Sludge reduction treatment device and treatment method for city pipe network

A treatment device and reduction technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of high water content of sludge at the cleaning site and harsh surrounding environment impact, high cleaning and transportation costs, etc., to achieve the effect of fully automated processing, improve the construction environment, and reduce the intensity of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

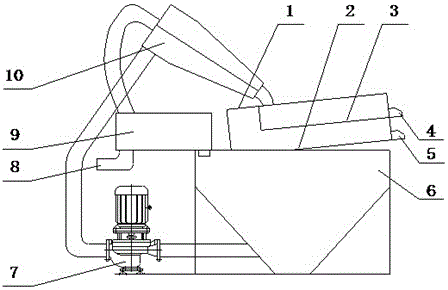

[0059] figure 1 It is a mobile or vehicle-mounted urban pipe network sludge reduction treatment device, which consists of a coarse material separation screen 2, a fine material separation screen 3, a first slurry storage tank 6, a high-pressure sewage suction pump 7, and a middle storage tank 9 And cyclone separator 10 composition.

[0060] Both the coarse material separating sieve 2 and the fine material separating sieve 3 are vibration sieves which are overlapped up and down, and the coarse material separating sieve 2 is arranged below the fine material separating sieve 3 .

[0061] Below the coarse material separating screen 2, a first slurry storage tank 6 with an open top and a bucket-shaped bottom is arranged.

[0062] A high-pressure sewage suction pump 7 is provided outside the first slurry storage tank 6, and the outlet at the bottom of the first slurry storage tank is connected to the cyclone separator 10 through the slurry pump.

[0063] The high-pressure sewage s...

Embodiment 2

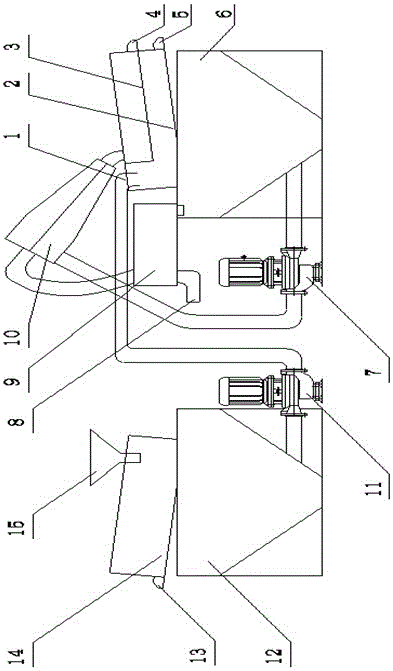

[0072] figure 2 It is a fixed urban pipe network sludge reduction treatment device, and on the basis of the mobile treatment device in Example 1, the corresponding equipment required for pretreatment is added. The pretreatment equipment is composed of a slurry pump 11 , a second slurry storage tank 12 and a pre-separation screen 14 .

[0073] The pre-separation screen 14 is a vibrating screen, and a second slurry storage tank 12 is arranged below it. The second slurry storage tank 12 has the same structure as the first slurry storage tank 6 of the subsequent process, and is also an open upper mouth and a bucket-shaped bottom. The bottom of the second slurry storage tank 12 communicates with the slurry inlet 1 of the coarse material separating screen through a slurry pump 11 .

[0074] The slurry pump 11 adopts a conventional pressure centrifugal pump.

[0075] Since there are many equipments in this embodiment, a fixed sludge treatment device is made. That is to say, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com