Bottom die and core mould integrated slidable stencil and construction process

A bottom mold and sliding technology, which is applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of lack of construction technology, etc., and achieve the effect of simple operation procedures, guaranteed quality, and convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The bottom mold core mold integrated slidable formwork and construction technology of the present invention will be further described in detail in conjunction with embodiments.

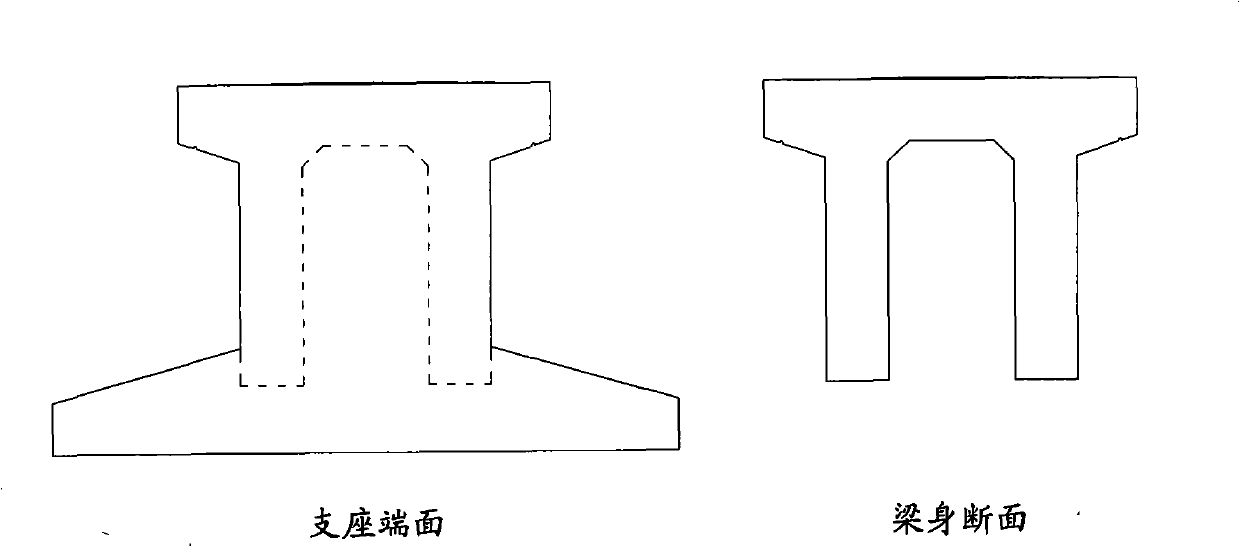

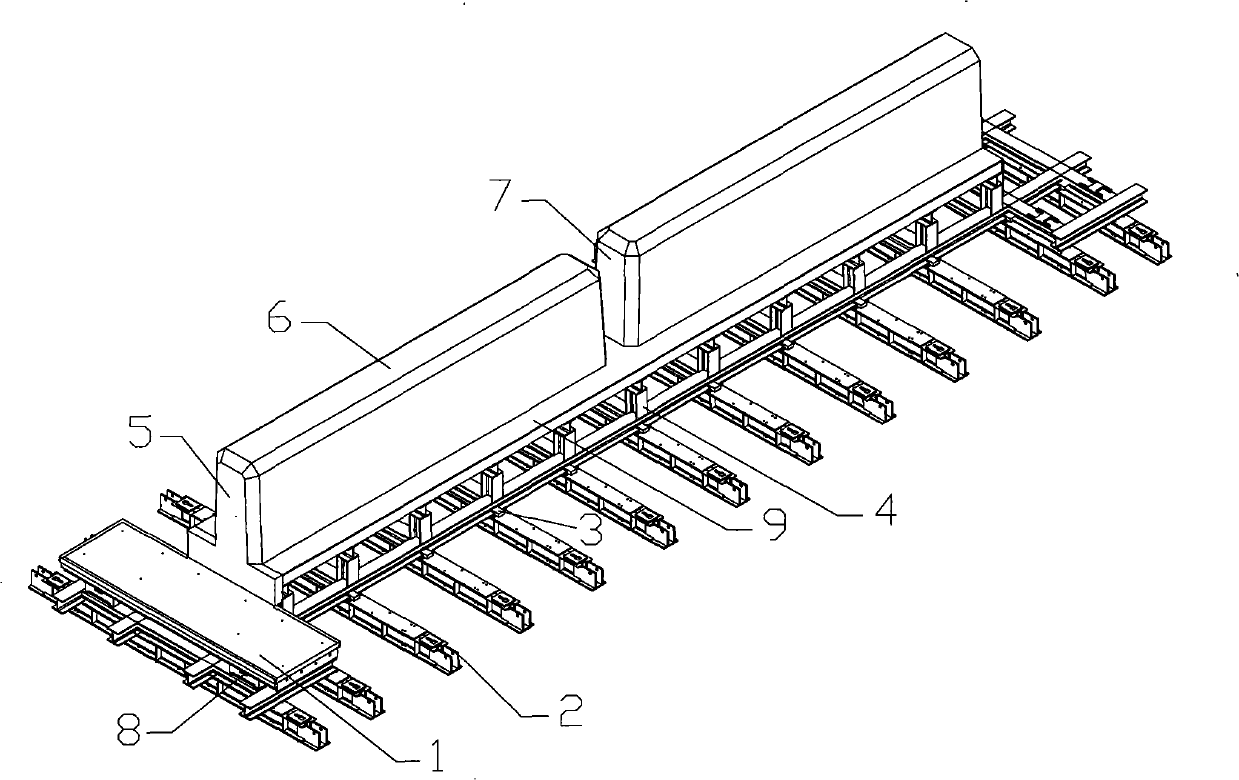

[0026] see figure 2 , which is a structural schematic diagram of the integrated sliding formwork of the bottom mold and mandrel in a