Patents

Literature

44results about How to "Shorten the total construction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

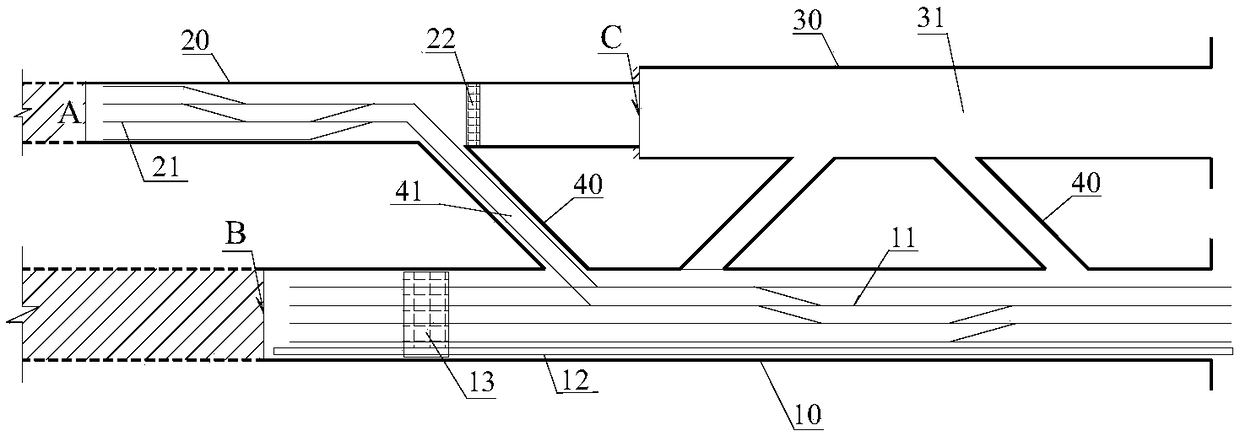

Construction method for lifting whole steel structural roof with large span and complicated design

InactiveCN101519913ALow costShorten the construction periodBuilding material handlingIndustrial engineeringBuilding construction

The invention discloses a construction method for lifting whole steel structural roof with large span and complicated design. The method comprises the following steps: (1) dividing the roof into a plurality of lifting units according to the construction requirements and lifting the units independently; (2) completing the preliminary assembly of the lifting units, lifting the units respectively once again to the height near the designed elevation, and then carrying out expanded assembly and lifting at different elevations to the designed elevation of a rack after expanding and assembling all the lifting units into a whole; (3) assembling outdoor racks by units while assembling and lifting indoor racks, and then butting the outdoor racks with the indoor racks respectively; and (4) unloading the racks step by step after butting the indoor racks and the outdoor racks into a whole. The construction method for racks is to carry out assembling and welding on the ground entirely, thereby avoiding aloft work. The method has the advantages of more accurate and convenient positioning, reduction of the cost for erecting the racks and great shortening of total construction period.

Owner:青建集团股份公司

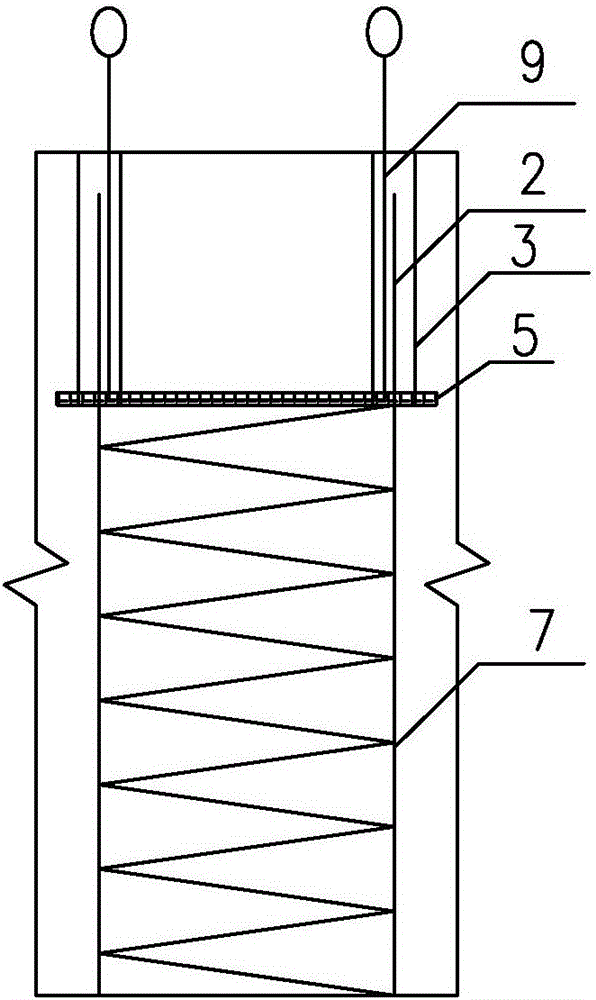

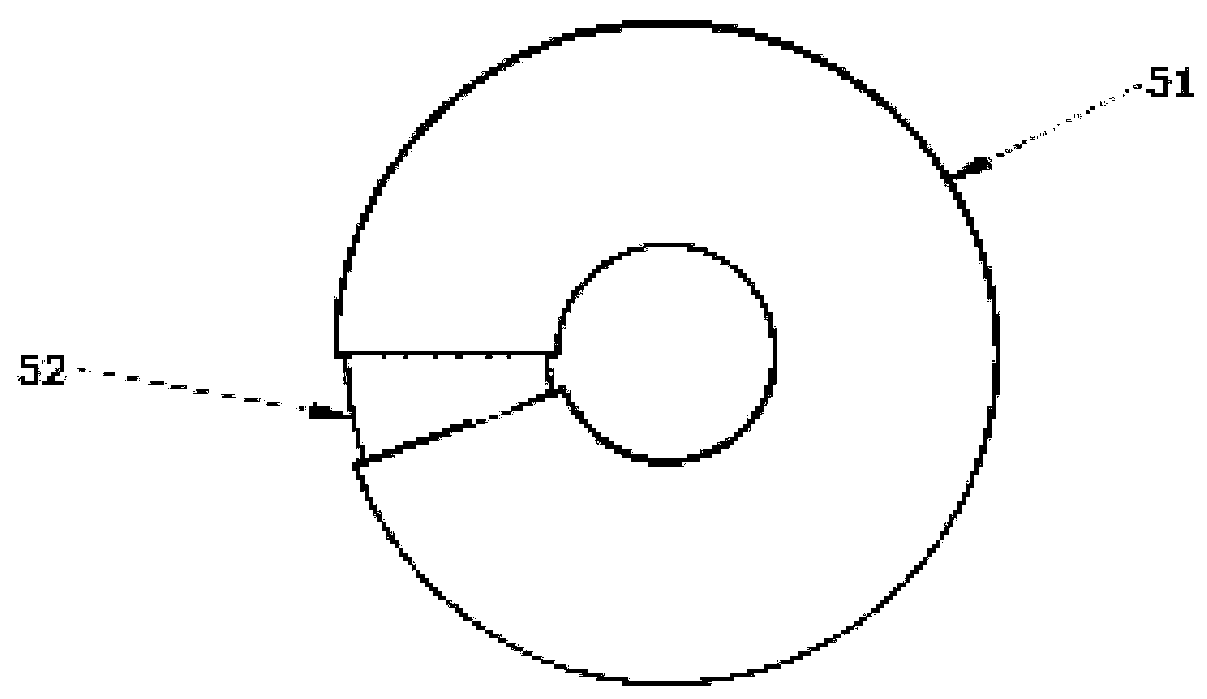

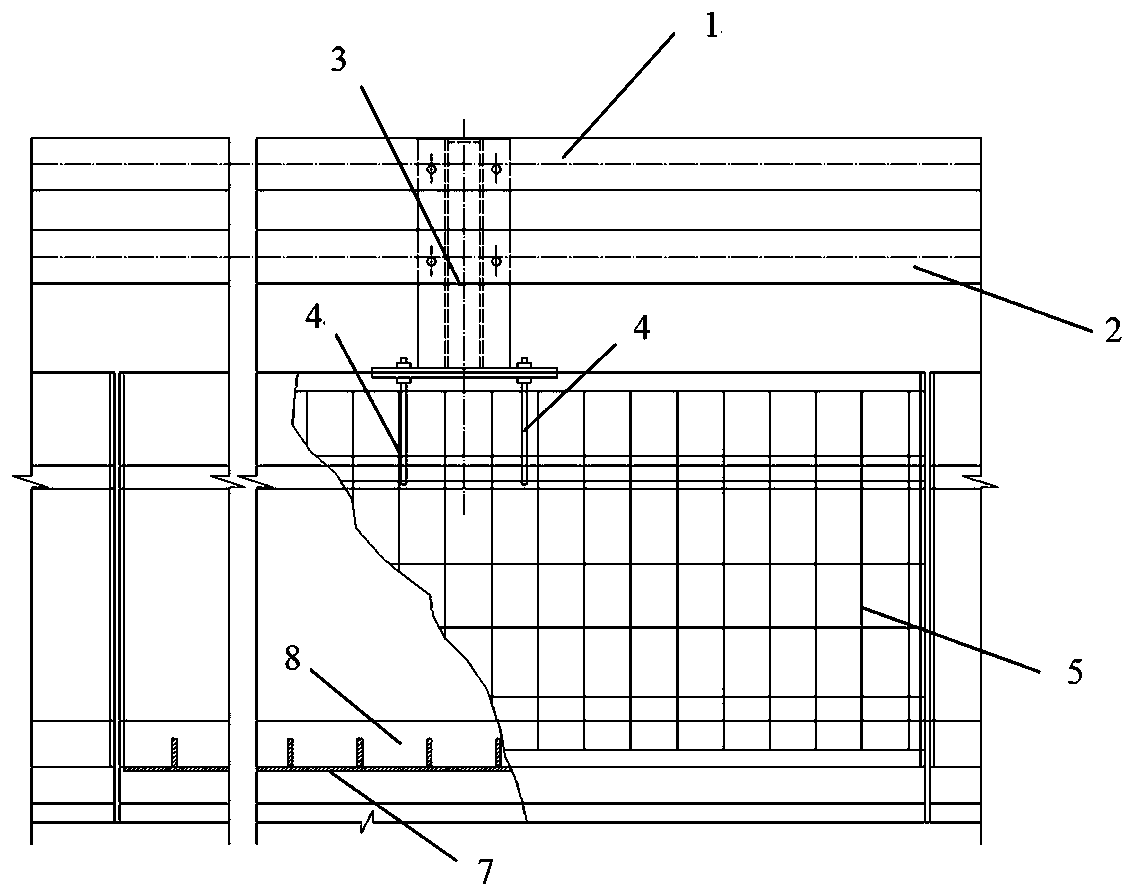

Construction method of cone-shaped top structure of large silo

ActiveCN104100122AShorten the total construction periodSave man hoursBulk storage containerEngineeringForming processes

The invention provides a construction method of a cone-shaped top structure of a large silo. The construction method comprises the steps of burying embedded parts in the inner wall of the silo wall at the height close to the silo top in the slip form process of the silo wall of the large silo, forming reserved holes in the silo wall above the embedded parts, welding steel corbels on the embedded parts, and then constructing a concrete column, a funnel board and a column top beam in the silo, and burying a foundation bolt in the top of the concrete column, building a scaffold supporting platform on the steel corbels, arranging a silo top formwork support frame on the scaffold supporting platform, and then arranging a cone-shaped shell concrete structure supporting system of the silo top on the silo top formwork support frame, and finally, carrying out pouring. The construction method of the cone-shaped top structure of the large silo is capable of reducing the construction cost and increasing the construction progress, and the construction process is safer and more convenient.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

