Horizontal drilling and segmented pressure maintaining grouting device and method for water-bearing layer of coal seam floor

A technology of coal seam floor and horizontal drilling, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc. The effect of shortening the total construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

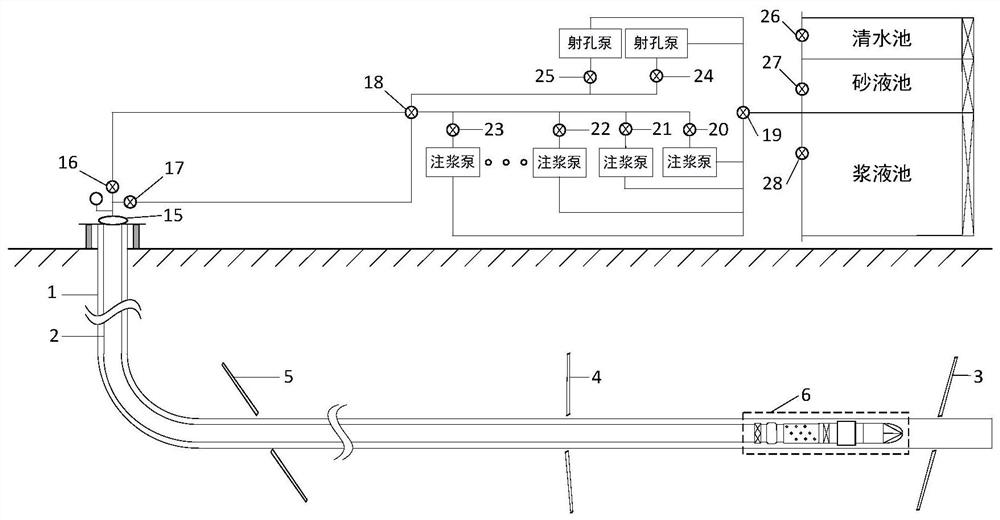

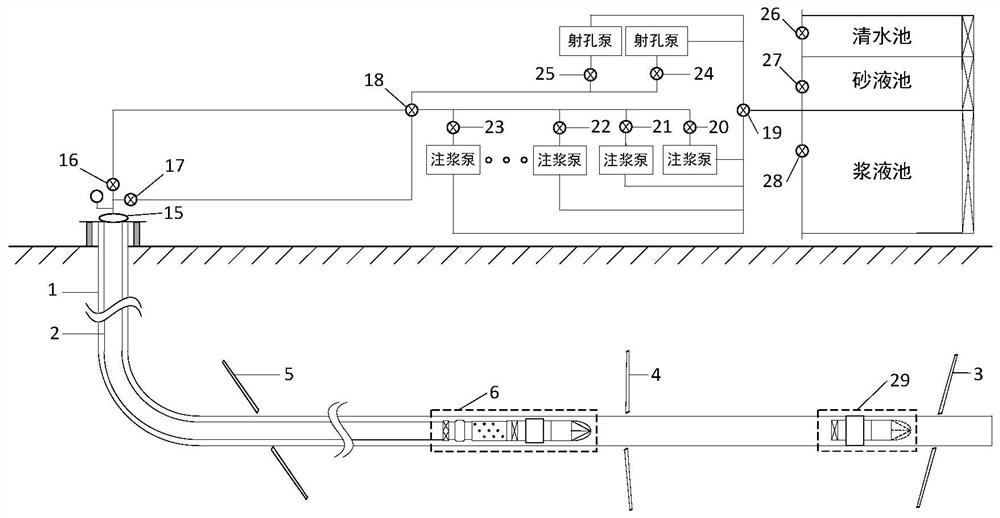

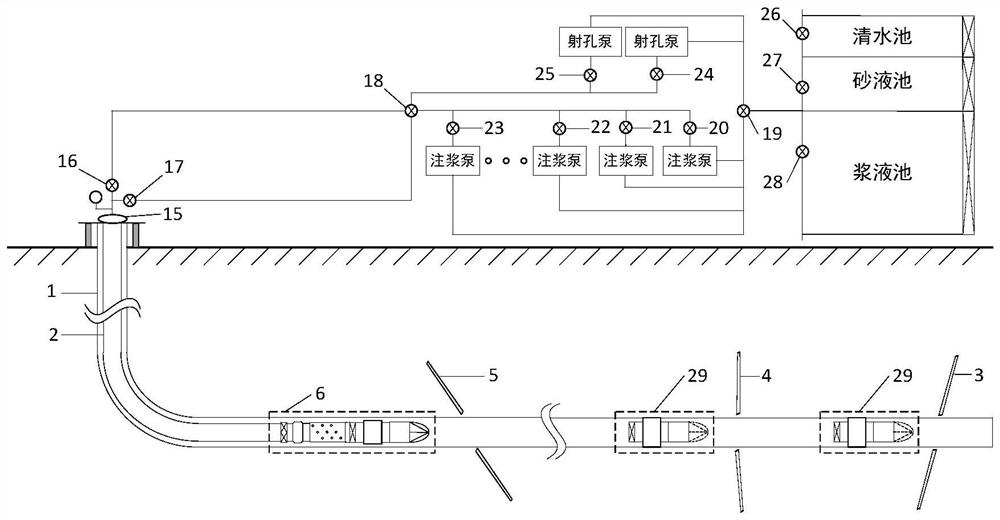

[0034] This embodiment firstly provides a segmented pressure-maintaining grouting device for horizontal drilling in the aquifer of the coal seam floor. The segmental pressure maintaining grouting device for horizontal drilling includes:

[0035] A segmented pressure-maintaining grouting device for horizontal drilling of an aquifer on a coal seam floor, comprising:

[0036] The perforating gun 9 is used to connect with the coiled tubing 2, and several injection holes 10 are arranged on it;

[0037] The tubing packer 12 is connected with the perforating gun 9 through a hands-off tool 11, and is used for setting the casing 1 where it is under pressure.

[0038] The pressure shedding device is connected to the tubing packer 12 through a one-way valve 13. The front end of the pressure shedding device is in the shape of a petal, and each petal body of the petal shape can be opened when driven by pressure.

[0039] In this embodiment, the perforating gun 9 may be connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com