An elastic felt hanging method for a large full-containment low-temperature storage tank

A low-temperature storage tank and elastic felt technology, which is applied in the field of construction and installation of the cold insulation layer of large-scale all-inclusive low-temperature storage tanks, can solve problems such as difficult quality control, slow construction progress, and low construction efficiency, so as to improve construction safety and improve construction efficiency. The effect of cost reduction and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] This plan is illustrated by the construction of the cold insulation layer of a 160,000 cubic meter LNG fully contained low-temperature storage tank for an LNG project.

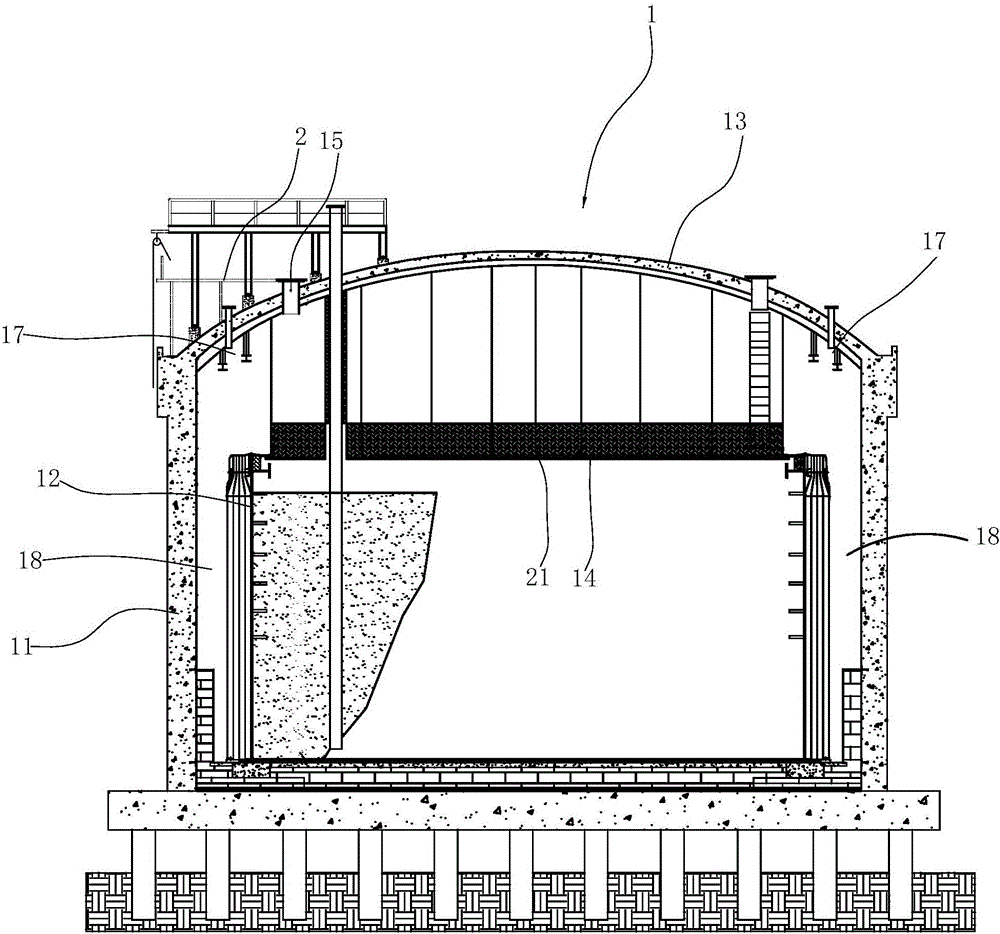