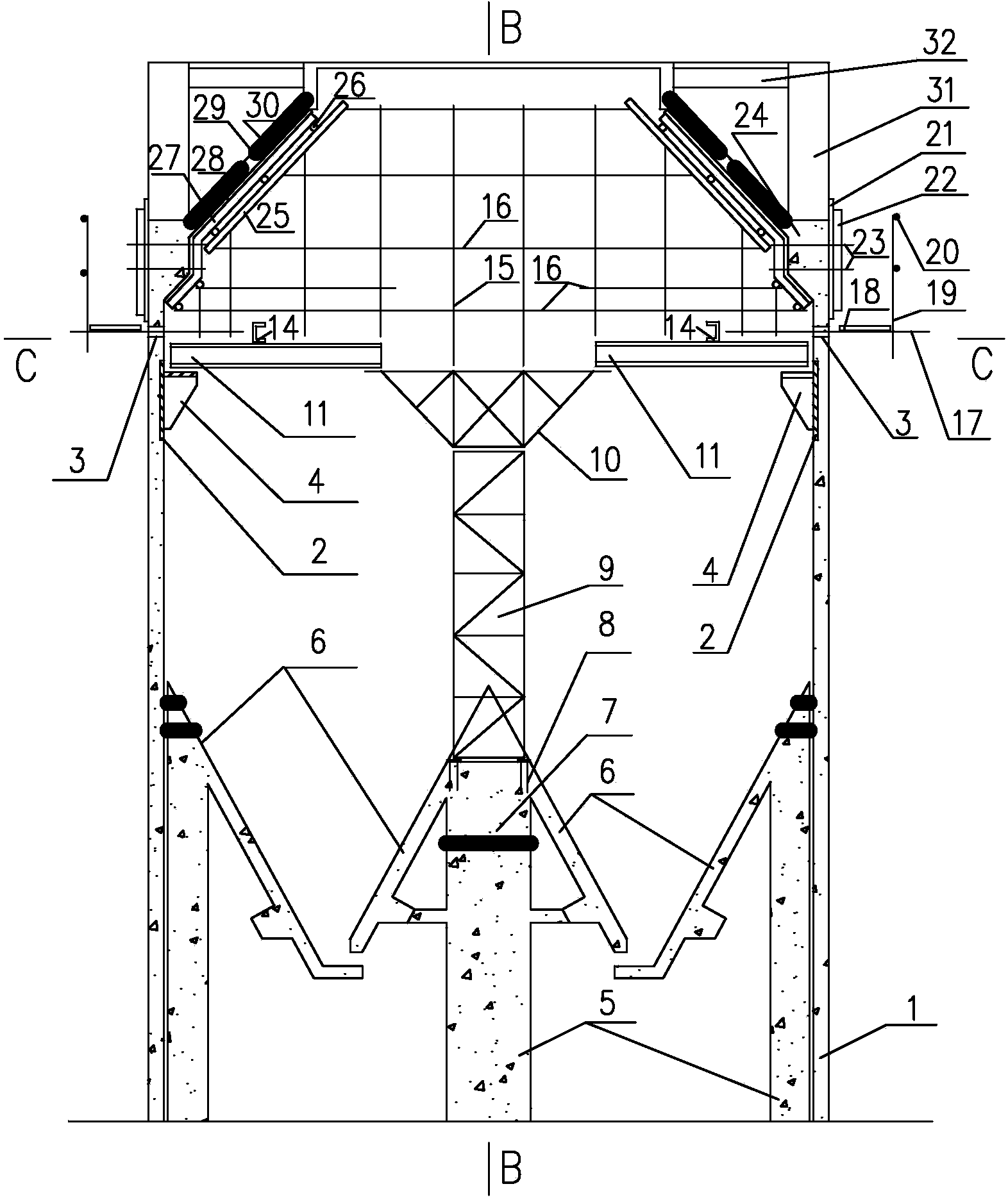

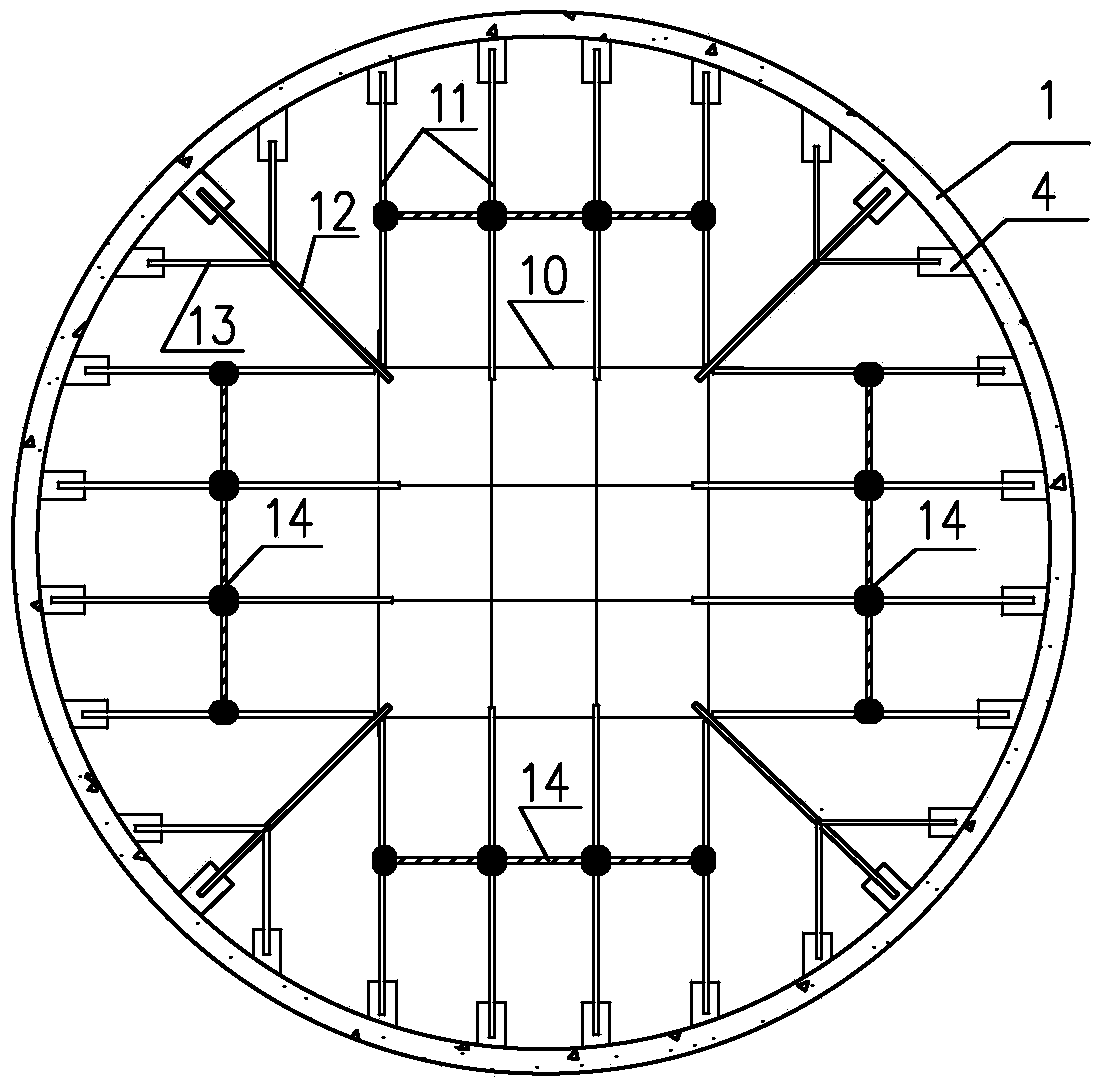

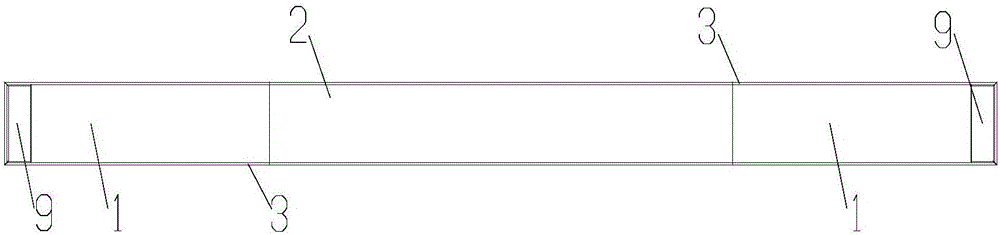

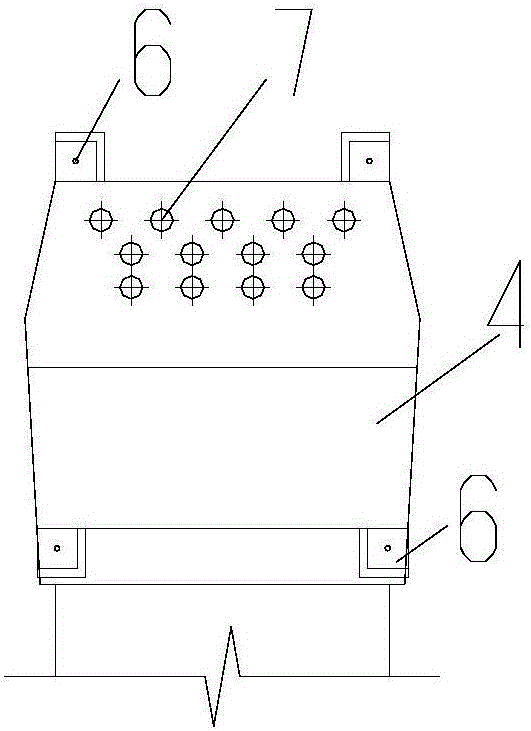

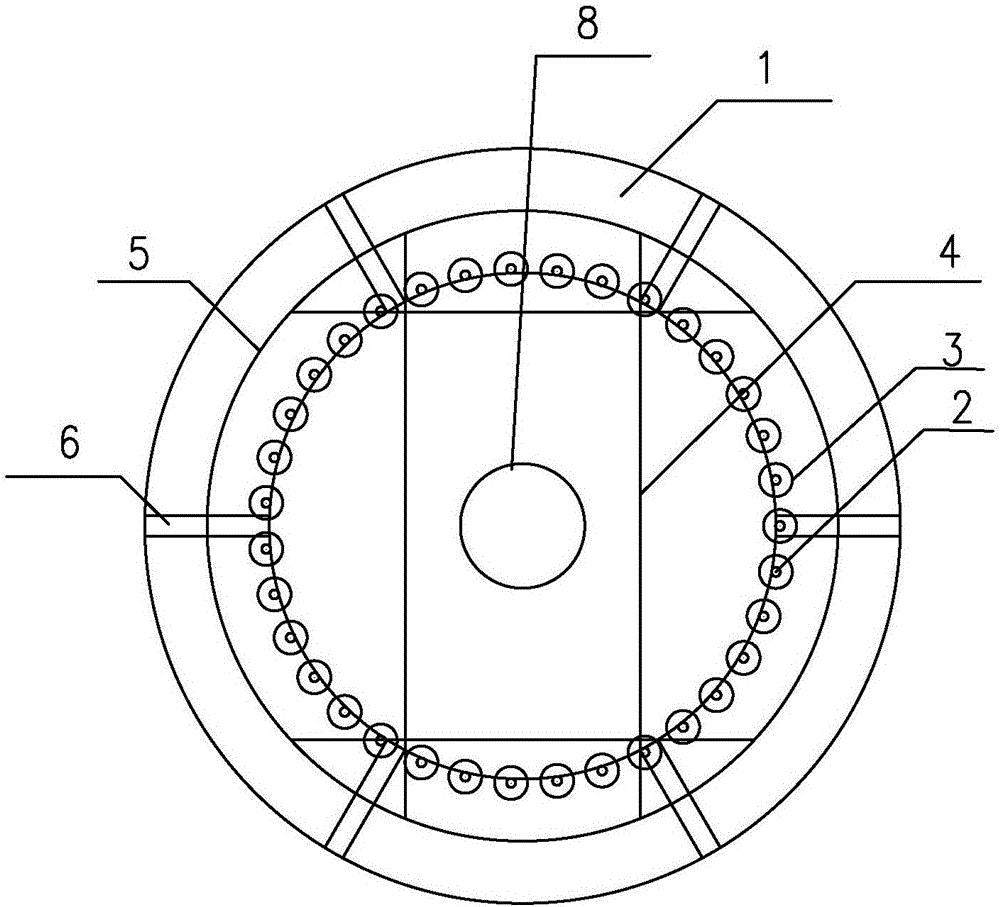

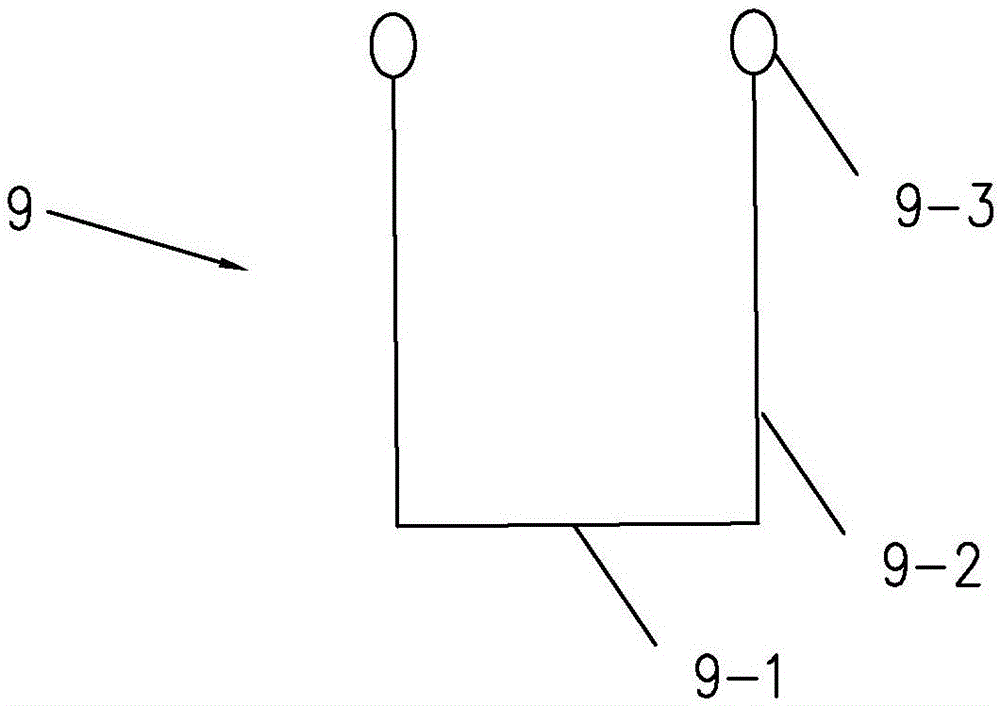

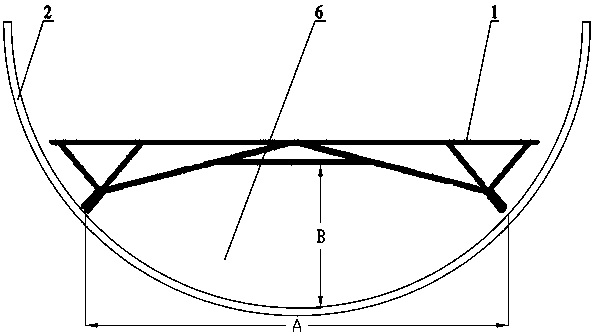

Large prefabricated assembly cap beam with corbel structure and construction method

InactiveCN106320164ASave formwork materialShorten the total construction period of the projectBridge structural detailsBridge erection/assemblyRebarEngineering

The invention relates to a large prefabricated assembly cap beam with a corbel structure and a construction method. The cap beam consists of members at two outer hanging type cantilever sections and a member in a middle section, wherein the assembly junction surfaces of the two sides of the member in the middle section are respectively provided with a corbel, and laser beam relative position calibrating receiving points are arranged on four corner point positions of the assembly crossing surfaces; a joint part of the member in the middle section and a bridge pier is provided with a vertical connector and a relative position calibrating transmitting point; a connecting part of each of the members at the two outer hanging type cantilever sections and the member in the middle section is in a trapezoid shape, and laser relative position calibrating transmitting points are arranged on the four corner points of the junction surfaces; both ends of a prestressed reinforcement are tensioned by a back tension method to connect into a whole. The large prefabricated assembly cap beam has the advantages that compared with the structure of arranging small shear keys on a plane, the corbel structure has stronger anti-shear capability; the prefabrication construction is convenient, and the refining treatment time of special parts in a member prefabrication process is favorably shortened; in a quantitative production step, the working efficiency is greatly improved, the construction risk is decreased, and a large amount of labor and material resources are reduced.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Tube truss manufacture process

The invention provides a tube truss manufacture process which comprises the steps as follows: blanking of steel tubes, positioning of intersecting points of tube fitting, welding of tube fitting, calibrating of members, pre-assembling, and disassembling of the pre-assembled truss, wherein all the manufacturing and processing links are carried out in sequence. The manufacture process has the advantages as follows: the assembly precisions of intersecting ends and intersecting holes are high; the size deviation is small; a truss body can be assembled quickly; the workload of calibration is small; formation of physical appearance is good; workload and time for polishing are greatly reduced; the quality of construction and formation can be guaranteed; smoothness and progression of all manufacture links are guaranteed; total construction period is guaranteed; material cost of manufacturing of the tube truss can be saved; inputs of manpower and goods and materials are saved; and economical effects of production are improved.

Owner:河北二十冶建设有限公司

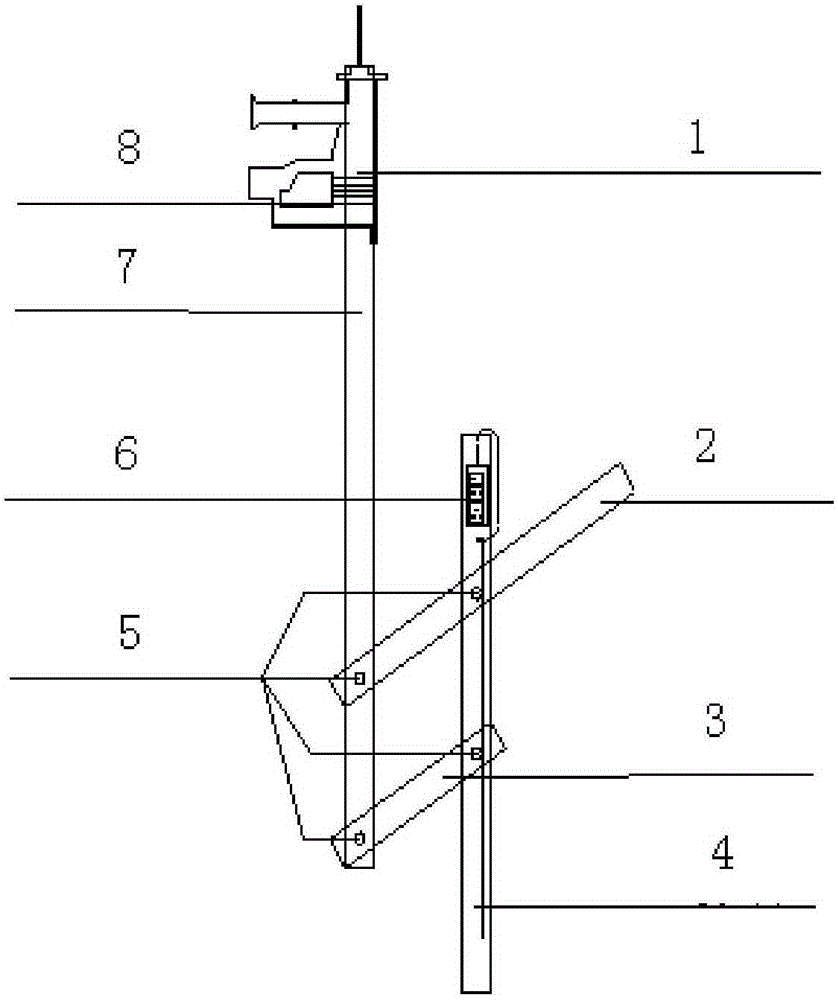

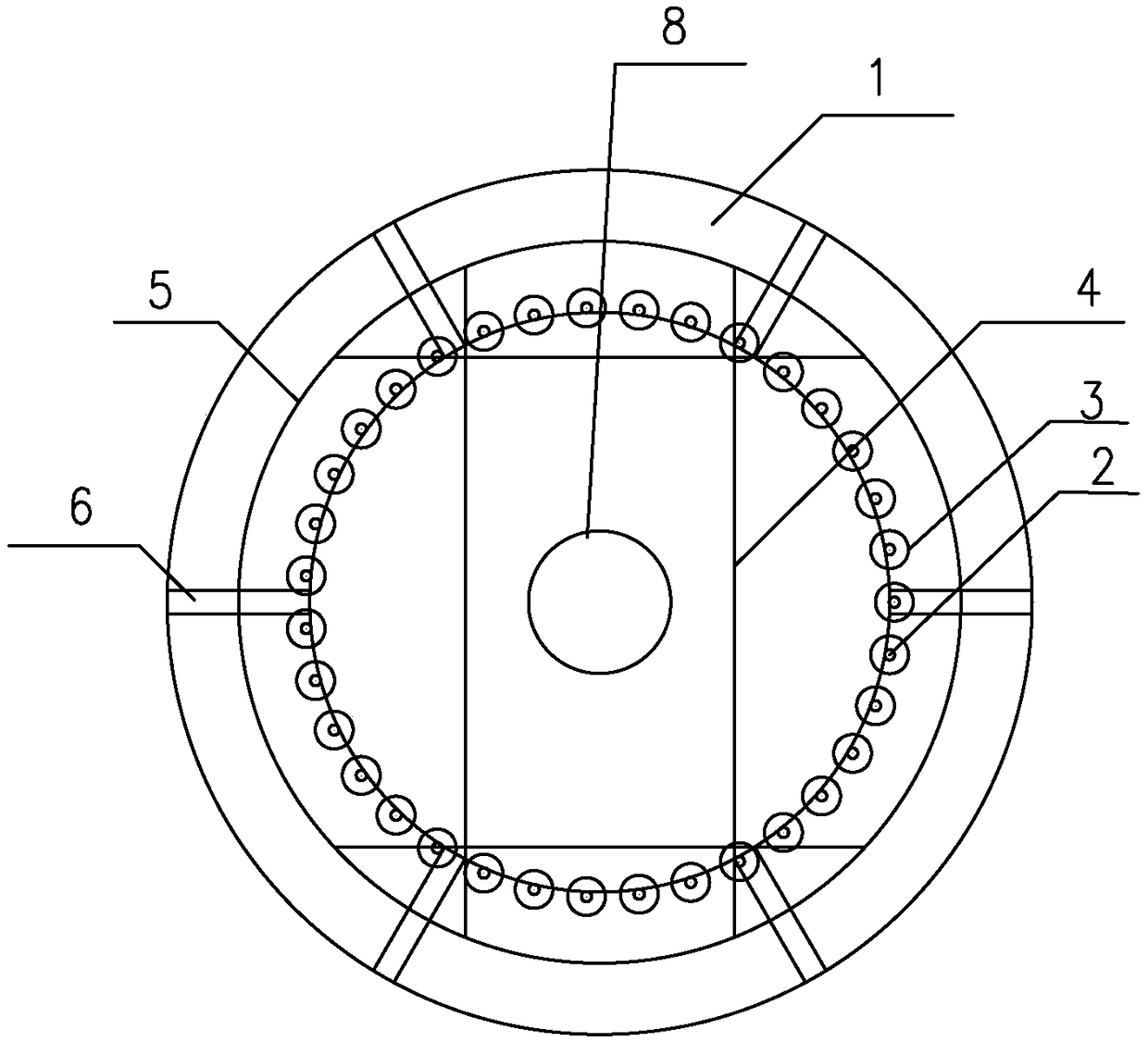

Integral quick lifting method for pile head of drilled pile during pre-embedding and drilling-free ring-cutting

ActiveCN106400802AReduce security risksReduce construction difficultyExcavationsBulkheads/pilesChinese charactersRebar

The invention discloses an integral quick lifting method for a pile head of a drilled pile during pre-embedding and drilling-free ring-cutting. The integral quick lifting method comprises the following steps of: mounting the drilled pile in front of a reinforcement cage after the drilling is ended, directly embedding foam sponge pipes into main ribs of an exposed supporting table of the reinforcement cage and an outer-end surface of a sounding pipe, fixing the foam sponge pipes by use of rubber bands to ensure that the foam sponge pipes do not slide; coating the foam sponge pipes outside a reinforcement positioning frame in the shape of Chinese character jing and a ring-shaped reinforcement positioning ring in advance; replacing drilling by use of a PVC tube every 40-50 cm along the perimeter of the pile body on the positioning frame, covering the foam sponge pipes for conveniently identifying positions during breaking construction; after foundation pit excavation is completed, lightly knocking at a position 10 cm above elevation of a pile top to expose the PVC tubes and the positioning ring, inserting a separating wedge into the PCV tubes, knocking with external force until the pile head is completely separated from the pile body; and utilizing lifting equipment to perpendicularly lift the upper pile head. The construction method is suitable for integral breaking and lifting construction of pile heads of foundation projects of highways, high speed railways, subways and high-rise buildings.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

Construction method for suspended building structure

ActiveCN110616809AEnsure safetySatisfy the principle of forceFoundation engineeringGirdersStress conditionsVertical load

The invention discloses a construction method for a suspended building structure. The method comprises the following steps that S1, a peripheral core tube bearing platform foundation region is excavated, a peripheral core tube bearing platform foundation is constructed at the foundation region, and a vertical load-bearing structure is installed on the core tube bearing platform foundation; S2, a support jig is erected at a position, outside the core tube bearing platform foundation, of the foundation region; S3, a roof truss is installed above the support jig and the vertical load-bearing structure, and the support jig is removed after the roof truss is installed; and S4, a floor steel structure is installed below the roof truss from top to bottom in a layer-by-layer mode. According to themethod, construction is carried out by obeying the structure stress sequence, actual deformation and stress conditions of the suspended structure are convenient to obtain, the structure safety in theconstruction process is ensured, the construction flow and a hoisting process are optimized, a construction site is fully utilized, the construction cost is reduced, the construction efficiency is improved, moreover, the construction quality is ensured, and the method can be widely applied to construction of the suspended structure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

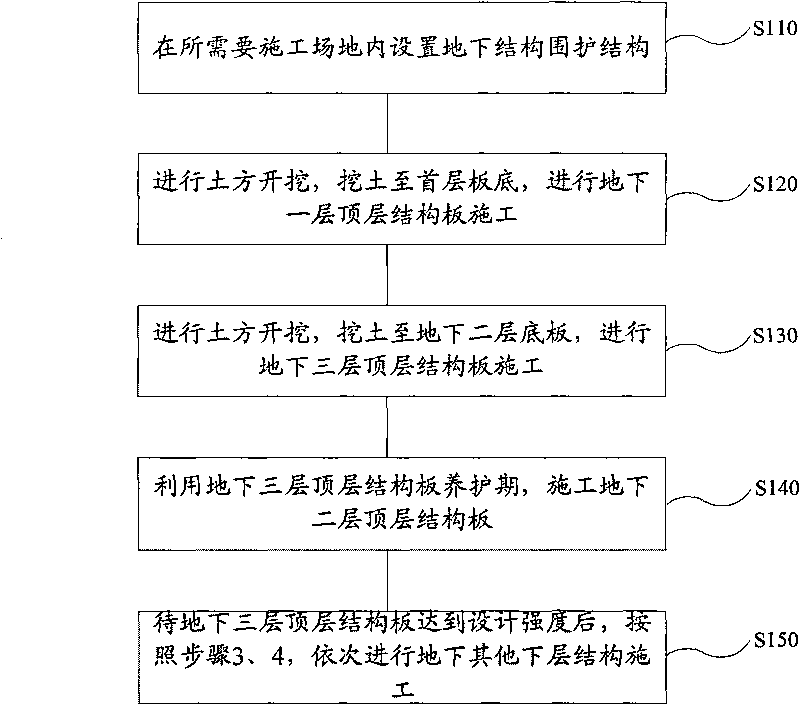

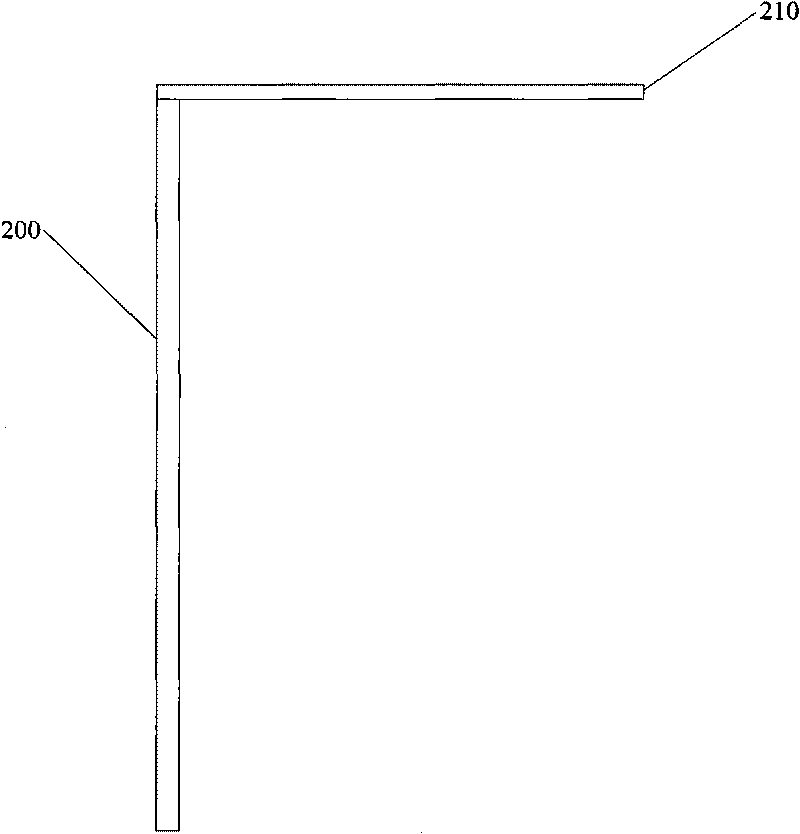

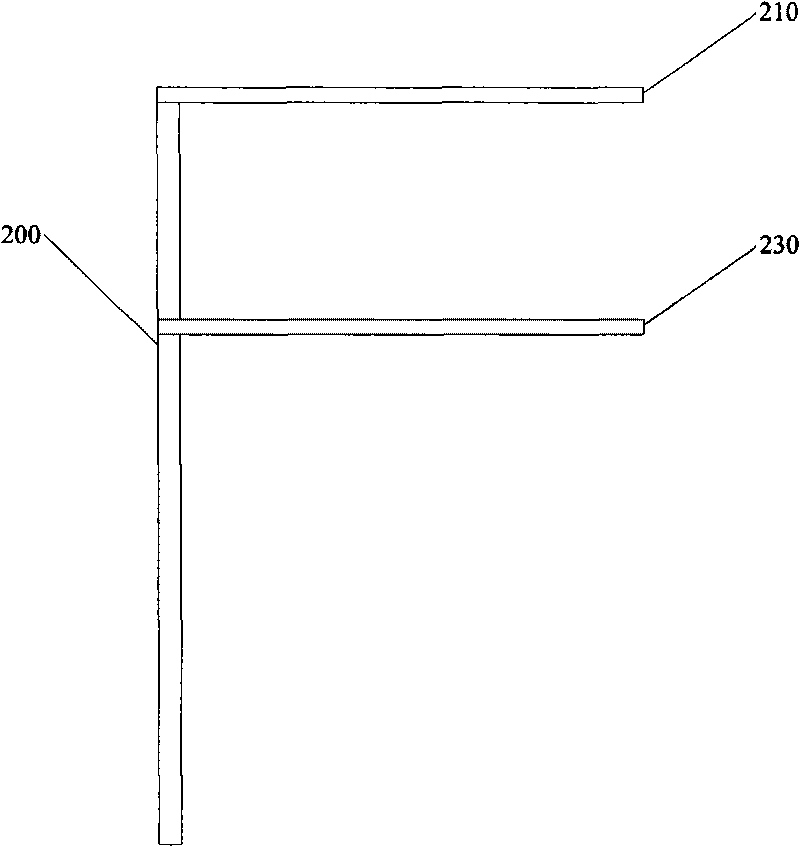

Method for constructing soft soil foundation reverse interlayer

ActiveCN101736756AShorten the total construction periodGuarantee the construction qualityArtificial islandsExcavationsEconomic benefitsUltimate tensile strength

