion fine stone concrete and quick-setting fine stone concrete; the support foundation is cast-in-place reinforced concrete structure, the connecting type steel column is located on the support foundation, lateral anchoring ribs are arranged on the adjacent sides, close to the contour line of a tunnel, of the support foundation and the support foundation is anchored in the outer stratum of the tunnel, inverted arch reserved ribs are reserved on the outer side surface of the support foundation, and the support foundation is provided with grooves for placing water collecting pipes;the steel arch and the connecting type steel column are connected by bolts or welding; the steel plate is a light and thin straight-surface steel plate or corrugated steel plate, and the steel plate and the steel arch are connected by welding and units of the steel plate are connected by welding. The novel tunnel initial support structure has beneficial effects that compared with a traditional initial support structure, the structure of the novel tunnel initial support structure is relatively simple, the implementability is better, the micro-expansion fine stone concrete filled tunnel excavation surface plays a certain backpressure role, and stability of the tunnel excavation surface can be ensured.

Owner:ZHEJIANG ZHENGFANG TRAFFIC CONSTR CO LTD

An elastic felt hanging method for a large full-containment low-temperature storage tank

ActiveCN105952008AAvoid accessImprove ventilationHeat proofingBulk storage containerHanging basketClerestory

The invention provides an elastic felt hanging construction method for a large full-containment low-temperature storage tank. The method comprises the steps of 1) building a material platform, lifting materials to the material platform and carrying the materials to a suspended roof floating plate in a tank; 2) installing an electric hanging basket on a vault guide rail; 3) establishing a support on the suspended roof floating plate; 4) installing pulleys and a guide chain on the vault guide rail; 5) prefabricating elastic felt modules; 6) installing heat preservation nails; 7) installing clamping plates; 8) winding glass cloth; 9) installing a hanging hook, a temporary hanging hook and temporary clamping plates; 10) pushing one elastic felt module and stops pushing with a remaining length being 5-6m; 11) hitching the temporary hanging hook to the guide chain and slowly pushing the remaining part of the elastic felt module; 12) moving the pulleys and moving the elastic felt module to a predetermined position of a tank wall; 13) dismounting the temporary clamping plates, ropes and the temporary hanging hook and finishing formal hanging on the tank wall; 14) successively hoisting and conveying the other elastic felt modules to predetermined positions, dismounting temporary clamping plates, ropes and temporary hanging hooks, making the elastic felt modules abut on the adjacent properly-installed elastic felt modules and finishing formal hanging on the tank wall; 15) tying ropes to rope holes of the clamping plates and the corresponding tank bottom concrete ring beam pre-buried pull ring; completing the hanging construction.

