Gum dipping, stentering forming method of earthwork grid cloth

A technology of geogrid and stenter setting, which is applied to the device for coating liquid on the surface, the elongation of the fabric, coating and other directions, and can solve the problems of irregular grid, shrinkage of geogrid cloth, uneven gluing, etc. , to achieve the effect of reasonable structure, square grid without deformation, and uniform gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with accompanying drawing:

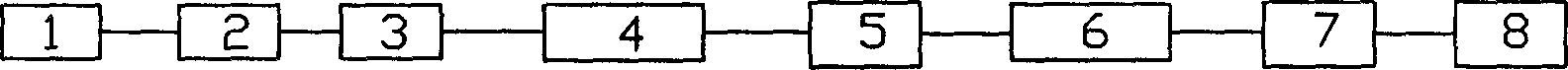

[0011] figure 1 Shown is the process flow diagram of the prior art, which includes unwinding 1, cloth storage 2, rubber dipping 3, pressing roller extrusion 4, tenter drying 5, cloth output cooling traction 6, cloth storage 7, roll Take 8.

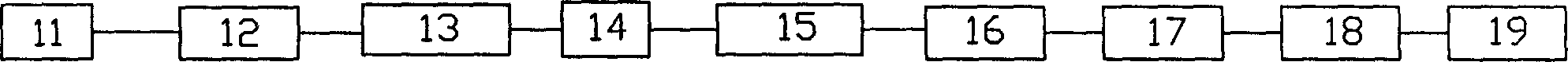

[0012] figure 2 Shown is a process flow diagram of the present invention, which includes: unwinding 11, weft trimming 12, cloth storage 13, constant tension traction 14, dipping 15, tenter drying 16, constant tension cloth cooling traction 17, Cloth storage 18, coiling 19 again. In the present invention, after unwinding 11, the geogrid is seamed by a sewing machine first, and then enters the weft adjustment device, and the geogrid is straightened in the weft direction to realize its seaming and weft adjustment process; the geotextile weft After straightening, it enters the cloth storage machine for cloth storage 13, where the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com