The invention discloses a method for constructing a soft soil foundation reverse interlayer, which comprises the following steps of: 1. setting an underground enclosing structure in a field to be constructed; 2. carrying out soil excavation, excavating soil to the bottom of a first-floor plate and carrying out the construction of a top-floor structure plate of an underground first floor; 3. carrying out soil excavation, excavating soil to an underground second floor base plate and carrying out the construction of a top-floor structure plate of an underground third floor; 4. by utilizing the maintenance period of the top-floor structure plate of the underground third floor, constructing the top-floor structure plate of the underground second floor; and 5. after the top-floor structure plate of the underground third floor reaches the design strength, sequentially carrying out the construction of other underground lower floor structures according to the steps 3 and 4. By construction through the constructing method, the construction period and can be effectively shortened, the cost is saved, and the economic benefits and the social competitive force of enterprises are improved.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

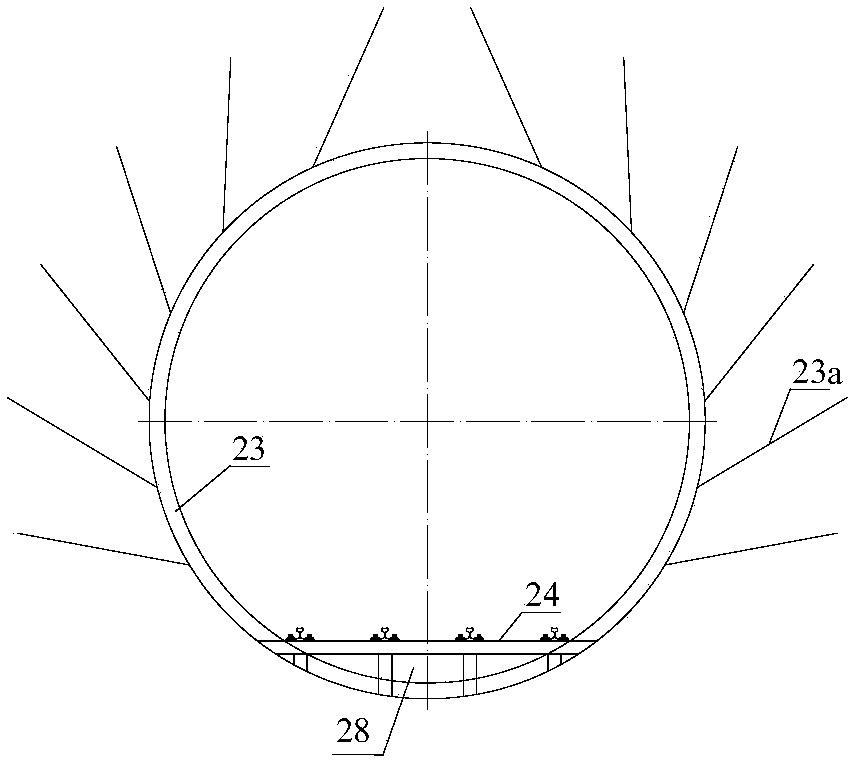

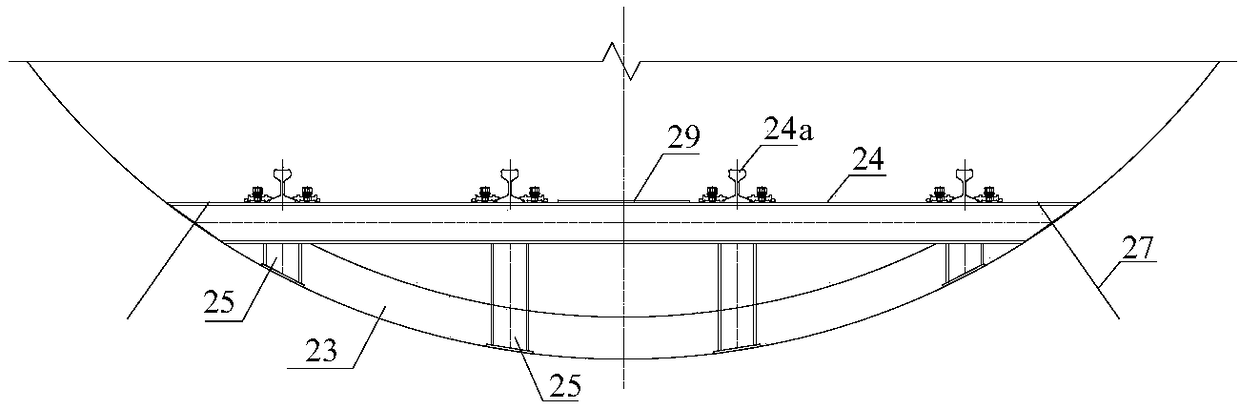

Construction method for simultaneous extension of parallel guide pits into double-line tunnel for TBM tunneling construction

PendingCN109403986AShorten the construction periodLow costTunnel/mines ventillationTunnelsArchitectural engineeringTunnel construction

The invention relates to a construction method for simultaneous extension of parallel guide pits into a double-line tunnel for TBM tunneling construction and aims to guarantee simultaneous construction of the double-line tunnel and an I-line tunnel, put into operation at the same time and realize effective shortening of the total construction period of the tunnel and great reduction of the construction cost. The method comprises steps that small-diameter open TBM is utilized for full-section excavation in-advance construction of the parallel guide pits; after lagging behind the tunneling surface of the parallel guide pits about 800m, large-diameter TBM full-section tunneling construction of the I I-line is utilized at the left or right side of the parallel guide pits at 30-50m, and a transverse passage between the parallel guide pits and the I-line tunnel is constructed along the extension direction of the line at intervals; after lagging behind the TBM tunneling surface of the I-linetunnel about 1200 meters, extension construction of the parallel guide pits is carried out, that is, when the parallel guide pits are continuously tunneled without interruption by the small TBM ahead,the borehole-blasting method is utilized to carry out simultaneous digging extension of the constructed parallel guide pits at about 2km lagging behind the tunneling surface of the parallel guide pits, and the double-line tunnel is formed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