Owner:SINOPEC NINGBO ENG +2

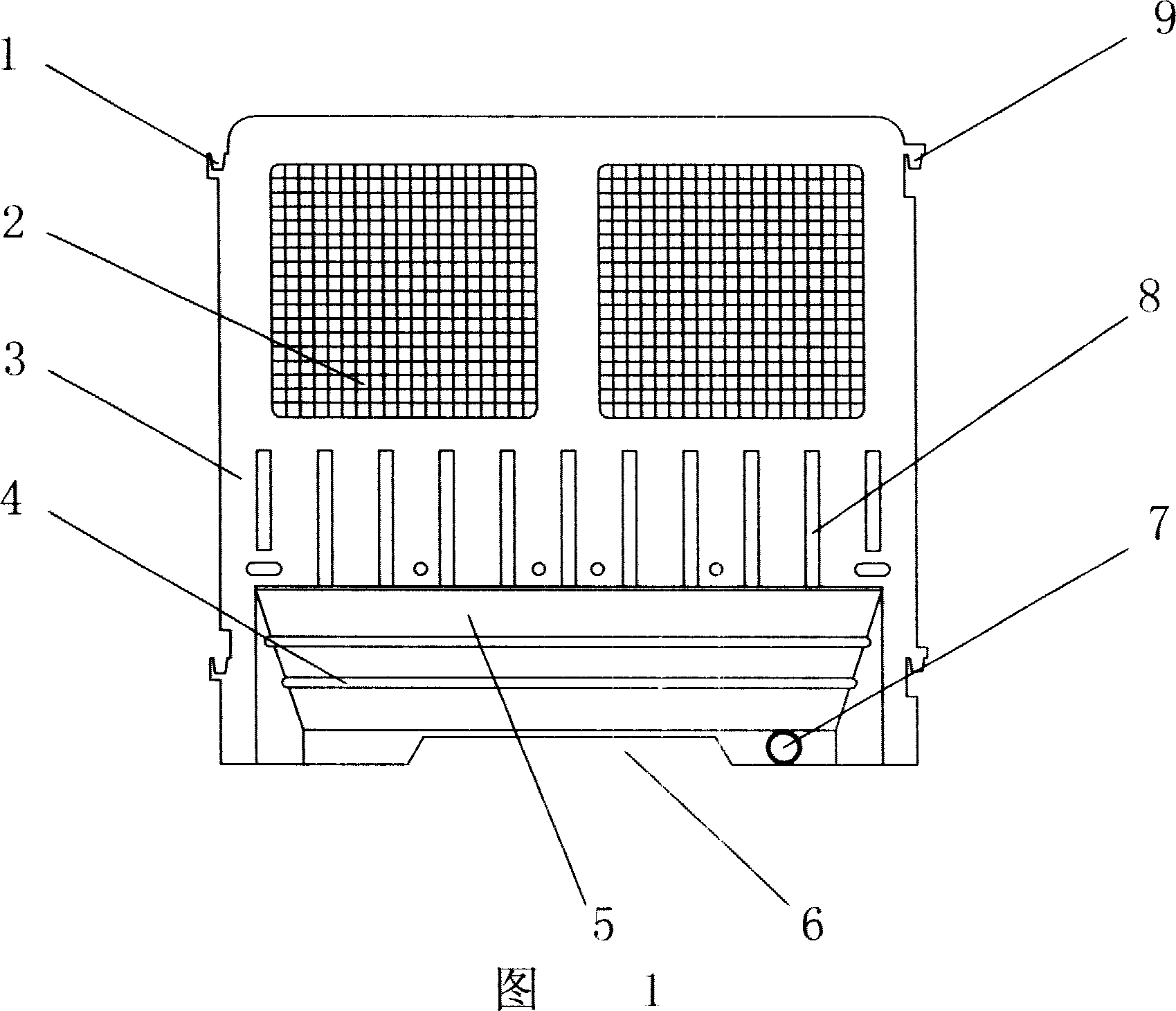

Oriented dust-exhaust dust-fall cover of high pneumatic DTH (Down-The-Hole) drill

The invention discloses an oriented dust-exhaust dust-fall cover of a high pneumatic DTH (Down-The-Hole) drill. The directional dust-exhaust dust-fall cover comprises a dust fall cover, a filter screen and a dust exhaust oriented plate; the dust-fall cover comprises left and right parts which are completely symmetric to each other, the upper part of the dust-fall cover is provided with an airtight piece, and a gridding hollow part is arranged all around the lower part of the dust-fall cover; the filer screen is arranged in the dust-fall cover, and the outer surface of the gridding hollow part covers the movable dust exhaust oriented plate; one sides of the left and right parts of the dust-fall cover are provided with a rotating shaft, the left and right parts are connected through the rotating shaft, and the other sides of the left and right parts of the dust-fall cover are provided with clamping bolts. According to the oriented dust-exhaust dust-fall cover provided by the invention, the effective control of the dust of the high pneumatic DTH drill can be realized, the strong anti-interference to wind can be realized, the dust diffusion can be realized, a worker can be prevented from sucking excessive dust, and the construction environment can be improved; the device is simple to operate, low in price and environmental-friendly in material, and is likely to be maintained, thereby being applicable to various drilling and construction environments, especially applicable to the operation of a windy wild drilling machine.

