Aqueous metal baking varnish and preparation method thereof

A metal baking paint, water-based technology, applied in the field of baking paint, achieves good compatibility, reduces construction hazards, and solves the effects of traditional pinholes and prickly heat problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

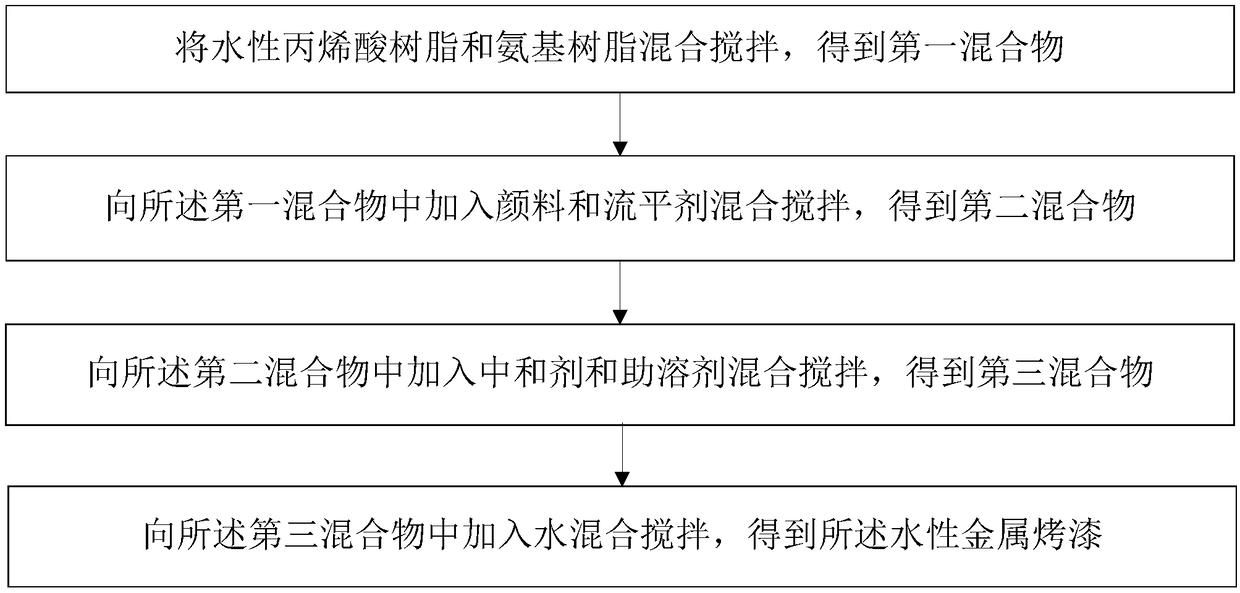

[0045] It can be understood that the preparation method of the water-based metallic baking paint also has an important influence on the performance of the water-based metallic baking paint. In order to further make the overall system compatibility better, the present invention also provides a preparation method of water-based metal baking paint, please refer to figure 1 , the preparation method of water-based metal baking varnish comprises the steps:

[0046] S110: mixing and stirring the water-based acrylic resin and the amino resin to obtain a first mixture;

[0047] For example, the water-based acrylic resin and the amino resin are mixed at a speed of 450 rpm to 590 rpm and stirred for 6-10 minutes, so that the water-based acrylic resin and the amino resin are evenly mixed. Preferably, the water-based acrylic resin and the amino resin are mixed and stirred at a speed of 580 rpm for 7.5 minutes, so that the water-based acrylic resin and the amino resin are mixed more unifor...