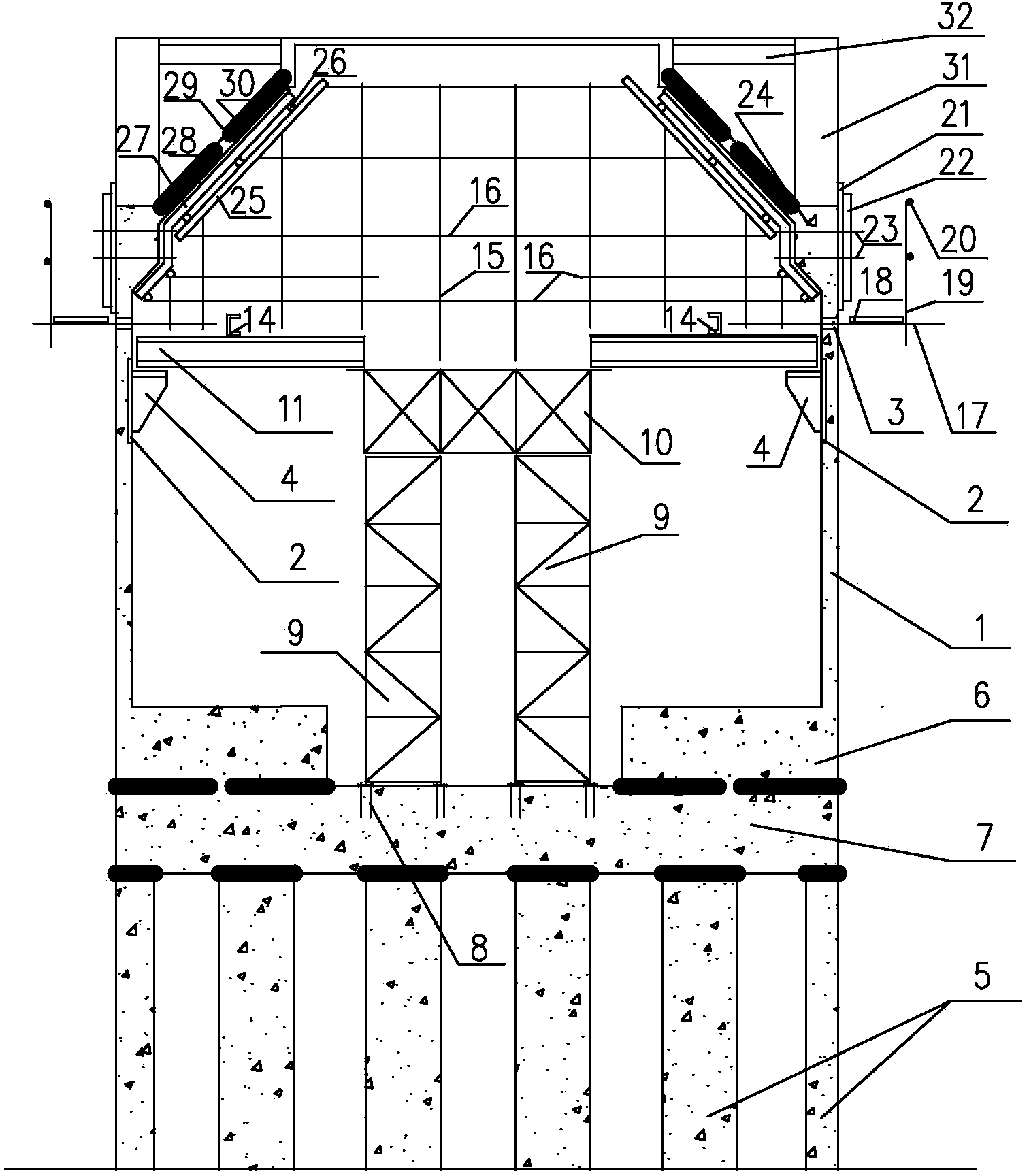

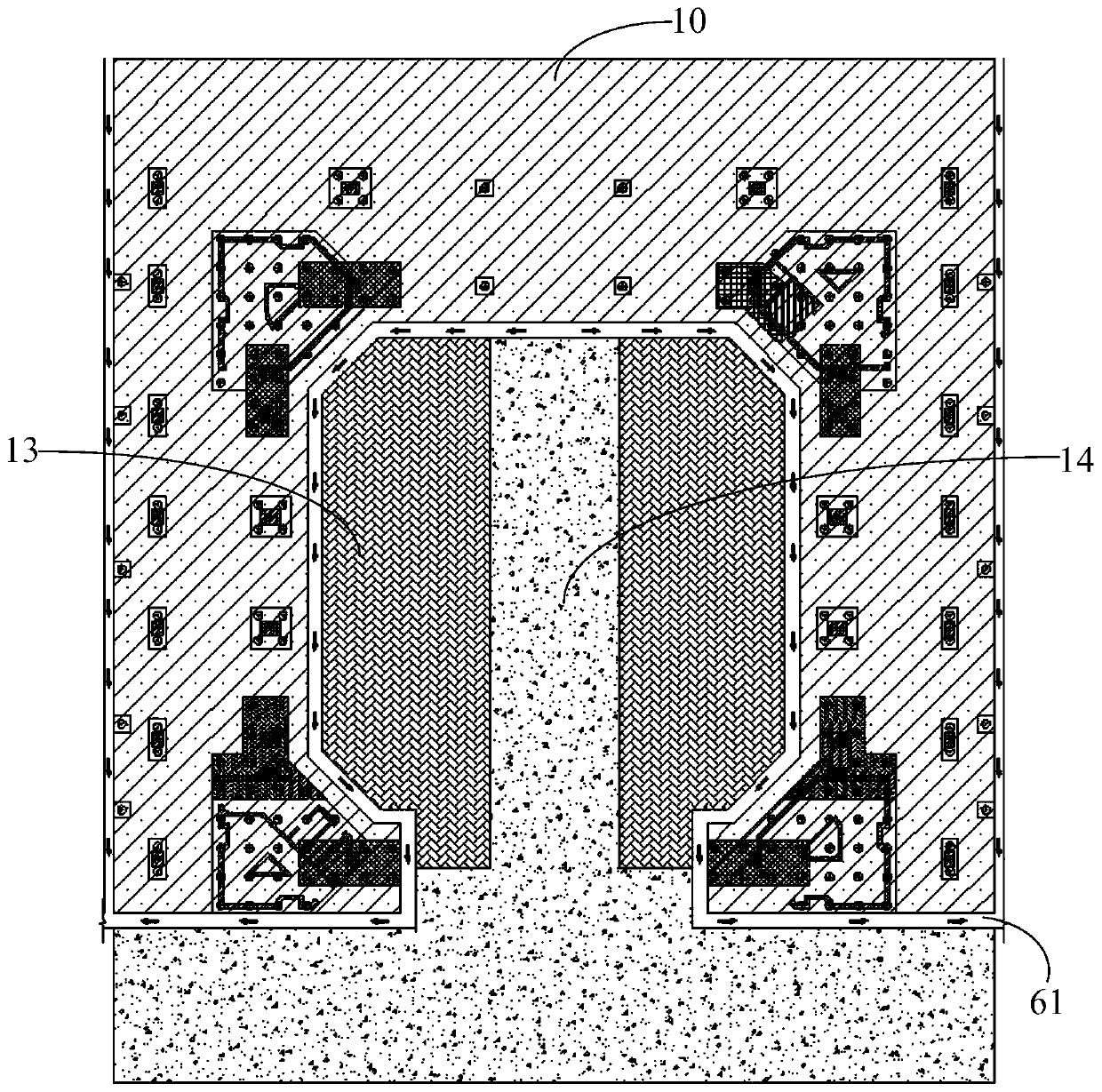

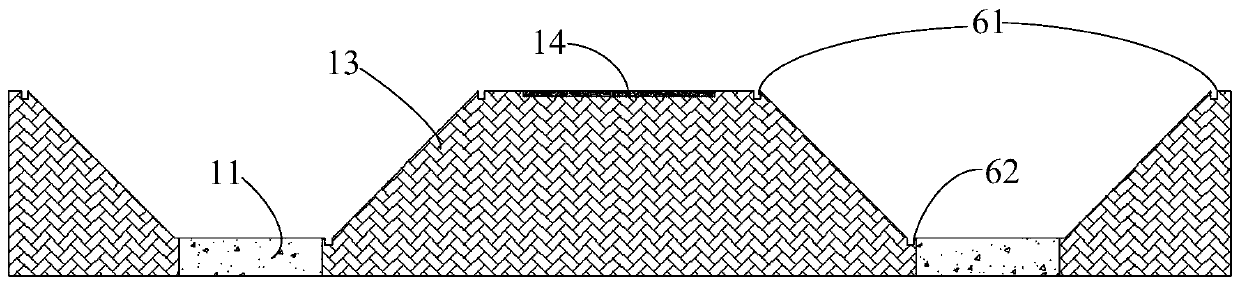

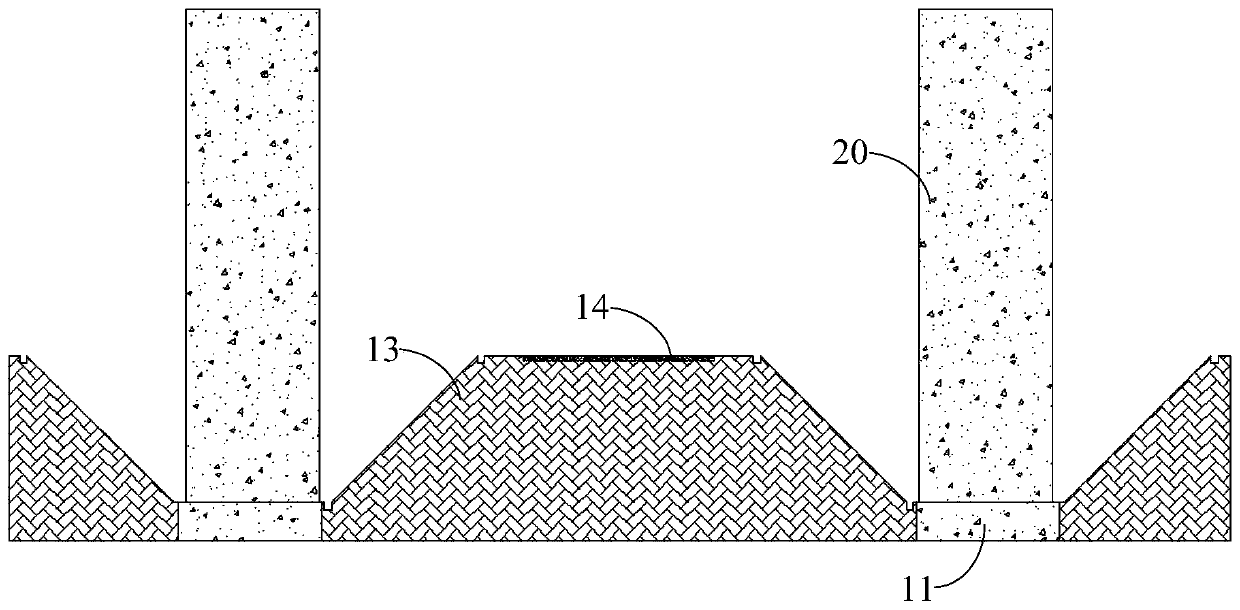

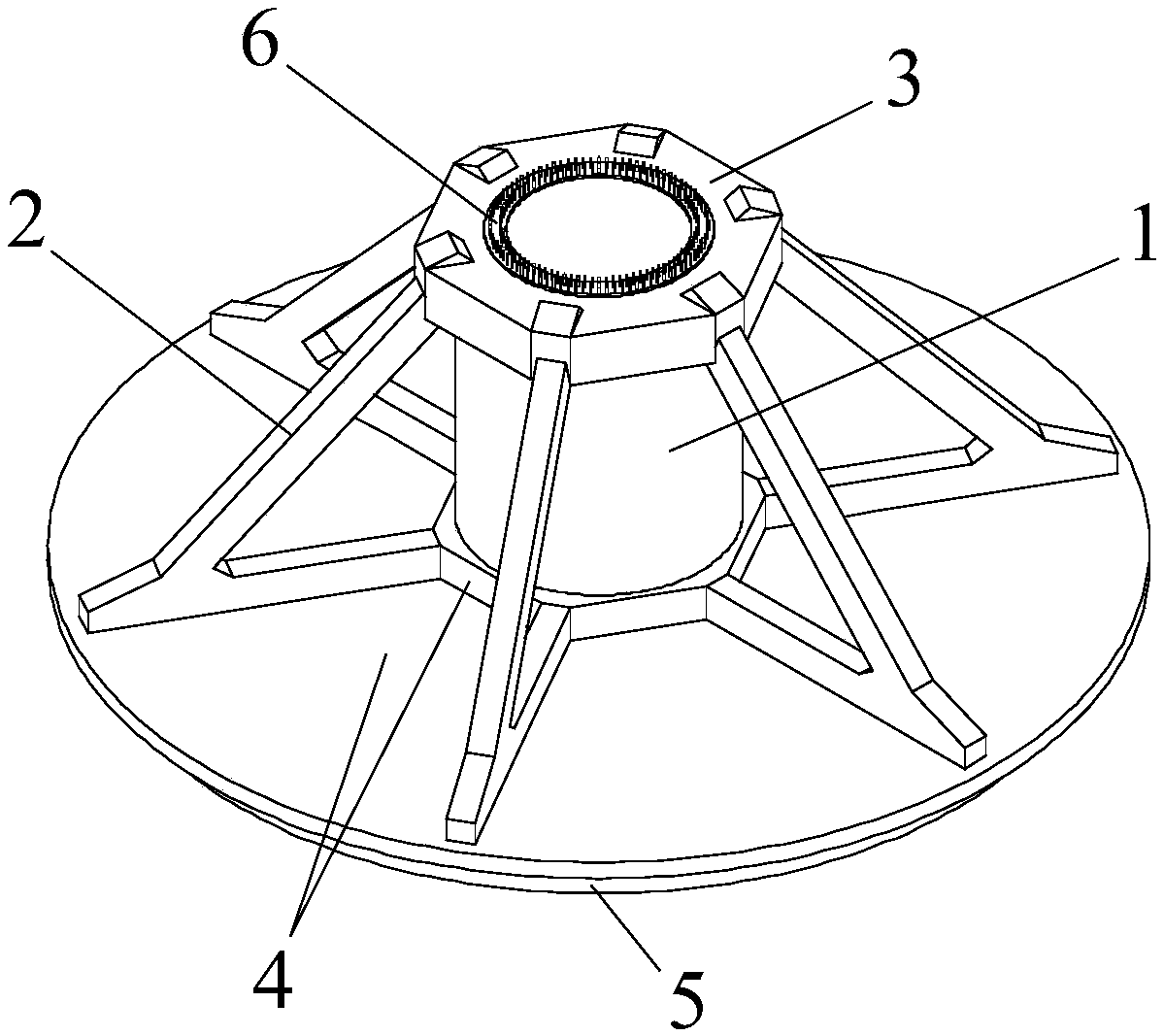

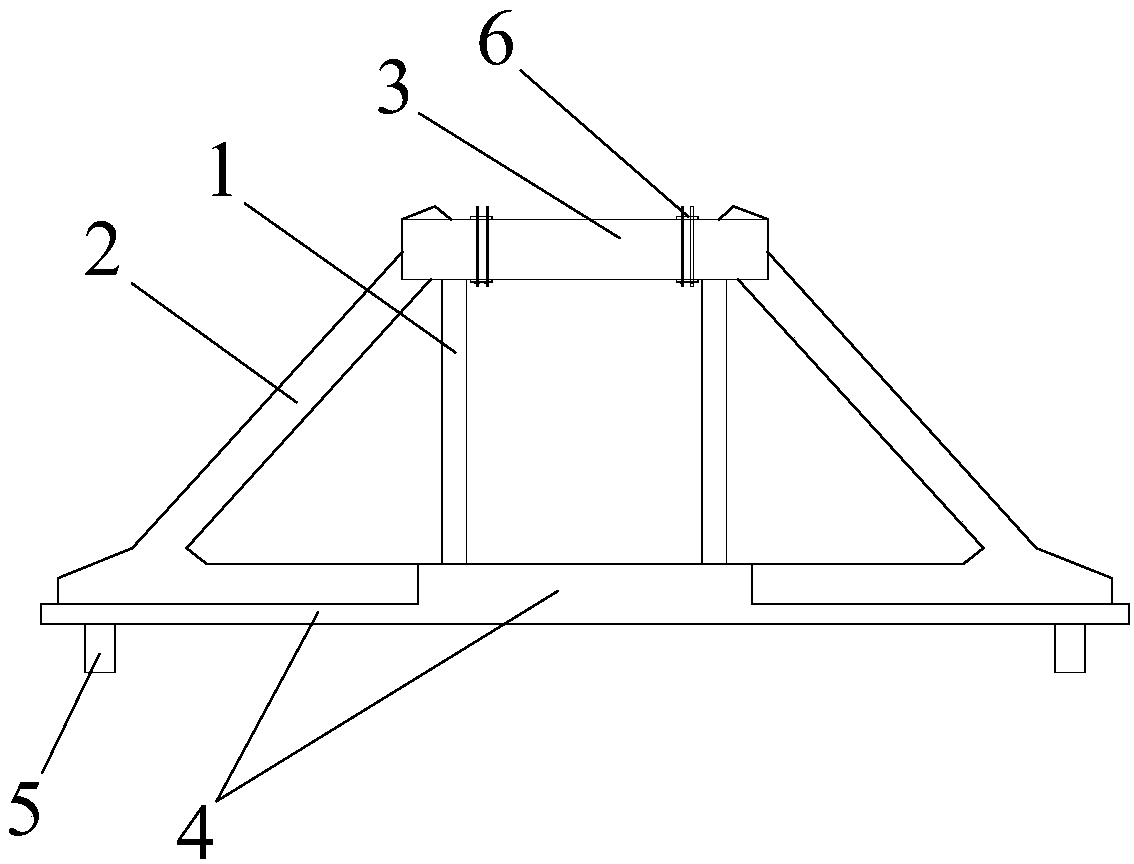

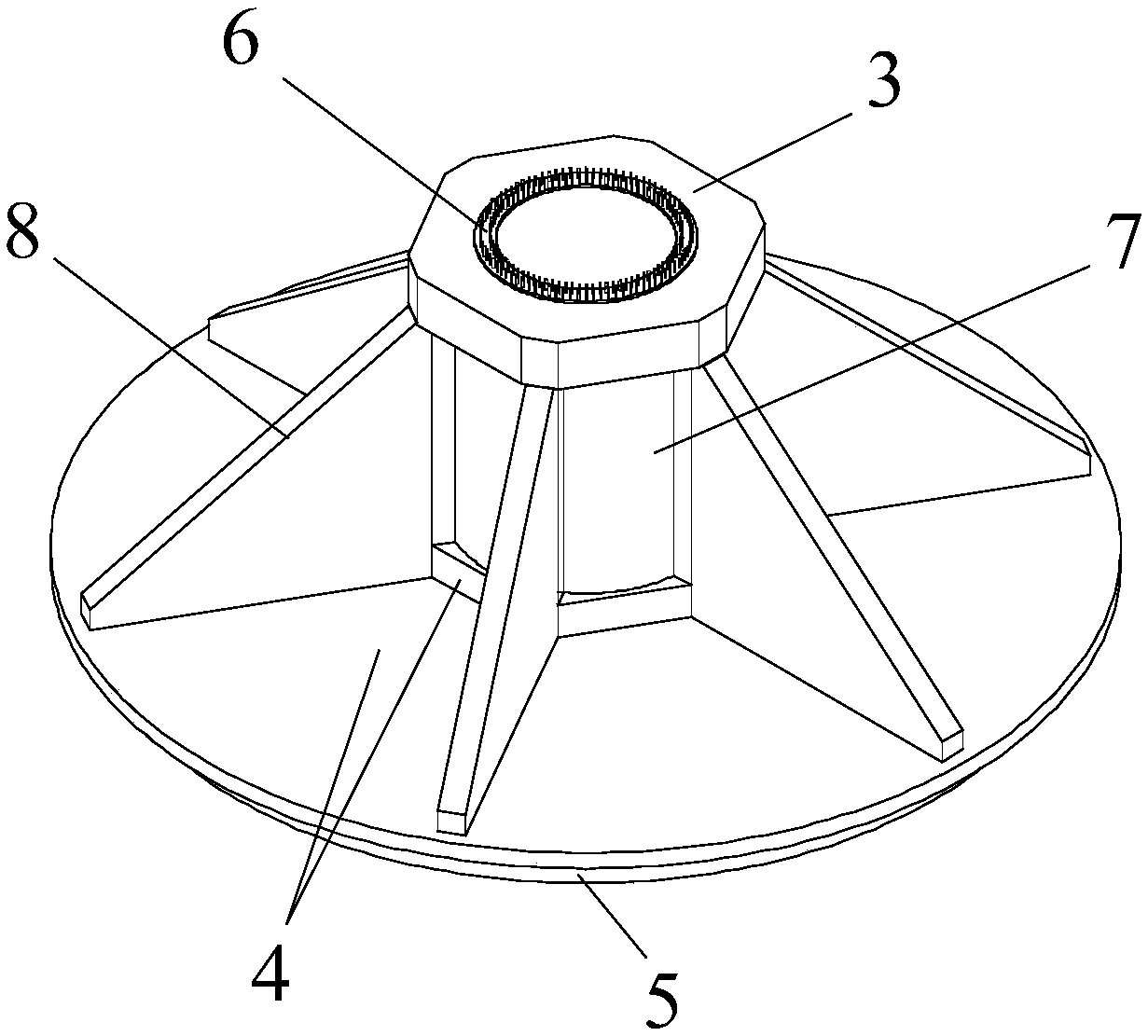

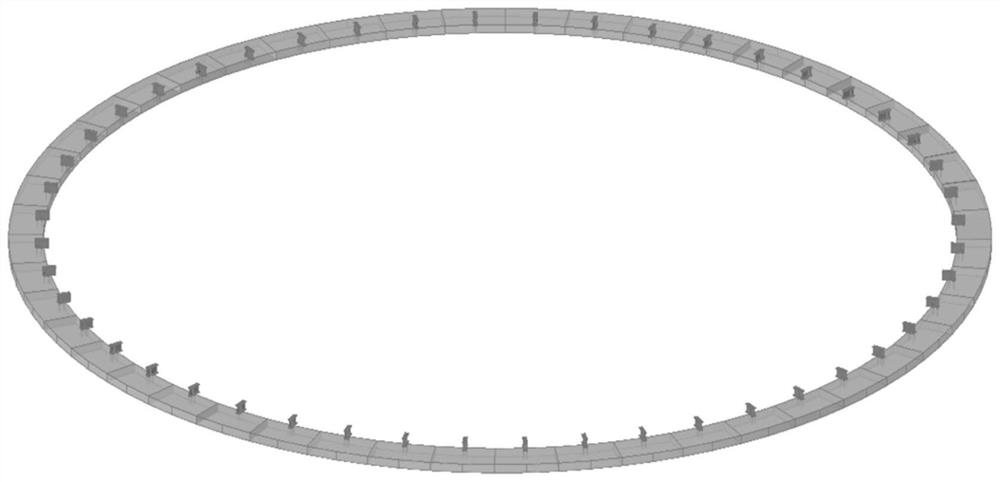

Assembly type wind-powered tower barrel base and construction method thereof

InactiveCN109518712AIncrease stiffnessImprove anti-overturn performanceFoundation engineeringElectricityTower

The invention provides an assembly type wind-powered tower barrel base. The assembly type wind-powered tower barrel base comprises a prefabricated or superposed central barrel body, a plurality of prefabricated supporting parts, a cast-in-place top plate, a cast-in-place bottom plate and a side beam, wherein the prefabricated or superposed central barrel body is arranged on the cast-in-place bottom plate; the prefabricated supporting parts are arranged on the cast-in-place bottom plate at equal distance around the prefabricated or superposed central barrel body; the cast-in-place top plate isarranged on the prefabricated or superposed central barrel body; and the side beam is arranged in annular direction of the periphery of the cast-in-place bottom plate. The assembly type wind-powered tower barrel base basically realizes assembly of the tower barrel base, is reasonable in structure, can effectively reduce material utilization amount, reduces the construction cost, and shortens the working period. The invention further provides a construction method of the assembly type wind-powered tower barrel base.

Owner:SHENZHEN SINO CAPITAL ELECTRIC NEW POWER DESIGN INST CO LTD

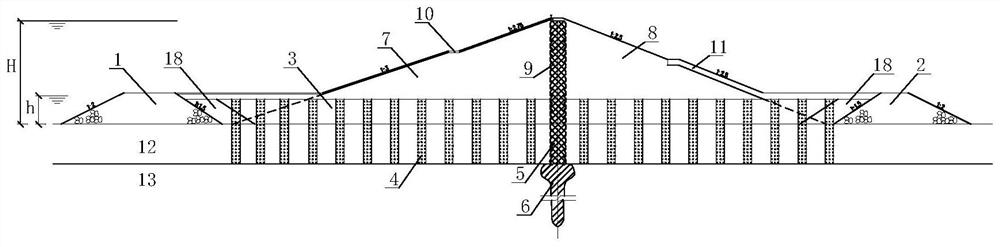

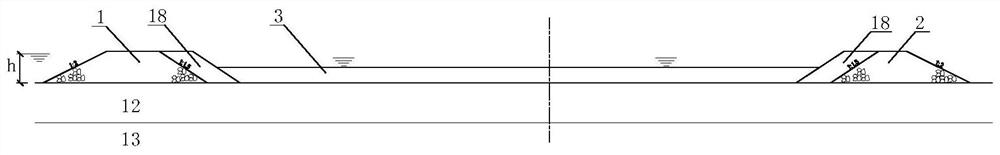

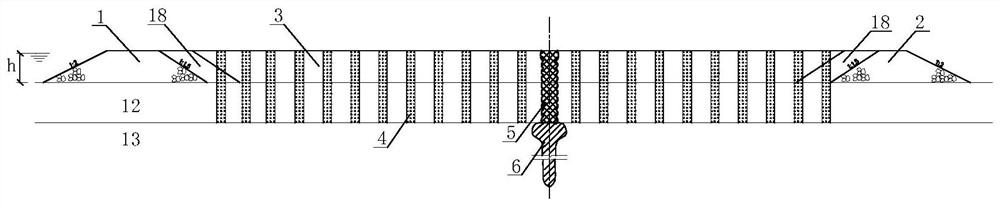

Construction method and structure of poured anti-seepage core earth-rock dam

PendingCN111851505AFast filling speedEasy constructionEmbankmentsEarth-fill damsLand acquisitionCofferdam

The invention discloses a construction method and structure of a poured anti-seepage core earth-rock dam. The method comprises an underwater dam body filling and dam foundation treatment method, a poured anti-seepage core wall formation method, and a dam material selection and control method. The dam structure is divided into an upper dam body, a lower dam body and an anti-seepage system. The lower dam body is directly completed by vibrating and densifying the underwater dumping and filling dam material. The upper dam body is completed by layered compaction of sand gravel, soft rock, gravel soil, weathered materials and excavation slag in a reservoir area, and compaction control is carried out by a comprehensive method of test, calculation and analysis, filling indicators and constructionparameters. The anti-seepage system is composed of the connection of anti-seepage core walls formed in the dam bodies and overburden through a pulsating grouting technology and a bedrock curtain. Themethod and structure expands the application scope of earth-rock dams, direct underwater dumping and filling construction is achieved, the construction period is effectively shortened, cofferdam filling, weir seepage prevention, foundation pit excavation, foundation pit pumping are saved, and material yard, slag yard land acquisition and related water conservation and environmental protection measures are saved.

Owner:CHINA WATER RESOURCES PEARL RIVER PLANNING SURVERYING & DESIGNING +1

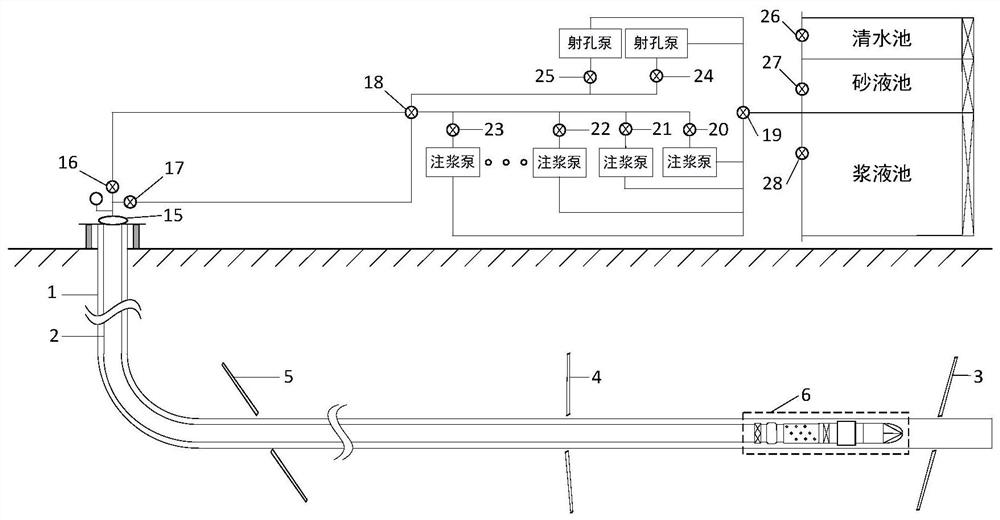

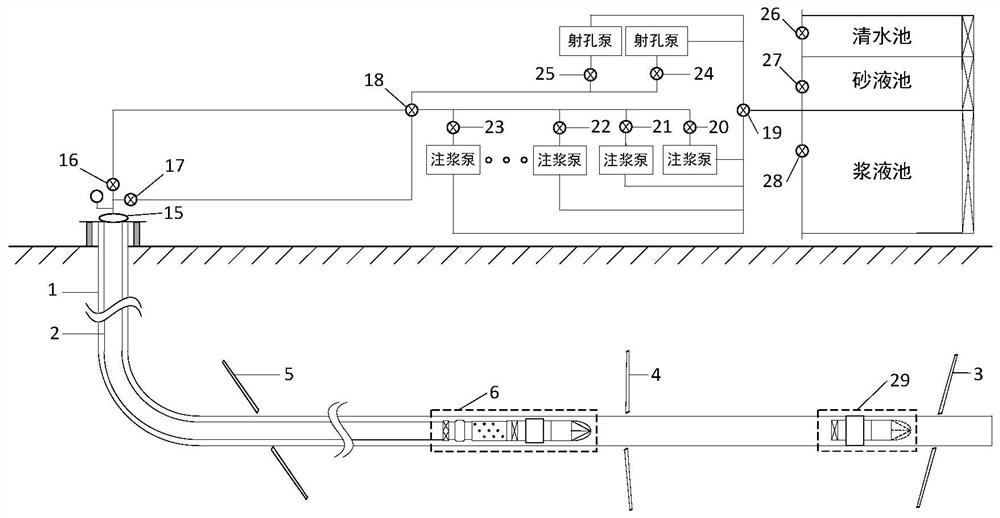

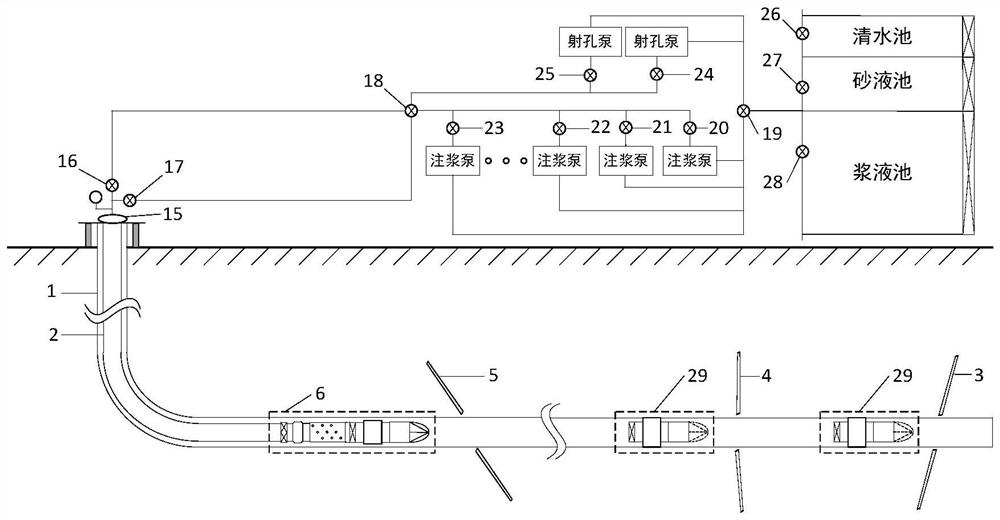

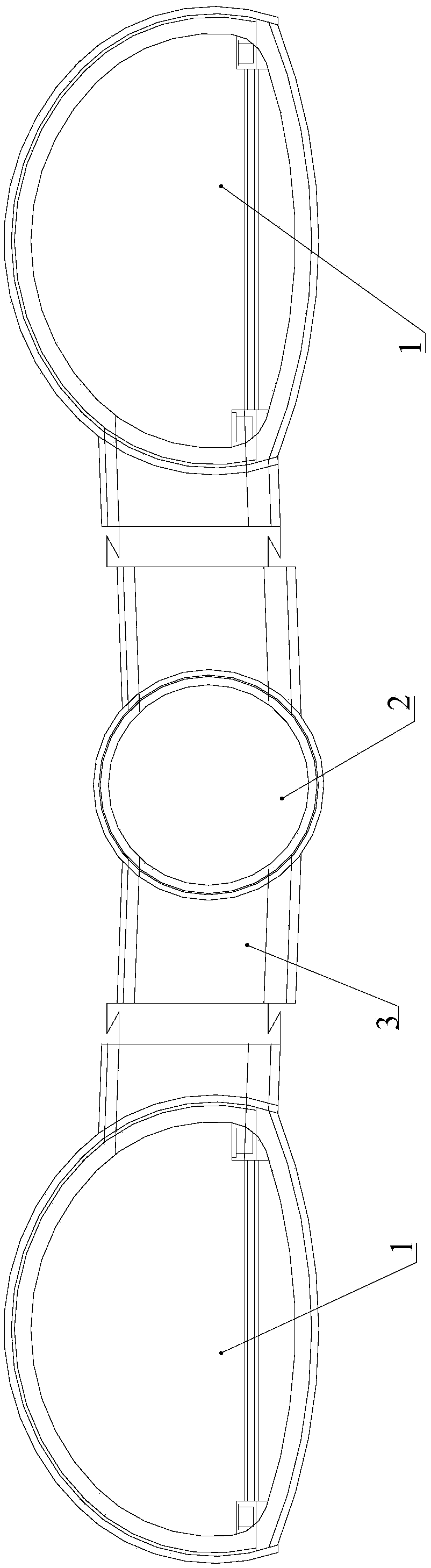

Horizontal drilling and segmented pressure maintaining grouting device and method for water-bearing layer of coal seam floor

