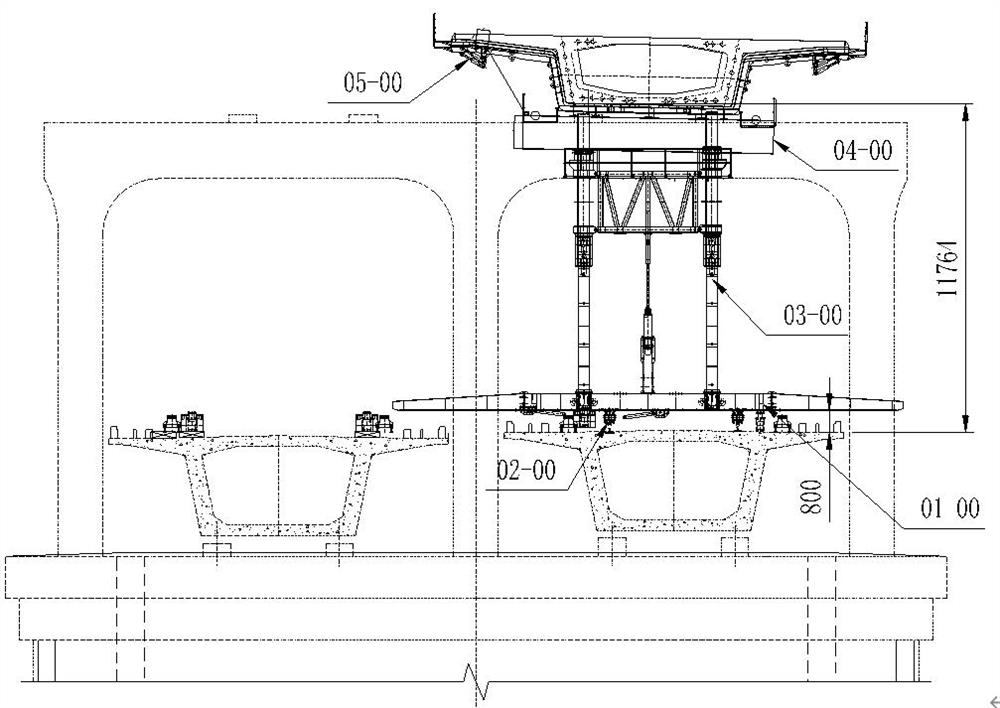

Variable-breadth movable support and construction method thereof

A technology of moving brackets and construction methods, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of narrow operating space, high installation and dismantling risks, and high labor intensity, achieving a high degree of mechanization, saving total construction period, reducing labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

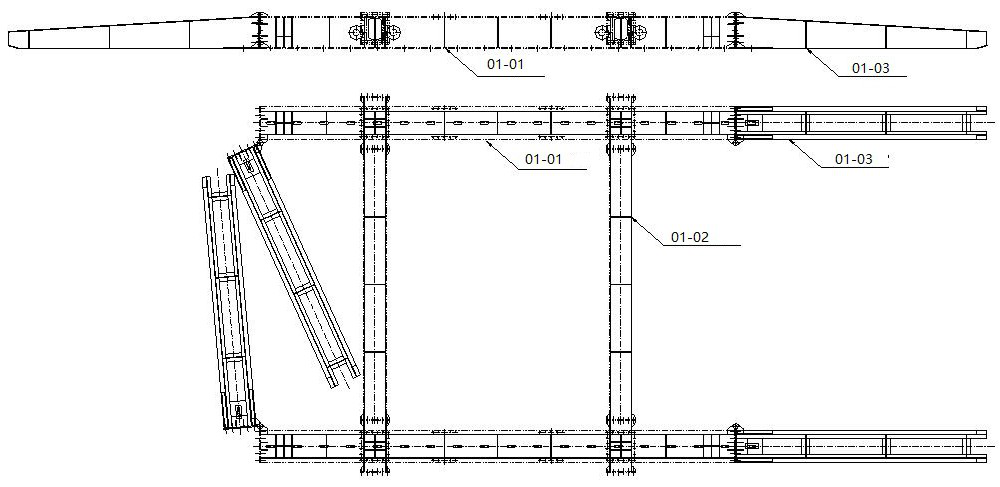

Method used

Image

Examples

Embodiment 1

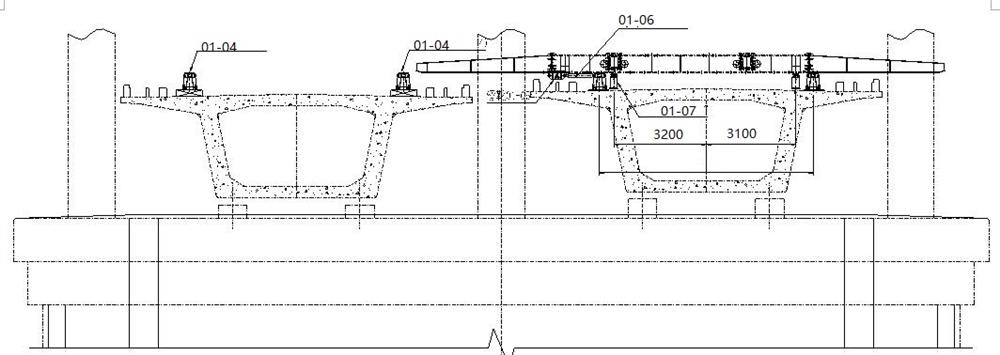

[0088] The following examples will further describe the construction procedures of longitudinally moving through holes and transversely moving across the width of this patent.

[0089] 1. The construction steps of floor formwork lateral movement are as follows:

[0090] as attached Figure 8 As shown, step one:

[0091] ① After the construction of the concrete box girder is completed, the vertical restraint of the floor formwork is released.

[0092] ②The drop mold cylinder (01-07) works to lower the formwork by 150mm as a whole. At this time, the mold bed is separated from the concrete box girder, and the bracket is supported on the supporting trolley (01-04).

[0093] ③The drop frame device (03-03) works to lower the mold bed by 150mm, check the performance of the drop frame device, and then lower the mold bed as a whole by 2900mm (2 working strokes).

[0094] as attached Figure 9 As shown, step 2: ① After the die is in place, rotate the luffing beams at both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com