Patents

Literature

67results about How to "Avoid cross assignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

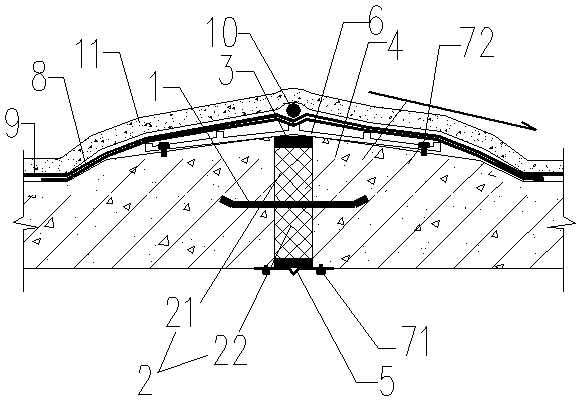

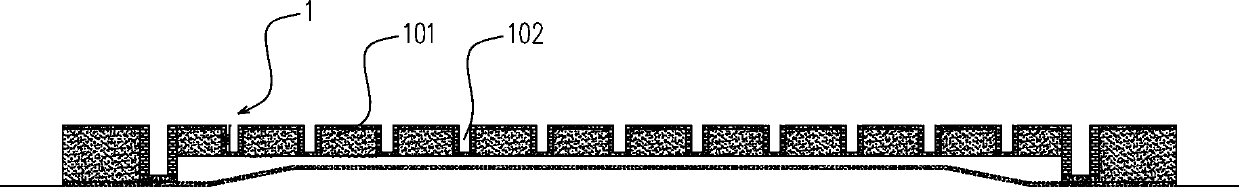

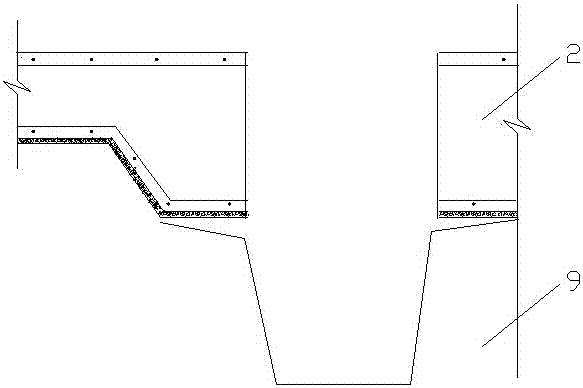

Construction method for waterproof structure of high-rise building basement top plate deformation joint

ActiveCN106284425ATimely replacementSolve easy deviationArtificial islandsUnderwater structuresBasementPolystyrene

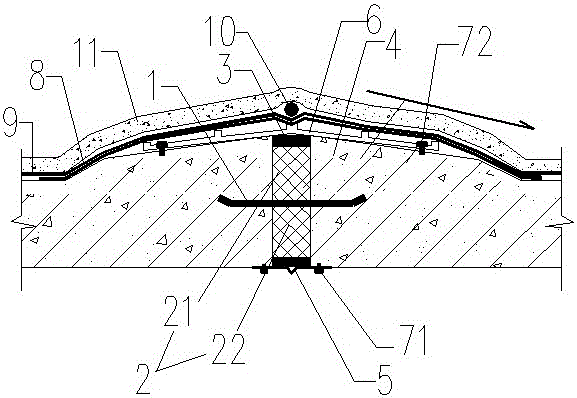

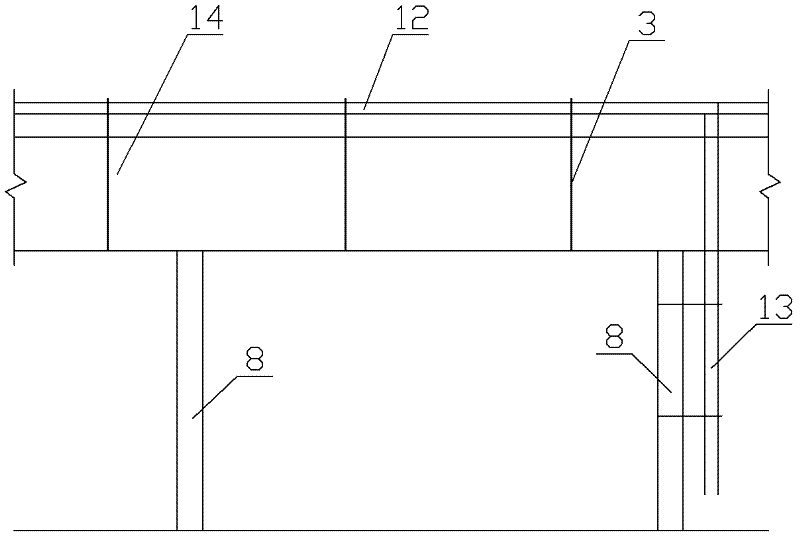

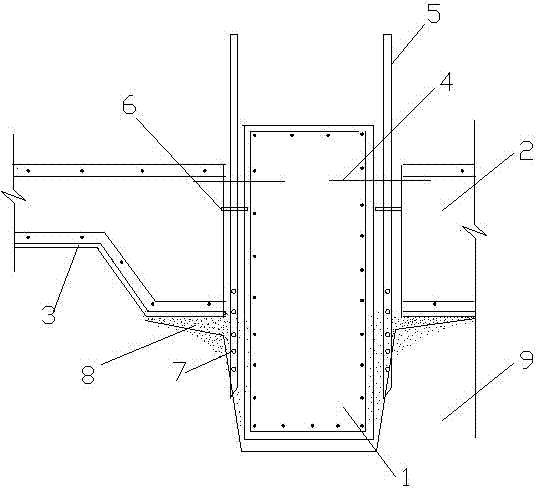

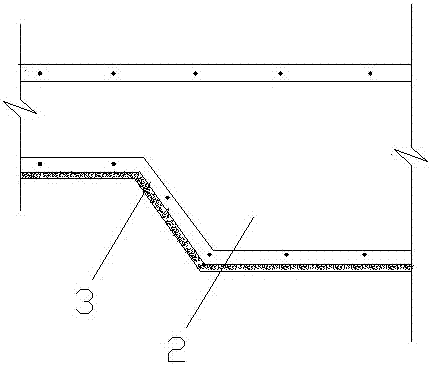

The invention relates to a construction method for a waterproof structure of a high-rise building basement top plate deformation joint. The construction method includes the following steps that a water stop steel plate is arranged at the position of the basement top plate deformation joint in the length direction of the deformation joint; an extruded polystyrene board is inlaid in an upper deformation joint and a lower deformation joint of the water stop steel plate; a concrete top plate is poured; the upper surface of the extruded polystyrene board is compactly filled with waterproof sealing paste in an embedded manner along the deformation joint; face edges of a water stop belt face upwards; a waterproof coil strengthening layer is arranged on the outer side of the rubber water stop belt; and a waterproof layer is arranged on the outer side of the waterproof coil strengthening layer. According to the construction method, the problems that when the concrete top plate and the external bonding water stop belt are constructed at the same time, the external bonding water stop belt is likely to be deflected, concrete at the lower side portion of the water stop belt is not vibrated compactly, the protection cost of the external bonding water stop belt and a finished sealing paste product is high, and repairing is difficult after damage is caused are solved; the upper portion of the top plate is made into a slope concrete returning table, water draining on the surface is facilitated, and the seepage probability is lowered; and the phenomenon that body structure construction is affected due to cross operation of relevant processes is avoided, limitation on the construction time is avoided, and the overall construction quality is ensured.

Owner:CHINA 22MCC GROUP CORP

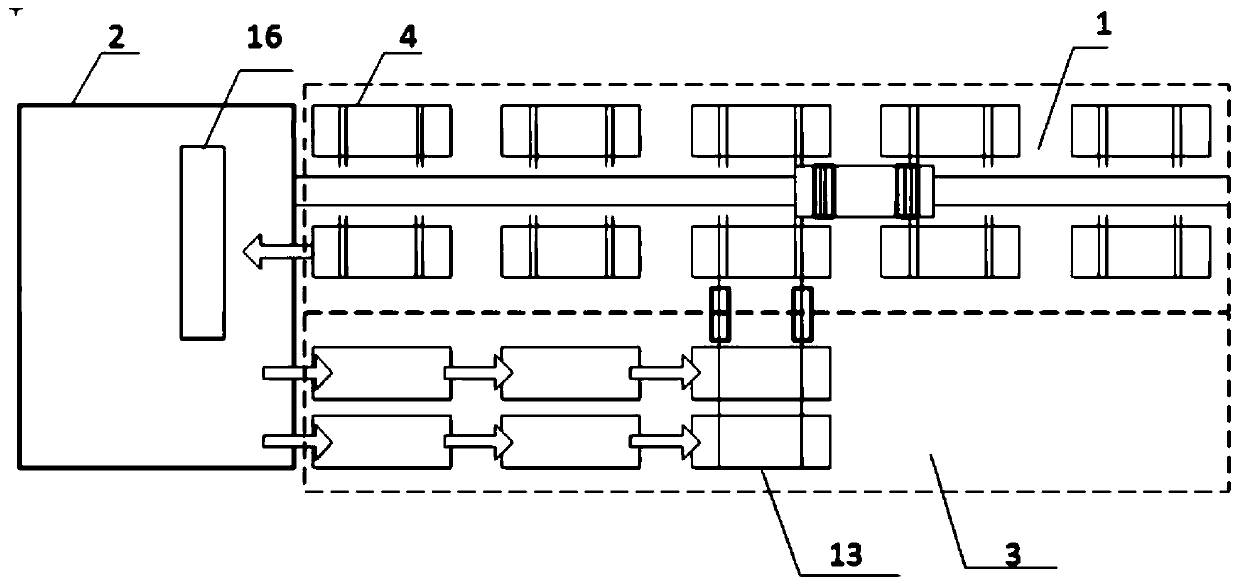

Manual assembly line layout for automobile tires

ActiveCN102756614AIncrease productivityLess investmentWheel assembling toolsBalancing machineAssembly line

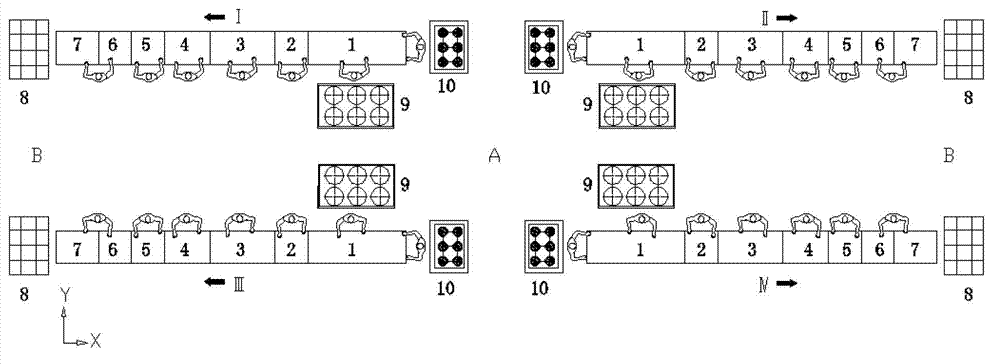

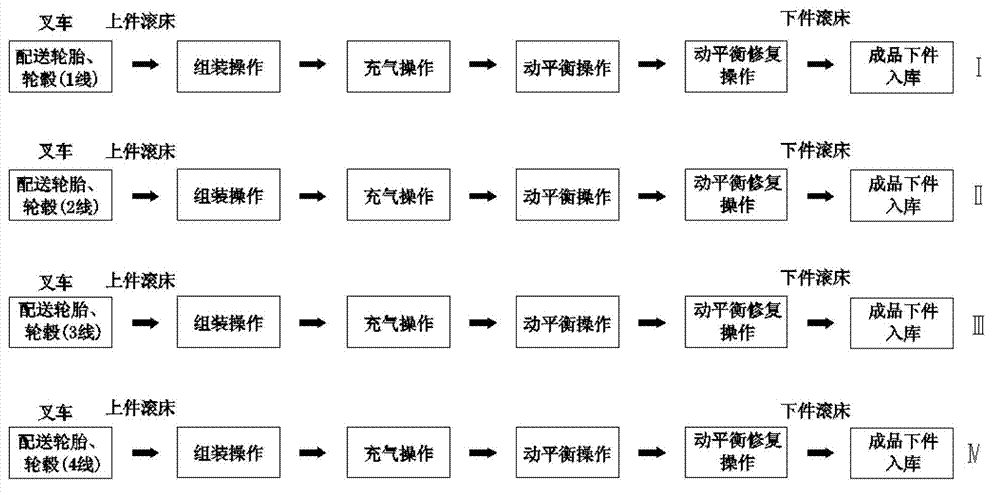

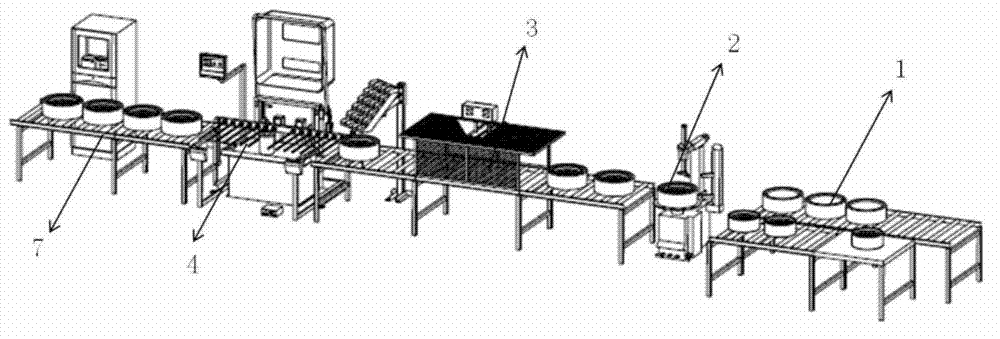

The invention discloses a manual assembly line layout for automobile tires, belonging to the field of automobile tire assembly. The manual assembly line for the tires comprises more than two assembly lines, wherein each assembly line comprises a dismantling and assembling machine, an aerator, a balancing machine, a correction roller machine which are arranged in parallel along the Y-axis direction, and each assembly line is perpendicular to an assembly type part loading roller machine and an assembly type part unloading roller machine which are arranged along the X-axis direction. The manual assembly line layout has the advantages that the scattered part loading roller machines in the prior art are assembled into the part loading roller machine, the scattered part unloading roller machines in the prior art are assembled into the part unloading roller, the assembly type part loading roller machine and the assembly type part unloading roller machine are driven through a motor for transmission, the transmission spacing is carried out through an optoelectronic switch, and therefore, the convenience of manual assembly is increased, the production efficiency of the assembly line is improved, the operation region of a forklift is reduced, operating personnel are not needed in the production process, the cross operation of the forklift in the production process is eliminated, and the fluency of tire line physical distribution and the operation safety are increased. The length of equipment stations is shortened; and the effective usable areas of plants are increased.