Embodiment 1

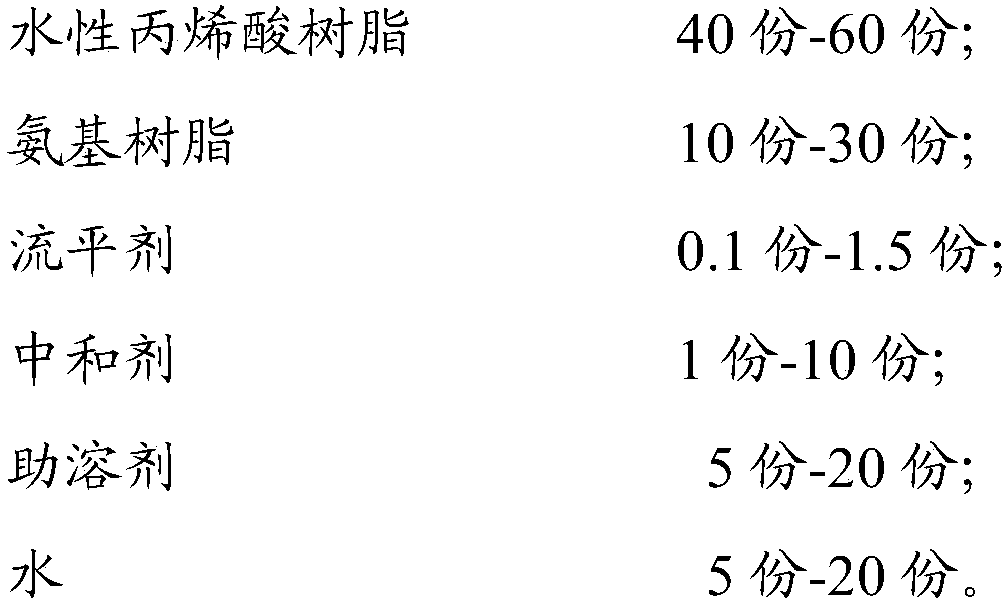

[0068] Water-based metallic baking varnish comprises each component of following mass parts:

[0069]

[0070]

[0071] Its preparation method is as follows: water-based acrylic resin and amino resin are mixed and stirred at a rotating speed of 580rpm for 7.5 minutes to obtain the first mixture, after adding pigment and leveling agent to the first mixture, mixed and stirred at a rotating speed of 500rpm for 6 minutes , to obtain the second mixture; add neutralizing agent and cosolvent to the second mixture and mix and stir for 9 minutes at a rotating speed of 450rpm~590rpm to obtain a third mixture; add water to the third mixture at a rotating speed of 560rpm Mix and stir for 12 minutes to obtain the water-based metallic baking paint.

[0072] Its use method is as follows: add the water-based metallic baking varnish to a diluent to dilute to obtain a diluent, wherein the diluent is water; wherein the ratio of the water-based metallic baking varnish to the diluent is 1:0....

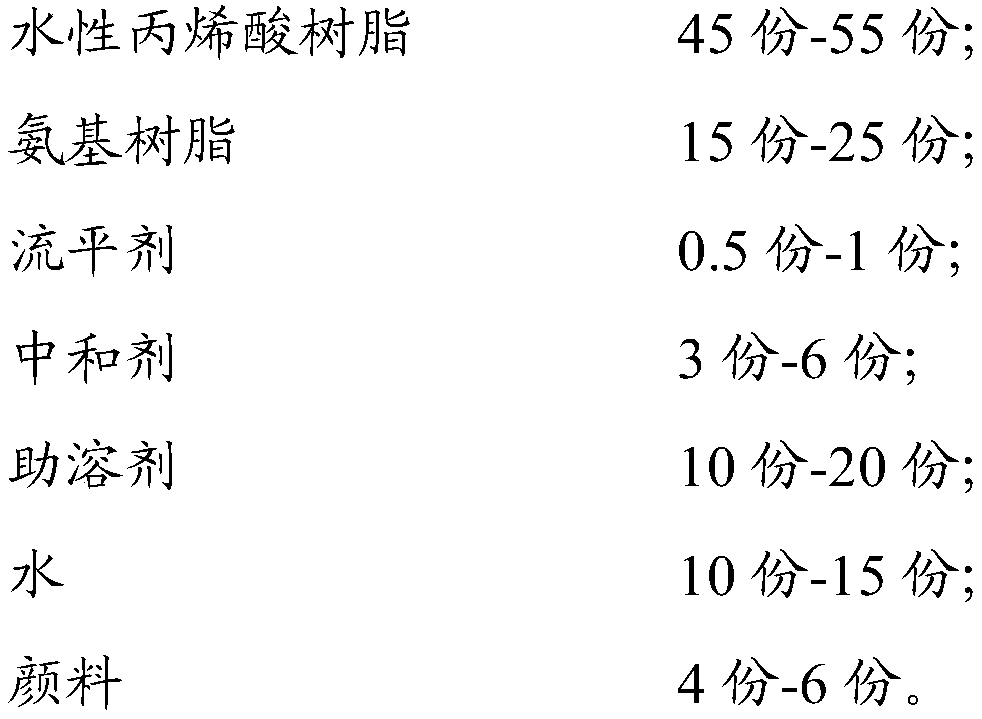

Embodiment 2

[0074] The difference with embodiment 1 is:

[0075] Water-based metallic baking varnish comprises each component of following mass parts:

[0076]

[0077] Other methods are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com