A directional dust-exhausting and dust-reducing cover for a high-pressure down-the-hole drilling rig

A down-the-hole drilling rig and dust cover technology, which is applied in construction and other directions, can solve problems such as affecting air quality, long distances between different types of personnel, troublesome maintenance, etc., achieve strong anti-interference, improve the construction working environment, and reduce the spread of dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

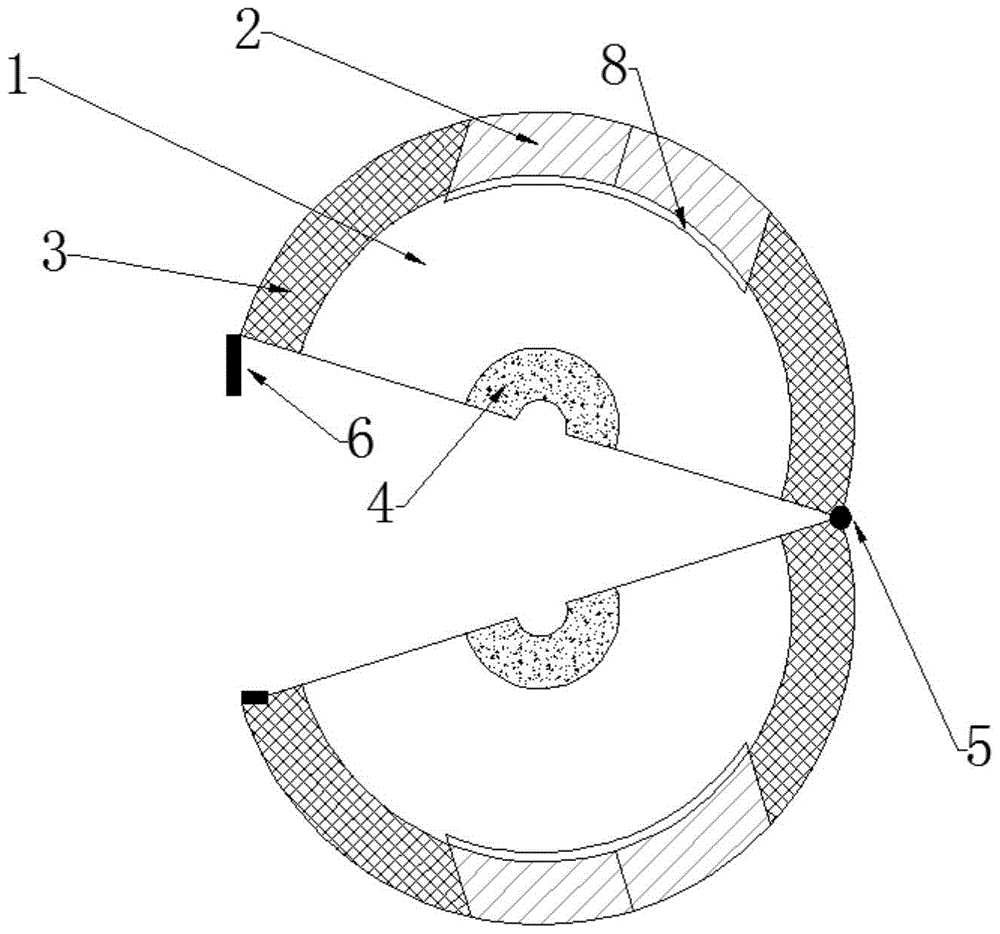

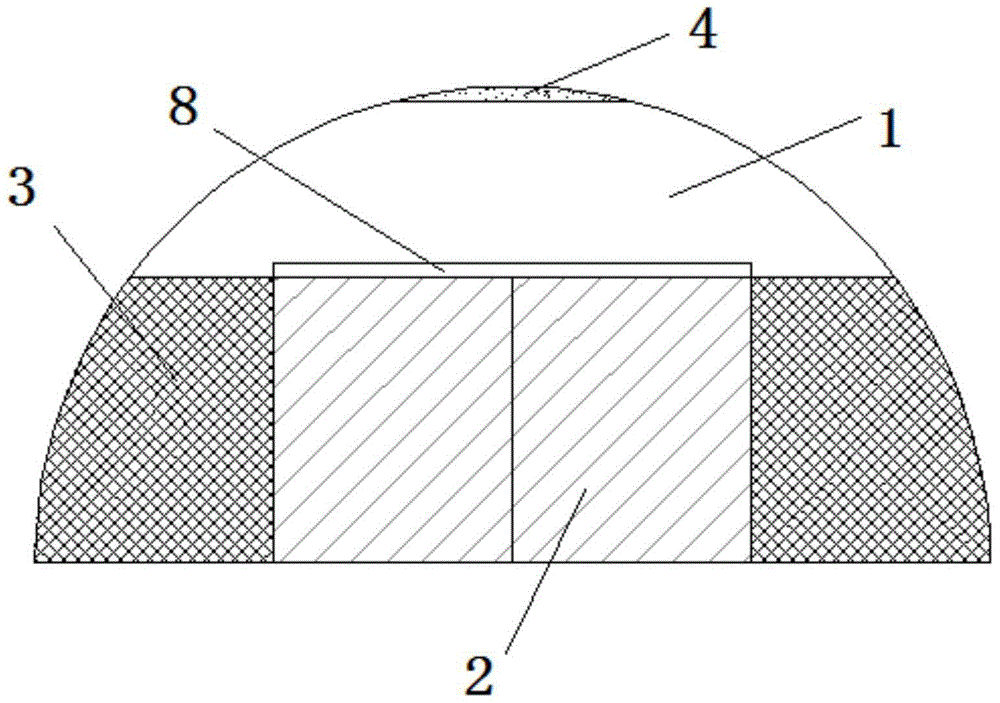

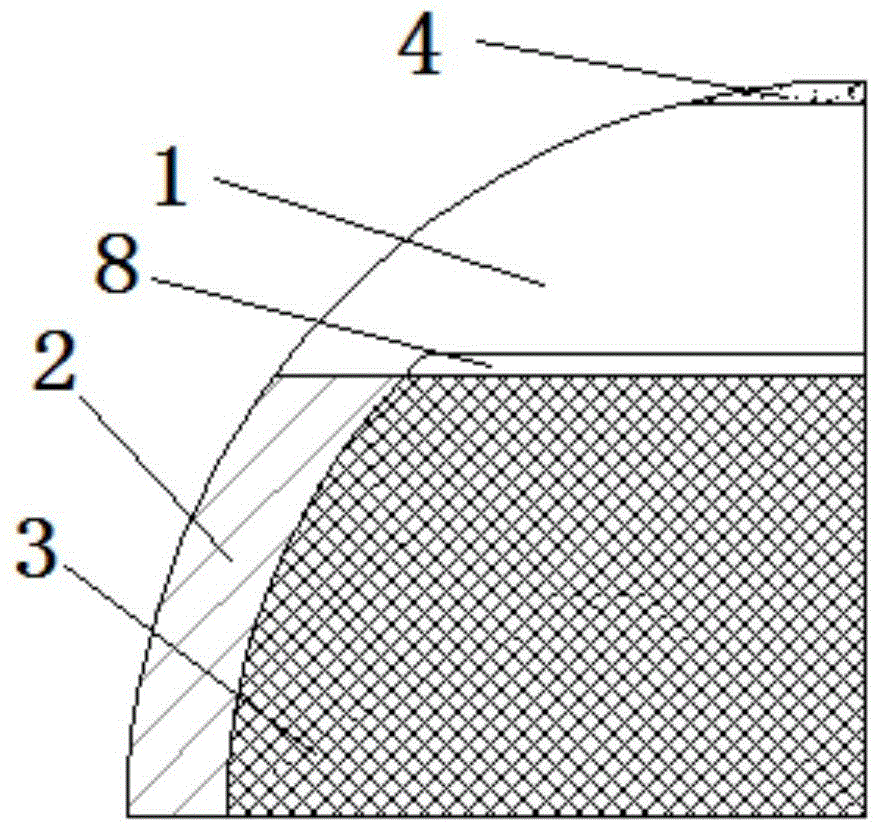

[0024] Such as Figure 1-Figure 5 As shown, the high wind pressure down-the-hole drilling rig directional dust discharge dust cover includes a dust cover, a filter screen 7, and a dust discharge directional plate 2. Dust with large particle size is filtered through the filter screen 7 , and fine dust and gas are directional discharged through the grid hollow part 3 under the constraint of the dust discharge directional plate 2 . The dust cover and the dust discharge directional plate 2 are corrosion-resistant metals, and the dust cover is two quarter spherical shells that are symmetrically closed. The lower part of the dust cover is a hollow grid part 3, the grid is a regular quadrilateral, and the upper part is an airtight part 1. There is a filter screen 7 inside the dust cover, which is attached to the inner wall of the dust cover with the air pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com