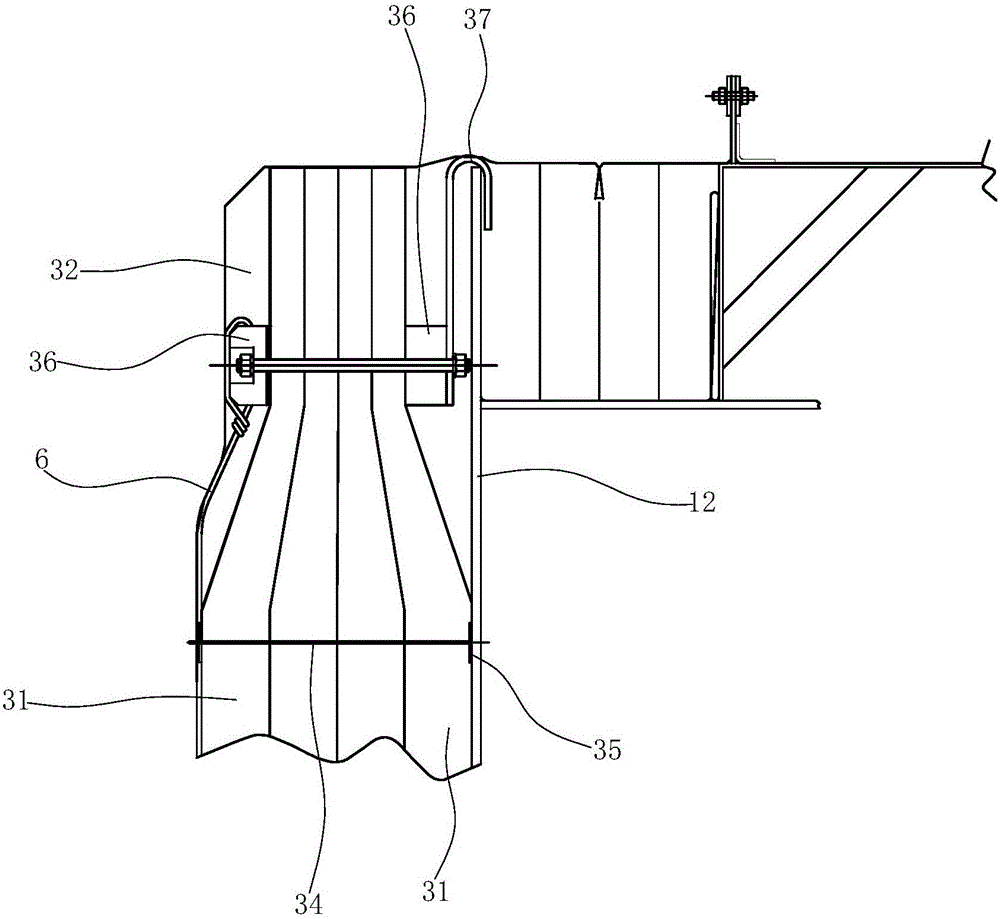

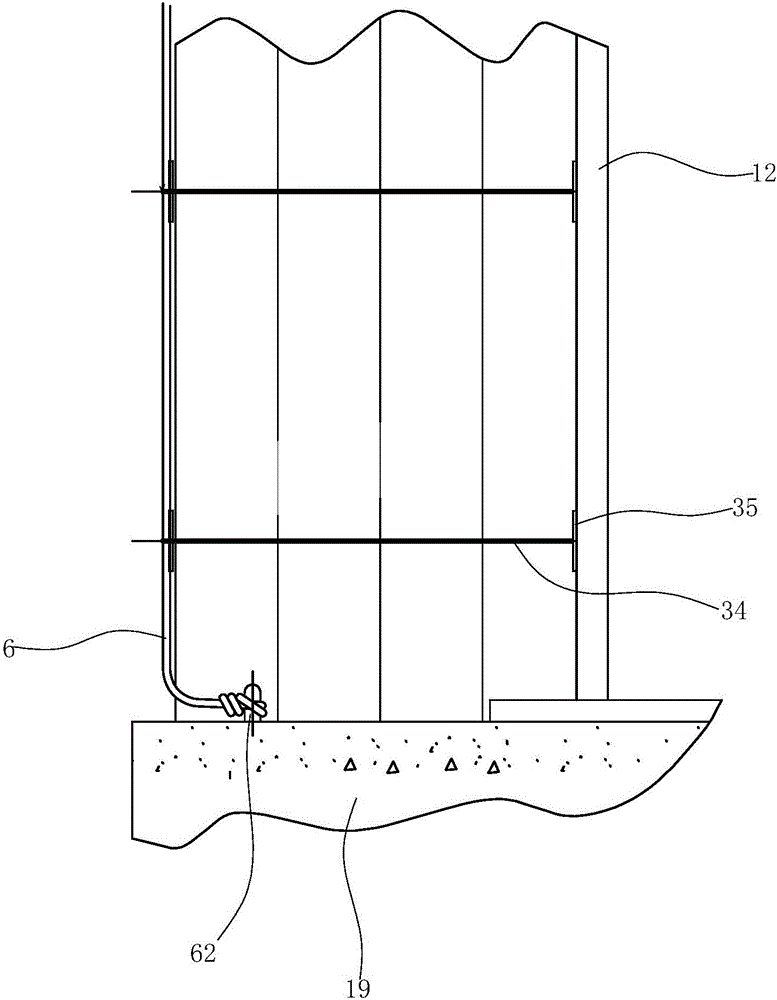

[0041] Such as figure 1 As shown, the outer tank 11 of the 160,000 cubic meter LNG cryogenic storage tank 1 has an inner diameter of 78 meters, a wall thickness of 750 mm, and a top height of 53.175 meters. It adopts a prestressed concrete structure; the inner tank 12 has a diameter of 76 meters and a height of 39.42 meters. All connecting pipes protrude from the tank top, and the inner wall of the tank top 13 is provided with a ceiling floating plate 14, and the ceiling floating plate 14 is provided with reinforcing ribs 21; the tank top 13 is provided with material holes 15 and manholes; An annular vault guide rail 17 is also provided, and the vault guide rail 17 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com