Owner:CHERY AUTOMOBILE CO LTD

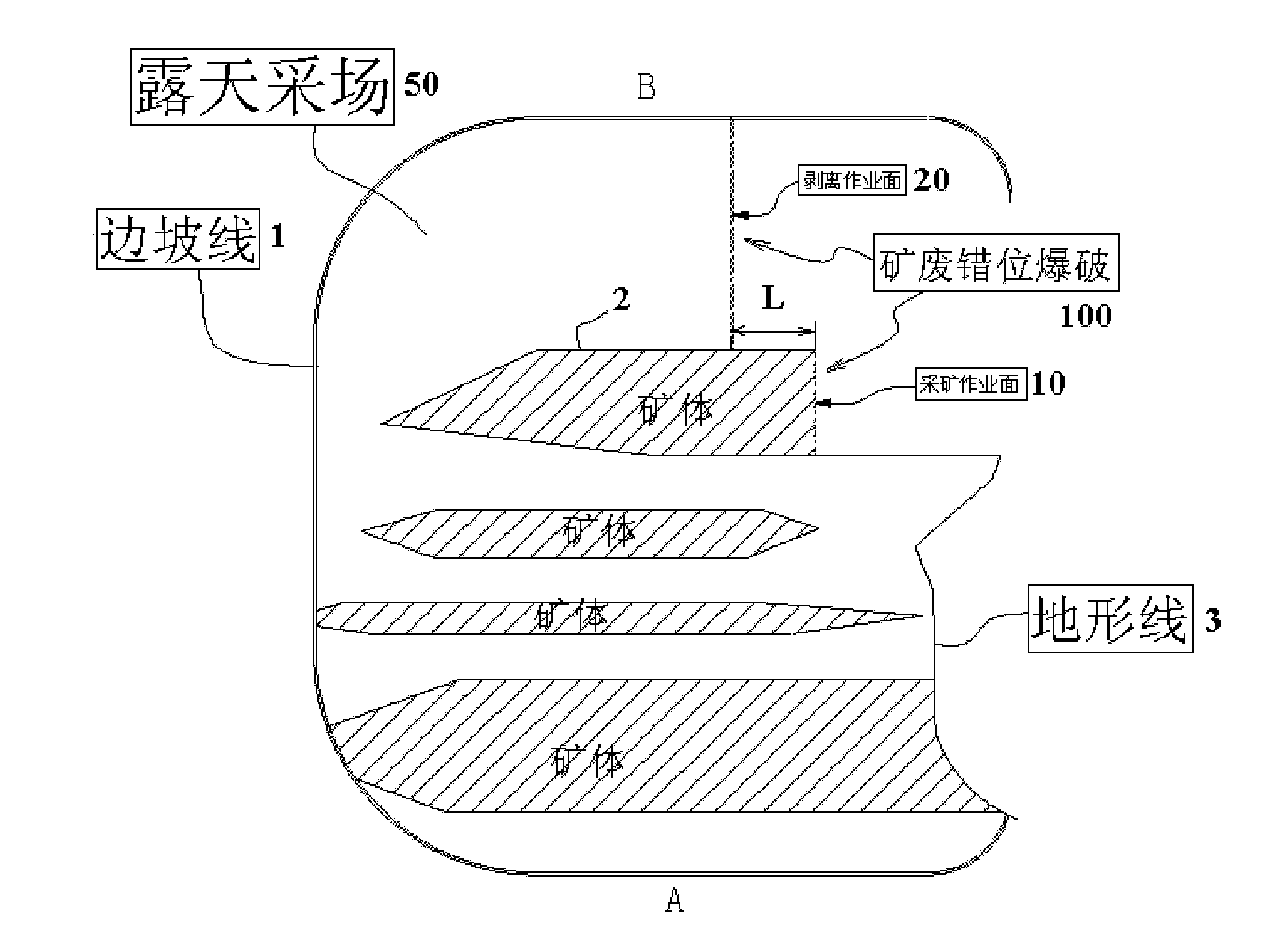

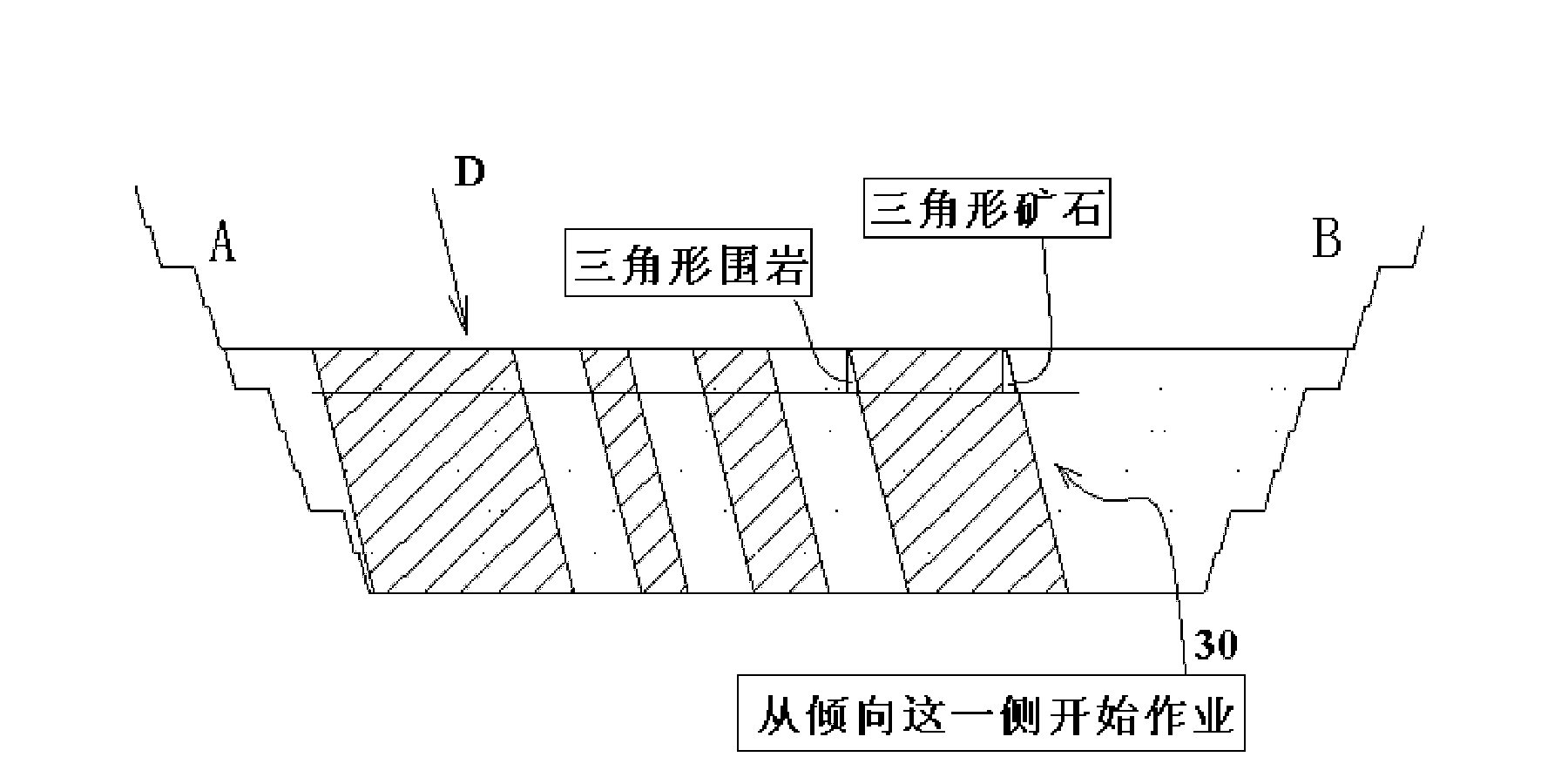

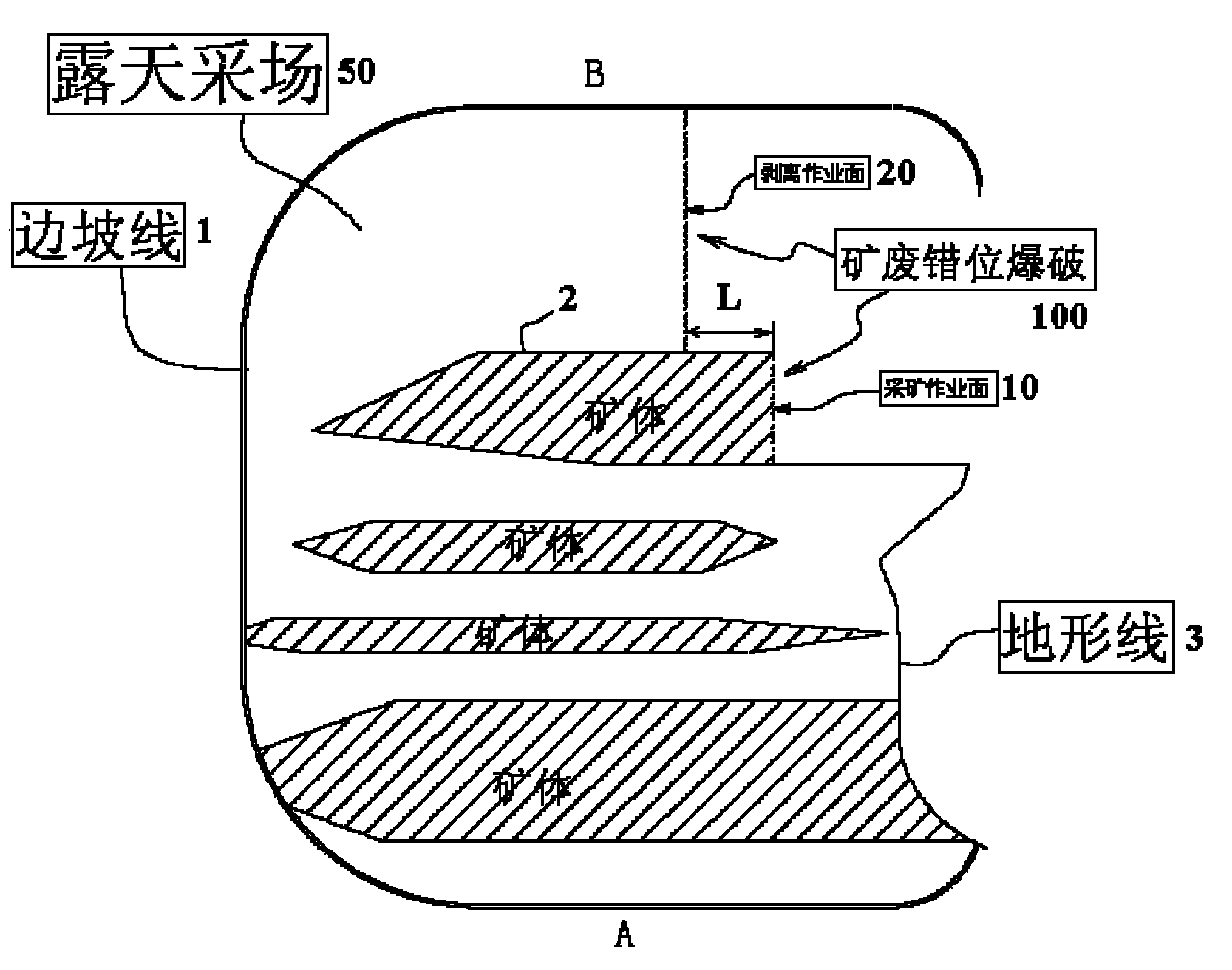

Mining technology for inclined orebodies in opencast mines

The invention provides a mining technology for inclined orebodies in opencast mines. The mining technology is characterized in that boring is carried out in the inclined direction of an orebody; the sequence of operation is from the outer side of the inclined direction of the orebody to the inner side; dissection and mining are staggered for blasting; and the staggered distance of secondary blasting is larger than or equal to 28 meters to avoid mixed stacking of ore and waste. The mining technology can fully utilize mineral resources, improve ore recovery rate, production efficiency and operation safety degree, and reduce ore dilution rate and production cost.