Owner:SHANDONG UNIV +2

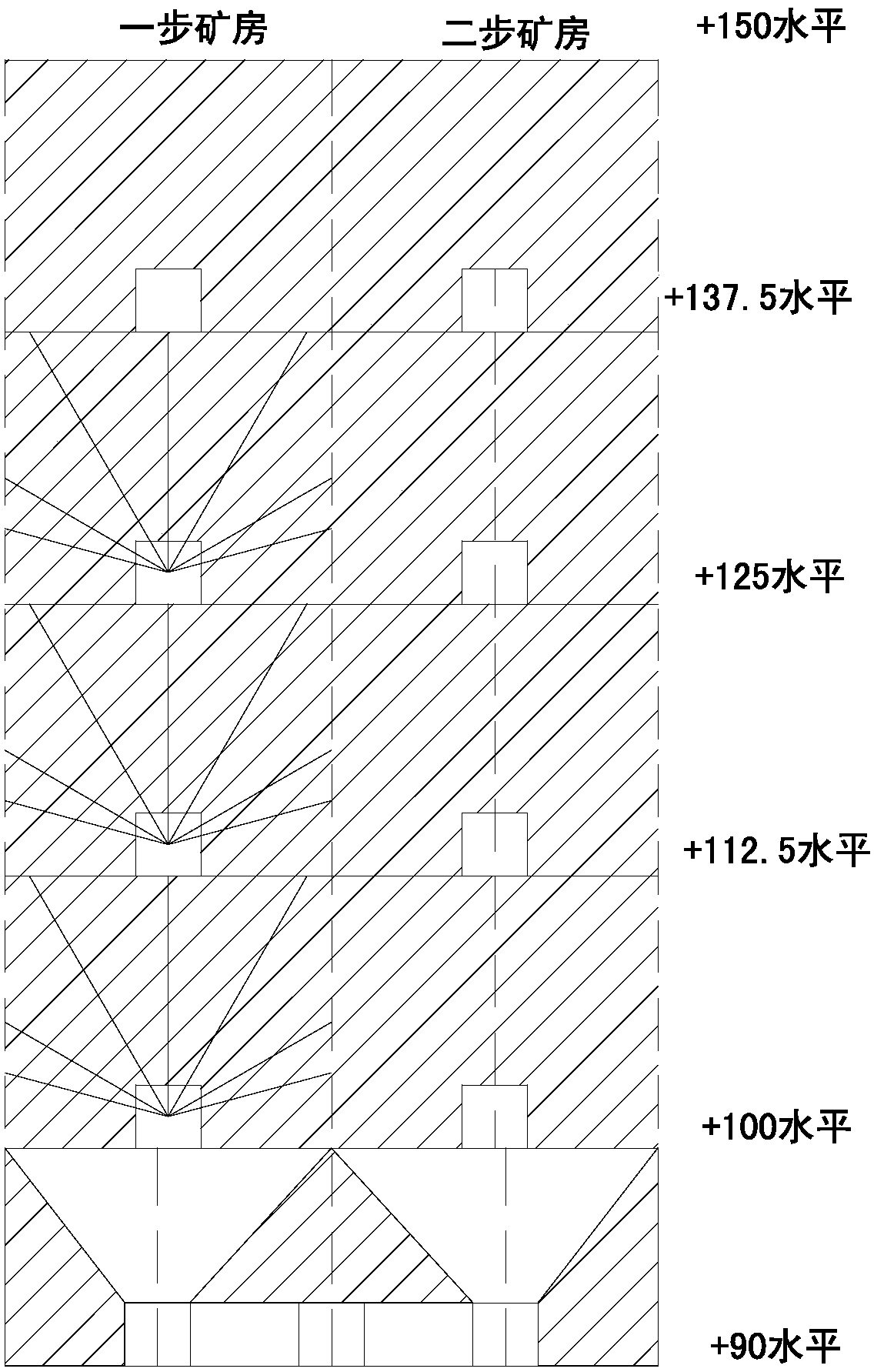

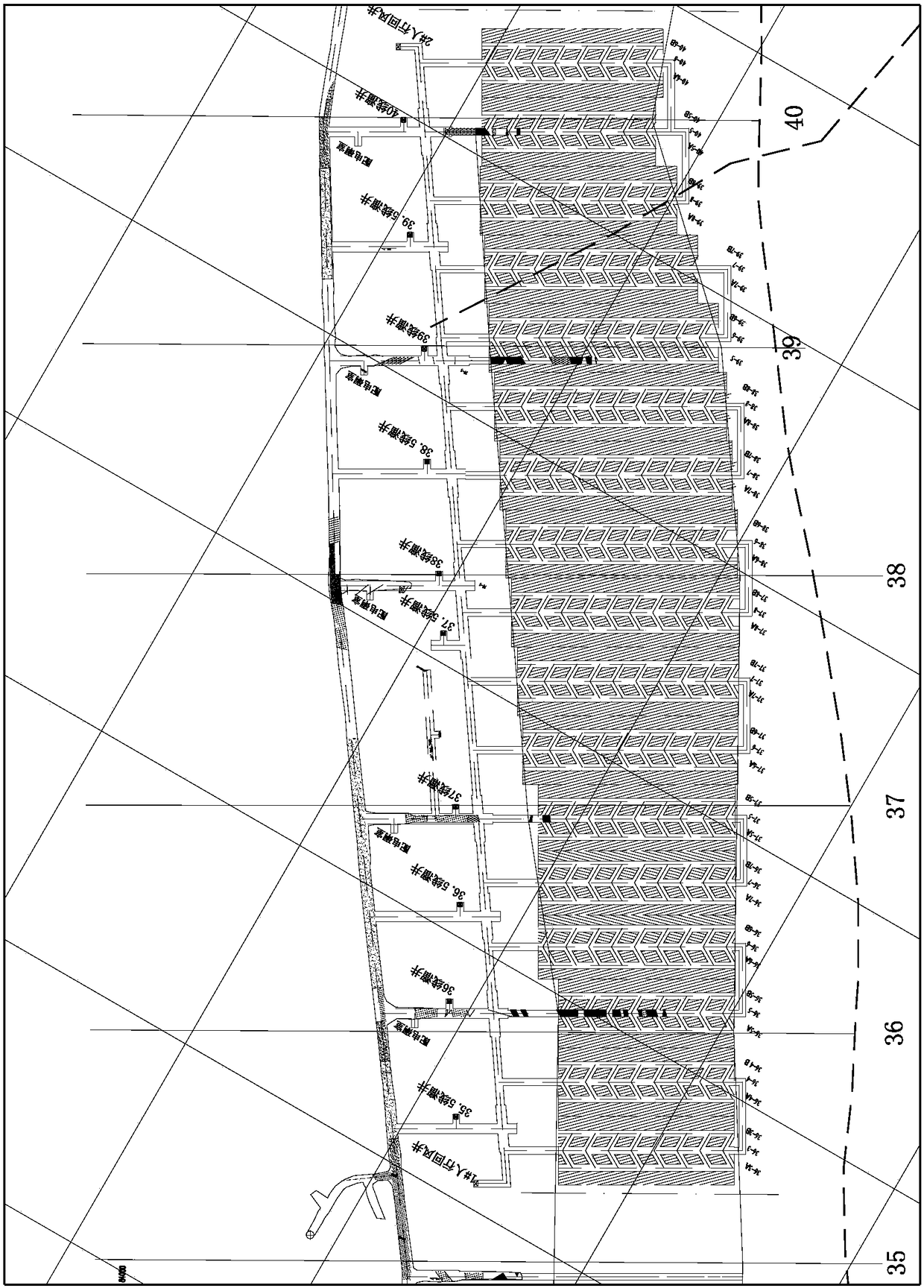

Sublevel open subsequent filling stoping method

InactiveCN109403972AImprove the construction work environmentReduce manufacturing costUnderground miningSurface miningArchitectural engineeringBuilding construction

The invention relates to a sublevel open subsequent filling stoping method, belongs to the field of mining engineering and is particularly applicable to ore bodies with large and continuous dip anglesand larger thickness. An optimization technology of the sublevel open subsequent filling stoping method is provided, the problem that mining engineering construction is operated in spaces with largeropen roof areas is solved, mining operators can always perform construction in roadways instead of entering large gobs for operation by changing a traditional mining method, so that a better construction operation environment is created, and the production cost is reduced.