ActiveCN113107418AReduce waiting timeShorten the total construction periodSealing/packingCoiled tubingSlurry

The invention relates to a horizontal drilling and segmented pressure maintaining grouting device and method for a water-bearing layer of a coal seam floor. The device comprises a perforating gun and an oil passing pipe packer, wherein the perforating gun is used for being connected with a coiled oil pipe, and is provided with a plurality of spraying holes; and the oil passing pipe packer is connected with the perforating gun through a releasing tool and is used for setting a located casing pipe when receiving pressure. The device and method provided by the invention have the advantages that segmented reliable grouting is achieved; repeated hole sweeping work during grouting of a next grouting point in the advancing type grouting process is reduced; the construction efficiency is improved; the construction cost is reduced; by using the split grouting mode, the wellhead pressure is enabled to be effectively transferred to a grout leakage point; a prefabricated pressure maintaining device is used for segmented pressure maintaining; the grouting construction can be performed on the next grouting point while pressure maintaining is performed on the previous grouting point; the waiting time for solidification of grout in a hole is reduced; and the total construction period of a grouting project is effectively shortened.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Three-hole highway tunnel and middle drift TBM-double main hole drilling and blasting joint construction method

PendingCN107916941AImprove construction progressSolve the problem of insufficient escape and rescue capabilitiesTunnelsStructural engineeringMechanical engineering

The invention discloses a three-hole highway tunnel. The three-hole highway tunnel comprises two main holes, and a middle drift is formed between the two main holes, is communicated with the two mainholes through several vehicle running transverse holes separately and is a channel at least satisfying one-way vehicle running. The invention further discloses a middle drift TBM-double main hole drilling and blasting joint construction method. The method comprises the steps of adopting a drilling and blasting method for construction on hole opening sections of the main holes and the middle driftin the period of TBM production, assembly and debugging; making a TBM walk to a working surface of the middle drift to start TBM tunneling and making the two main holes continue drilling and blastingconstruction; constructing preliminary supporting of the middle drift; constructing an inverted arch of the middle drift; adopting the drilling and blasting method to dig the vehicle running transverse holes and entering the main holes to dig main hole auxiliary working surfaces; digging the initial working surfaces of the main holes and the main hole auxiliary working surfaces in the same direction; utilizing a TBM method to complete digging of the middle drift and utilizing the drilling and blasting method to complete digging of the main holes.

Owner:CCCC SHEC DONGMENG ENG CO LTD

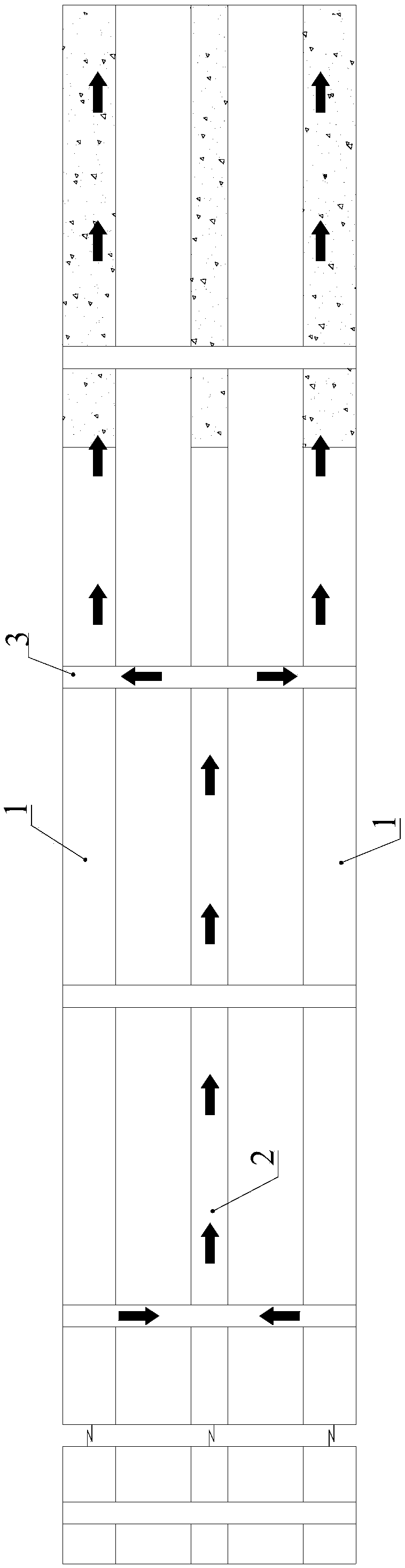

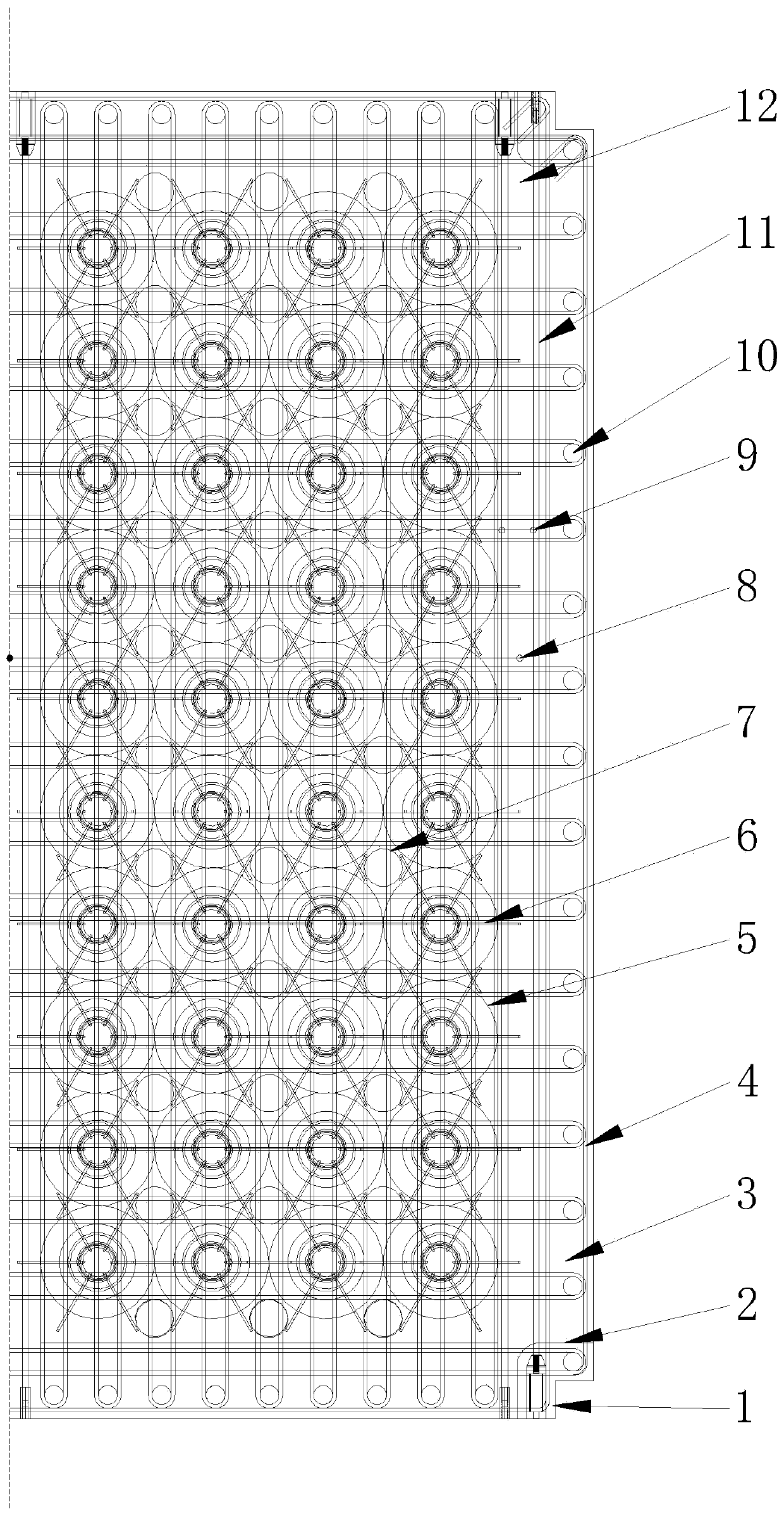

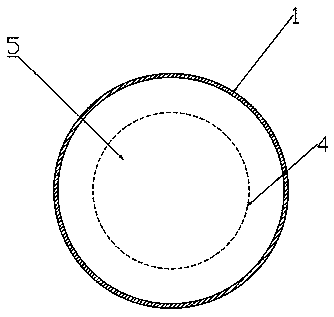

Composite prefabricated floor slab for fabricated building

ActiveCN110107019AReduce weightImprove sound insulationFloorsBuilding reinforcementsSupporting systemFloor slab

The invention discloses a composite prefabricated floor slab for a fabricated building, and belongs to the technical filed of fabricated buildings. The composite prefabricated floor slab comprises a concrete prefabricated plate, composite filling rings are preburied on the inner side of the concrete prefabricated plate at intervals, a center tension anchor rebar system is arranged between every two adjacent composite filling rings, reinforcing bearing beams are arranged on the inner side of the concrete prefabricated plate at intervals, and bearing beam rebar trusses are arranged in the reinforcing bearing beams. According to the composite prefabricated floor slab, the composite filling rings are adopted to effectively decrease the overall weight of the prefabricated floor slab, meanwhile,the concrete pouring amount is decreased, the soundproof and heat-insulation effects of the prefabricated floor slab are reinforced, a complete rebar supporting system is formed by tension anchor rebar meshes, the center tension anchor rebar systems and the bearing beam rebar trusses, the work load of the prefabricated floor slab is borne, lots of work procedures, labor, costs, materials and timeare saved, and the easy-machining property of prefabricated components and the building overall quality performance are improved.

Owner:CHINA MCC17 GRP

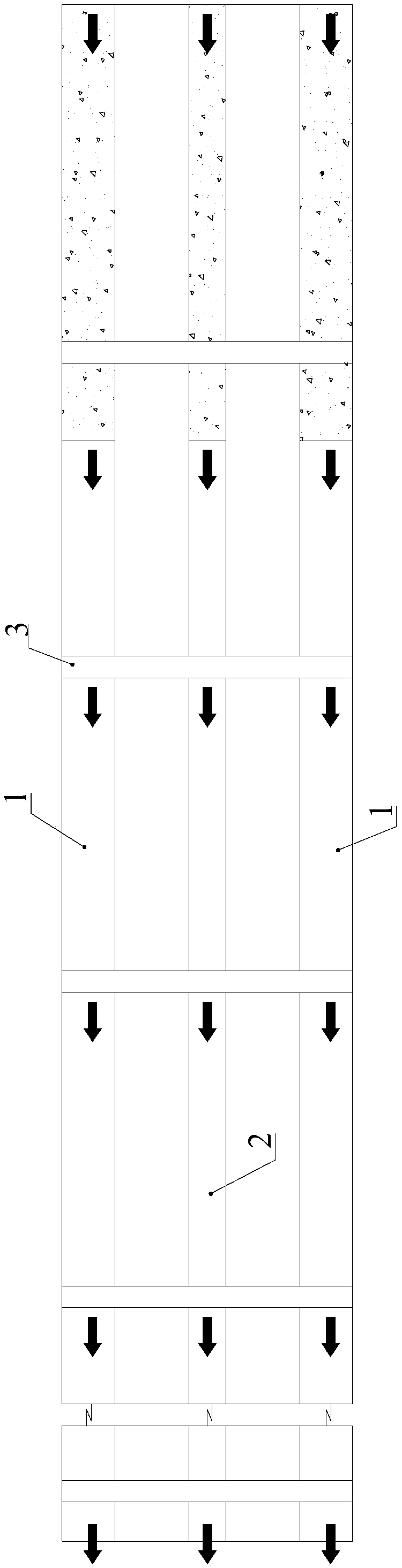

Interpenetrating construction effect-raising method of entire cast-in-place outer wall high-rise housing

InactiveCN108049496AImprove the level of refinementShorten the total construction periodBuilding material handlingArchitectural engineeringProject management

The invention discloses an interpenetrating construction effect-raising method of entire cast-in-place outer wall high-rise housing. The method comprises the steps of construction at a main body structure construction layer of the N layer; construction at a dismantling construction layer of the N-1 layer; construction at a propped sealing construction layer of the N-2 layer; construction at an inner wall plate construction layer of the N-3 layer; construction at a drainage installation construction layer of the N-4 layer; construction at a pipeline installation construction layer of the N-5 layer; construction at a ceiling putty construction layer of the N-6 layer; construction at a kitchen and bathroom tiles paving construction layer of the N-7 layer; construction at a step and floor tiles paving construction layer of the N-8 layer; construction at an inner wall face first putty construction layer of the N-9 layer; construction at an inner wall face second putty construction layer ofthe N-10 layer; and construction at a staircase construction layer of the N-11 layer. It is guaranteed that the entire cast-in-place outer wall high-rise housing all kinds of professional type of jobscan be in interspersed operation continuously, so that the total construction time is shortened, the work efficiency is improved, and the refinement level of project management is promoted.

Owner:佛山市万科置业有限公司 +1

Underpinning structure and underpinning construction method for shock isolation and reinforcing of existing building

PendingCN107795144AReduce consumptionReduce the overall heightBuilding repairsProtective buildings/sheltersArchitectural engineeringUltimate tensile strength

The invention discloses an underpinning structure and an underpinning construction method for shock isolation and reinforcing of an existing building. The underpinning structure comprises an upper structure, a lower structure and a plurality of supporting columns; the upper structure is located on the upper portion of the mounting position of a shock isolation supporting seat of the existing building, and the lower structure is located on the lower portion of the mounting position of the shock isolation supporting seat of the existing building; and the multiple supporting columns are located on the outer side of the mounting position of the shock isolation supporting seat, and the two ends of the multiple supporting columns tightly abut against the upper structure and the lower structure correspondingly. During construction, after the supporting columns abut tightly, column concrete on the mounting position of the shock isolation supporting seat is cut, the shock isolation supporting seat is mounted, gaps between the shock isolation supporting seat and the upper structure as well as the lower structure are filled, grouting and compaction are conducted, and after the concrete strength meets requirements, the supporting columns are removed. Therefore, according to the underpinning structure and the underpinning construction method for shock isolation and reinforcing of the existing building, the underpinning structure utilizes an original structure component, model selection is simple, the underpinning construction method is convenient to construct, and the construction period is short.

Owner:南京分震建筑科技有限公司

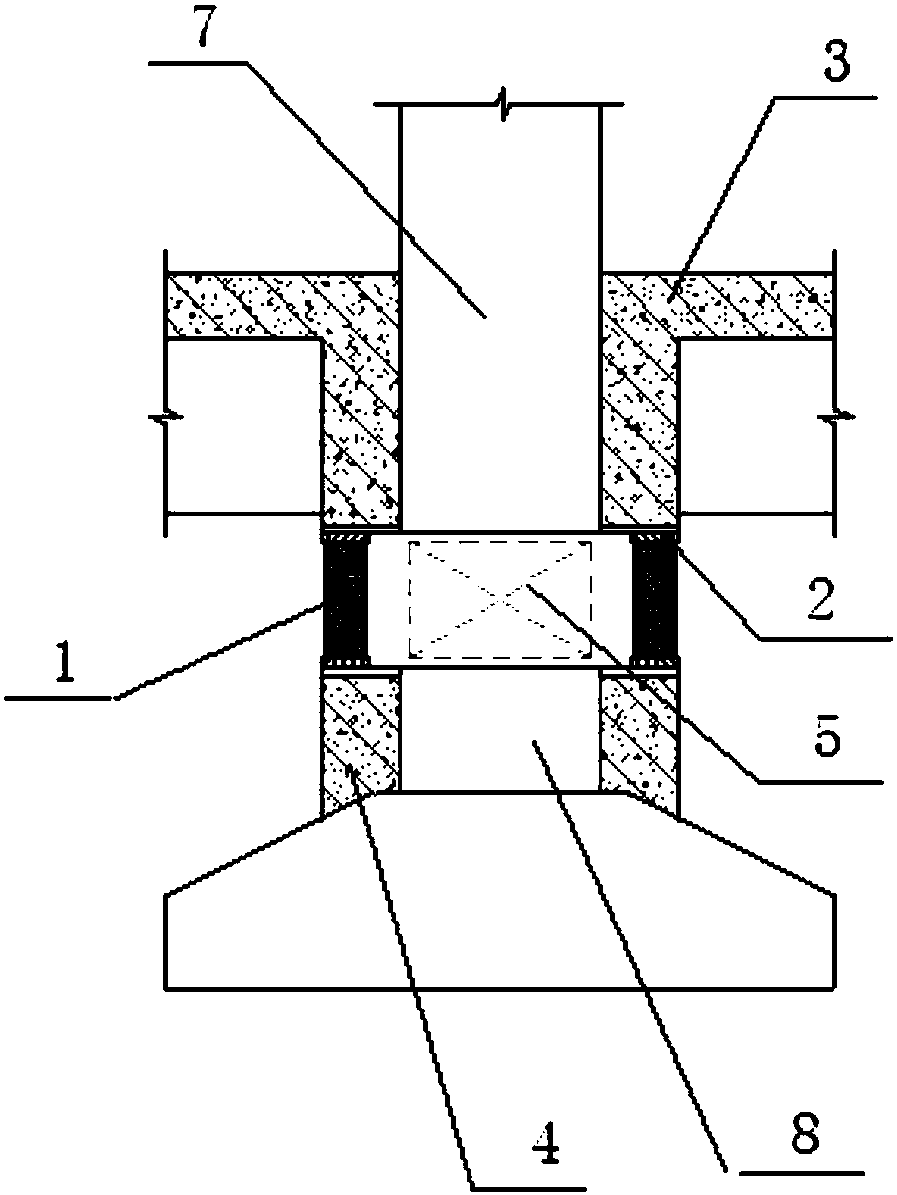

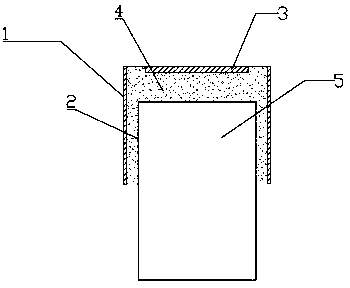

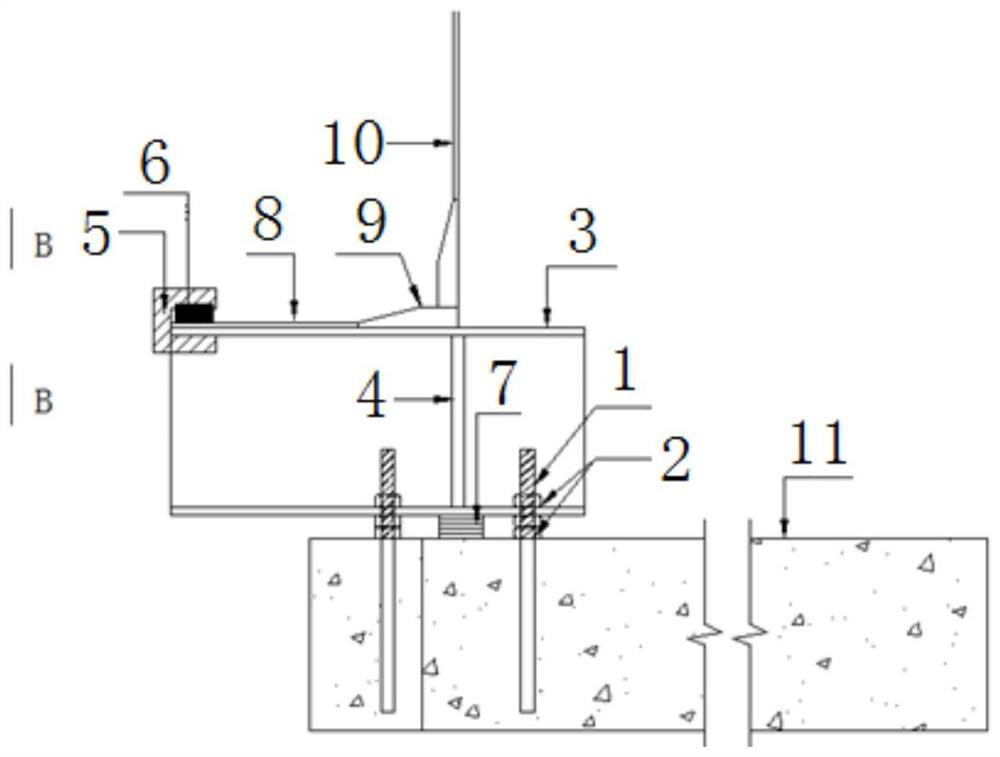

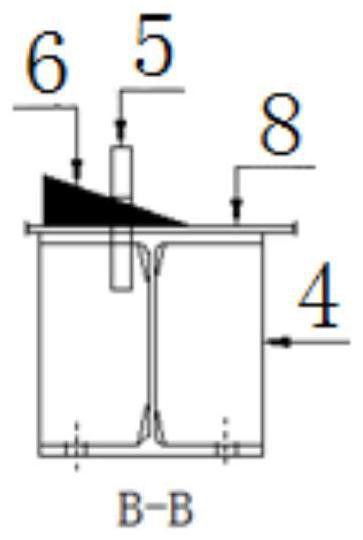

Pile cap for single pile bearing capacity detection of CFG pile and using method thereof

InactiveCN110847253ASimple structureEasy to manufactureFoundation testingBulkheads/pilesPile capPipe

The invention relates to a pile cap for single pile bearing capacity detection of a CFG pile. The pipe cap is used for bearing the CFG pile with a single pile bearing capacity of less than or equal to1000 KN. The pile cap comprises a steel protection barrel and a steel plate, and is characterized in that the steel protection barrel is a round hollow steel pipe matched with the end head of the CFGpile, and the steel pipe can movably sleeve the end head of the CFG pile to form the pile cap; the inner wall of the periphery of the hollow steel pipe abuts against the outer side of the end head ofthe CFG pile, and is filled with fine sand in the middle; the steel plate is a circular steel plate; and the round steel plate is centrally placed on the top of the fine sand on the upper opening ofthe steel pipe. The pile cap for the single pile bearing capacity detection of the CFG pile has the advantages that the pile cap is simple in structure, convenient to manufacture, safe and reliable indetection engineering quality, the pile inspection period is greatly shortened, and thus the construction total period is reduced, the material price of the pile cap is low, and the pile cap can be reused, and the construction cost is reduced.

