Construction method for simultaneous extension of parallel guide pits into double-line tunnel for TBM tunneling construction

A construction method and technology for tunnels, which can be used in mine/tunnel ventilation, tunnels, earth-moving drilling, etc., and can solve the problems of high construction cost, slow mechanical excavation, and unfavorable operation safety of I-line tunnels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

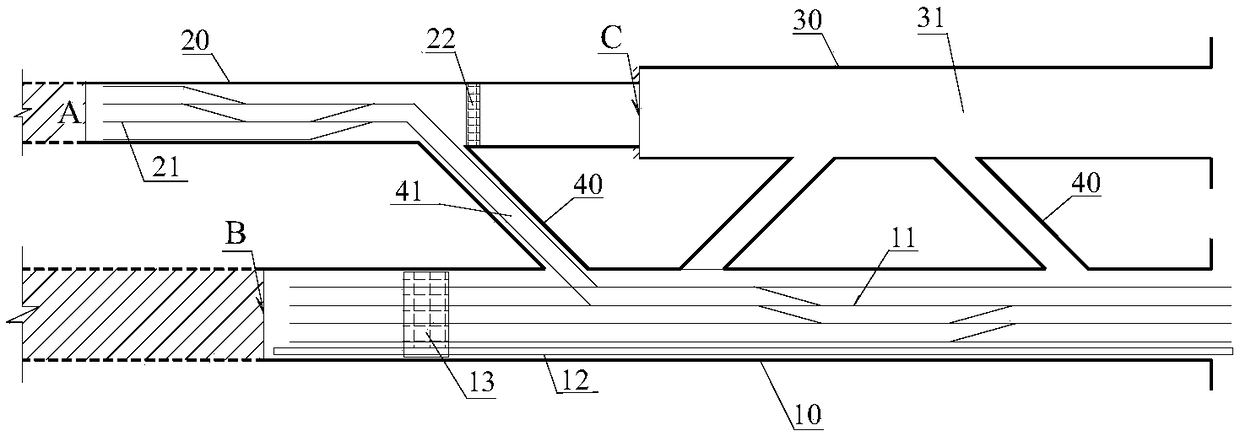

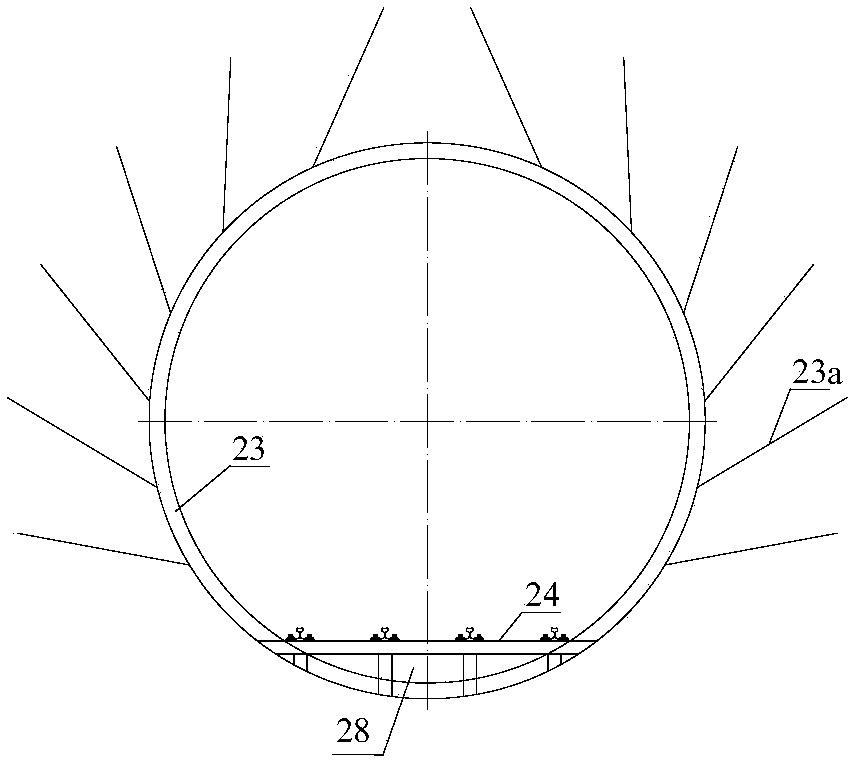

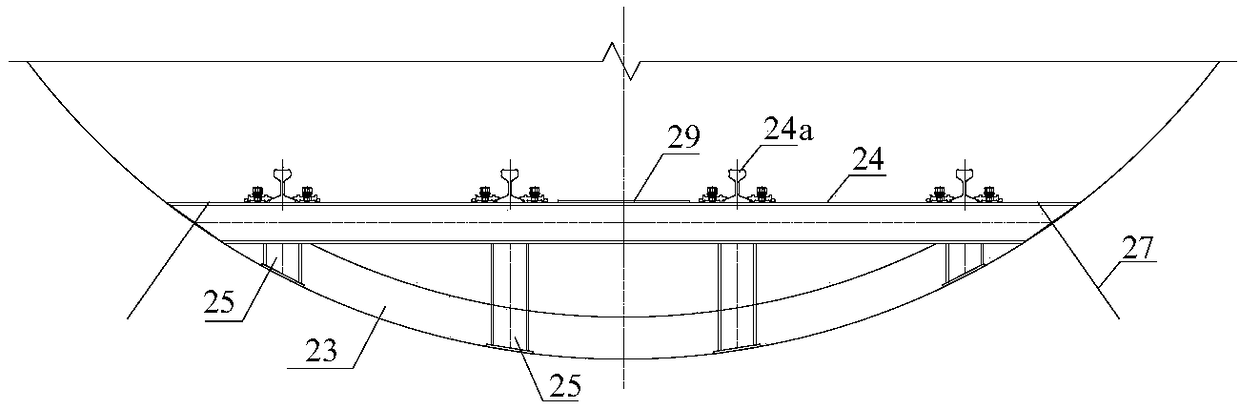

[0023] refer to figure 1 , the parallel pilot pit synchronous expansion of TBM excavation construction of the present invention is the construction method of double track tunnel, comprises the following steps:

[0024] 1. Use small-diameter open TBM to carry out full-section excavation and advance construction of parallel pilot pits 20;

[0025] 2. Lag parallel guide pit excavation surface A is about 800m, use large-diameter TBM full-face excavation to construct line I tunnel 10 at 30-50m to the left or right side of parallel guide pit 20, and connect parallel guide pits at intervals along the line extension direction The cross passage 40 between the pit 20 and the line I tunnel 10;

[0026] 3. The extension construction of the parallel pilot pit 20 is carried out after about 1200m behind the TBM excavation surface B of the tunnel of the first line, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com