Dismounting-free building formwork

A construction formwork and disassembly-free technology, which is applied in construction, building structure, formwork/formwork components, etc., can solve problems such as affecting the construction period of construction projects, increasing construction costs, wasting wood and steel plates, and saving time for dismantling formwork. , The effect of reducing the amount of follow-up engineering and poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

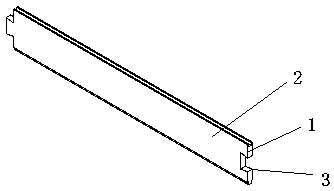

[0008] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as figure 1 In this example, the glass fiber mesh cloth commonly used in this industry is selected, and the mesh size is 3 mm X 3 mm. As the mesh surface 1 in this example, a matching mold is made according to the size of the pouring component required by the template, and the The mesh surface 1 is laid in the inner cavity of the mold; in this example, the gypsum building material proposed by the Chinese invention patent (application number: 2017112334219) was selected as the gypsum powder of the core body 2, and stone powder, EPS particles, And foaming agent sodium dodecylsulfonate and water reducer, add water and stir to form gypsum slurry, pour the gypsum slurry into the mold, lay a layer of mesh surface 1 on the outer surface, and press to embed In the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com