Owner:SHANDONG HUALIAN MINING

A directional dust-exhausting and dust-reducing cover for a high-pressure down-the-hole drilling rig

The invention discloses an oriented dust-exhaust dust-fall cover of a high pneumatic DTH (Down-The-Hole) drill. The directional dust-exhaust dust-fall cover comprises a dust fall cover, a filter screen and a dust exhaust oriented plate; the dust-fall cover comprises left and right parts which are completely symmetric to each other, the upper part of the dust-fall cover is provided with an airtight piece, and a gridding hollow part is arranged all around the lower part of the dust-fall cover; the filer screen is arranged in the dust-fall cover, and the outer surface of the gridding hollow part covers the movable dust exhaust oriented plate; one sides of the left and right parts of the dust-fall cover are provided with a rotating shaft, the left and right parts are connected through the rotating shaft, and the other sides of the left and right parts of the dust-fall cover are provided with clamping bolts. According to the oriented dust-exhaust dust-fall cover provided by the invention, the effective control of the dust of the high pneumatic DTH drill can be realized, the strong anti-interference to wind can be realized, the dust diffusion can be realized, a worker can be prevented from sucking excessive dust, and the construction environment can be improved; the device is simple to operate, low in price and environmental-friendly in material, and is likely to be maintained, thereby being applicable to various drilling and construction environments, especially applicable to the operation of a windy wild drilling machine.

Owner:SHANDONG UNIV +2

Throttling expansion type gas dynamic and static exchange detection and treatment device for underground coal mine

PendingCN114592915AReduce the risk of manual inspectionReduce riskMining devicesDust removalProcess engineeringEnvironmental engineering

The invention discloses an underground coal mine throttling expansion type gas dynamic and static exchange detection and treatment device which comprises a positioning frame, a dynamic and static exchange type gas ventilation detection mechanism, a throttling expansion type environment treatment mechanism and a negative pressure recovery mechanism. The dynamic and static exchange type gas ventilation detection mechanism, the throttling expansion type environment treatment mechanism and the negative pressure recovery mechanism are fixedly arranged on the side wall of the positioning frame. The invention belongs to the technical field of coal mine safety equipment, and particularly provides a throttling expansion type gas dynamic and static exchange detection and treatment device for an underground coal mine, which applies a reverse action principle to detection of a mine roadway ventilation effect and gas accumulation, remarkably reduces human input and gas detection risks, and improves the detection efficiency. The automation degree and the detection accuracy of equipment are improved; the intermediary principle and the throttling expansion effect are applied to dust falling treatment and environmental management of the mine laneway, the probability of accidents caused by dust accumulation of a mine is remarkably reduced, and the working environment of the mine is improved.

Owner:HUATING COAL GRP

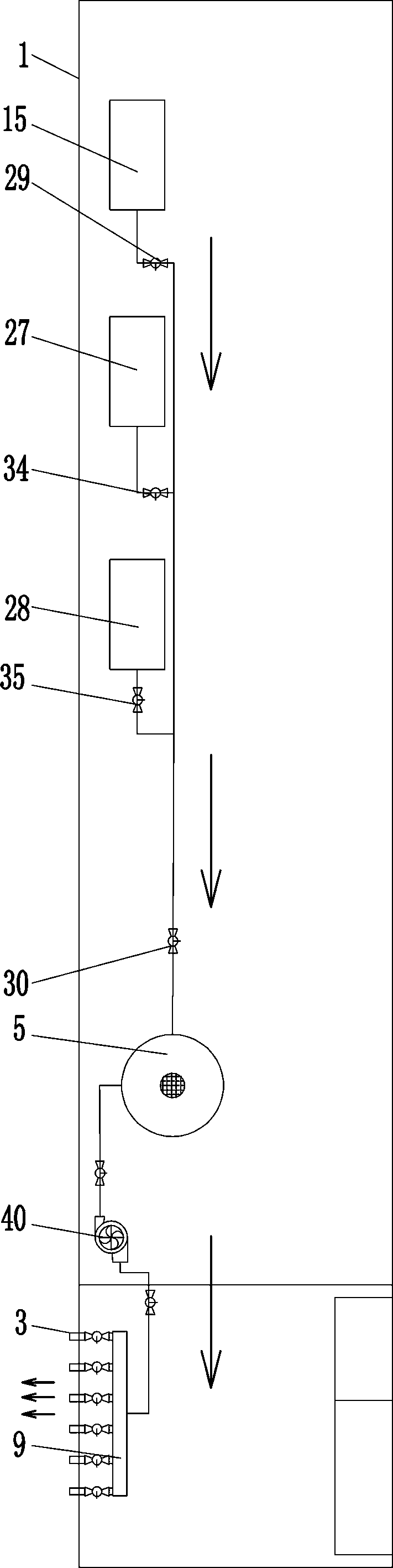

Soil/underground water integrated injection system and single-source, double-source and mixed micro-nano bubble liquid injection method thereof