Owner:CHINA MCC20 GRP CORP

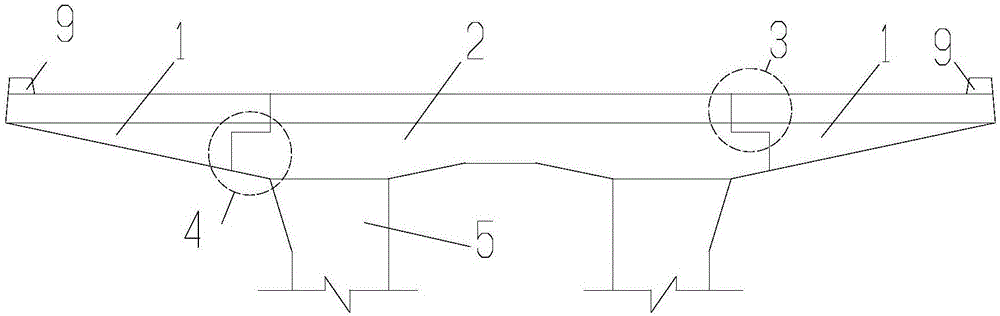

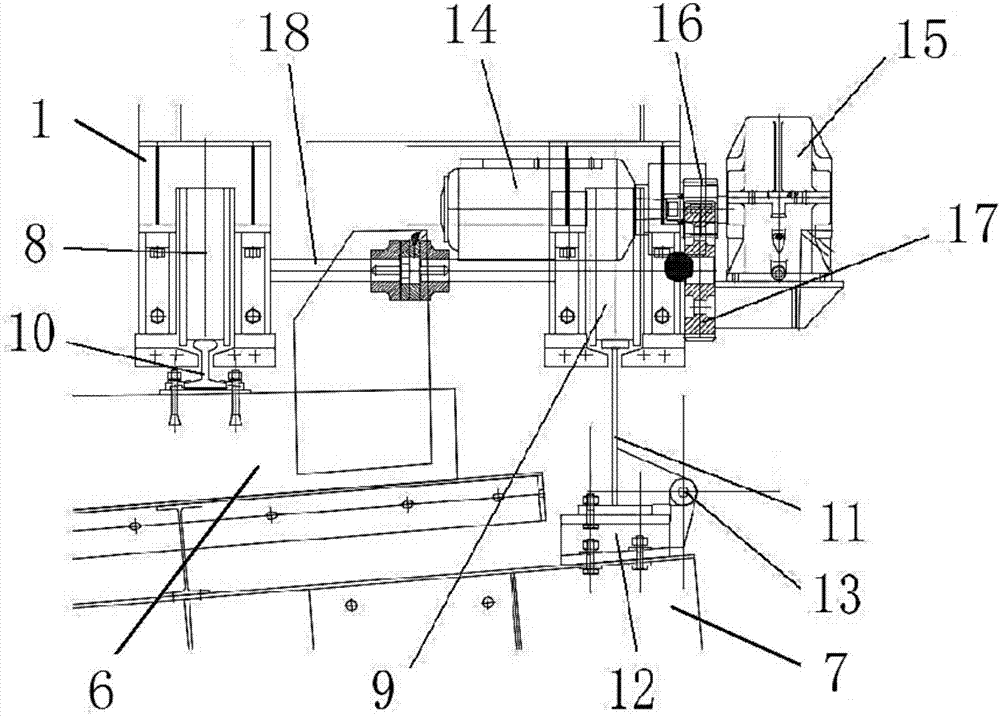

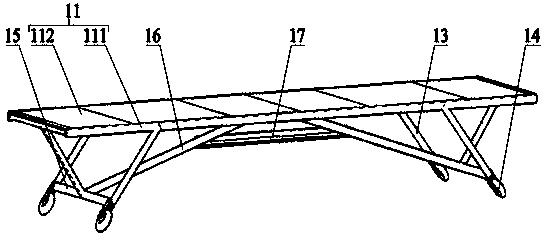

Variable-breadth movable support and construction method thereof

PendingCN112064505AHigh degree of mechanizationLabor savingBridge erection/assemblyConcrete beamsArchitectural engineering

The invention relates to a variable-breadth movable support and a construction method thereof. A poured lower-layer railway concrete beam is used as a bearing, and an upper-layer box girder construction platform capable of moving longitudinally and transversely is used. The variable-breadth movable support has the advantages of all tubular pile supports, and longitudinal moving wheel sets and transverse moving trolleys are installed at the bottom of the support so that the purposes of longitudinal hole passing and transverse breadth passing of the movable support can be achieved. Secondly, inorder to avoid a highway frame pier capping beam, side wing formworks of the movable support are made into bendable structures, and supporting stand columns are designed to be telescopic stand columns; and in the hole passing or breadth passing process, the height of a body of the whole movable support is reduced in a manner that the side wing formworks are rotatably bent and the movable support is integrally lowered, so that it is guaranteed that the movable support can smoothly pass through a highway frame pier door opening. The operation mechanization degree of the whole movable support ishigh.

Owner:THE 2ND ENG CO LTD MBEC

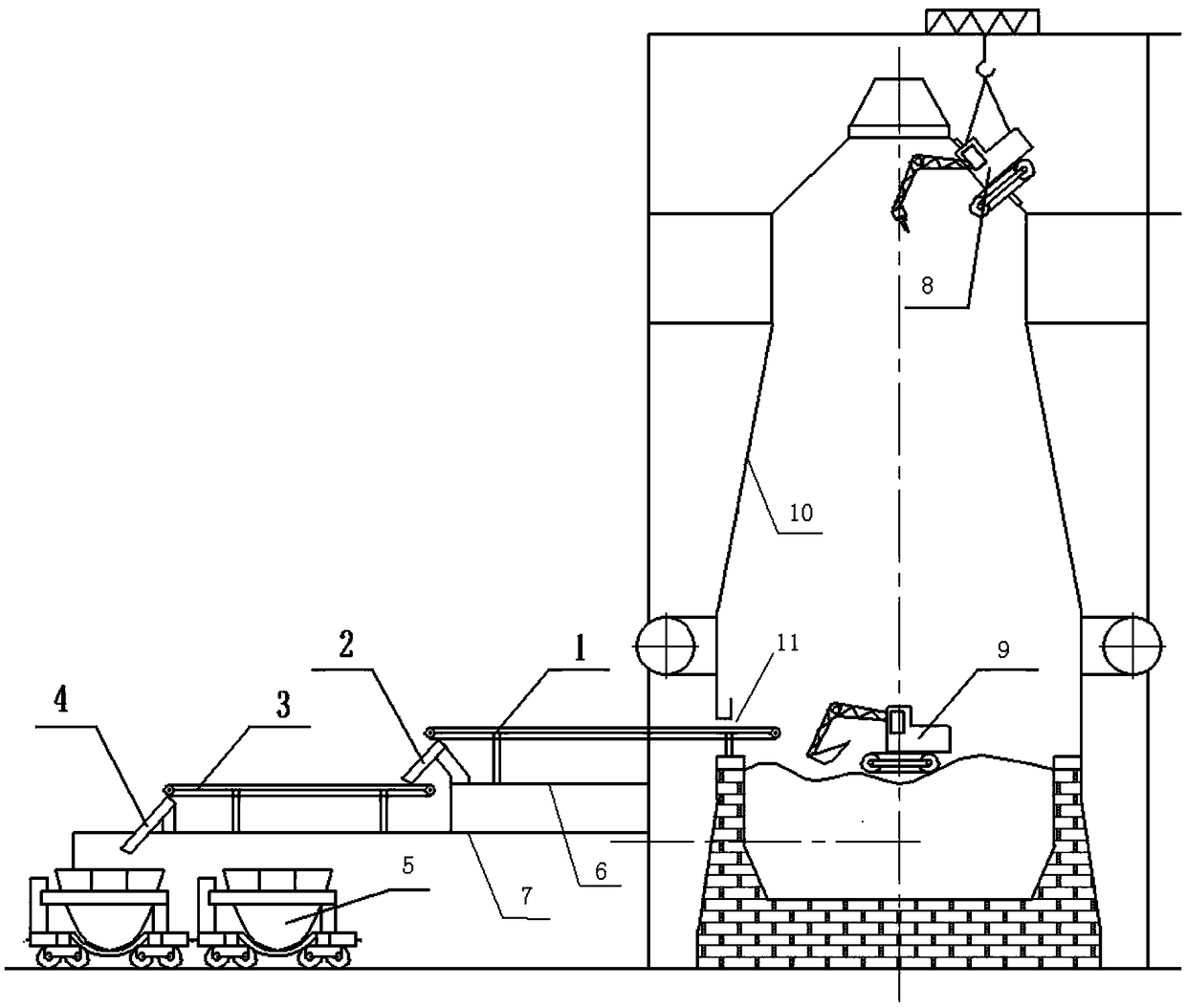

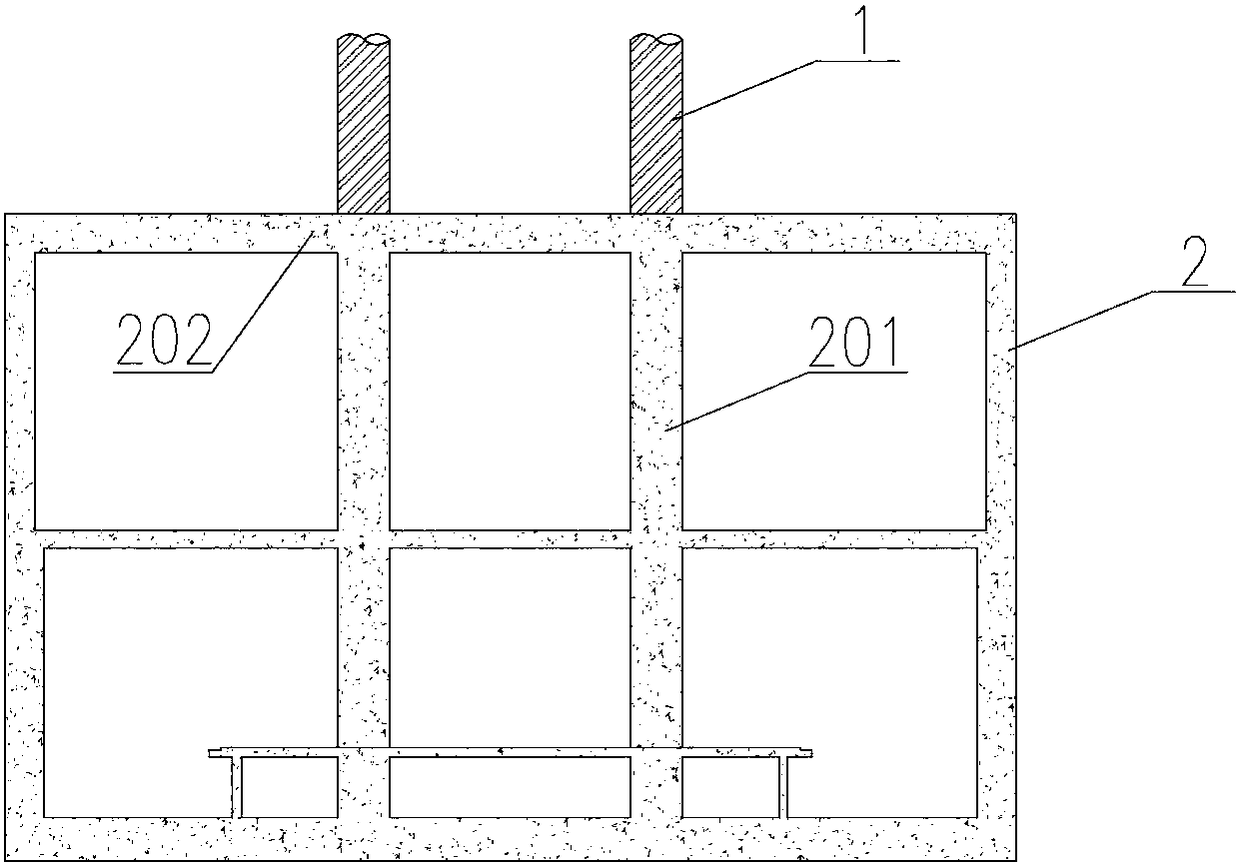

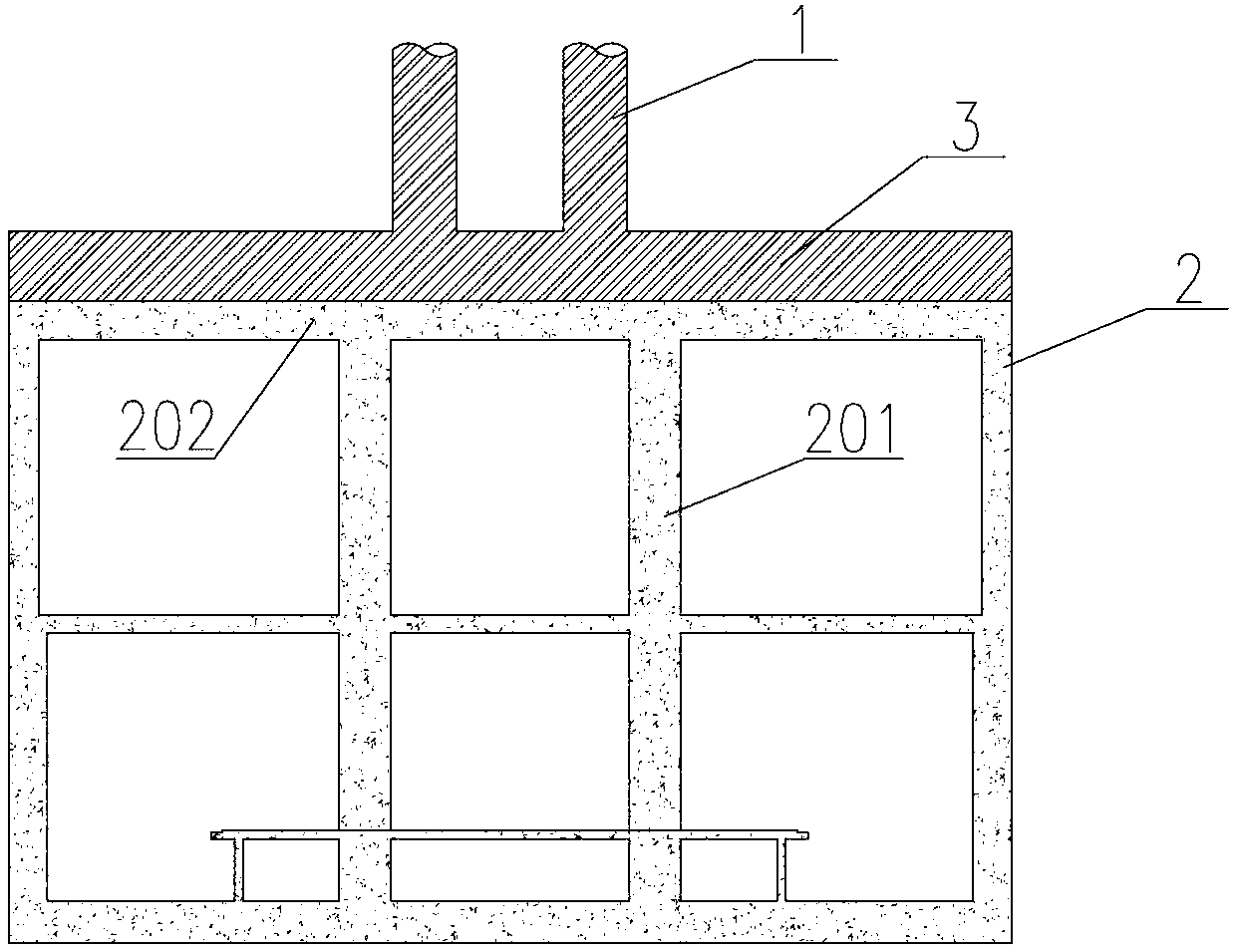

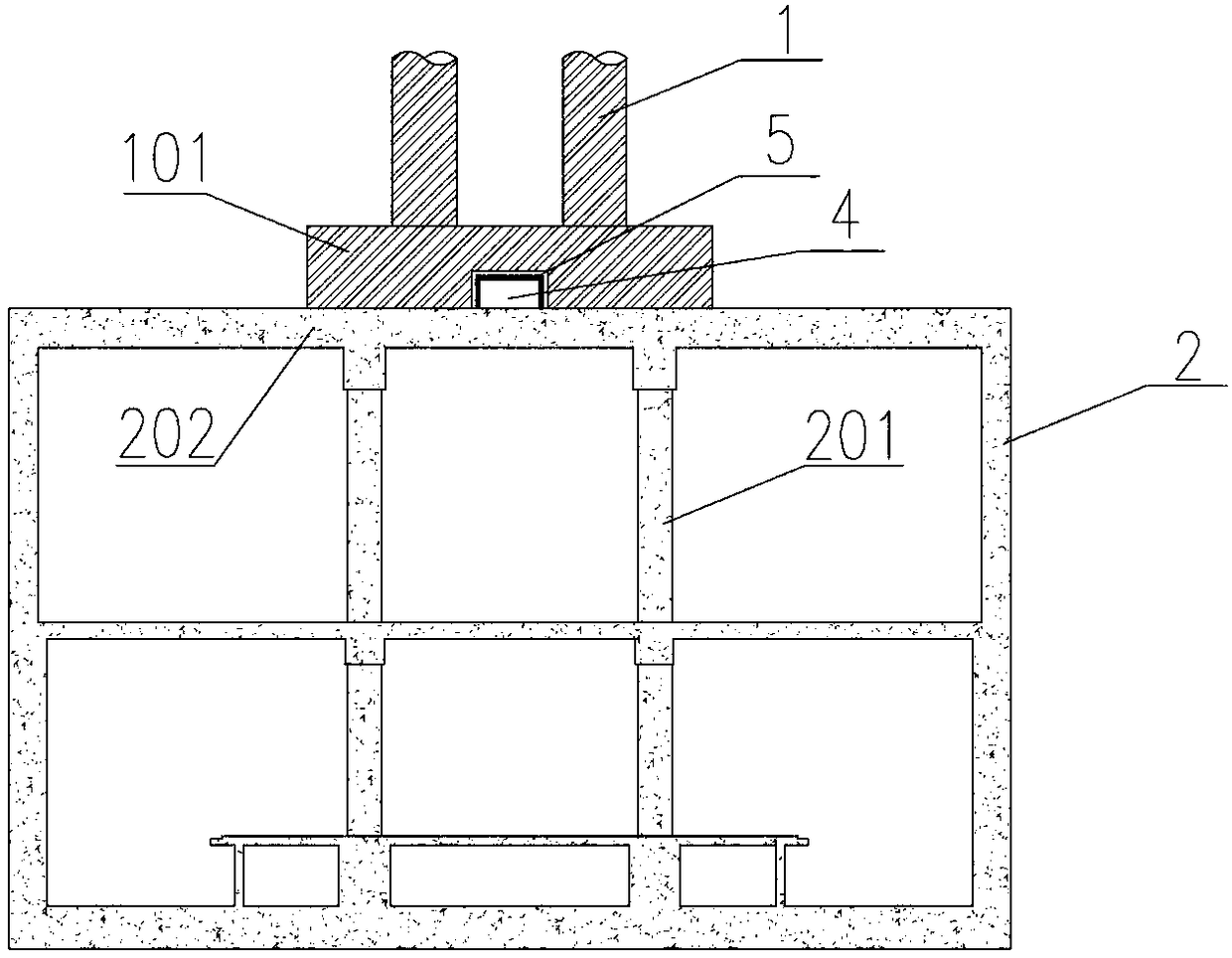

A system and method for cleaning in-furnace waste materials during major overhaul of a large blast furnace

PendingCN108624730ANo deformation, cracking and water leakageNo cracking or leakageBlast furnace componentsBlast furnace detailsSlagEngineering

The invention belongs to the field of blast furnaces in iron making, and particularly relates to a system and method for cleaning in-furnace waste materials during major overhaul of a large blast furnace. The system includes excavators, roller belt conveyors, spouts and slag receivers. The two excavators are lifted into the furnace from a top manhole, one of the excavators is provided with a hydraulic hammer and used for crushing waste materials, and the other excavator is provided with a bucket shovel and used for loading and transporting the waste materials. One of the roller belt conveyorsis arranged on a blast furnace tuyere platform, and the front end of the roller belt conveyor extends into the furnace from a blast furnace air supply port. A blast furnace cast house platform is provided with the other roller belt conveyor the front end of which is connected to the tail end of the roller belt conveyor on the blast furnace tuyere platform through a spout, and the tail end of whichis connected to the slag receivers on the ground through a spout. The waste materials in the furnace are conveyed through the excavators, the roller belt conveyors, and the spouts, from the blast furnace air supply port to the ground slag receivers, while passing through the tuyere platform and the cast house platform, and therefore manual work is replaced by mechanical operation, the working efficiency is greatly increased, in-furnace waste material cleaning time during major overhaul of the blast furnace roller is effectively shortened, the construction cost is saved, and the blast furnacecan be used for production in advance.