Owner:江西分宜珠江矿业有限公司

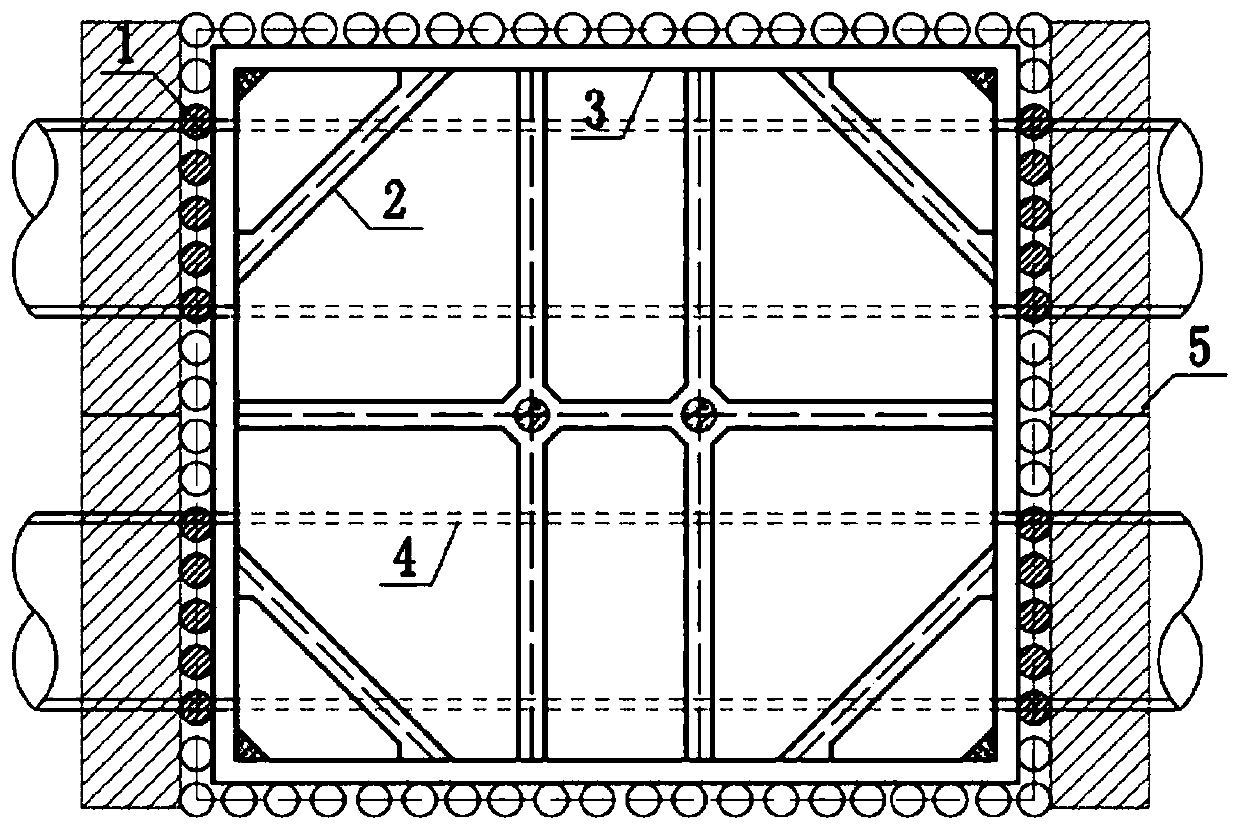

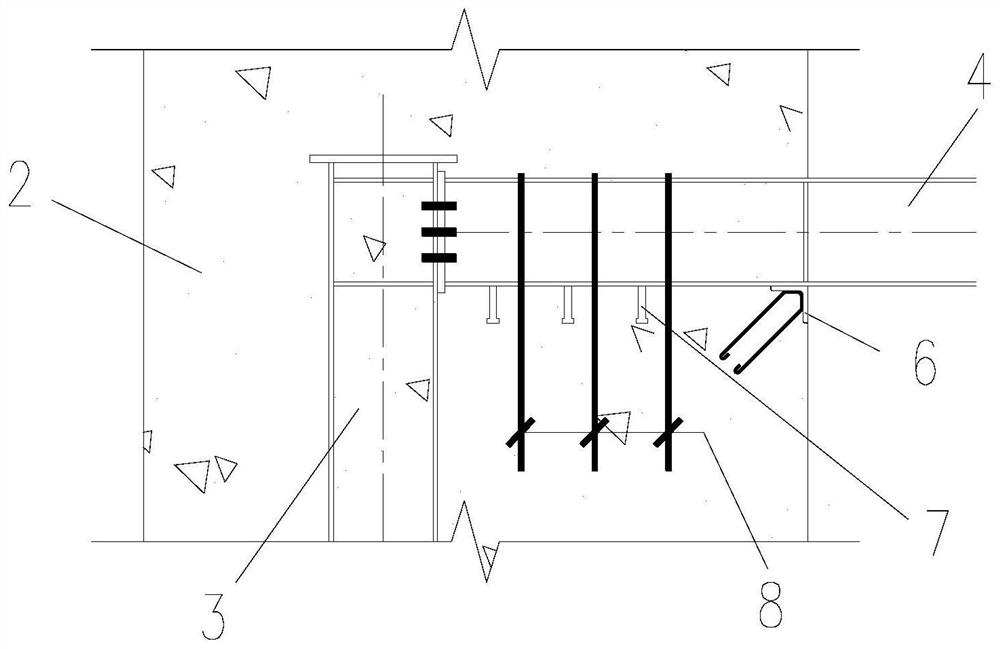

Shield before well construction method of underground comprehensive pipe gallery structure

InactiveCN110306592AShorten the construction periodEasy to planArtificial islandsUnderwater structuresPurlinReinforced concrete

The invention discloses a shield before well construction method of an underground comprehensive pipe gallery structure. The method comprises the steps of constructing a joint well enclosure pile, constructing high-pressure jet grouting pile foundation reinforcement, tunneling a shield of a pipe gallery standard section to a node well, cutting a node well enclosing pile, completing the crossing ofthe range of the node well and assembling shield pipe segments, reinforcing 10 adjacent ring pipe segments on the two sides of a well site, breaking the road surface, starting node well foundation pit excavation, drawing and tying the top of the enclosing pile into a ring by using a crown beam, and adopting a reinforced concrete support I for the first road, excavating foundation pits layer by layer from top to bottom, erecting steel supports layer by layer, when the foundation pit is excavated to the top of the shield segment, pouring a reinforced concrete support II and a reinforced concrete purlin, dismantling and hanging the shield segment in the range of the node well, excavating earthwork to the pit bottom, pouring box body concrete of the node well layer by layer from bottom to top, and dismantling the support layer by layer to complete the main body structure of the node well. Construction organization is more flexible, and the construction period of the shield pipe gallery can be greatly reduced.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

