Composite prefabricated floor slab for fabricated building

A prefabricated panel and composite technology, applied in the direction of floors, buildings, building components, etc., can solve the problem that the pull-out test of small-sized steel bars fails to meet the connection quality requirements of the application technical regulations, and the quality of prefabricated buildings cannot be equal to that of cast-in-place buildings and grouting. Problems such as insufficient positioning of the sleeve anchoring steel bars to shorten the total construction period, improve the overall quality and performance, and enhance the overall stability and shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

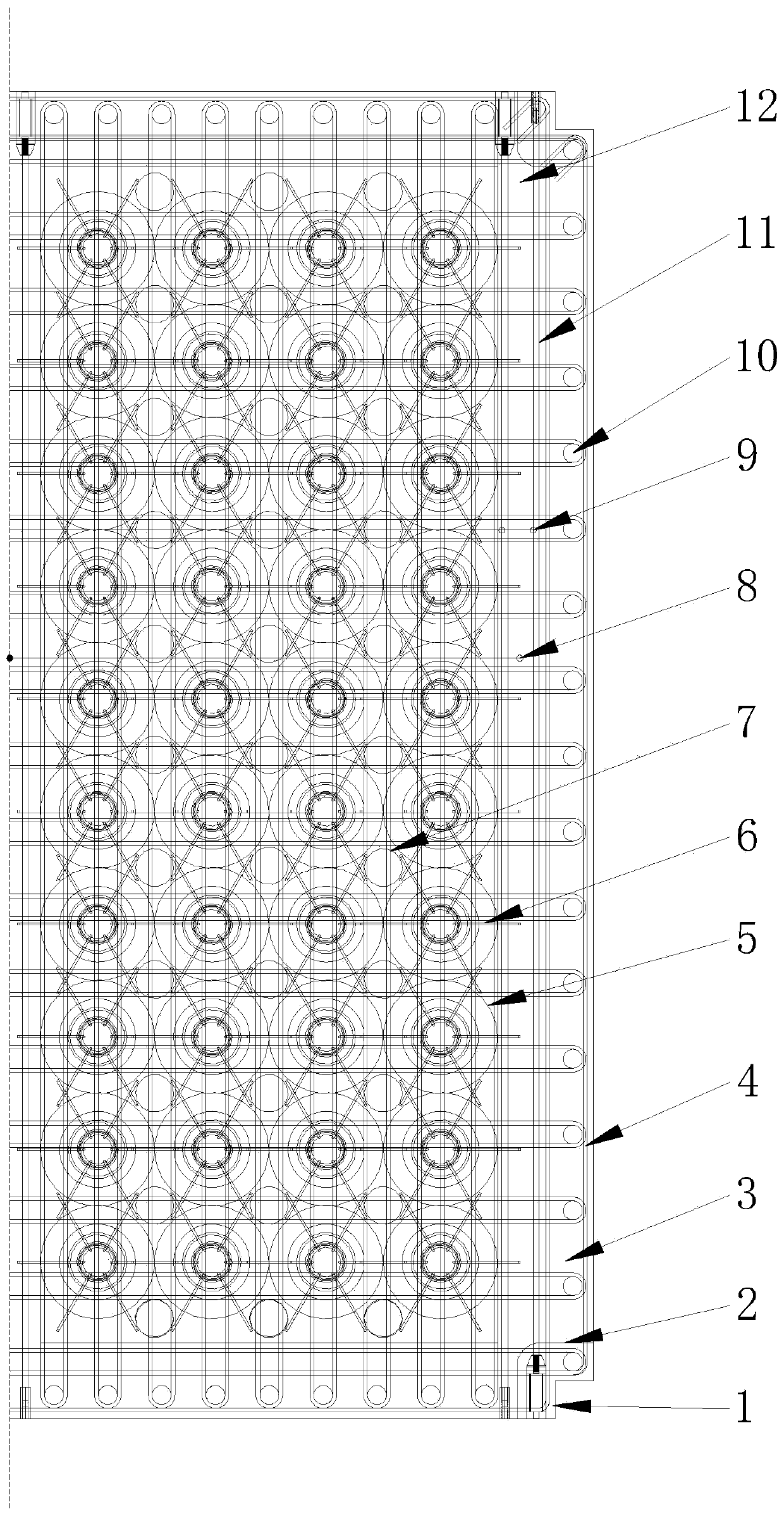

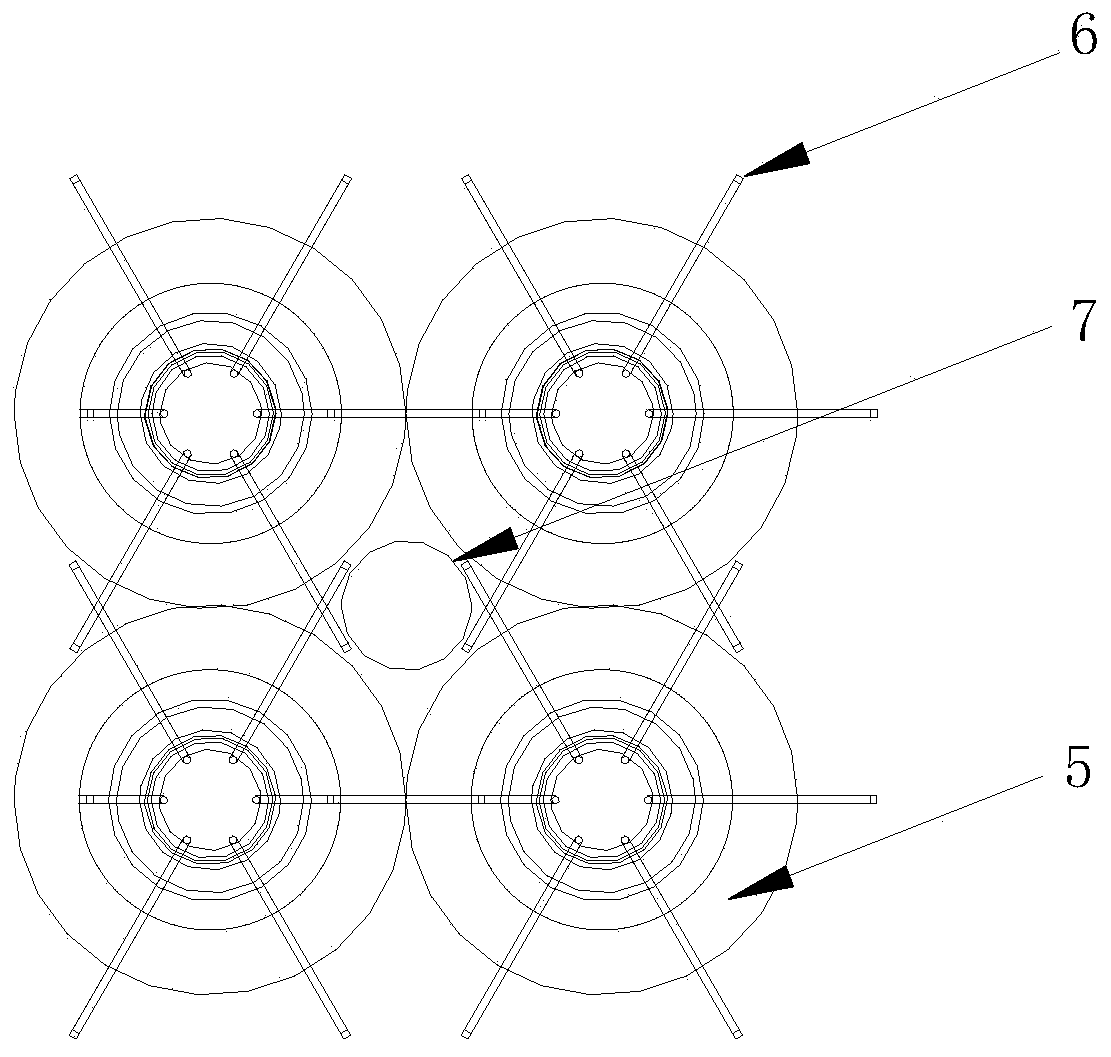

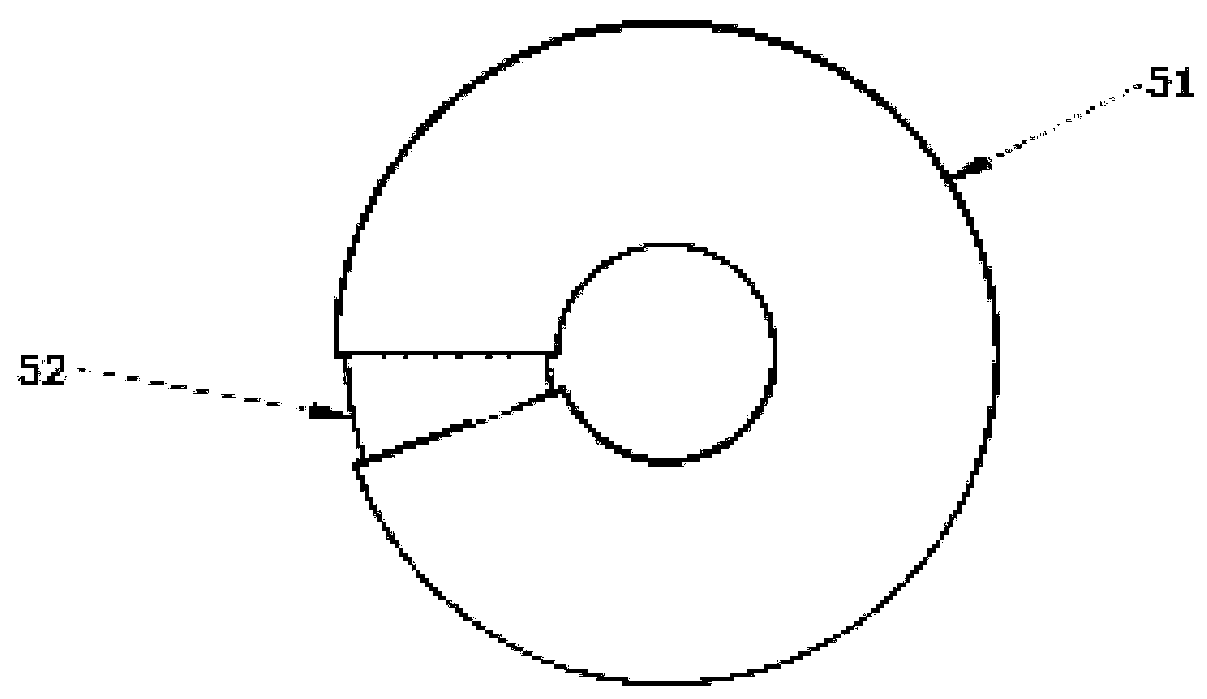

[0026] from Figure 1-7 It can be seen that a composite prefabricated floor slab for prefabricated buildings in this embodiment includes a concrete prefabricated slab 12, a frame beam 3 is arranged at the edge of the concrete prefabricated slab 12, and the frame frame beam 3 is a solid core structure and Concrete prefabricated slabs 12 are poured and formed together, the main function is to ensure the overall stability of the floor slab and to ensure the function of forming high-strength connection nodes with the connected prefabricated beams, slabs and walls. The ring-shaped reinforced beam 4 is composed of no less than 4 ring bars, and the specification of the ring bars should be set according to the size and force of the prefabricated slab. The overlapping parts of the ribs can be set up densely, the frame beam 3 and the frame annular steel beam 4 are fixedly bound, and the inner interval of the concrete prefabricated slab 12 is embedded with a composite filling ring 5, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com