Large prefabricated assembly cap beam with corbel structure and construction method

A prefabricated assembly and construction method technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of not meeting the requirements of transportation and hoisting, and the width of the bridge deck cannot be too wide, so as to shorten the total construction period of the project and save formwork Material, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

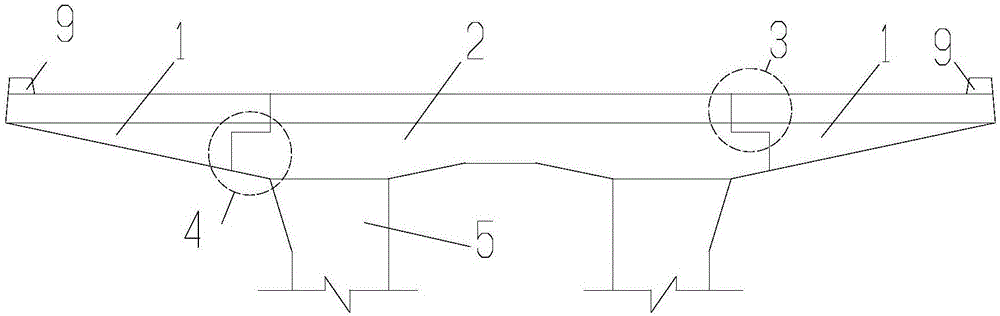

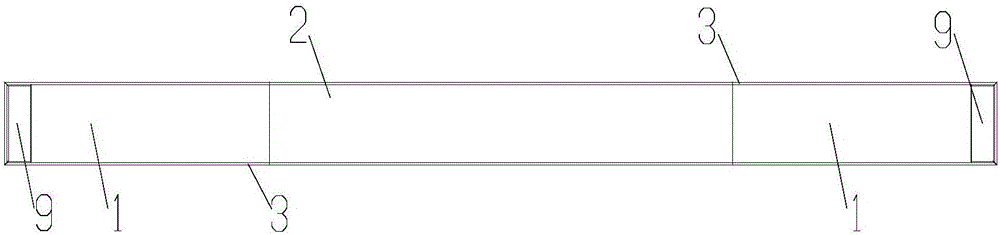

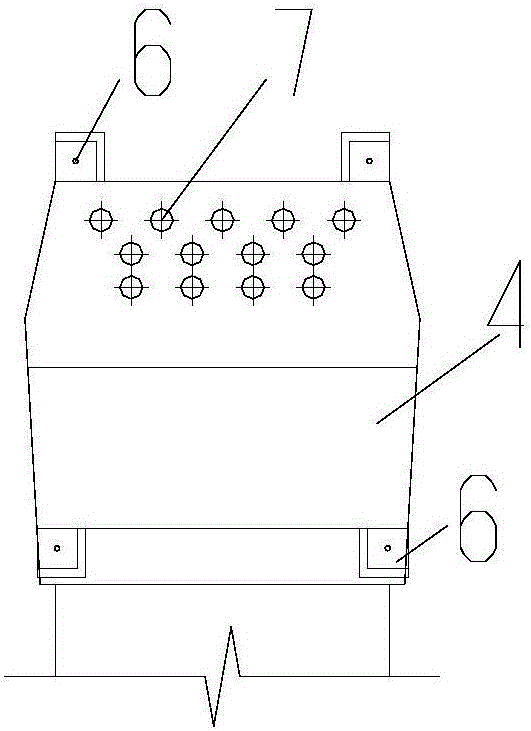

[0022] Such as Figure 1 to Figure 4 As shown in the figure, a large-scale prefabricated assembled cover beam adopts the structure of "corbels". Legs" 4, and the laser beam relative position calibration receiving points are set at the four corners of the assembly interface; the middle segment member 2 and the pier junction are provided with a vertical connection port and a relative position calibration emission point; two external The connection between the cantilever section member 1 and the middle section member 2 is a trapezoidal 3 or "reverse S" type interface ( Figure 5 ), and laser relative position calibration emission points are set at the four corners of the interface; the two external cantilever section members 1 and the middle section member 2 are reserved for prestressed steel pipes 7 running through the longitudinal direction, using prest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com