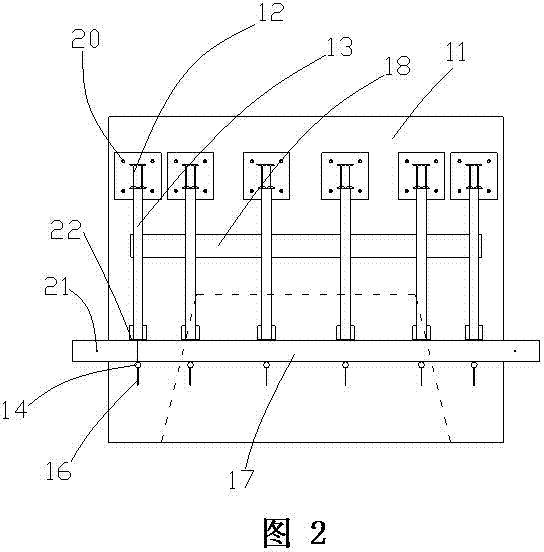

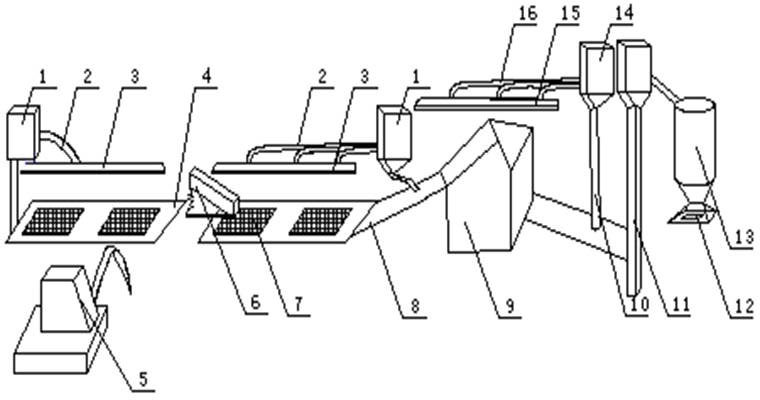

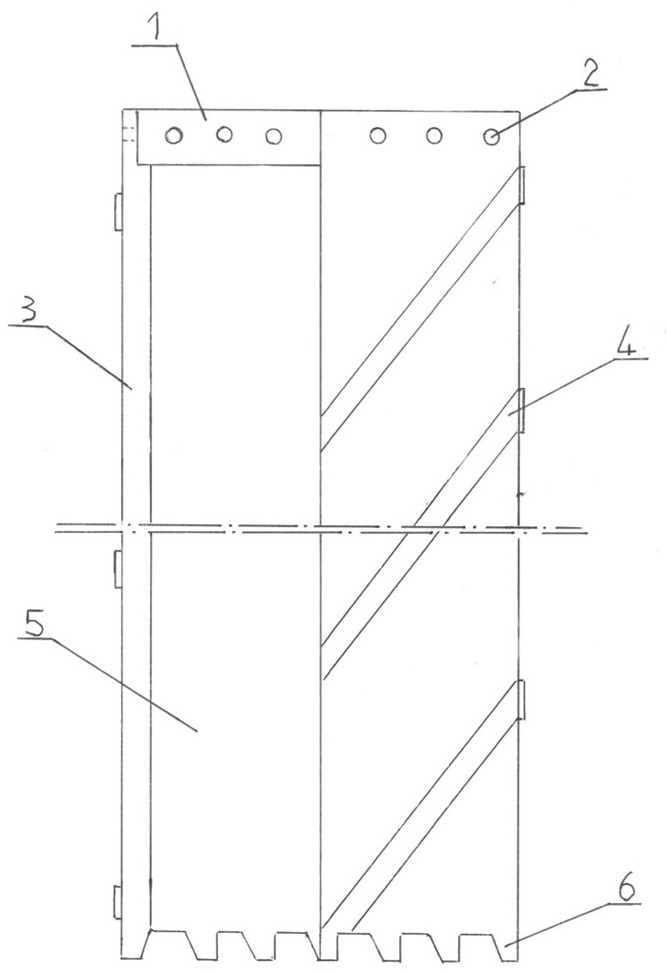

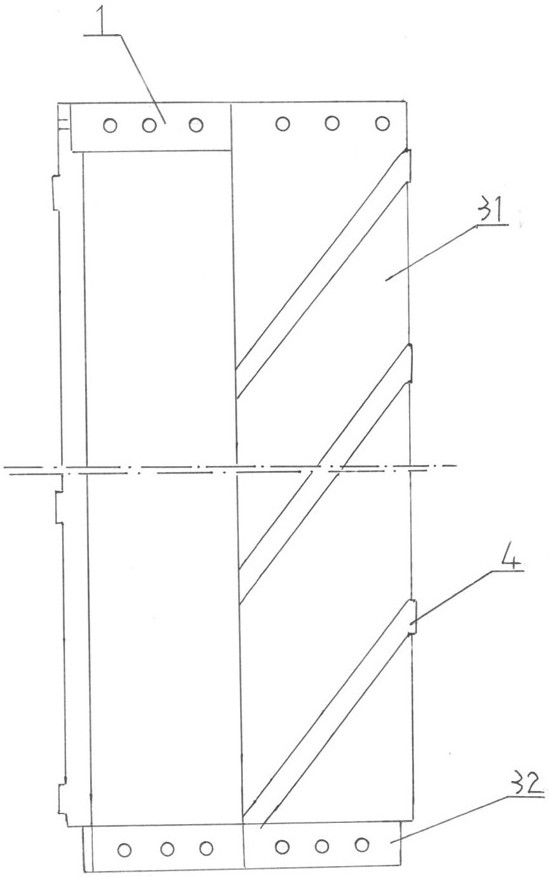

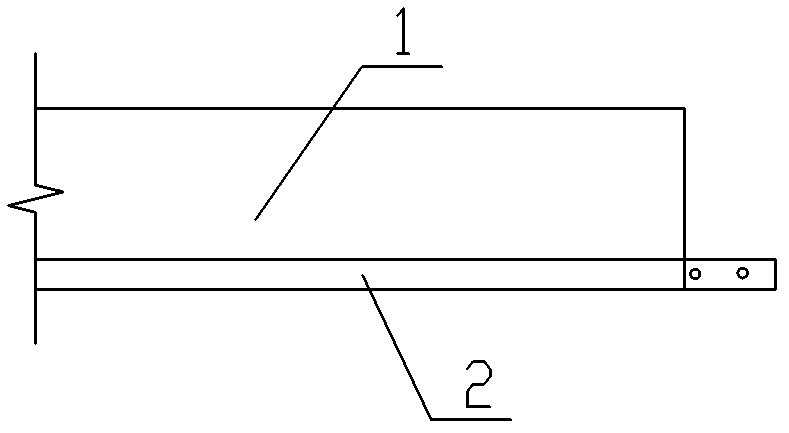

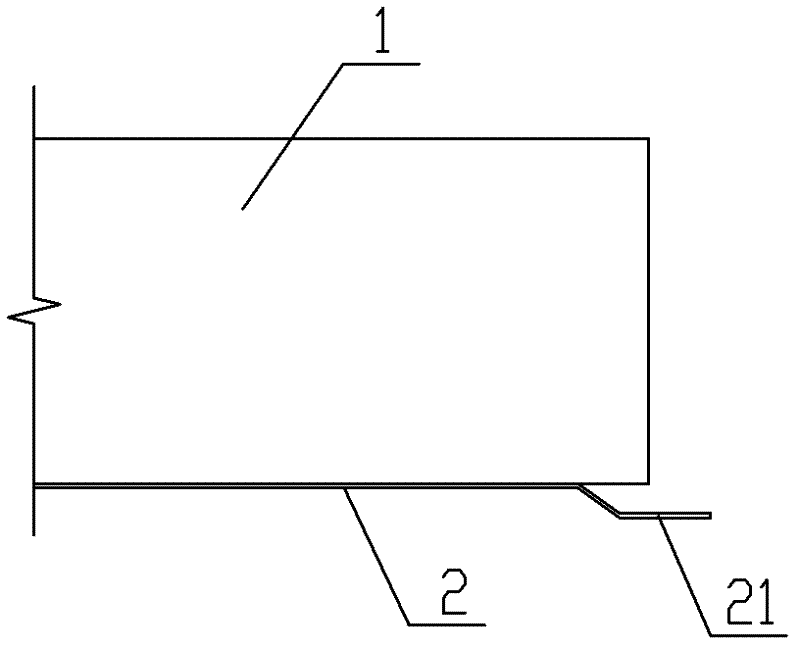

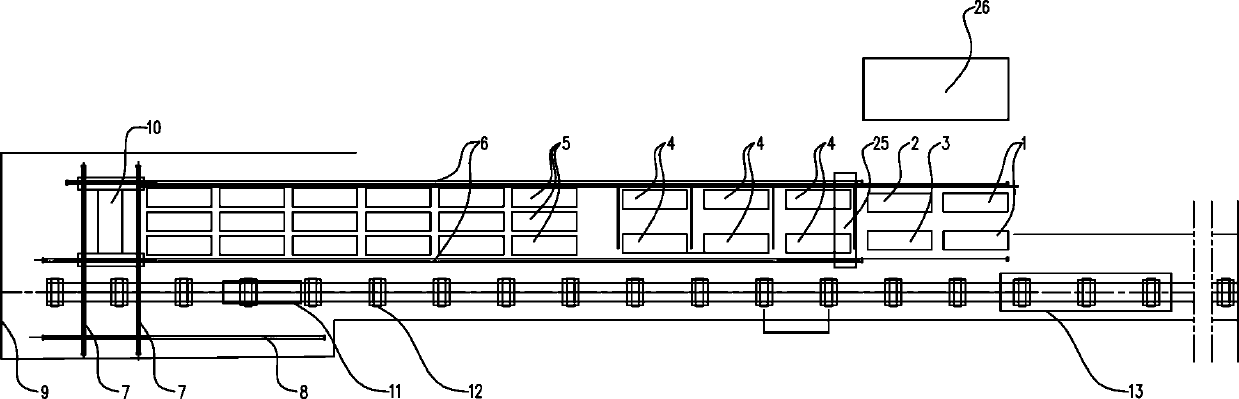

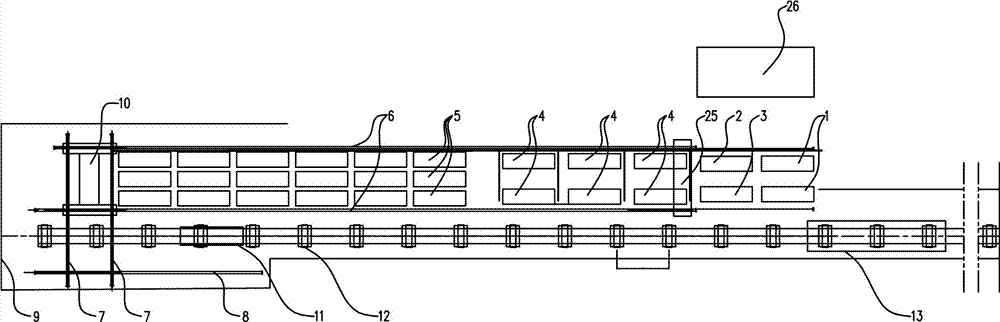

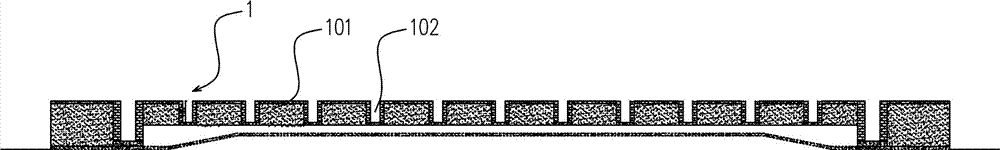

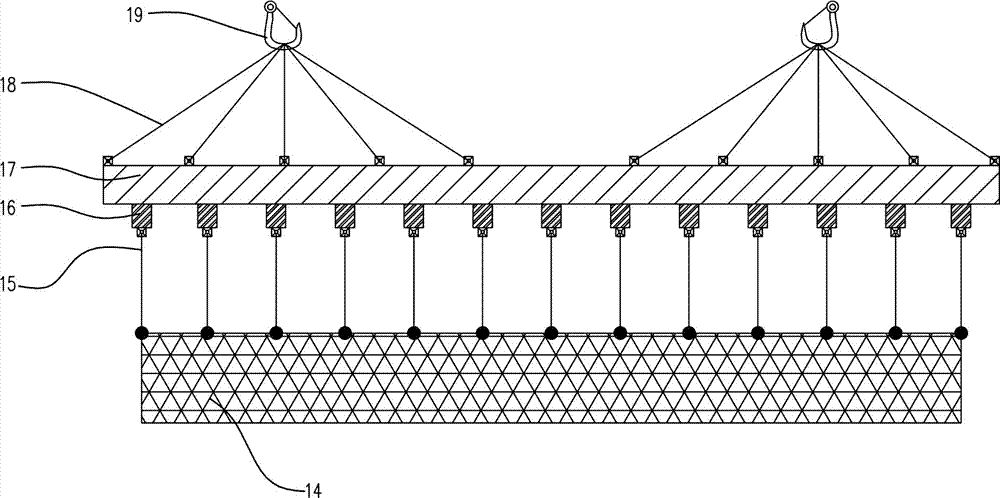

Prefabricated component production line

The invention provides a prefabricated component production line. The prefabricated component production line comprises a first area, a second area and curing kilns, and the curing kilns are arrangedat one ends of the first area and the second area in an adjoining neighbor mode side by side; the first area comprises a plurality of fixed stations arrayed in rows, bench formworks placed on the upper parts of the fixed stations, a horizontal track parallel to the fixed stations, a vertical track arranged on each fixed station and perpendicular to the horizontal track, and a child-mother vehicle,and the child-mother vehicle conveys the bench formworks into the curing kilns through the horizontal track and the vertical tracks; and the second area comprises a plurality of flowing stations anda transverse conveying line connecting the multiple flowing stations, and the bench formworks subjected to curing procedures in the curing kilns are circulated on all the flowing stations along the transverse conveying line. The prefabricated component production line can be suitable for production of prefabricated components with different structural types, has flexible production and organization modes, and can also achieve assembly line operation, the bench formworks enter the curing kilns for three-dimensional storage and curing, and the advantages of both a fixed bench formwork productionline process and an assembly line production process are achieved.

Owner:筑友智造智能科技有限公司

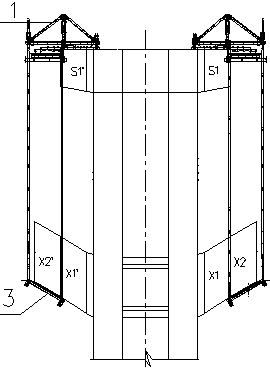

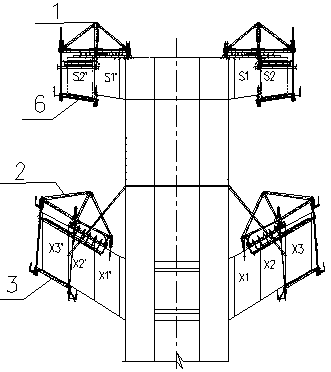

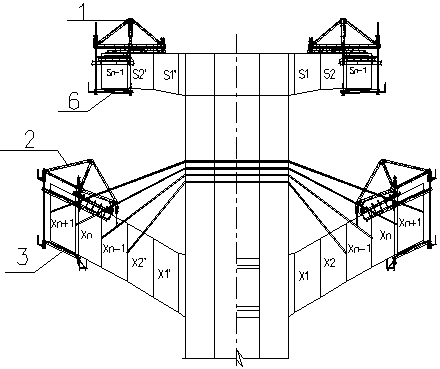

Construction process for triangular area of open-web rigid frame bridge

ActiveCN111335187AOptimize quantityAvoid Construction Work Safety RisksBridge erection/assemblyArchitectural engineeringHanging basket

The invention provides a construction process for a triangular area of an open-web rigid frame bridge. Suspension casting downward-bent steel bundles are arranged in the sections of webs of the firstto nth beam sections of the upper chord. Vertical force in upper chord section suspension casting construction is provided through the lower bent steel bundle; the sections provided with the downwardbent steel bundles can achieve balanced cantilever construction, the number of the supporting stand columns is further optimized, the construction operation safety risk of the supporting stand columnsof the (n-1) sections is avoided, the safety guarantee is improved, the construction period is shortened, and the complex system stress condition of a triangular area is optimized. Supporting stand columns are only arranged between n-m beam sections of the upper chord and the lower chord to support the n-m beam sections. The upper chord hanging basket does not cross the stand column; the mobile end is downwards embedded in the bottom fixed section, a fixed stand column is changed into a telescopic adjustable supporting stand column, the problems of conflict between a hanging basket bottom basket and the stand column, complex procedures of refitting the hanging basket bottom basket and the like are solved, cast-in-place concrete wet weight is completely borne by the hanging basket, the stress condition of a steel pipe stand column and a buckle cable is improved, and the overall safety reserve of the structure is improved.

Owner:上海远通路桥工程有限公司

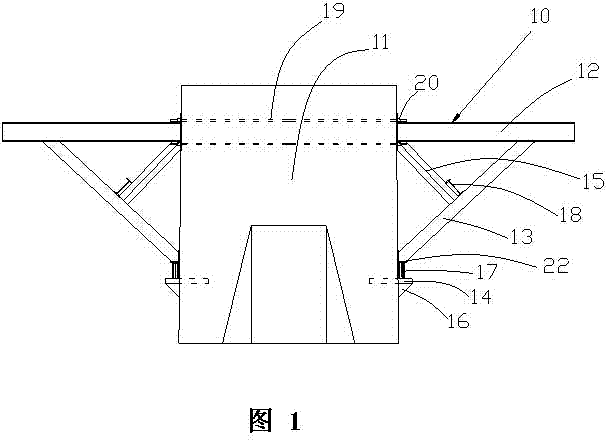

Triangular supporting bracket of suspended cast bridge block 0

ActiveCN104233961AStable supportImprove bearing capacityBridge erection/assemblyStructural engineeringUltimate tensile strength

The invention relates to engineering machinery, in particular to a triangular supporting bracket of a suspended cast bridge block 0. The triangular supporting bracket comprises at least one set of supporting frames, wherein the supporting frames comprise horizontal girders installed on bridge pier bodies and further comprise diagonal bracing beams, wherein the upper portions of the diagonal bracing beams are connected with the horizontal girders, the lower portions of the diagonal bracing beams are connected with reinforcing steel plates, the bottom faces of the reinforcing steel plates are connected with transverse beams, the lower portions of the transverse beams are connected with bolt rods, and the bolt rods are inserted into reserved holes in the bridge pier bodies. The fixing operation of the lower ends of the diagonal bracing beams can be completed only by inserting the bolt rods into the bolt rod reserved holes in the bridge pier bodies, the triangular supporting bracket is convenient to use, operation work types are few, cross operation and mutual interference are decreased, and labor intensity of workers is reduced. The triangular supporting bracket is low in installation technology difficulty, can be installed by adopting a common work type and does not need special workers, and manpower resource configuration is optimized. In conclusion, cost is effectively saved, efficiency is improved, and the triangular supporting bracket is safe and provides a guarantee.

Owner:福建第一公路工程集团有限公司

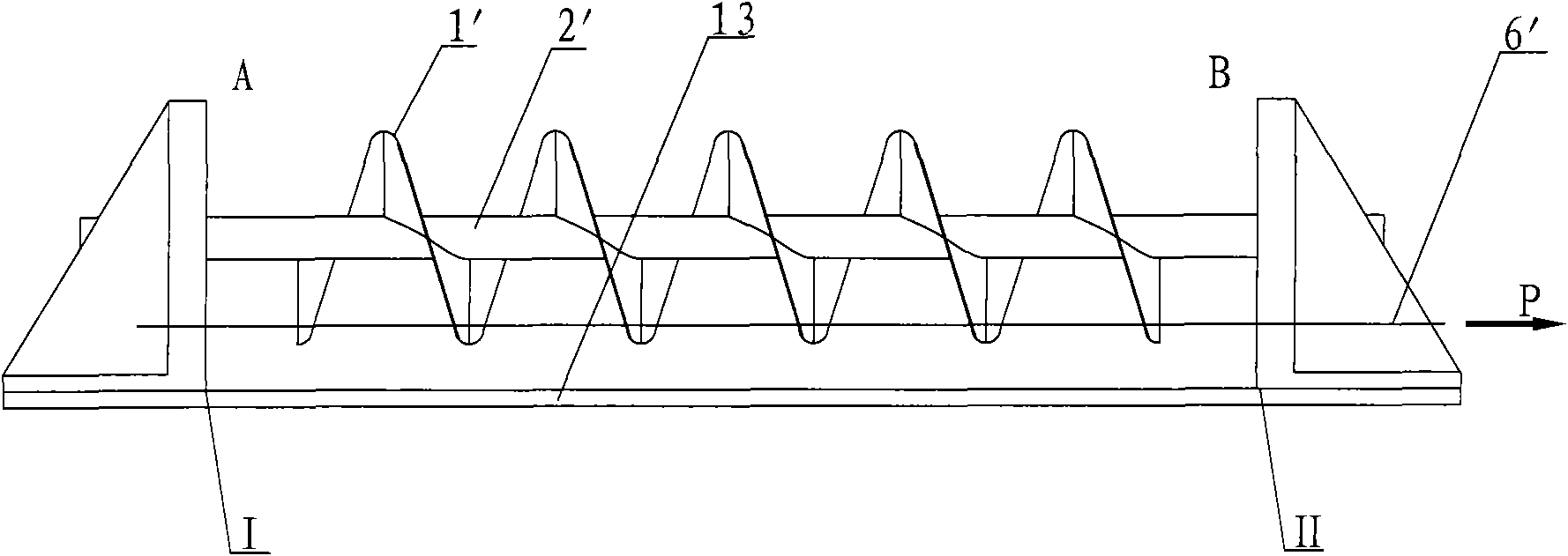

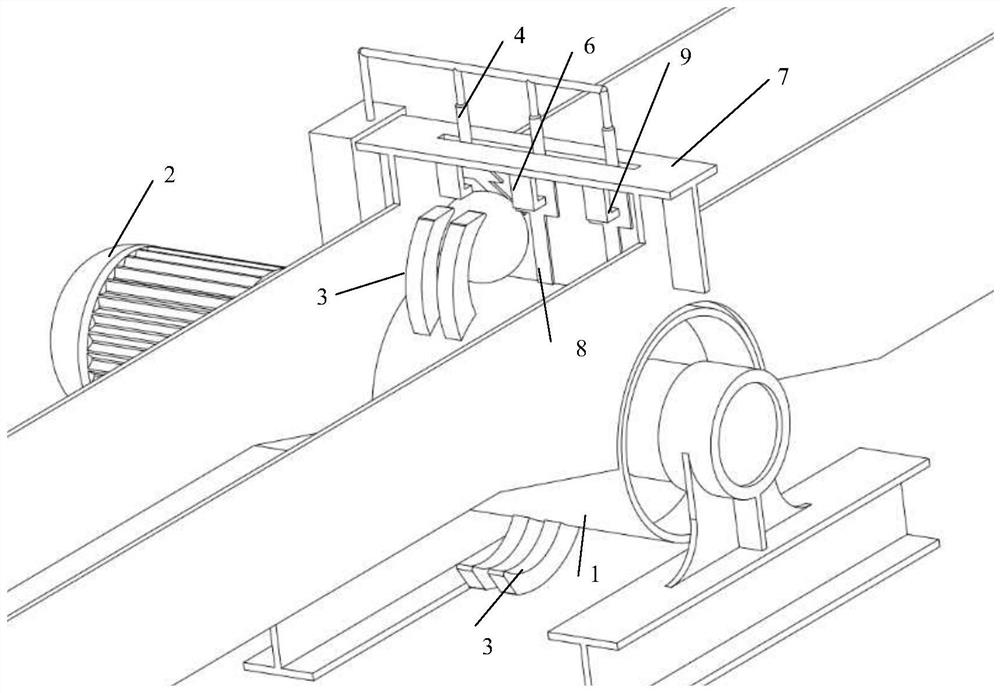

Method for manufacturing helical blade

The invention relates to a method for manufacturing a helical blade, comprising the following steps of: (1) stringing an overall blade on a mandrel, clamping a starting end of the overall blade through a driving conical roller and a driven conical roller capable of rotating around a shaft axis per se, and resisting the mandrel by utilizing a blocking roller capable of autorotating; (2) penetrating through the mandrel by utilizing a steel wire rope, connecting the B end of the mandrel to a universal joint, connecting the A end to a windlass, and linking the windlass and the driving conical roller; and (3) starting a driving device of the driving conical roller, stopping the driving device when the overall blade extends out 3-5 cm, firstly welding an inner diameter of the A end of the overall blade and the mandrel, fixing the overall blade, then restarting, temporarily stopping the driving device after the overall blade extends out a section again, welding the inner diameter of the overall blade and the mandrel, restarting the driving device, and repeating the operations in turn to obtain the helical blade. The method for manufacturing the helical blade has high working efficiency and favorable safety; and the obtained helical blade has accurate and uniform screw pitch and favorable quality.

