Printing machine

A printing machine and mechanical connection technology, which is applied in the direction of decorative art, sculpture, art painting, etc., can solve the problems that affect the batch process efficiency of printmaking printing processing, the uneven settlement of the re-engraving tool holder, and the cost of templates, etc. Achieve the effect of improving the effect of the coordinate scraper, improving the accuracy of punching and printing, and avoiding the use of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

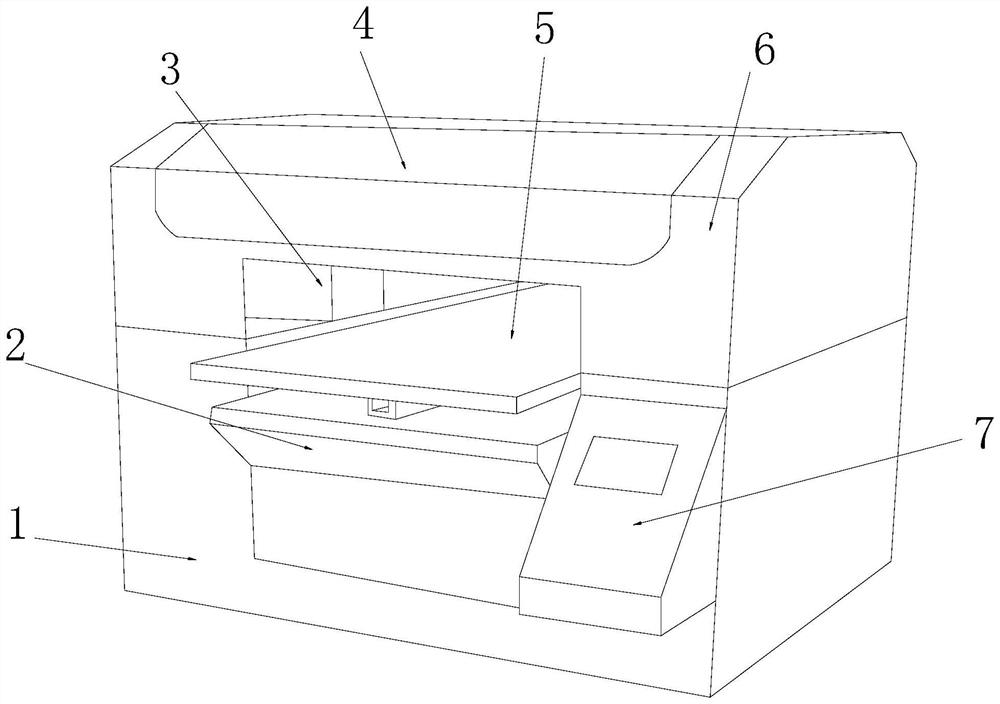

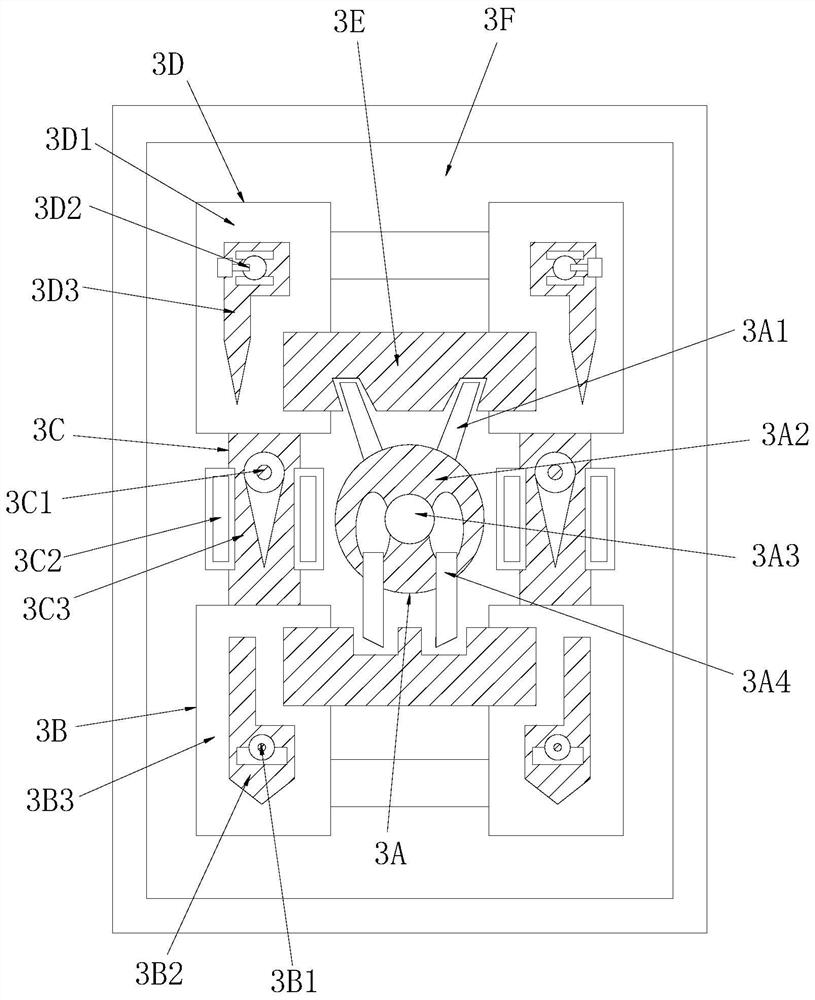

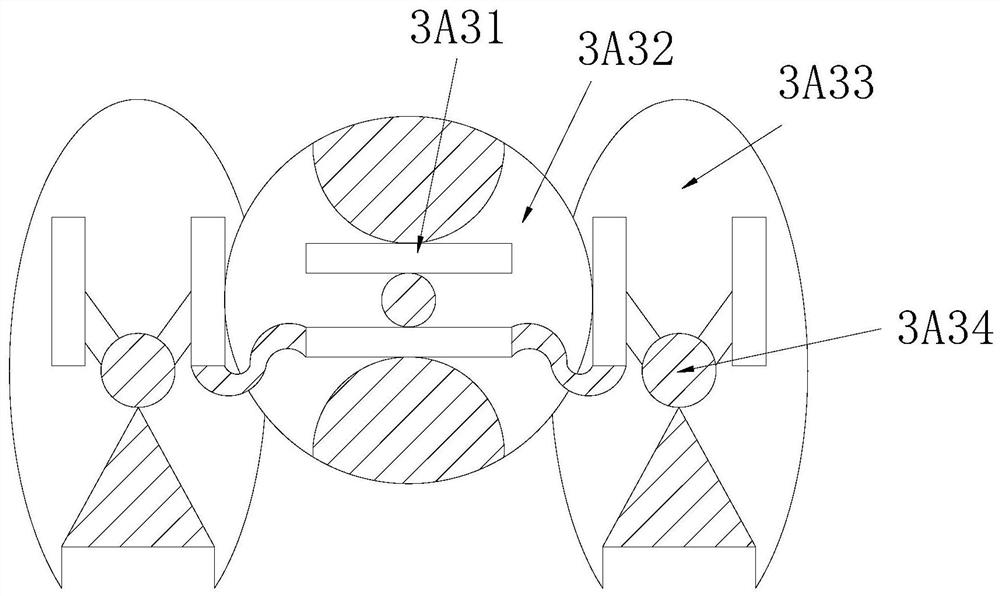

[0033] see Figure 1-Figure 6, the present invention provides a printing machine, the structure of which includes: a power distribution base box 1, a lining frame plate seat 2, a re-engraved counter-frame tool magazine 3, a glass cover plate 4, a printing table 5, a transmission top shell box 6, The industrial control console 7, the replica counter-frame tool magazine 3 is provided with two and installed on the left and right sides of the printing workbench 5 respectively, the glass cover plate 4 is mechanically connected with the transmission top case 6 through a hinge and is in the On the same horizontal plane, the transmission top case 6 is nested on the top of the power distribution base box 1, the industrial console 7 is plugged into the right front side of the power distribution base box 1, and the lining plate seat 2 is installed on the power distribution base box 1. On the top of the electric base box 1 and on the same level, the printing table 5 is inserted and embedd...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a kind of printing machine, other respects are identical with embodiment 1, and difference is:

[0041] see figure 2 , the high-position striker seat 3D is composed of a telescopic notch 3D1, a sliding hammer buckle block 3D2, and a striker plate 3D3. The striker plate 3D3 is movably connected with the telescopic notch 3D1 and is on the same vertical plane. The 3D2 is installed on the top of the striker plate 3D3, and the striker plate 3D3 is driven by the sliding hammer hook block 3D2 to raise and lower the three-dimensional facade groove of the engraved print, forming an overall effect of fine auxiliary processing and repair of the print print.

[0042] see Image 6 , the sliding hammer hanging buckle block 3D2 is composed of a damping slider 3D21, a horizontal buckle rod 3D22, a rotating brush wheel 3D23, and a corrugated pressure plate 3D24. The damping slider 3D21 is nested on the left side of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com