Adjustment tool and system applied to integral assembling of steel lining modules of nuclear power station

A steel lining, nuclear power plant technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of easy deformation of welding, high alignment accuracy, long component size, etc., to save the total construction period, stabilize the support system, avoid The effect of cross work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

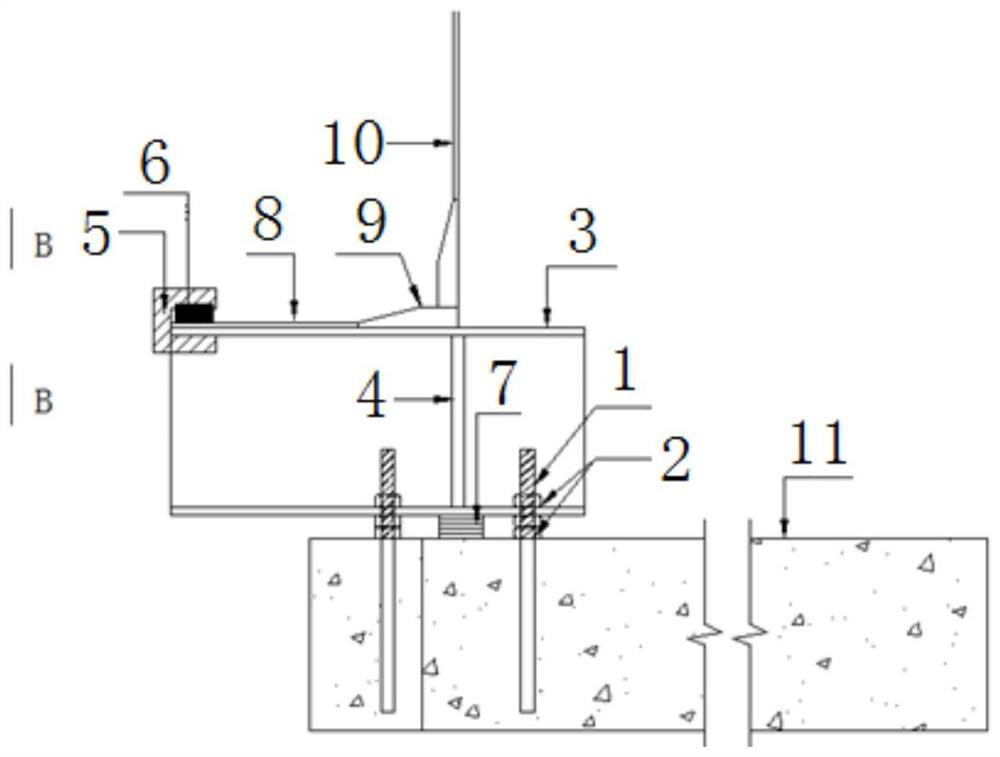

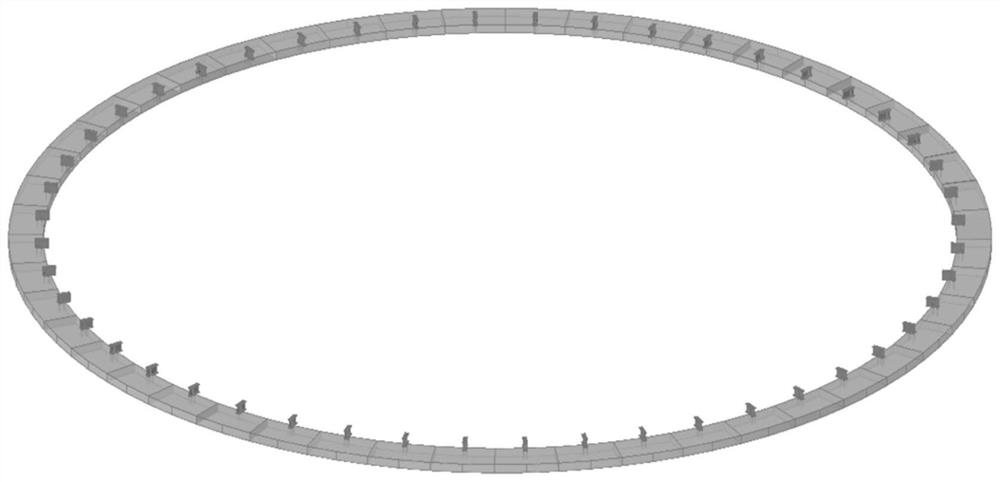

[0042] This embodiment provides an adjustment tool applied to the overall assembly of steel lining modules in nuclear power plants, such as figure 1 and figure 2As shown, including the buttress 3, the buttress 3 is also provided with height adjustment parts and clamping parts; the buttress 3 adopts H-shaped steel, and the two side flanges of the H-shaped steel are respectively used to connect with the cement buttress 11 below and the added cement pier above. Armpit area module base contacts.

[0043] The height adjustment part includes an adjusting bolt 1 and an adjusting nut 2; a through hole is opened on the lower side of the pier 3, and one end of the adjusting bolt 1 passes through the through hole and is used to be embedded in the cement pier 11; the adjusting nut 2 is threaded Sleeved on the adjusting bolt 1, and located between the cement pier 11 and the pier 3, the outer diameter of the adjusting nut 2 is larger than the inner diameter of the through hole;

[0044] ...

Embodiment 2

[0046] Further improvement on the basis of Example 1, two adjusting nuts 2 are provided on the adjusting bolt 1 and on the screw rod section between the cement pier 11 and the pier 3; along the axial direction of the adjusting bolt 1, The lower end surface of the adjusting nut 2 