Owner:太仓市宝马油脂设备有限公司

Construction method of waterproof structure for roof deformation joints in basement of high-rise buildings

ActiveCN106284425BTimely replacementSolve easy deviationArtificial islandsUnderwater structuresBasementArchitectural engineering

The invention relates to a construction method for a waterproof structure of a high-rise building basement top plate deformation joint. The construction method includes the following steps that a water stop steel plate is arranged at the position of the basement top plate deformation joint in the length direction of the deformation joint; an extruded polystyrene board is inlaid in an upper deformation joint and a lower deformation joint of the water stop steel plate; a concrete top plate is poured; the upper surface of the extruded polystyrene board is compactly filled with waterproof sealing paste in an embedded manner along the deformation joint; face edges of a water stop belt face upwards; a waterproof coil strengthening layer is arranged on the outer side of the rubber water stop belt; and a waterproof layer is arranged on the outer side of the waterproof coil strengthening layer. According to the construction method, the problems that when the concrete top plate and the external bonding water stop belt are constructed at the same time, the external bonding water stop belt is likely to be deflected, concrete at the lower side portion of the water stop belt is not vibrated compactly, the protection cost of the external bonding water stop belt and a finished sealing paste product is high, and repairing is difficult after damage is caused are solved; the upper portion of the top plate is made into a slope concrete returning table, water draining on the surface is facilitated, and the seepage probability is lowered; and the phenomenon that body structure construction is affected due to cross operation of relevant processes is avoided, limitation on the construction time is avoided, and the overall construction quality is ensured.

Owner:CHINA 22MCC GROUP CORP

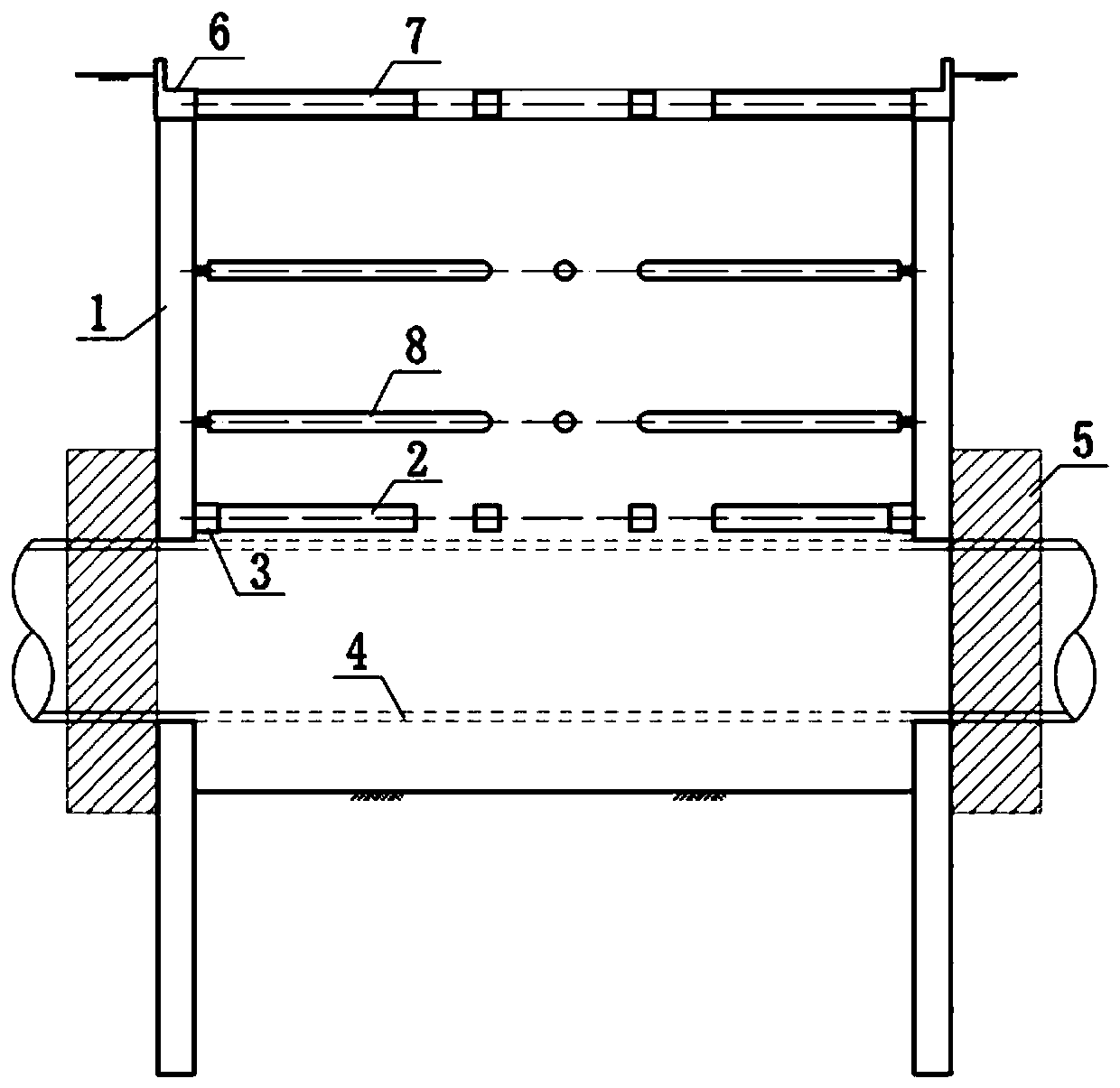

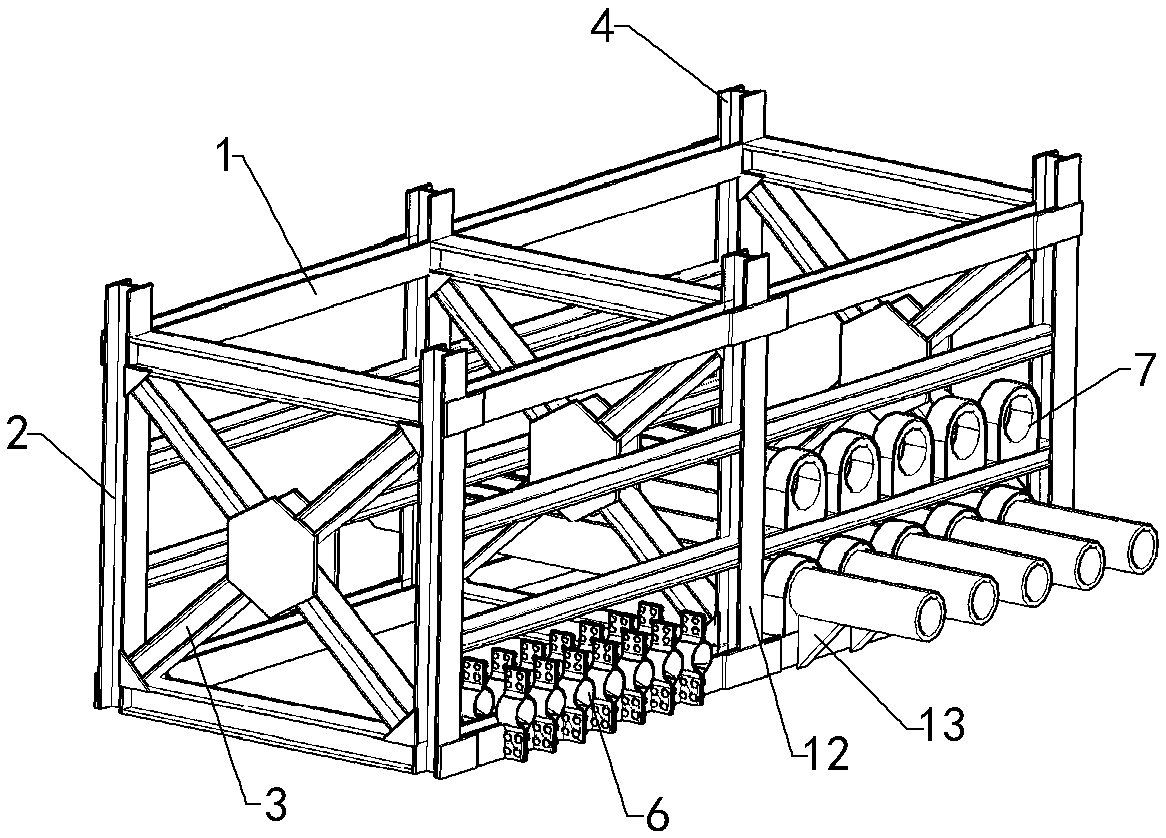

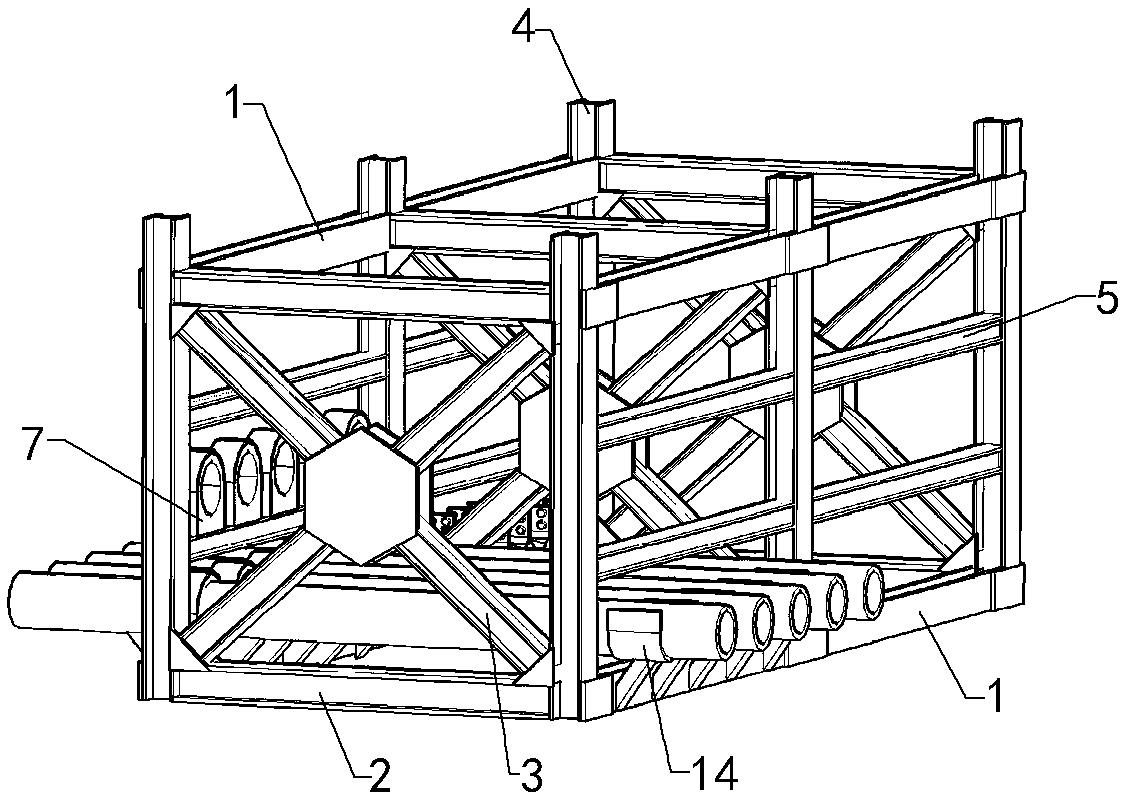

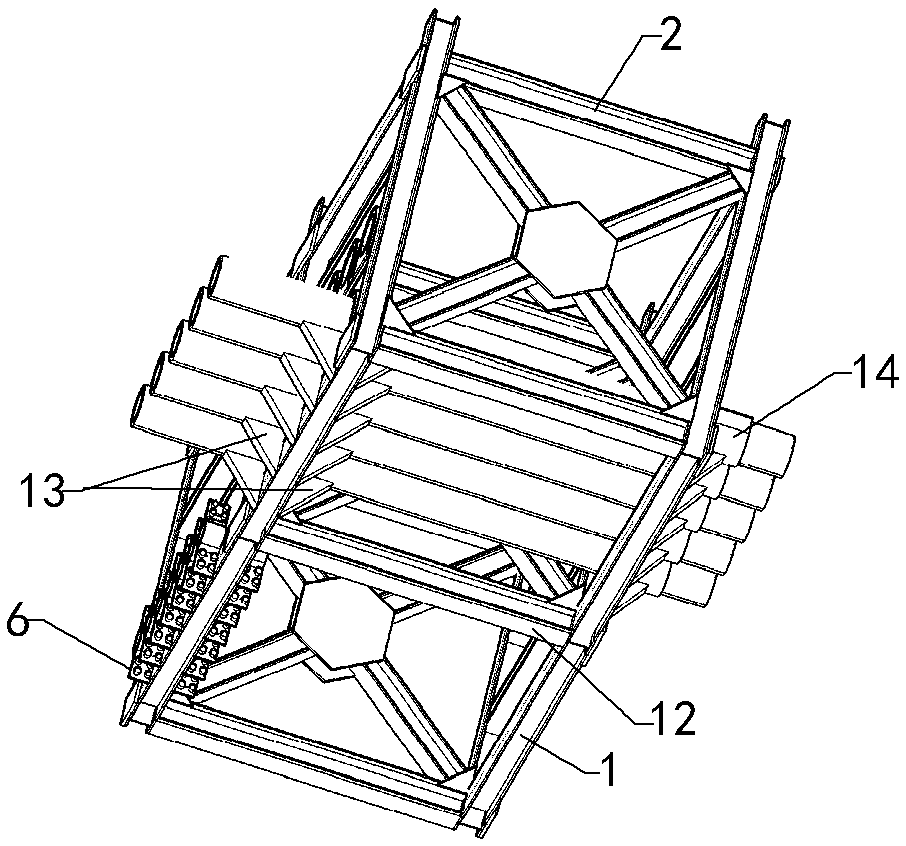

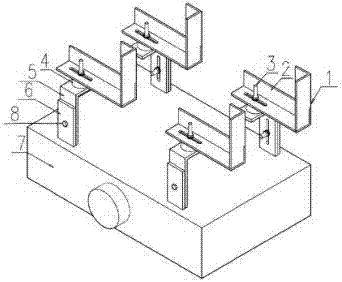

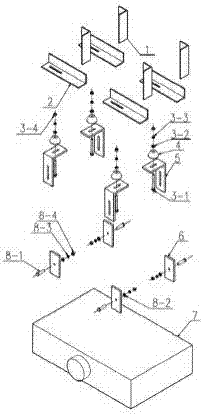

Multi-pipeline fixed support and construction method thereof

PendingCN109780330AReduce sizeSmall footprintPipe supportsThermal insulationStructural engineeringEngineering

The invention relates to the technical field of building pipeline fixing, and discloses a multi-pipeline fixed support and a construction method thereof. The fixed support is of a cuboid framework structure and is formed by four parallel horizontal beams and square reinforcement frames at the two ends of the horizontal beams in a defined manner. The top ends of two stand columns of each square reinforcement frame extend vertically upwards to form connecting portions connected with rear embedded parts in a top-layer basic structure. Cross arms are arranged between every two horizontal beams adjacent up and down. The cross arms are parallel to the horizontal beams. Pipelines are perpendicular to the horizontal beams and horizontally penetrate through the fixed support. The two side verticalfaces, where the pipelines penetrate, of the fixed support are a fixed face and a guide face in sequence. The pipelines and the horizontal beams or the cross arms on the fixed face are fixed through apipeline fixing assembly. According to the multi-pipeline fixed support, the problems that pipelines are concentrated, the pipe diameter is large, and loads are dispersed in space with large mountingheight and in the process that pipeline operation is hindered are solved, and design requirements are completely met.

