scoring device

A technology for scribing lines and substrates, applied in the field of scribing devices, can solve problems such as troublesome alignment operations, and achieve the effect of efficient and high-precision scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

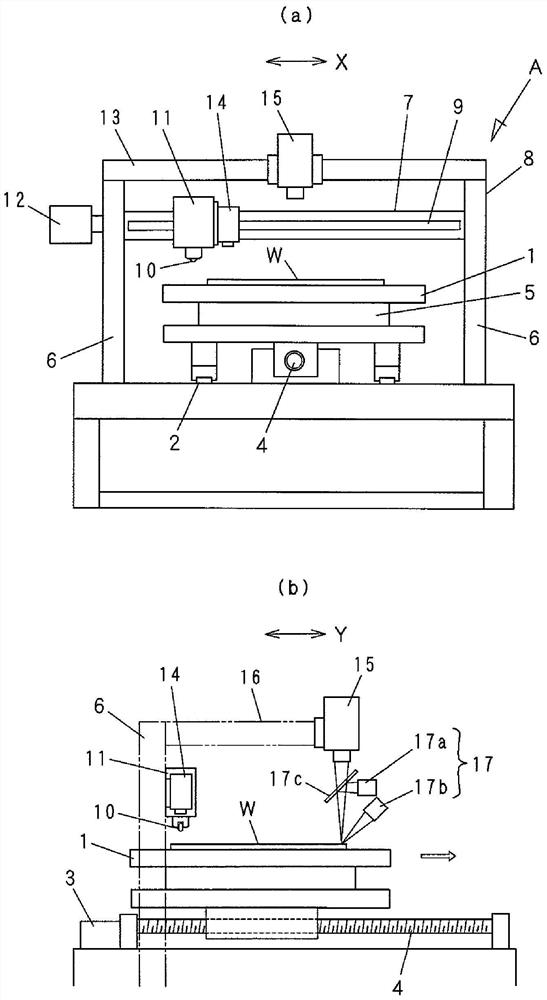

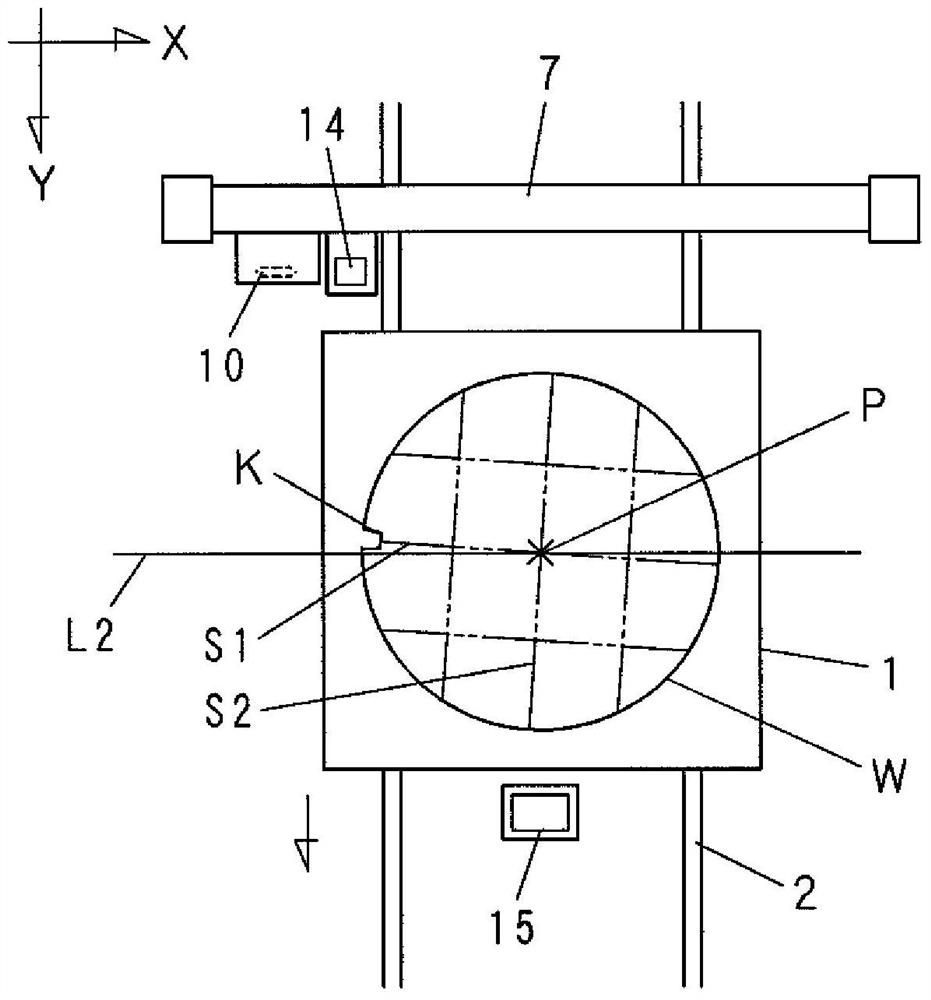

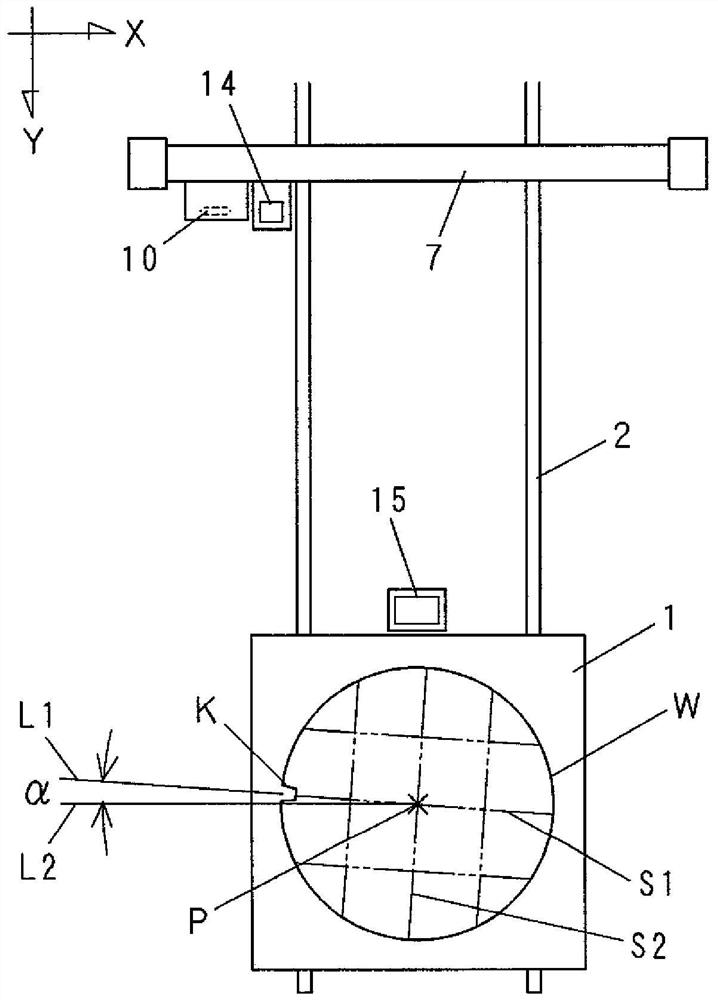

[0032] Hereinafter, the present invention will be described in detail based on the embodiments shown in the drawings. The circular substrate to be scribed in this embodiment is a semiconductor substrate W for an image sensor in which a glass wafer and a silicon wafer are laminated. Such as figure 2 As shown, chips including electronic components such as circuits are arranged in a grid pattern on the semiconductor substrate W, and lines in the X-Y direction that divide these chips form predetermined scribing lines (scribing lanes) S1 and S2 . Moreover, on any one of the predetermined scribe lines passing through the center point P of the semiconductor substrate W, in this embodiment, on the predetermined scribe line S1, and on the edge of the semiconductor substrate W, a notch or a positioning plane is provided as a mark. The incision part K.

[0033] figure 1 (a) and (b) show an embodiment of the scribing apparatus A of the present invention, which includes a stage 1 on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com