Owner:BENGANG STEEL PLATES

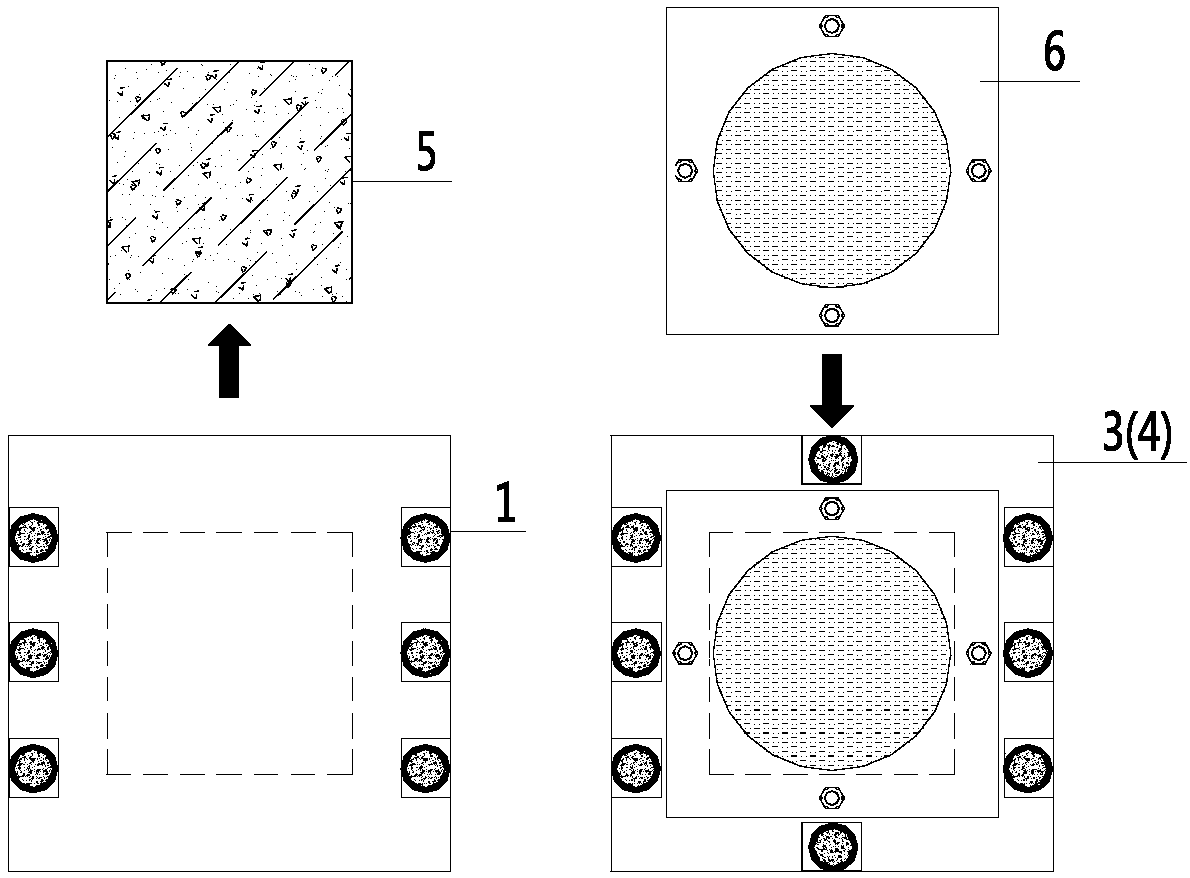

Pier plate column combination part structure

PendingCN108130918AFunction does not affectHigh implementabilityArtificial islandsCellarsLine tubingIndependent function

The invention discloses a pier plate column combination part structure which comprises bridge piers which are mutually fixedly connected with each other and an underground space structure; the underground space structure comprises upright columns and a top plate; a plurality of upright columns are embedded into the ground and support underground; the top plate is fixed at the top ends of a plurality of upright columns; the bridge piers are fixed on the top plate; and a plurality of upright columns are arranged corresponding to a bridge direction of the bridge piers. The pier plate column combination part structure provided by the invention can have both the respective independent functions of an elevated bridge and the underground space structure; the bridge piers are combined with or separated from the top plate of the underground space structure, the arrangement of the bridge piers does not influence the function of the underground space structure, the underground space structure istaken as a bearing foundation of a bridge at the same time, separate independent design, construction and building of the elevated bridge and the underground space structure are facilitated, and the implementation of the bridge and the underground space structure is realized; and the bridge piers utilize the underground space structure as the bearing foundation, occupy less underground space, areconvenient in laying of underground pipelines and save underground precious space resources.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

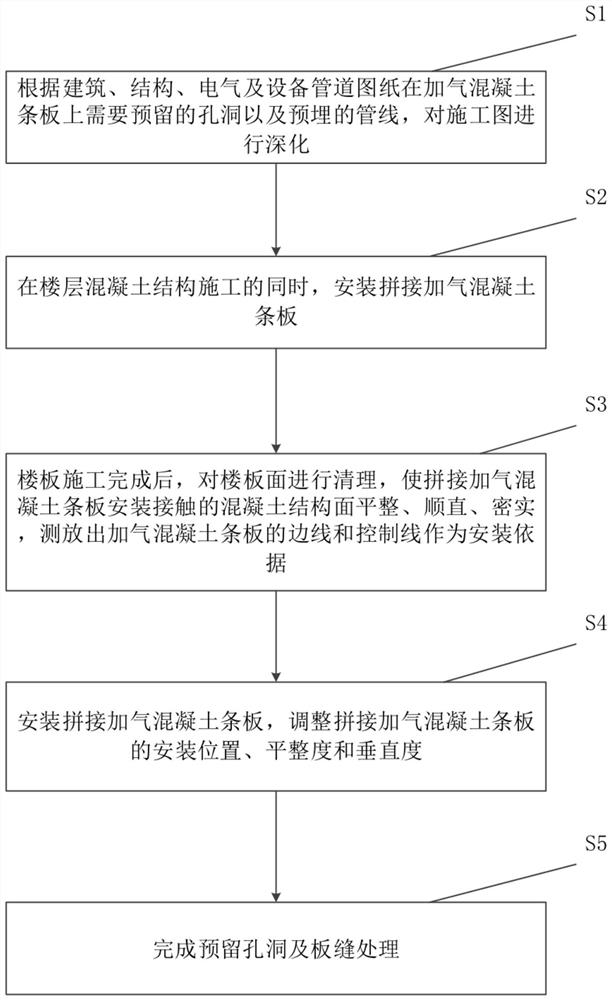

Spliced aerated concrete batten construction method

InactiveCN112177352ALight weightHigh strengthBuilding material handlingEarthquake resistanceFloor slab

The invention relates to the technical field of building construction, and discloses a spliced aerated concrete batten construction method. The spliced aerated concrete batten construction method comprises the following steps of S1, deepening a construction drawing according to holes needing to be reserved and pre-buried pipelines on aerated concrete battens in building, structure, electrical andequipment pipeline drawings; S2, mounting and splicing the aerated concrete battens while a floor concrete structure is constructed; S3, after floor slab construction is completed, cleaning a floor slab surface, enabling a concrete structure surface making contact with the spliced aerated concrete battens during installation to be smooth, straight and compact, and measuring side lines and controllines of the aerated concrete battens to serve as the installation basis; S4, mounting the spliced aerated concrete battens, and adjusting the installation positions, flatness and perpendicularity ofthe spliced aerated concrete battens; and S5, finishing reserved hole and slab joint treatment. According to the spliced aerated concrete batten construction method, a construction process is simplified, the mechanical construction degree is improved, the total construction period is shortened, and the anti-seismic property is improved.

Owner:唐山盾石建筑工程有限责任公司

Combined prefabricated bridge guardrail

PendingCN110820553AMeet the collision avoidance requirementsImprove landscapeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a combined prefabricated bridge guardrail. The guardrail comprises a concrete anti-collision wall body, a steel structure stand column, a steel anti-collision guardrail, a steel pipe guardrail and a concrete hanging plate, wherein the concrete anti-collision wall body is prefabricated in a factory, and the anti-collision requirement is met. The steel structure stand columnplays a role in fixing of a steel pipe cross beam, and the steel anti-collision guardrail acts as an anti-collision beam, and the steel pipe guardrail is provided with a LED lamp strip for achieving the effect of road illumination. After the concrete anti-collision wall body is installed, a longitudinal seam exists with the side surface of a bridge deck, in order to achieve the whole attractiveness effect, the concrete hanging plate is used for shielding, and meanwhile, the hanging plate plays a role in water dripping. The novel combined bridge guardrail is prefabricated in a factory and installed in a field, meanwhile, a guardrail lamp and the anti-collision guardrail are combined, bridge high-pole lamps and guardrail outer side backpacks are omitted, the whole construction period of a bridge can be shortened, meanwhile, the linear effect of a prefabricated part is more attractive, batch production can be achieved, the bridge guardrail can be suitable for a municipal road viaduct, andthe economic benefit is high.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

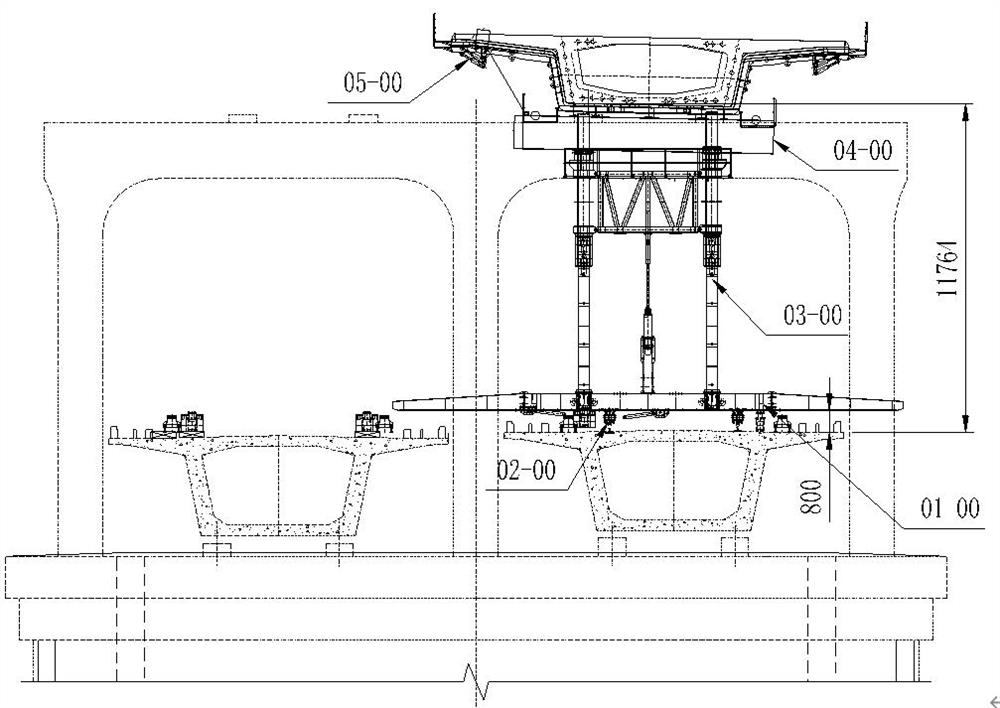

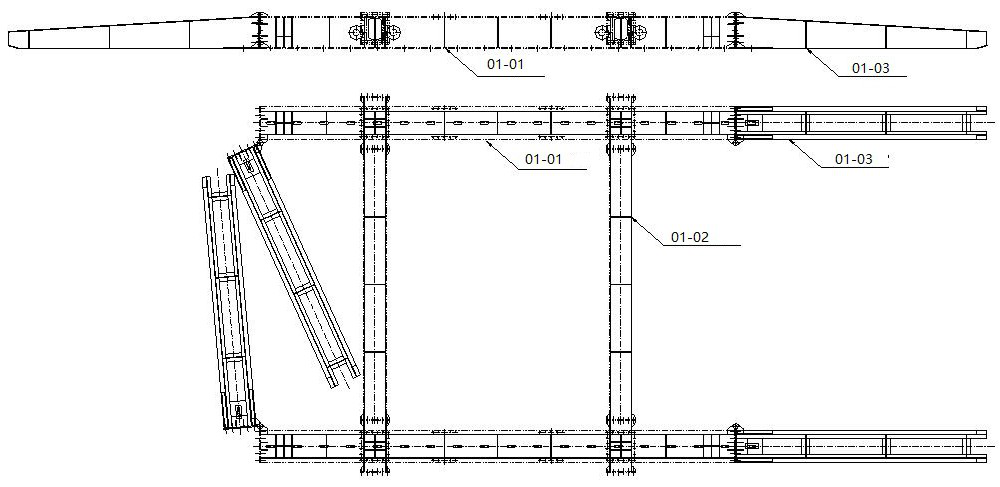

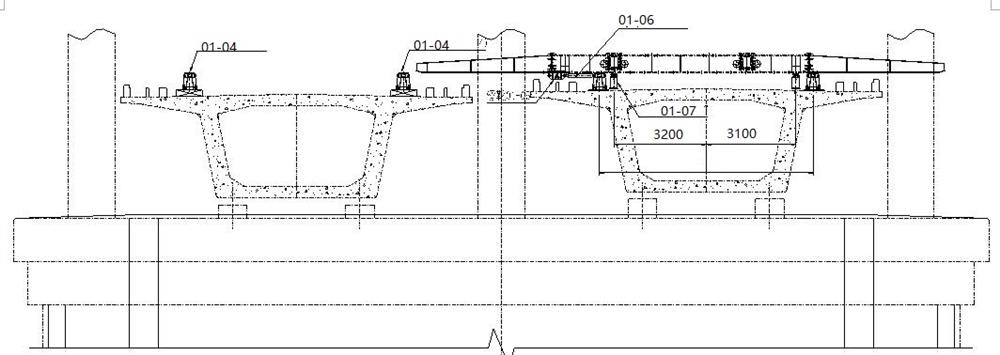

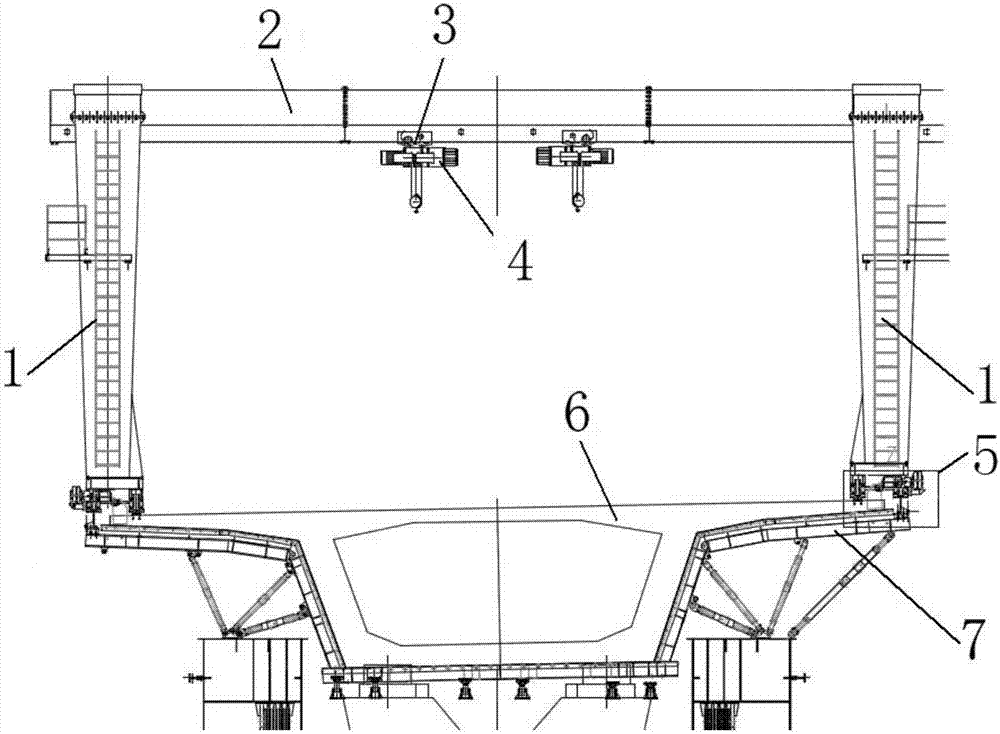

Gantry crane system being matched with movable die frame for being used and construction method of gantry crane system

PendingCN107881925AShorten the construction periodShorten the total construction periodBridge erection/assemblyRebarControl theory

The invention discloses a gantry crane system being matched with a movable die frame for being used and a construction method of the gantry crane system. The gantry crane system comprises a bridge frame, two supporting legs fixed to both sides of the bridge frame, travelling mechanisms, first guide rails and second guide rails, and the travelling mechanisms, the first guide rails and the second guide rails are mounted at the lower ends of the supporting legs; each travelling mechanisms comprises a driving device, an inner side travelling part and an outer side travelling part, and the inner side travelling parts and the outer side travelling parts are mounted at the lower ends of the supporting legs; and the driving devices are used for driving the inner side travelling parts to travel along the first guide rails and used for driving the outer side travelling parts to travel along the second guide rails. The gantry crane system can conveniently transfer steel reinforcement cages, the construction period is greatly shortened, and the construction efficiency is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Alternative construction efficiency improvement method for full cast-in-place outer-wall high-rise housing kitchens and baths

InactiveCN108086714AImprove the level of refinementShorten the total construction periodBuilding constructionsDwelling buildingLine tubingFrame based

The invention discloses an alternative construction efficiency improvement method for full cast-in-place outer-wall high-rise housing kitchens and baths. The method includes the following step of installing a main structure construction layer of the kitchens and baths on the N-th floor, a template detaching construction layer of the kitchens and baths on the N-1-th floor, a top supporting and water stopping construction layer of the kitchens and baths on the N-2-th floor, an inner-wall plate construction layer of the kitchens and baths on the N-3-th floor, a water supply and drainage installation layer of the kitchens and baths on the N-4-th floor, a pipeline installation layer of the kitchens and baths on the N-5-th floor, a ceiling putty layer of the kitchens and baths on the N-6-th floor, a wall tile laying layer of the kitchens and baths on the N-7-th floor, a platform and floor tile laying layer of the kitchens and baths on the N-8-th floor, a door frame base layer of the kitchensand baths on the N-9-th floor, and bath equipment of the kitchens and baths on the N-10-th floor. According to the alternative construction efficiency improvement method for the full cast-in-place outer-wall high-rise housing kitchens and baths, alternative continuous operation of each professional work type of the full cast-in-place outer-wall high-rise housing kitchens and baths is ensured; notonly is the total construction period shortened, but also the work efficiency is improved, and the precision level of project engineering management is improved.