Owner:BEIJING UNI CONSTR GRP CO LTD THIRD DEV & CONSTR CO LTD

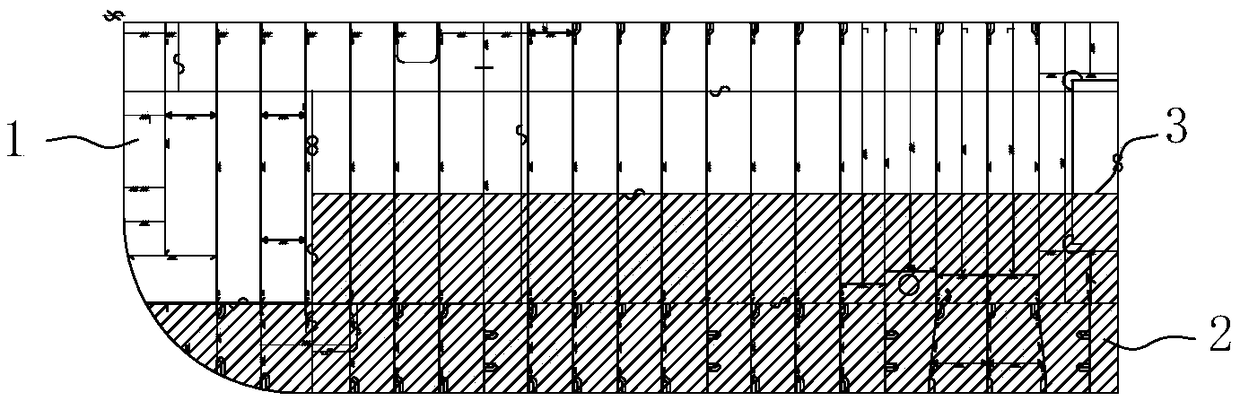

Ship engine room position segment division method

The invention discloses a ship engine room position segment division method. During the segmentation construction of the engine room of the ship, wall plates connecting the bottom section and the upper section of an outfitting area of an engine room basin are divided into upper wall plates and lower wall plates according to the dividing position lines, the upper wall plates are constructed with the upper segment, the lower wall plates are constructed with the bottom segment; the upper wall plates are butt-jointed with the lower wall plates in a stage where the upper and bottom segments are folded together; corner joining of the wall plates in the narrow space can be avoided after the outfitting is installed in the engine room, the problems of narrow construction space of the hull operation, poor construction environment, potential safety hazards, and influence of water accumulation and other factors can be solved, and the on-site production efficiency is greatly improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

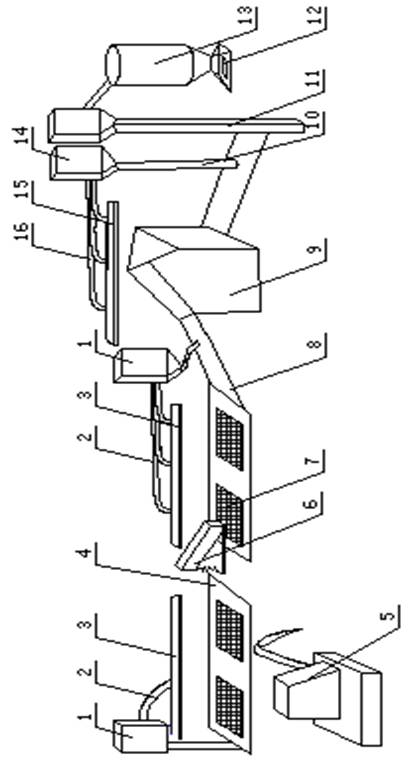

Electrolytic aluminum anode scrap cleaning and crushing system and recovery method

InactiveCN102430561AIncrease labor intensityImprove working environmentSolid waste disposalGrain treatmentsAluminum anodeRecovery method

The invention provides an electrolytic aluminum anode scrap cleaning and crushing system and a recovery method thereof. The production efficiency can be improved, the work environment of workers is improved, the work intensity of the workers is reduced, the danger degree in the production is reduced, and the energy-saving and consumption-reduction effect is also realized. The electrolytic aluminum anode scrap cleaning and crushing system comprises more than one cleaning platform, more than one dismounting crushing machine, more than one dust remover, a large-inclination-angle belt conveyor, a reaction type crushing machine and a material cabin. The recovery method comprises the following steps that anode scraps are conveyed onto the cleaning platform to be crushed on a grate by the dismounting crushing machine, crushed large and small material blocks are conveyed to the reaction type crushing machine to be crushed again through the large-inclination-angle belt conveyor, the crushed powder materials are conveyed to the material cabin through a bucket hoisting machine, and dust generated in the crushing and transportation process is conveyed to the large-inclination-angle belt conveyor through a spiral conveyor and is finally conveyed to the material cabin.

Owner:山东魏桥铝电有限公司

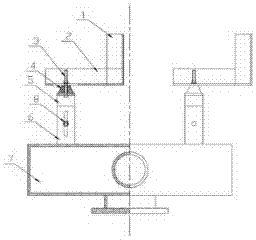

Multipurpose elastic and adjustable ventilation terminal seat frame of engineering ship

InactiveCN107957130AReduce spreadAvoid cross assignmentDucting arrangementsLighting and heating apparatusGeotechnical engineeringBuilding construction

The invention discloses a multipurpose elastic and adjustable ventilation terminal seat frame of an engineering ship. The multipurpose elastic and adjustable ventilation terminal seat frame of the engineering ship comprises a ventilation terminal. Four corners of the top of the ventilation terminal are all welded to ventilation terminal connecting angle steel. The ventilation terminal connecting angle steel is connected with conversion bracket angle steel through first connecting bolt sets. Elastic rubber is arranged in the middle of the top of each piece of conversion bracket angle steel. Adjustment angle steel is fixed to the middle of the top of each piece of elastic rubber through a second connecting bolt set, and one side surface of each piece of adjustment angle steel is connected with welding supporting angle steel. Each first connecting bolt set comprises a first connecting bolt, a first connecting flat gasket, a first connecting elastic gasket and a first connecting nut. A round hole is formed in the middle of each piece of ventilation terminal connecting angle steel. Each first connecting bolt penetrates through the corresponding round hole and is connected with the corresponding first connecting flat gasket and the corresponding first connecting elastic gasket. The multipurpose elastic and adjustable ventilation terminal seat frame of the engineering ship is simple in structure, convenient to install and high in universality, and the various construction cross-operation problems can be solved.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

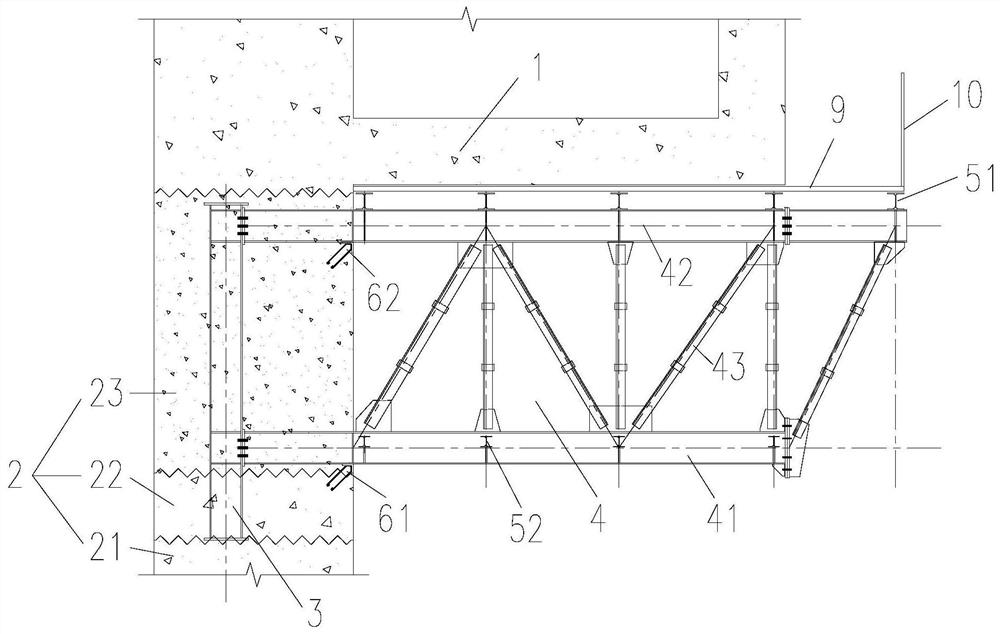

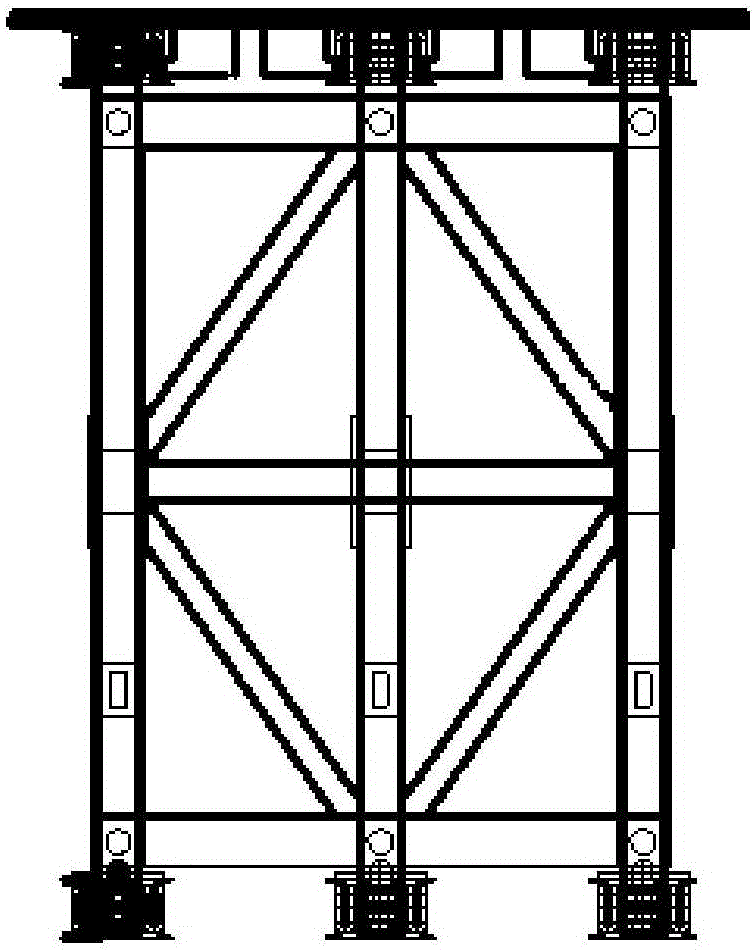

High-altitude large-span cantilever structure construction platform and method

ActiveCN112049235ASolve construction problemsImprove construction efficiencyNuclear energy generationForms/shuttering/falseworksArchitectural engineeringLong span

The invention discloses a high-altitude large-span cantilever structure construction platform and method. The construction platform comprises a concrete structure, a stand column pre-buried in the concrete structure, a parallel chord truss arranged on the stand column, an upper chord secondary beam arranged on a truss upper chord, a lower chord secondary beam arranged on a truss lower chord, and acontour plate or a supporting formwork arranged on the upper chord secondary beam. The construction platform can be used as the high-altitude cantilever concrete structure construction platform, andis particularly suitable for the situations of large suspension height, large span and large construction load. The construction platform is simple in structure and convenient to construct and install, the construction problem of the high-altitude large-span cantilever structure can be effectively solved, the construction method saves materials, the danger of high-altitude operation is reduced, the construction difficulty and the construction safety risk are reduced, meanwhile, cross operation with surrounding structures is avoided, and the construction efficiency of the high-altitude large-span cantilever structure is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Method and device for installing steel sheet piles in sandstone stratum through rotary drilling rig

The invention belongs to a method and device for installing steel sheet piles in a sandstone stratum through a rotary drilling rig. The device for installing the steel sheet piles in the sandstone stratum through the rotary drilling rig comprises the rotary drilling rig and further comprises a spiral wing rotary drilling barrel with rotary drilling teeth, a lengthened steel protection barrel and a steel sheet pile jacking and pressing disc in butt joint with the lower end of a drilling rod of the rotary drilling rig. According to the method for installing the steel sheet piles in the sandstone stratum through the rotary drilling rig, hole guiding can be completed only through one rotary drilling rig, the spiral wing rotary drilling barrel with the rotary drilling teeth, the lengthened steel protection barrel and the steel sheet pile jacking and pressing disc are driven through the drilling rod of the rotary drilling rig, it is guaranteed that the drilling rod enables the spiral wing rotary drilling barrel with the rotary drilling teeth to drill footage through rotating power, and hole sleeving is completed; then a drilling bucket of the rotary drilling rig is used for cleaning a pebble bed and a sandstone in the barrel, then the barrel is backfilled with clay, then the barrel is pulled out through reverse rotating force of the drilling rod of the rotary drilling rig, and finally the steel sheet pile jacking and pressing disc is used for jacking and driving a steel sheet pile till a cofferdam is closed. According to the method and device for installing the steel sheet piles in the sandstone stratum through the rotary drilling rig, steel sheet pile implanting can be finally completed only through one rotary drilling rig, the steel sheet pile cofferdam is completed, and the steel sheet pile implanting speed and efficiency can be improved.

Owner:NO 1 ENG CO LTD OF FHEC OF CCCC

Method for mounting cable bridge on gas pipeline

InactiveCN102506232AChange the installation methodLess construction requirementsPipe supportsCable trayEconomic benefits

The invention discloses a method for mounting a cable bridge on a gas pipeline. A bridge fixing device and sectional bridges are made on the ground; grounding main lines are preset on the sectional bridges and a single bridge; and the structure of the bridge fixing device meets the requirement that the bridge fixing device can be fixed to an accessory of the pipeline through a bolt, and the requirement that the bridge can be spliced through bolts. The method has the advantages that: the constructional requirement is low; welding and flame operation in dangerous regions can be avoided; the cable bridge can be safely and conveniently constructed; the engineering cost is low; and the economic benefit is high.