located below is used for contacting the upper surface of the cement pier 11 , and the upper end surface of the adjusting nut 2 located above is used for contacting the lower surface of the abutment 3 . An adjusting nut 2 is threaded on the rod section of the adjusting bolt 1 corresponding to the upper end of the through hole away from the cement pier 11, and the lower end surface of the adjusting nut 2 is used for contacting the surface of the pier 3 at the port of the through hole.

[0047] It includes four height-adjusting parts, and one height-adjusting part is respectively arranged at the four corners of the pier 3; four through holes are evenly distributed on the lower wing plate of the H-shaped s...

Embodiment 3

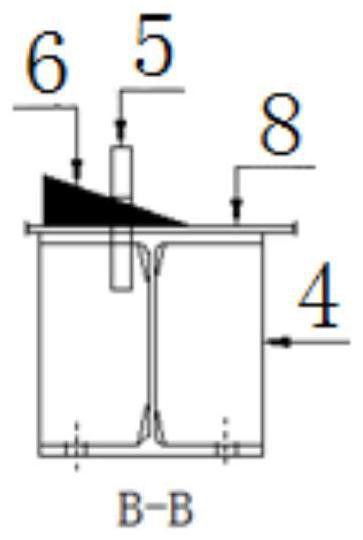

[0050] Further improvement on the basis of Example 2, the base of the module in the armpit area includes a bottom plate 8 and an L-shaped thickened plate 9; In the U-shaped card slot of the U-shaped card 5. Also includes inclined iron 6; the inner surface of one side of the U-shaped card 5 is in contact with the lower surface of the edge of the wing plate of the buttress 3, the lower surface of the bottom plate 8 is in contact with the upper surface of the wing plate of the buttress 3, and the upper surface of the bottom plate 8 is in contact with the upper surface of the wing plate of the buttress 3. The lower surface of the inclined iron 6 contacts, and the inclined surface of the inclined iron 6 is used to press the other side wing plate of the U-shaped card 5 to carry out line-surface contact.

[0051] The H-shaped steel also includes a steel stiffening plate 4, and a stiffening plate 4 is also provided between the upper wing plate and the lower wing plate of the H-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com