In-tunnel reverse construction method for mined metro station with oversized cross section based on arch cover method in soft rock area

A technology of super large section and reverse method, applied in underground chambers, shaft linings, tunnel linings, etc., can solve the problems of high investment, long construction period, and many temporary supports, so as to ensure stability, strengthen bearing capacity, and improve construction operations. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

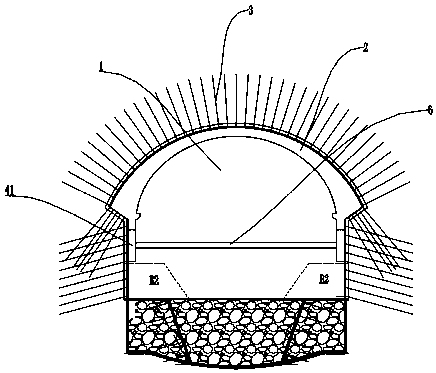

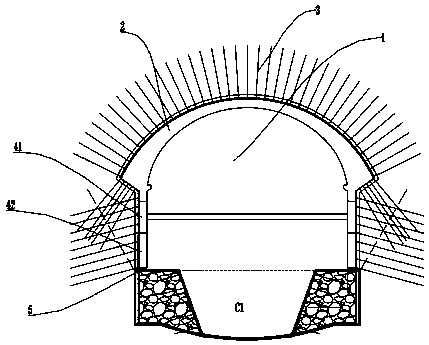

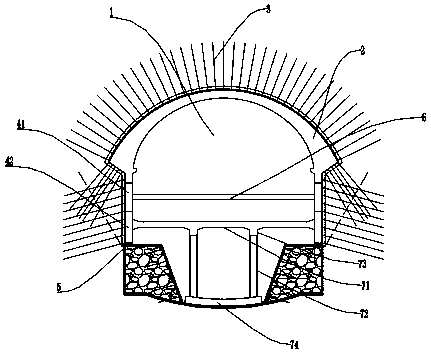

[0039] Example 1, please refer to Figure 1~15 , the present invention provides a kind of inversion method in soft rock area based on the arch cover method in super large cross-section underground excavation station tunnel, comprising the following steps: Step S01, arch excavation and arch foot arch cover construction; during tunnel excavation, It is necessary to complete the excavation of the upper arch first, and complete the construction of the arch cover of the arch foot. The excavation of the arch is excavated by the double side wall pilot pit method. The excavation sequence is as follows: figure 2 As shown, pilot holes are excavated on the left and right sides of the upper part; image 3 As shown, the pilot tunnels are excavated on the left and right sides of the upper part; Figure 4 As shown, the upper, middle and upper pilot pits are excavated; Figure 5 As shown, the upper, middle and lower pilot pits are excavated; Image 6 As shown, the upper waterproof layer i...

Embodiment 2

[0053] Embodiment 2, the present invention also provides a kind of top-down method in the large-section underground excavation station hole based on the arch cover method in the soft rock area. The middle and lower part of the section is vertically divided into two layers according to the length of the station. From top to bottom are the top layer and the bottom layer, and the excavation area of each layer includes the middle hopping area and the two side areas for excavation. The specific excavation method can be found in Example 1; the implementation method is as follows:

[0054] Step S01, arch excavation and arch foot arch cover construction;

[0055] Step S1, complete the excavation of the excavation area of the top layer, and the excavation of the job-hopping area in the middle of the bottom layer; the height ratio of the top layer and the bottom layer is 4:6;

[0056] Step S2, carry out the construction of the local inverted arch, side wall and station hall laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com