Owner:TIANJIN 20 CONSTR

Aqueduct storing table carrying pole beam consignment device and method

InactiveCN107650260AFast constructionGuarantee the construction qualityBridge applicationsCeramic shaping apparatusDecompositionArchitectural engineering

The invention provides a factory type large aqueduct construction system. A steel bar table base, a steel bar sling storage area, a steam shed storage area, an aqueduct making table base and an aqueduct storing table base are arranged nearby an aqueduct pier; a track is arranged nearby the steel bar table base, the steel bar sling storage area, the steam shed storage area, the aqueduct making table base, the aqueduct storing table base and the aqueduct pier; and an aqueduct lifting machine and a portal crane are installed on the track. A construction method includes the following steps that asteel bar cage of an aqueduct is bound on the steel bar table base as a whole; a bottom mold is installed on the aqueduct making table base; the steel bar cage is hoisted to the bottom mold of the aqueduct making table base by adopting an overall steel bar hoisting device; concrete is poured; the aqueduct is erected; and assembly line construction of the large aqueduct is achieved through the above steps. By decomposing and teasing the aqueduct construction procedure and by adopting the scheme that factory-like assembly line construction and modularized construction are combined, the aqueductconstruction speed is increased, the construction period is shortened, safe management is optimized, and the construction quality of the aqueduct is guaranteed.

Owner:CHINA GEZHOUBA (GRP) FIRST ENG CO LTD

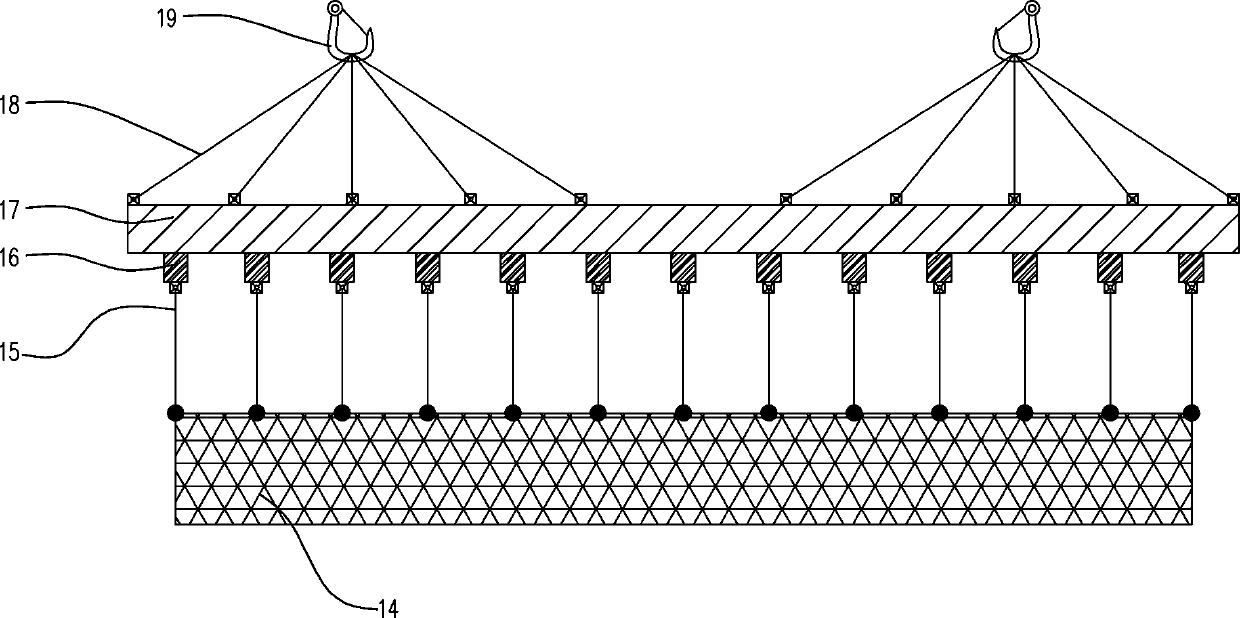

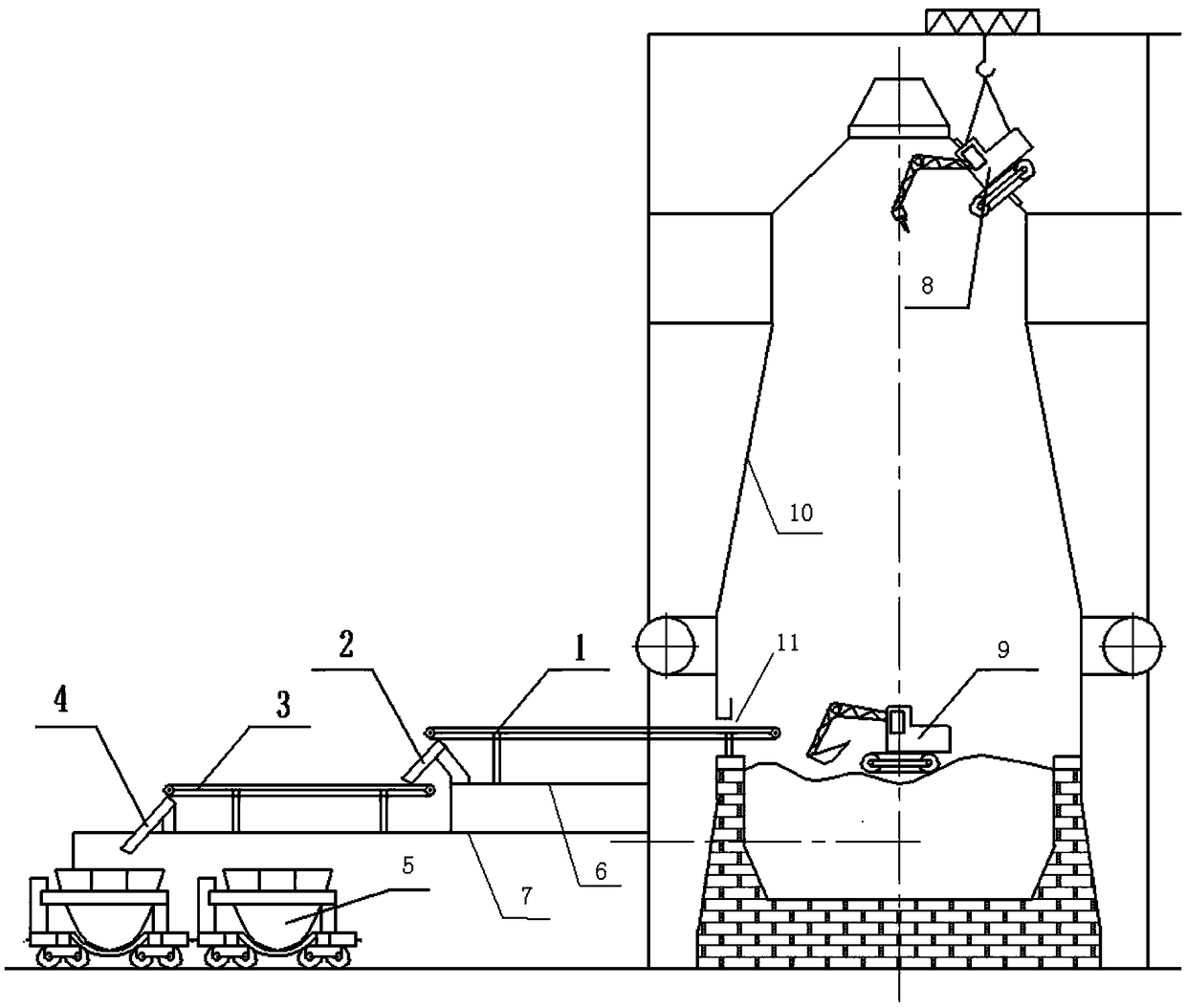

A system and method for cleaning in-furnace waste materials during major overhaul of a large blast furnace

PendingCN108624730ANo deformation, cracking and water leakageNo cracking or leakageBlast furnace componentsBlast furnace detailsSlagEngineering

The invention belongs to the field of blast furnaces in iron making, and particularly relates to a system and method for cleaning in-furnace waste materials during major overhaul of a large blast furnace. The system includes excavators, roller belt conveyors, spouts and slag receivers. The two excavators are lifted into the furnace from a top manhole, one of the excavators is provided with a hydraulic hammer and used for crushing waste materials, and the other excavator is provided with a bucket shovel and used for loading and transporting the waste materials. One of the roller belt conveyorsis arranged on a blast furnace tuyere platform, and the front end of the roller belt conveyor extends into the furnace from a blast furnace air supply port. A blast furnace cast house platform is provided with the other roller belt conveyor the front end of which is connected to the tail end of the roller belt conveyor on the blast furnace tuyere platform through a spout, and the tail end of whichis connected to the slag receivers on the ground through a spout. The waste materials in the furnace are conveyed through the excavators, the roller belt conveyors, and the spouts, from the blast furnace air supply port to the ground slag receivers, while passing through the tuyere platform and the cast house platform, and therefore manual work is replaced by mechanical operation, the working efficiency is greatly increased, in-furnace waste material cleaning time during major overhaul of the blast furnace roller is effectively shortened, the construction cost is saved, and the blast furnacecan be used for production in advance.

Owner:BENGANG STEEL PLATES

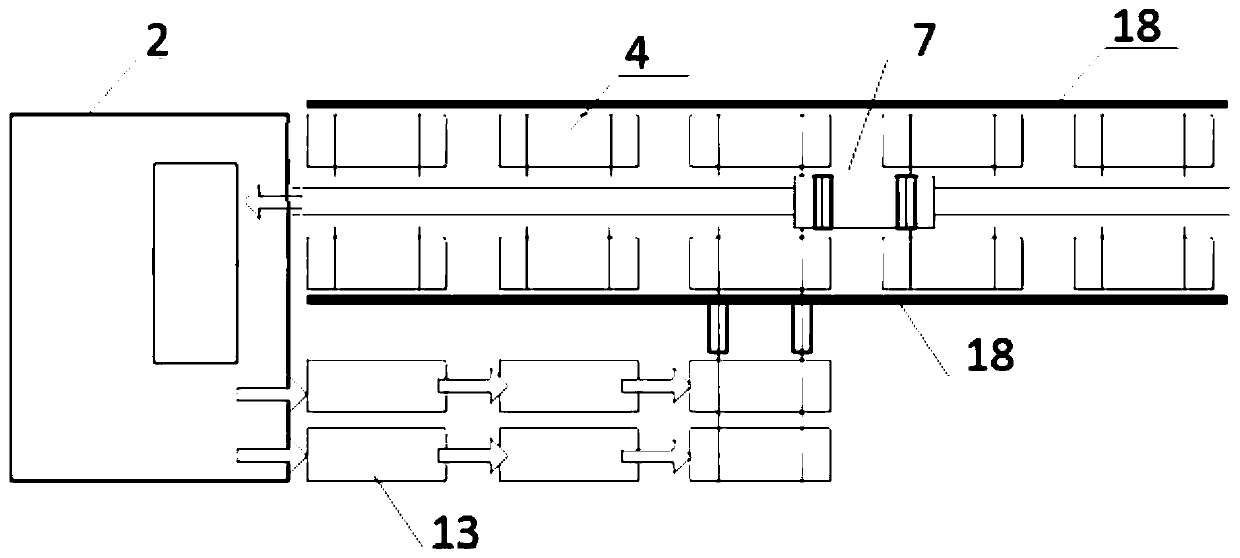

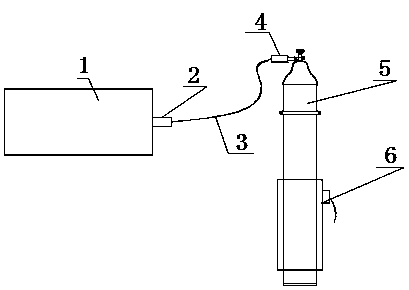

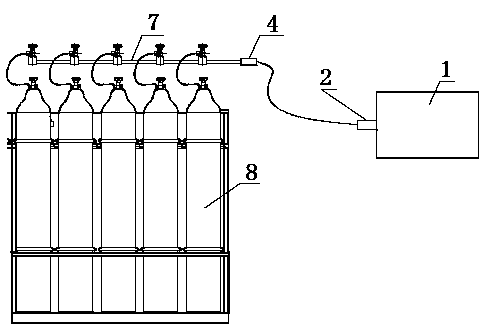

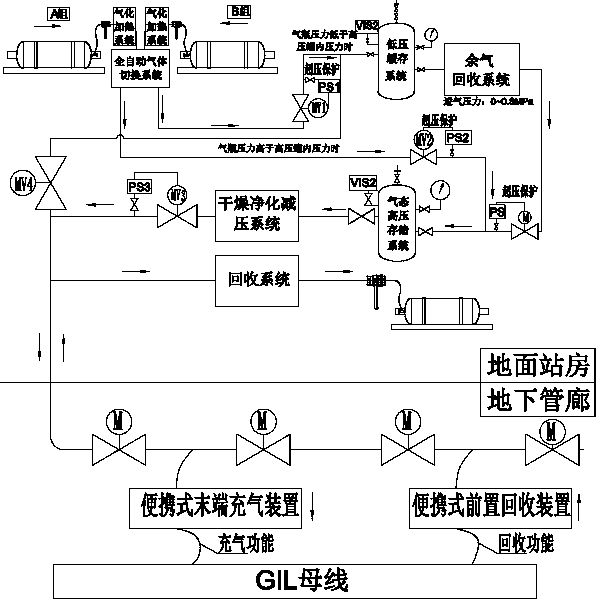

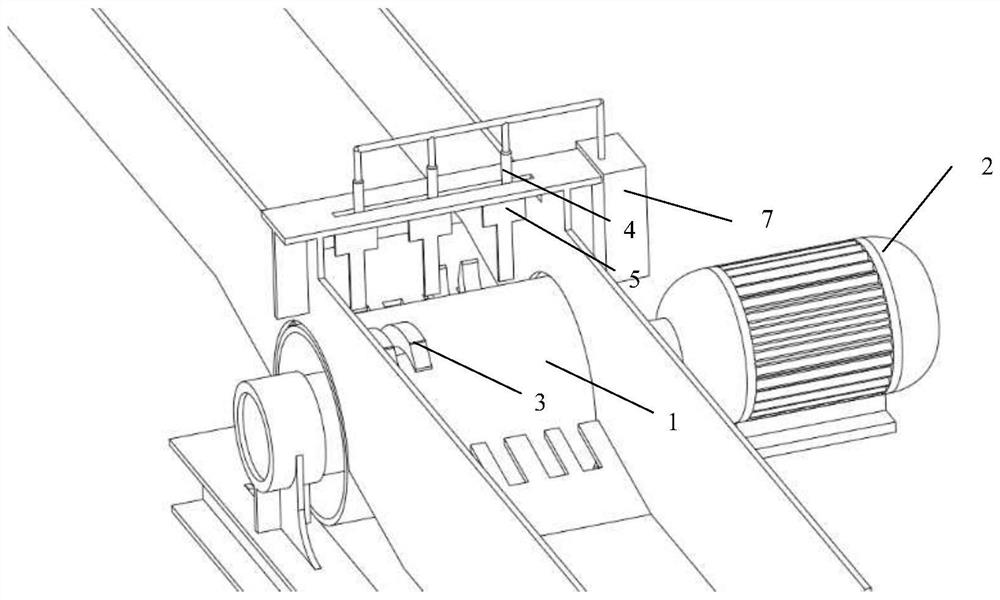

Ultrahigh-purity SF6 pipe gas transmission system

PendingCN111089228AAvoid cross assignmentShorten filling timeVessel mounting detailsGas handling/storage effectsSulfur hexafluorideGas cylinder

The invention discloses a ultrahigh-purity SF6 pipe gas transmission system. The system is characterized by comprising an automatic safety monitoring system, a gas supply station building, an intermediate station storage system and a gas charging system; the gas supply station building, the intermediate station storage system and the gas charging system are serially connected in sequence for communication; and the automatic safety monitoring system is electrically connected with the gas supply station building, the intermediate station storage system and the gas charging system. The device takes out liquid-state sulfur hexafluoride from a steel cylinder, and realizes gasification of sulfur hexafluoride in equipment to achieve high gasification speed and high heat exchange efficiency. The gas cylinder has no need to be transported in a pipe rack to prevent mutual crossing operations with GIL bus transportation and installation machines; through actual operation demonstration, the systemachieves the gas charging efficiency being 12 times of a traditional single-cylinder gas charging mode, greatly shortens the gas charging time, and effectively solves the construction period bottleneck problem caused by the traditional gas charging mode; and the sulfur hexafluoride gas cylinder is management on the grounded in a centralized mode to effectively control the safety risk.