ActiveCN111360060AFacilitated DiffusionStable and uniform high-pressure injectionMixing methodsTransportation and packagingInjection wellGroundwater

The invention relates to a soil / underground water integrated injection system and a single-source, double-source and mixed micro-nano bubble liquid injection method thereof. A medicament configurationunit, an air supply unit and a water supply unit, which are controllably connected through different channels, are arranged in a container body and controllably connected to an injection buffer and an injection distributor, and a controller is used for controlling opening and closing of all the channels under different requirements to complete injection operation of water / medicament / air, micro-nano bubble water and mixed micro-nano bubble liquid. The system is mainly used for repairing polluted sites and underground water, can be applied to polluted sites of various geologies, has a strong medicament mixing performance, can perform various remediation operations on the polluted regions such as liquid injection, liquid-gas injection, aeration, and the like, can dredge an injection well, issuitable for polluted sites of various geologies , has the advantages of mobility, efficiency, long service life, high safety in construction process, good construction and operation environment, andthus has a good application prospect.

Owner:中节能大地(杭州)环境修复有限公司

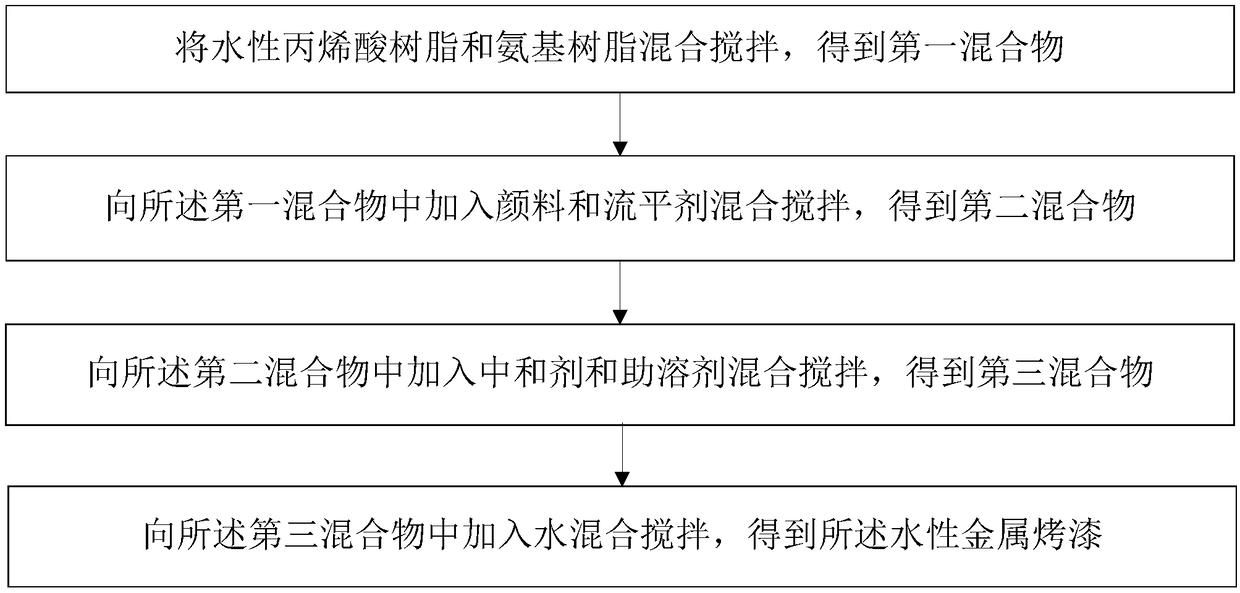

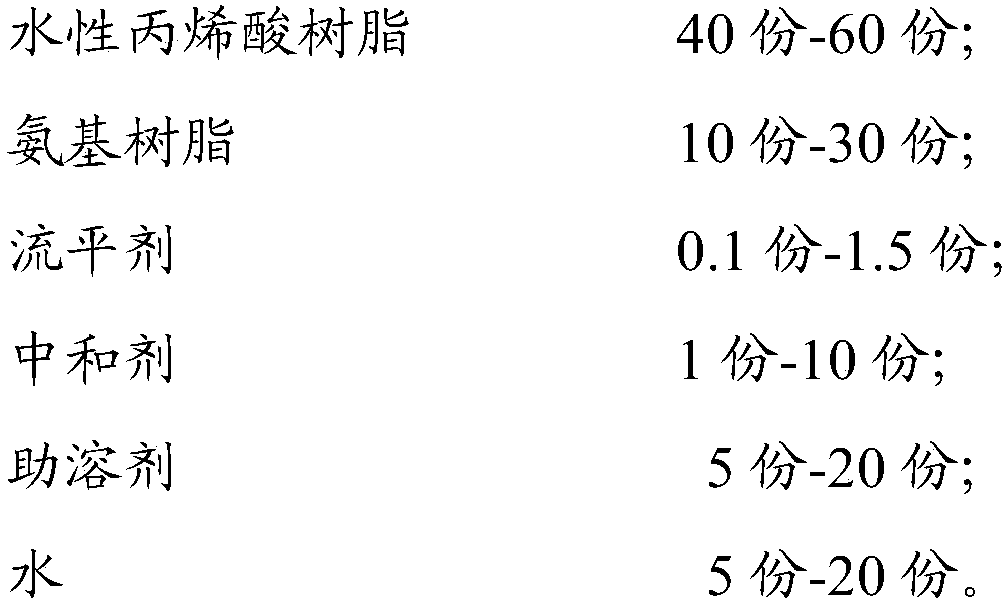

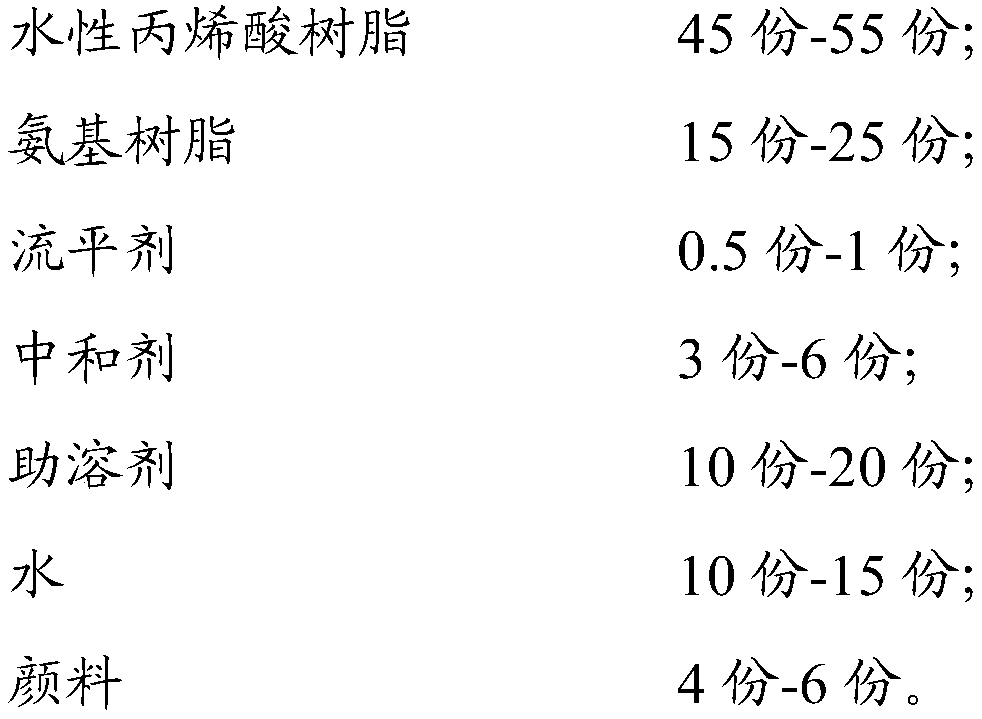

Aqueous metal baking varnish and preparation method thereof

The invention relates to an aqueous metal baking varnish and a preparation method thereof, wherein the aqueous metal baking varnish comprises, by mass, 40-60 parts of an aqueous acrylic resin, 10-30 parts of an amino resin, 0.1-1.5 parts of a leveling agent, 1-10 parts of a neutralizing agent, 5-20 parts of a cosolvent, and 5-20 parts of water. According to the present invention, the film formingsubstance is formed by using 40-60 parts of the aqueous acrylic resin and 10-30 parts of the amino resin, and is subjected to the cross-linking reaction under the high temperature baking during the use so as to form the continuous phase on the metal surface, such that the decoration and protection effect is provided for the metal surface, the characteristics of high adhesion, high hardness, salt spray resistance, boiling resistance, wear resistance and the like can be achieved, the harm of the organic solvent to the construction operation is reduced, the aqueous metal baking varnish has good environmental protection property, the construction hazard is low, and the problems of traditional pinholes and blistering of the aqueous metal baking varnish can be solved.

