a heat exchanger

A technology for heat exchangers and inlet headers, applied in heat exchange equipment, evaporators/condensers, lighting and heating equipment, etc., can solve problems such as deformation of refrigerant pipes, reduce deformation, enhance heat transfer effects, and prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

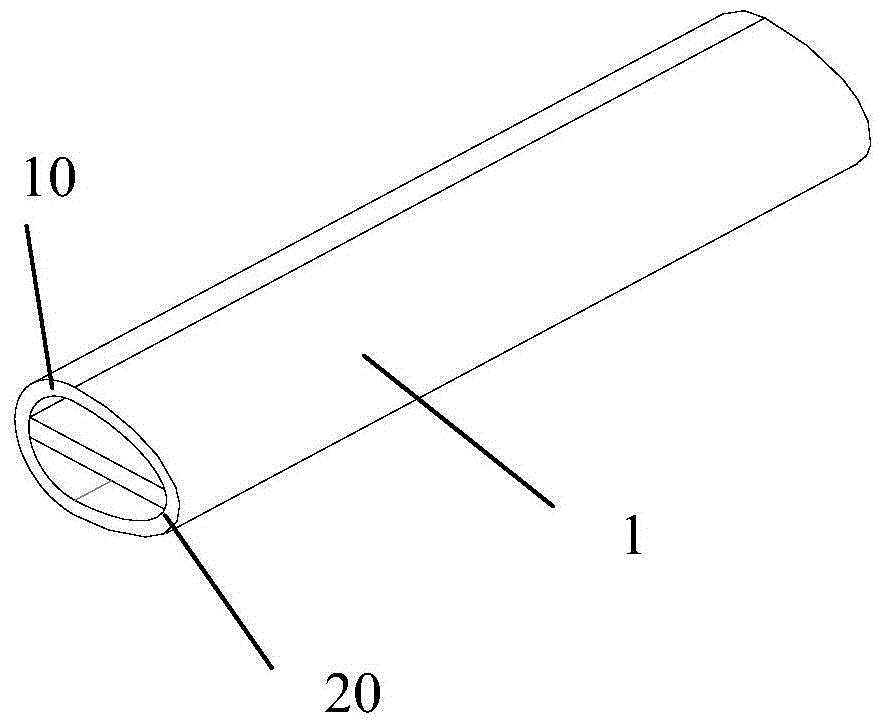

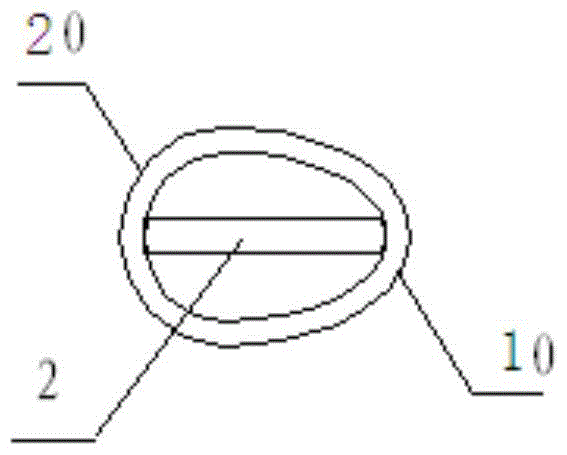

[0031] Embodiment 1: as figure 1 , figure 2 As shown, the special-shaped pipe 1 is formed by a windward end 10 and a leeward end 20, the windward end 10 is a half ellipse cut along the short axis of the ellipse, the leeward end 20 is a half circle, and the diameter of the circle is equal to that of the ellipse short diameter. During the heat exchange process, the high temperature makes the internal pressure of the elliptical tube continuously increase, and the pressure first acts on the tube wall at the windward end 10. The windward end 10 is a half ellipse cut along the short axis of the ellipse, and the half ellipse tends to become shorter. At this moment, the fan blows to the windward end 10 at first, so that the windward end 10 is cooled rapidly, the deformation is controlled on the half ellipse, and the overall deformation is reduced.

Embodiment 2

[0032] Embodiment 2: A support member 2 is provided along the axial direction of the special-shaped pipe in the long axis direction of the section of the inner hole of the special-shaped pipe 1 , and the support member 2 is in clearance fit with the inner wall of the special-shaped pipe. The support member is in the shape of a rectangular plate.

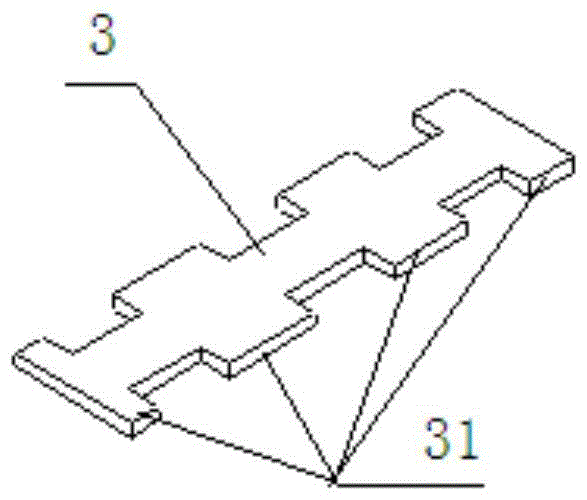

[0033] Such as image 3 As shown, the support member 2 is a continuous longitudinal I-shaped plate-shaped support 3, and the two sides of the I-shaped plate-shaped support 3 are formed with a flange portion 31 and a concave portion 32, and the gap between the flange portion 31 and the inner wall of the special-shaped pipe Cooperating, the cold medium can circulate up and down in the special-shaped pipe 1 through the I-shaped support member 3 through the recess 32 . The end of the supporting part abuts against the inner wall of the special-shaped pipe, and when the special-shaped pipe is heated, the windward end is deformed, and the ...

Embodiment 3

[0034] Embodiment 3: A support member 2 is provided along the axial direction of the special-shaped pipe along the axial direction of the special-shaped pipe 1 in the direction of the major axis and the short axis of the section of the inner hole of the special-shaped pipe, and the support member 2 is in clearance fit with the inner wall of the special-shaped pipe. The supporting part is a cross structure.

[0035] Such as Figure 4 -shown in -6, the support member 2 is a cross plate-shaped support 4, and the cross plate-shaped support 4 is composed of two symmetrical short sides and asymmetrical long and short sides; two symmetrical short sides and asymmetrical long and short sides The short sides in the center respectively correspond to the three end faces that support the inner wall of the leeward end 20 of the special-shaped pipe, and the two symmetrical short sides and the long side of the asymmetrical long and short sides support the end face of the inner wall of the win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com