Owner:佛山市万科置业有限公司 +1

Full cast-in-situ outer wall high-rise residential building living room interpenetrating construction efficiency-improving method

InactiveCN108104257AImprove the level of refinementShorten the total construction periodBuilding material handlingLiving roomHigh rise

The invention discloses a full cast-in-situ outer wall high-rise residential building living room interpenetrating construction efficiency-improving method. The full cast-in-situ outer wall high-riseresidential building living room interpenetrating construction efficiency-improving method comprises the following steps that N layers of living room main body structures are constructed; the N-1 layer is subjected to living room formwork-detaching construction; the N-2 layer is subjected to living room erected roof water-stopping; the N-3 layer is subjected to living room inner wallboard construction; the N-4 layer is subjected to living room water supply and drainage mounting; the N-5 layer is subjected to living room pipeline mounting; the N-6 layer is subjected to living room ceiling puttyconstruction; the N-8 layer is subjected to living room balcony and floor tile laying; the N-9 layer is subjected to living room inner wall surface first-time putty construction; and the N-10 layer is subjected to living room inner wall surface second-time putty construction. According to the full cast-in-situ outer wall high-rise residential building living room interpenetrating construction efficiency-improving method, it is ensured that interpenetrating continuous operation of various work types can be conducted during full cast-in-situ outer wall high-rise residential building living roomconstruction, the total construction period is shortened, the working efficiency is improved, and the refinement level of project engineering management is further promoted.

Owner:佛山市万科置业有限公司 +1

Method for improving efficiency of insertion construction of outdoor places of full cast-in-place outer-wall high-rise residence

InactiveCN108104472AImprove the level of refinementShorten the total construction periodBuilding material handlingResidenceLine tubing

The invention discloses a method for improving the efficiency of insertion construction of outdoor places of a full cast-in-place outer-wall high-rise residence. The method comprises the following steps of construction of N layers of outdoor main body structure construction layers, construction of <N-1>th layer outdoor formwork dismounting, construction of <N-2>th layer outdoor supporting waterstop, construction of <N-3>th layer balcony guardrail mounting, construction of <N-4>th layer balcony water supply and drainage mounting, construction of <N-5>th layer balcony pipeline mounting and construction of <N-8>th layer balcony floor tile laying and pasting. According to the method for improving the efficiency of insertion construction of the outdoor places of the full cast-in-place outer-wall high-rise residence, it is ensured that all the construction work types of outdoor engineering construction of the full cast-in-place outer-wall high-rise residence can conduct continuous insertionoperation, the total construction period is shortened, the work efficiency is improved, and the fine level of project engineering management is further improved.

Owner:佛山市万科置业有限公司 +1

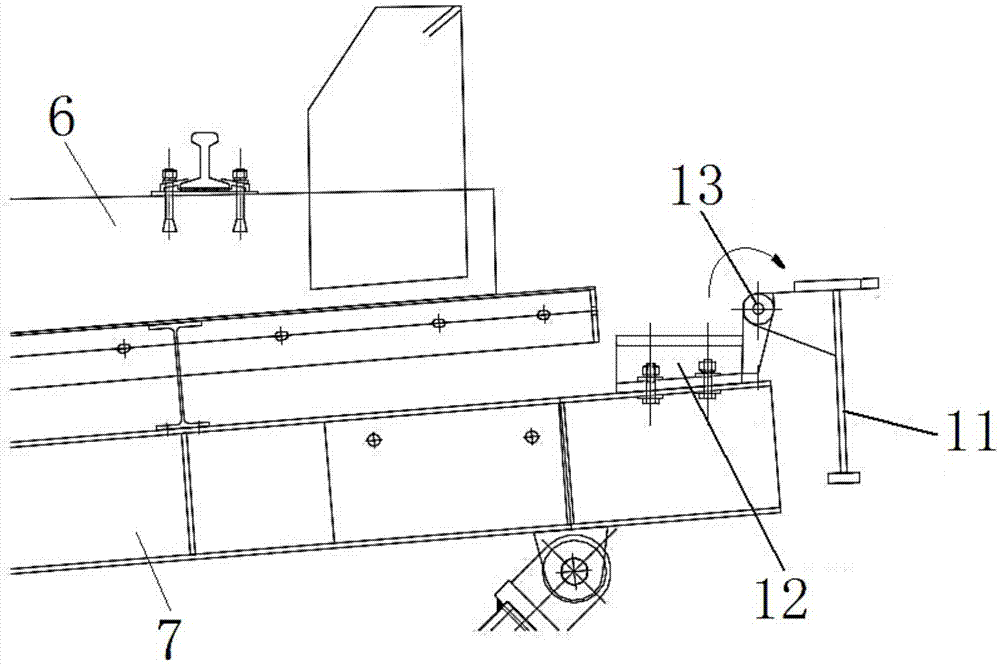

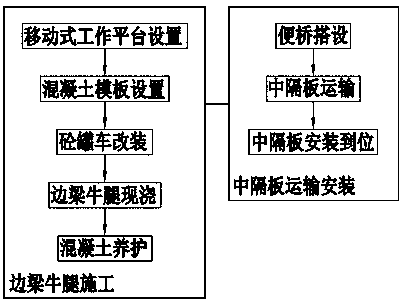

Construction method of middle partition of urban underground comprehensive pipe gallery

ActiveCN111271090AIncrease contact areaAvoid damageUnderground chambersTunnel liningArchitectural engineeringShield tunneling

The invention relates to the field of tunnels and underground engineering, in particular to a construction method of a middle partition of an urban underground comprehensive pipe gallery. The construction method of the middle partition of the urban underground comprehensive pipe gallery includes the following steps that S1, side beam brackets are constructed; and S2, the middle partition is transported and mounted. S1 includes the steps of S1.1, a movable working platform is arranged; S1.2, concrete formworks are arranged; S1.3, a concrete tank car is refit; S1.4, the side beam brackets are cast in place; and S1.5, concrete curing is carried out. S2 includes the steps that S2.1, a temporary bridge is built, wherein the temporary bridge is a steel structure component; S2.2, the middle partition is transported; and S2.3, the middle partition is mounted in place. The construction method is pertinently designed as for various problems in the mounting process of the middle partition of a shield tunnel, construction manners of a single equipment device are integrated and optimized into a set of continuous construction procedures, it is guaranteed that all the procedures are smoothly carried out, all the procedures in construction of the shield tunnel have the possibility of simultaneous execution, the construction total period is shortened while the construction quality is guaranteed, and the operation potential safety hazards are overcome.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

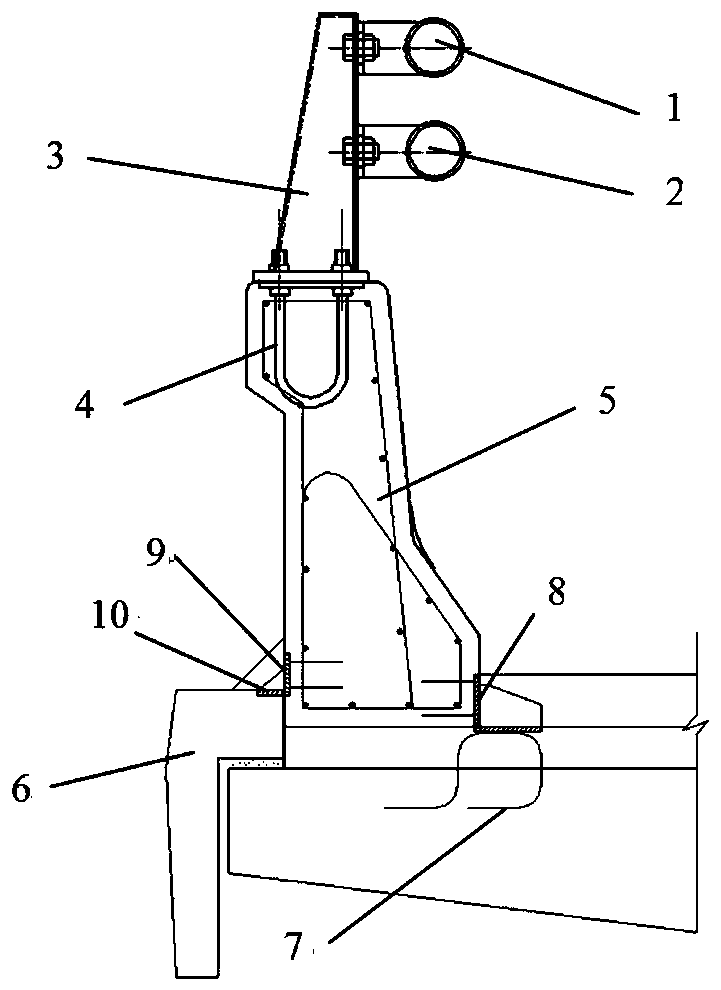

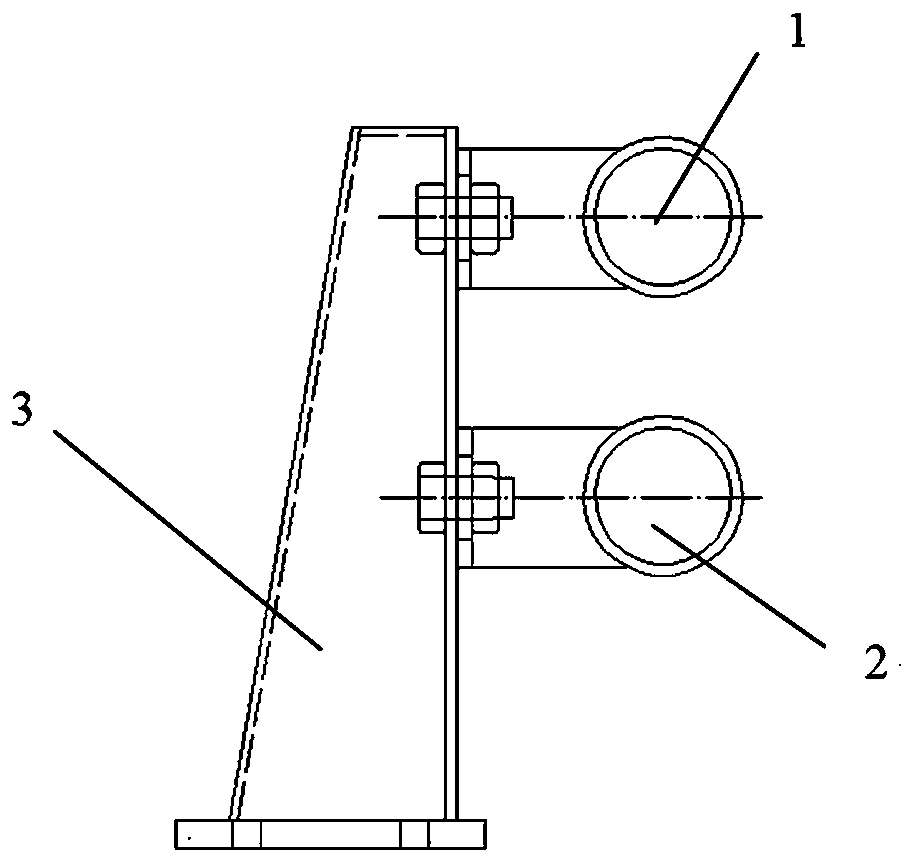

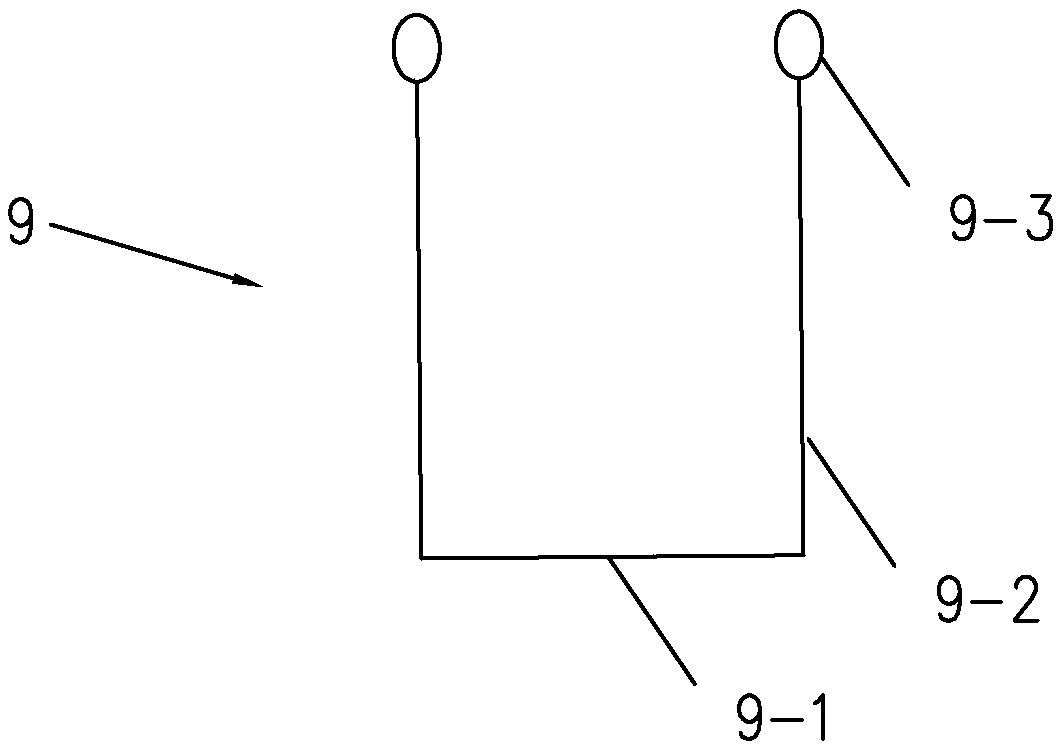

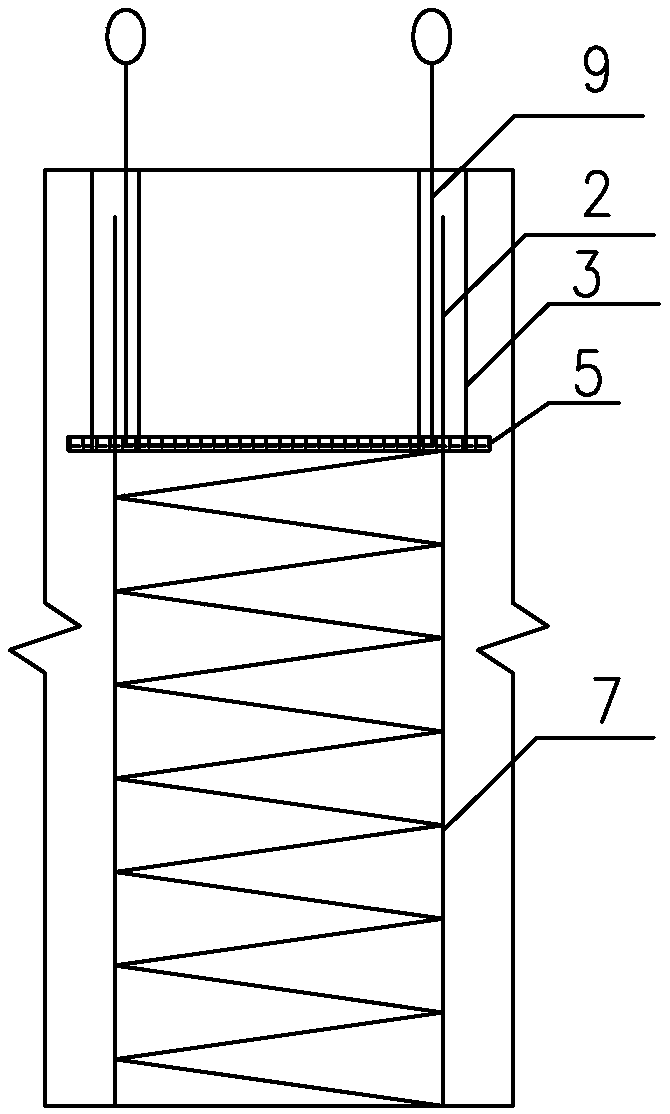

Pressure rack for rebar-planting

The invention provides a pressure rack for rebar-planting. The rack comprises a main longitudinal stressed rod, a support rod, a connection rod and a pressure rod. The top end of the main longitudinal stressed rod is fixedly equipped with an electric hammer. A rod body of the main longitudinal stressed rod is orderly connected with the pressure rod and the connection rod through bolts. The support rod is connected with the pressure rod and the connection rod through the bolts and parallel to the main longitudinal stressed rod. The pressure rack for rebar-planting has following beneficial effects: the rack is utilized on the ground so that rebar-planting can be achieved without climbing objects; rebar-planting can be finished indoors around floors; and the rack has a high safety coefficient and is convenient to operate and is simple in structure.

Owner:THE FOURTH ENGIENERING OF CHINA RAILWAY18 BUREAU GROUP +1

Method for improving efficiency of full insertion construction after top sealing of full cast-in-place outer-wall high-rise residence main body

InactiveCN108104278AImprove the level of refinementShorten the total construction periodBuilding constructionsDwelling buildingResidenceArchitectural engineering

The invention discloses a method for improving the efficiency of full insertion construction after top sealing of a full cast-in-place outer-wall high-rise residence main body. The method comprises the steps of top sealing of a main body structure, construction of a computer room, removing of a climbing frame and a construction elevator, mounting of an elevator, removing of a tower crane, construction of an outdoor garden, construction of outer wall hanging baskets, construction of a paint surface, storage and mounting, mounting of table faces and lamps, construction of doors and a secondary finishing coat, mounting of wooden floors and mounting of hardware equipment and residential cleaning. According to the method for improving the efficiency of full insertion construction after top sealing of the full cast-in-place outer-wall high-rise residence main body, it is ensured that all the construction work types can conduct continuous insertion operation after top sealing of the full cast-in-place outer-wall high-rise residence main body, the total construction period is shortened, the work efficiency is improved, and the fine level of project engineering management is further improved.

Owner:佛山市万科置业有限公司 +1

A method for integral rapid lifting of bored pile head pre-buried without drilling circumcision

ActiveCN106400802BReduce security risksReduce construction difficultyExcavationsBulkheads/pilesChinese charactersRebar

The invention discloses an integral quick lifting method for a pile head of a drilled pile during pre-embedding and drilling-free ring-cutting. The integral quick lifting method comprises the following steps of: mounting the drilled pile in front of a reinforcement cage after the drilling is ended, directly embedding foam sponge pipes into main ribs of an exposed supporting table of the reinforcement cage and an outer-end surface of a sounding pipe, fixing the foam sponge pipes by use of rubber bands to ensure that the foam sponge pipes do not slide; coating the foam sponge pipes outside a reinforcement positioning frame in the shape of Chinese character jing and a ring-shaped reinforcement positioning ring in advance; replacing drilling by use of a PVC tube every 40-50 cm along the perimeter of the pile body on the positioning frame, covering the foam sponge pipes for conveniently identifying positions during breaking construction; after foundation pit excavation is completed, lightly knocking at a position 10 cm above elevation of a pile top to expose the PVC tubes and the positioning ring, inserting a separating wedge into the PCV tubes, knocking with external force until the pile head is completely separated from the pile body; and utilizing lifting equipment to perpendicularly lift the upper pile head. The construction method is suitable for integral breaking and lifting construction of pile heads of foundation projects of highways, high speed railways, subways and high-rise buildings.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

Adjustment tool and system applied to integral assembling of steel lining modules of nuclear power station

ActiveCN112589347AHigh feasibilityShorten the total construction periodWelding/cutting auxillary devicesAuxillary welding devicesButtressNuclear power

The invention discloses an adjustment tool and an adjustment system applied to integral assembling of steel lining modules of a nuclear power station. The adjustment tool includes a buttress; the buttress is further provided with a height adjusting part and a clamping part; the height adjusting part includes an adjusting bolt and an adjusting nut; a through hole is formed in the buttress; one endof the adjusting bolt is buried in a cement buttress after penetrating through the through hole; the adjusting nut sleeves the adjusting bolt in a threaded connection manner and is located between thecement buttress and the buttress; the outer diameter of the adjusting nut is larger than the inner diameter of the through hole; and the clamping part includes a U-shaped clamp which is used for clamping the buttress and a module base in a haunching area. The adjustment system is composed of a plurality of tools. The adjustment tool disclosed by the invention has the advantages of simple assembling, lower construction difficulty and convenient adjustment, and facilitates quick and accurate assembling of modules in the haunching area.

Owner:CHINA NUCLEAR IND 24 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com