Owner:广东东明新材科技有限公司 +1

Full-plastic construction guard fender

InactiveCN1995661ANo pollution in the processMeet environmental requirementsFencingShock resistanceCoal

The invention relates to an all-plastic construction wall for urban municipal engineering road, groove construction and pipeline project such as coal, water, electricity, heat, communication and so on, comprising wall body, substructure and window. Said substructure is hollow cavity. Water inlet is set at the upper of substructure and water outlet is set at the lower of substructure. Bolt and bolt hole are set at two sides of said wall body respectively. Vertical reinforced ribs are set between said substructure and window and transverse reinforced ribs are set on said substructure. Beneficial effects of the invention are that 1) the figuration is beautiful and canonical, it is coincidence with the demand of the whole circumstance in big city, it is easy to clean; 2) working condition of construction is improved and working efficiency is improved; 3) the usage ratio is high and it is applied in the protection of urban municipal facility and building construction; 4) it is provided with high intensity, good tenacity, strong rigidity, heat resistance, cold resistance, acid resistance, alkali resistance, shock resistance and so on; 5) it is the product with energy saving and environmental protection.

Owner:LONGTENGXUANSU TRAFFIC SAFETY INSTALLATION MFG WUHAN +1

Dust removal and environment protection system of automatic mud jacking device

PendingCN106422926APrevent overflowRealize dust-free recyclingDispersed particle filtrationTransportation and packagingVehicle frameEngineering

The invention relates to a dust removal and environment protection system of an automatic mud jacking device. The system comprises a frame, a dust removal device on the frame and a PLC assembly electric cabinet at the front end of the frame. The dust removal device comprises a closed high-speed stirring tank, a closed automatic feeding machine and a dust removal device body, wherein the closed high-speed