a heat exchanger

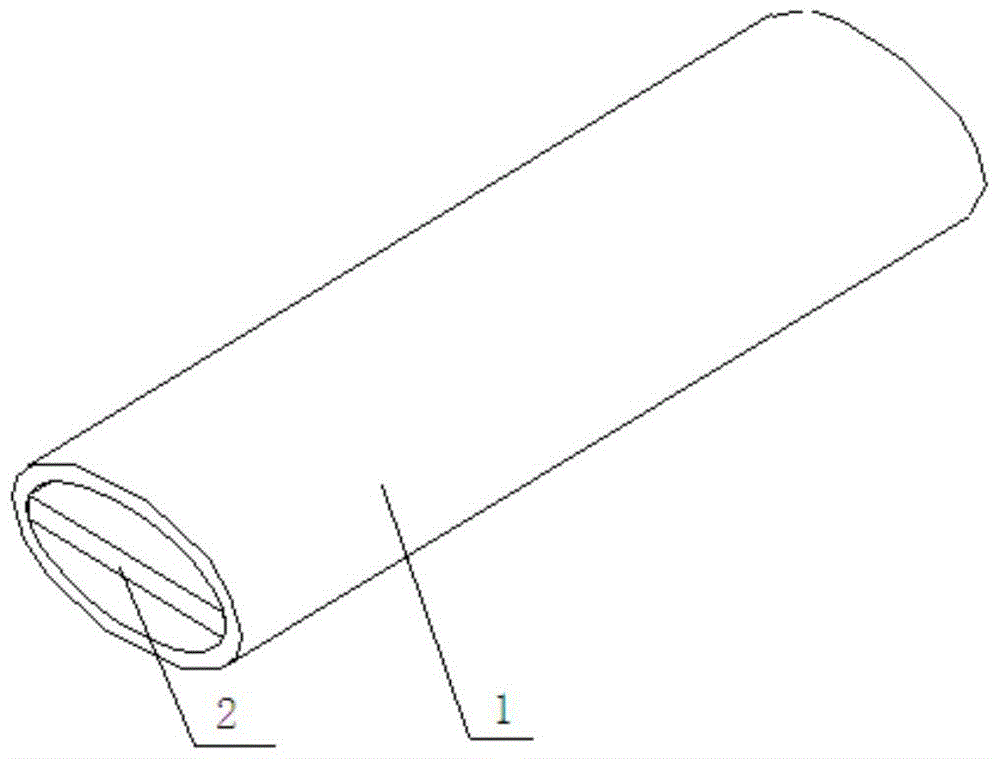

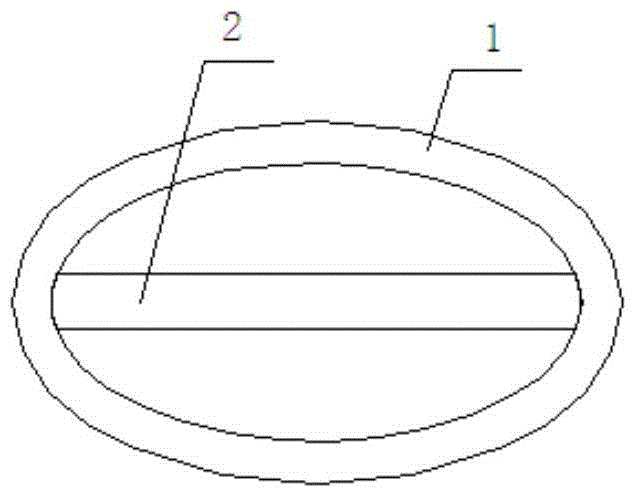

A heat exchanger, inlet header technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve problems such as deformation of elliptical tubes, and achieve the effect of preventing round tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

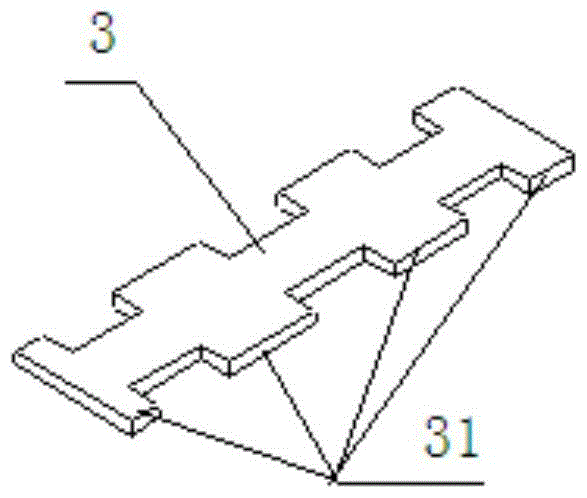

Embodiment 1

[0031] Embodiment 1: as image 3 As shown, the support plate part 2 is a first support plate 3 formed by a continuous vertical I-shape, and a convex portion 31 and a concave portion 32 are formed on both sides of the first support plate 3, and the convex portion 31 is as long as the oval tube length The shapes of the inner walls on both sides of the shaft are matched, and the refrigerant medium can circulate up and down in the oval tube 1 through the concave portion 32 . The support plate is in a continuous longitudinal I-shape, which is partially in contact with the inner wall of the oval tube. Multiple gaps are formed on the support plate, and the cold medium can flow up and down in the gaps. The I-shaped support plate plays the role of support and turbulence. Allow the flowing refrigerant to stay for a long time to enhance heat exchange. The thickness of the edge of the convex part is greater than the thickness of the support plate. When the elliptical tube is heated and e...

Embodiment 2

[0032] Embodiment 2: as Figure 4 , Figure 5 As shown, the support plate part 2 is a second support plate 4 formed by a longitudinal I-shaped support plate, and the second support plate 4 is formed by a support plate body and two long side portions 41 on both sides. The long sides 41 are adapted to the shapes of the inner walls on both sides of the long axis of the elliptical tube, preventing the elliptical tube from deforming. The thickness of the long side part 41 is greater than the thickness of the longitudinal I-shaped support plate 4, which matches the shape of the elliptical tube. When the elliptical tube is heated and expanded, the contact area is increased and the supporting effect is improved. In addition, the upper and / or lower parts of the second support plate 4 are provided with serrations 42 to further enhance the supporting effect and prevent the oval tube from deforming.

Embodiment 3

[0033] Embodiment 3: as Figure 6 , Figure 7 As shown, the support plate part 2 is a third support plate 5 formed by a continuous horizontal I-shape, and the third support plate 5 is sequentially arranged on the two side frame parts 52 by a plurality of single pillars 51, and the two side frame parts 52 are adapted to the shapes of the inner walls on both sides of the long axis of the elliptical tube respectively, and the refrigerant medium can circulate up and down in the elliptical tube 1 through the gap between the pillars. The frame part is in full contact with the elliptical tube wall, and the supporting effect remains unchanged. Refrigerant can flow up and down through the gap between the pillars, and the I-shaped support plate plays the role of turbulence and enhances heat exchange. The thickness of the frame part 52 is greater than the thickness of a single support 51, which conforms to the shape of the elliptical tube. When the elliptical tube is heated and expande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com