Construction method for fixing trapezoidal column cap formwork

A construction method and formwork fixing technology, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of concrete leakage, affecting the concrete forming effect, and excessive joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

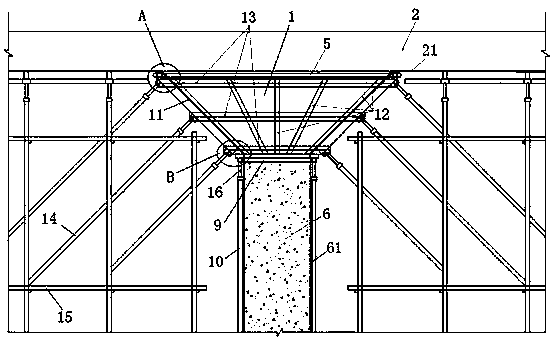

[0021] Example figure 1 , figure 2 and image 3 Shown, the fixing construction method of trapezoidal column cap formwork of the present invention comprises the steps:

[0022] Step 1. According to the design drawings, the trapezoidal column cap 1 template is cut, and the trapezoidal column cap 1 template is spliced and installed;

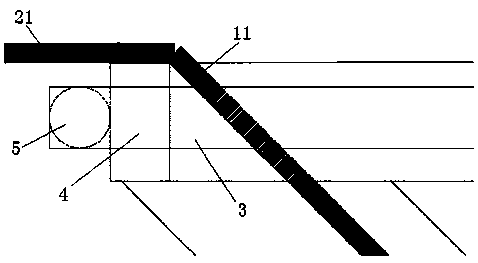

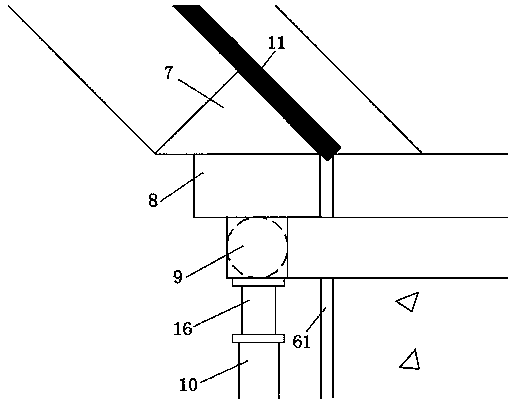

[0023] Step 2: Reinforce the seams between the trapezoidal column cap 1 formwork and the floor formwork 21, cut the square wood according to the angle formed by the trapezoidal column cap 1 and the floor 2, and cut it into a triangular square log 3 with the hypotenuse close to the trapezoidal column cap The upper edge of the formwork 11 is arranged horizontally, and the entire square timber 4 is used to be close to the tail end of the triangular square timber 3, and the triangle-shaped square timber 3 and the whole square timber 4 are set on all four sides at the seam between the trapezoidal column cap formwork 11 and the floor formwork 21 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com