stirring tank is arranged on the frame, the closed automatic feeding machine is communicated with the closed high-speed stirring tank, and the dust removal device body is disposed at the rear end of the frame and communicated with the closed high-speed stirring tank and the closed automatic feeding machine through connection pipes. The special dust removal device is arranged on an automatic mud jacking vehicle and can absorb and recycle dust generated in the work process of the mud jacking device, the construction environment is effectively improved, operation workers do not need to wear special dustproof masks, and health of construction operators can also be guaranteed.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Construction method of constructing subway station by using prefabricated lining combined with pba

ActiveCN106703828BEasy to industrializeDoes not affect trafficUnderground chambersTunnel liningMechanical equipmentEngineering

The invention disclose a construction method of building subway station with fabricated lining combination PBA, which is used to construct a small pilot tunnel the initial support; fabrication applies a bar foundation of a lower pilot tunnel, a upper pilot tunnel applies a side pilling, the outer side of the side The concrete backfilling is used between outer side of the side pilling and the pilot tunnel, a crown beam is moulded, a middle pilot tunnel steel pipe concrete the column is dug under the wall a pillar in the middle of the protective wall modifies the top girder; the excavation of the soil under the excavation arch is initially supported by the arch; modifies the arch of primary support, to step on the soil excavation, excavation to post crown beam elevation setting the first level support, down the steps the second earth excavation, construction of the second support, continue to stratified excavation to base; Using integrated mechanical equipment to assemble the arching; step five: pre-fabricated side panel and center board; assemble prefabricated roof arch; after the assembling backfill grouting; To form a complete station structure. The technical scheme has the advantages that the road traffic is not affected the environment pollution is small, the quality is reliable, the construction is quick, the overall stability of the station can be improved by fabricated component.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com