preferred embodiment. The integrated sliding formwork of the present invention is suitable for but not limited to making the "∏" cross-section in this embodiment. Concrete beams, for other concrete beams with a downward opening cavity, beams with or without diaphragm ribs, can be used through adaptive transformation by those skilled in the art.

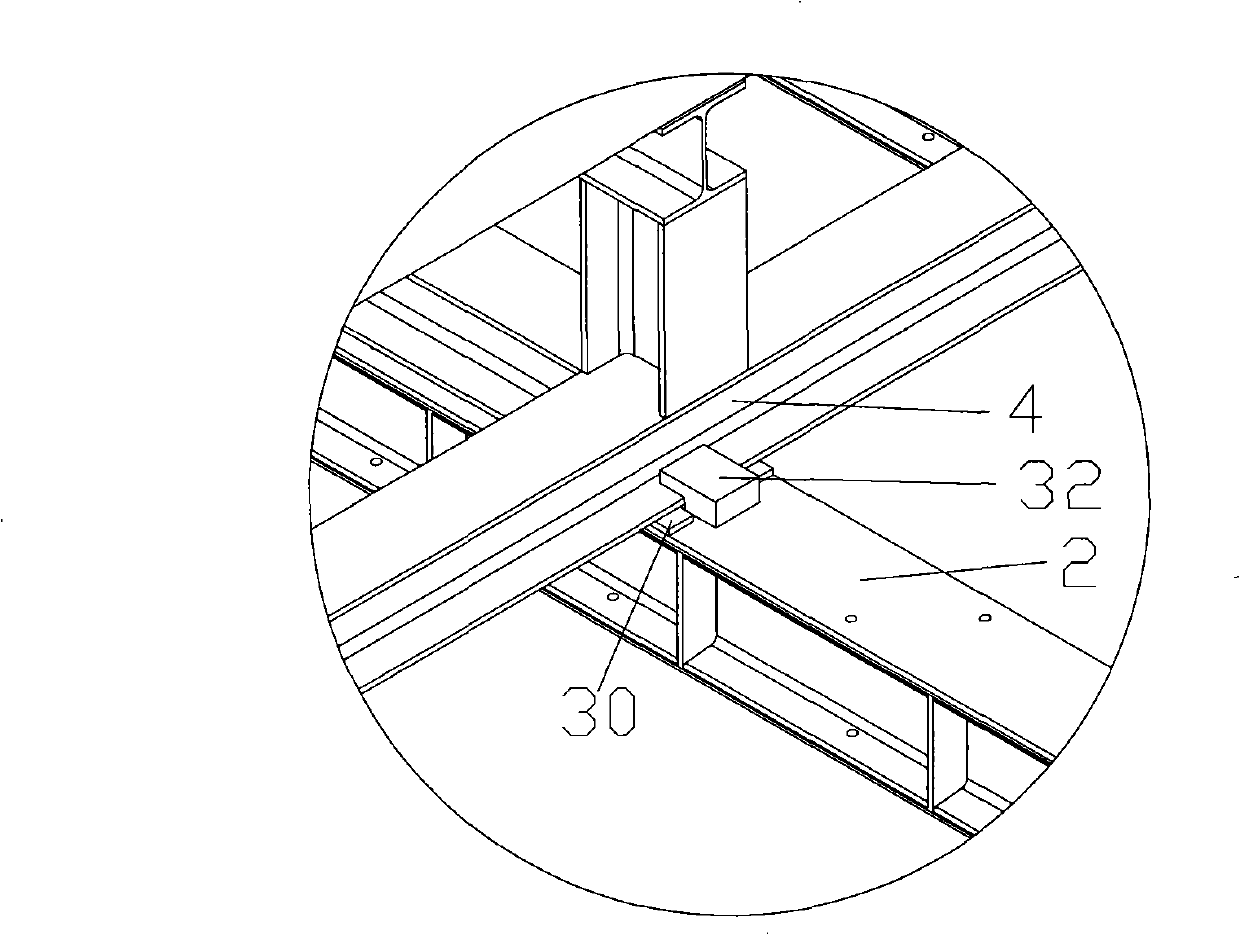

[0027] Such as figure 2 As shown, the bottom mold and mandrel integrated slidable formwork of this embodiment at least includes a support bottom mold 1, a ground beam 2, a sliding limit and locking mechanism 3, a bottom mold frame 4, and a first compressible block 5 , Beam section bottom mold 9 and core mold 6, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com