Owner:JIANGSU POWER TRANSMISSION & DISTRIBUTION CO LTD +2

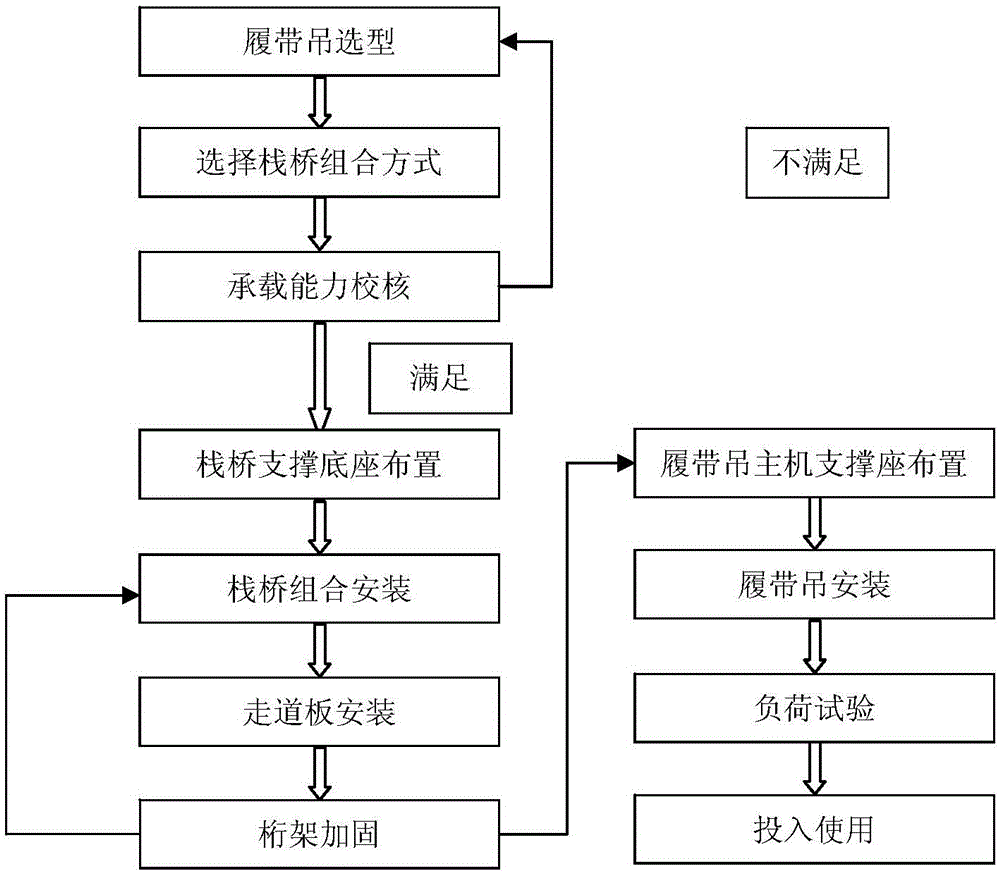

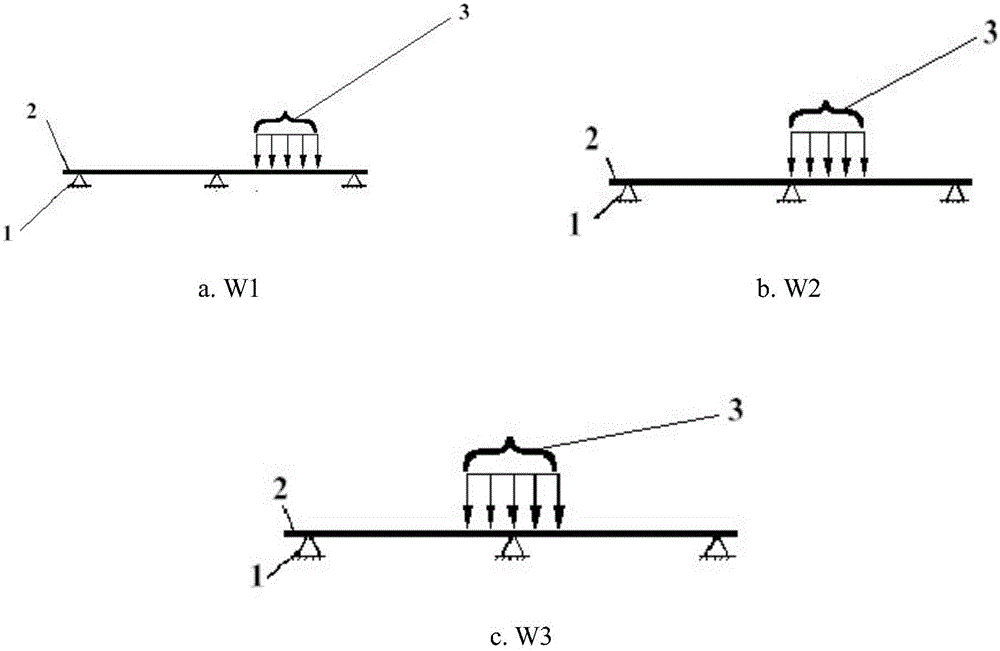

Construction method of trestle based on high-altitude crawler crane

ActiveCN105019360AExpand coverageAvoid cross assignmentBridge erection/assemblyElectric power industryIndustrial engineering

The invention provides a construction method of a trestle based on a high-altitude crawler crane. The construction method mainly comprises the following steps: selecting the type of a crawler crane; selecting the combined manner of a crawler crane; checking bearing capability; arranging a trestle supporting seat; assembling and mounting a trestle; mounting a walkway plate; strengthening trusses; arranging a supporting seat of a crawler crane host machine; mounting the crawler crane; performing a load test; and putting the crawler crane into use. According to the construction method disclosed by the invention, through the creative arrangement of a high-altitude trestle for a crawler crane in the construction of the power industry, the bottleneck problem that no place can be used for machine arrangement is solved, and the hoisting capacity and the moving capability of a crane during the reconstruction realizing energy conservation and emission reduction are greatly improved. The trestle is rapid and convenient to mount, and the crawler crane can be rapidly put into use; the reconstruction period is greatly shortened; the reconstruction cost is reduced; the equivalent usable coefficients of used machine units are increased.

Owner:中国能源建设集团江苏省电力建设第三工程有限公司

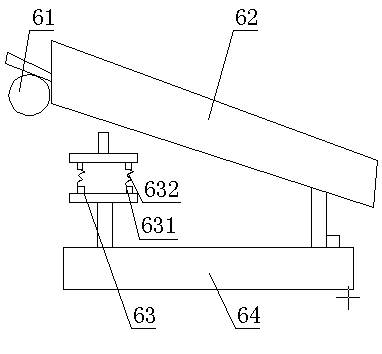

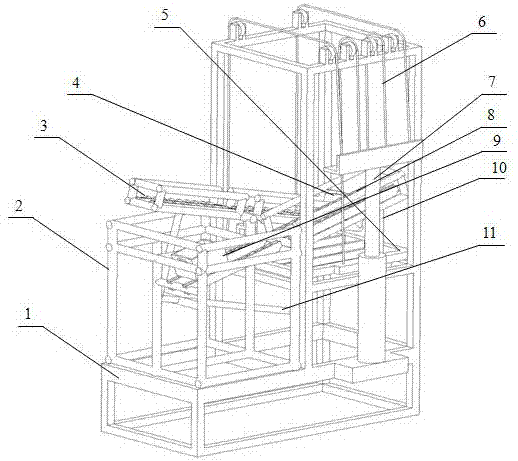

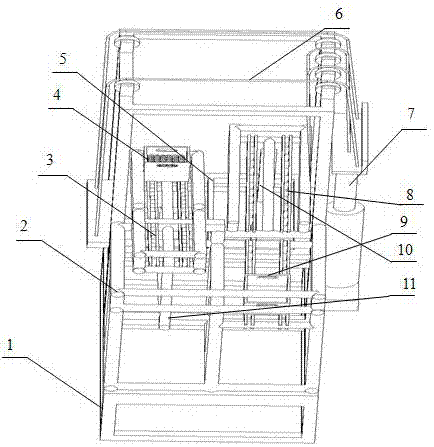

Light material high-station automatic feeding device

The invention relates to a material feeding device, and discloses a light material high-station automatic feeding device. The light material high-station automatic feeding device comprises a base frame (1), a material transfer table (2), a feeding slideway (3), a material carrying box (4), a material lifting platform (5), a hauling rope (6), an air cylinder (7), a discharge slideway (8), an empty material box (9), an ejection rod (10) and a lever connecting rod (11); the rectangular base frame is arranged at the bottom of the light material high-station automatic feeding device; the material transfer table is arranged on the base frame; the feeding slideway is arranged on one side of the material transfer table; the material carrying box is arranged on the feeding slideway; the material lifting platform is connected with the air cylinder by the hauling rope; the discharge slideway is arranged on one side of the material lifting platform; the empty material box which returns is placed on the discharge slideway; the ejection rod is arranged below the discharge slideway; and the lever connecting rod is connected below the feeding slideway. The light material high-station automatic feeding device can realize the effect of automatic switching feeding of materials in a high-station feeding process, and is applied to the high-station feeding field of small light materials in production lines of the automobile industry and the like.

Owner:沈阳永源光辉机械厂

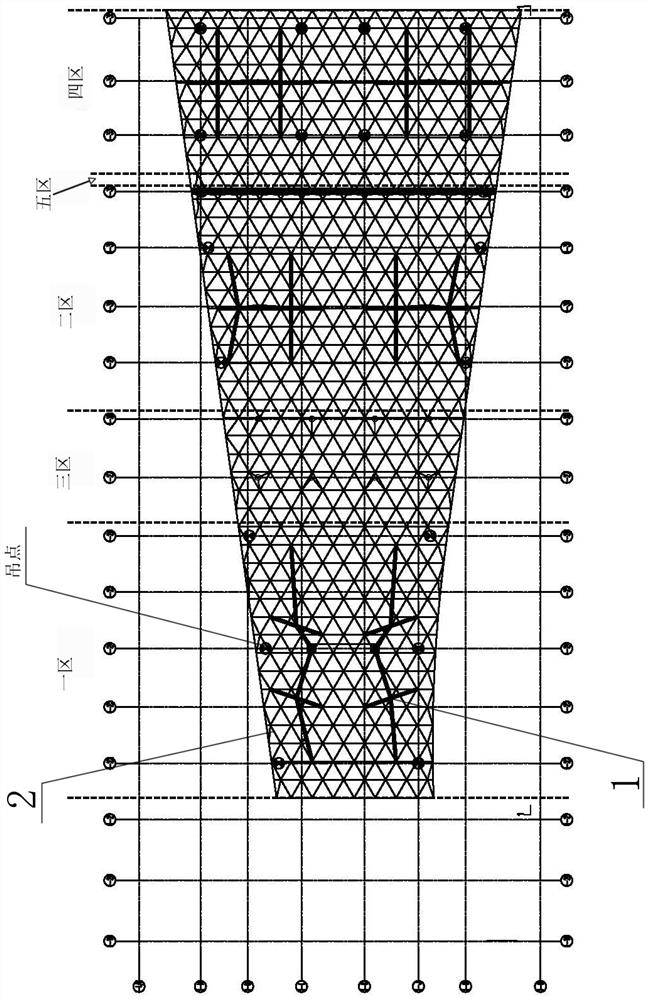

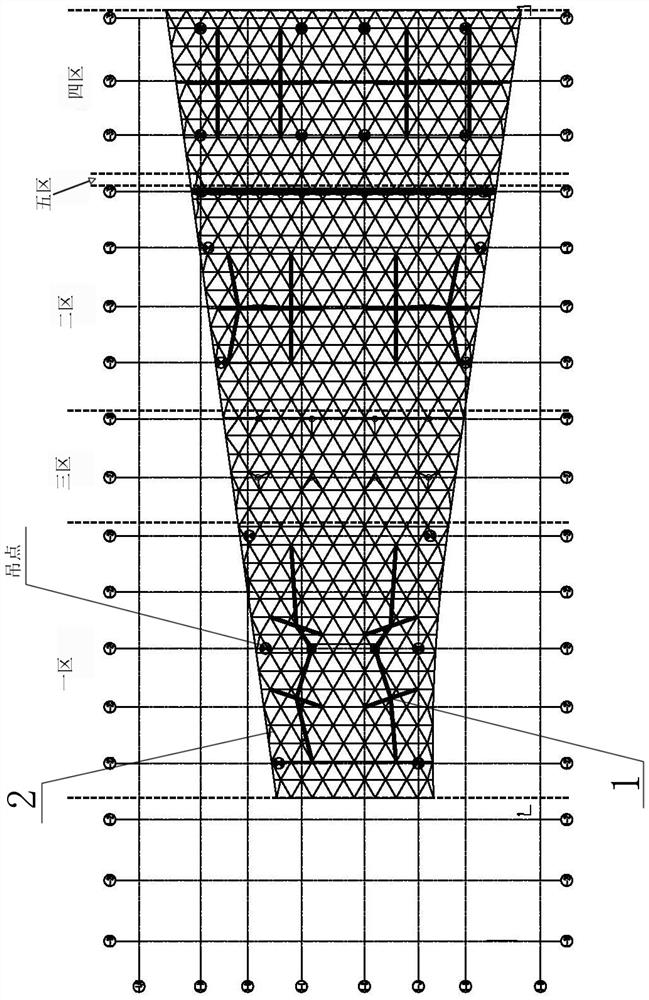

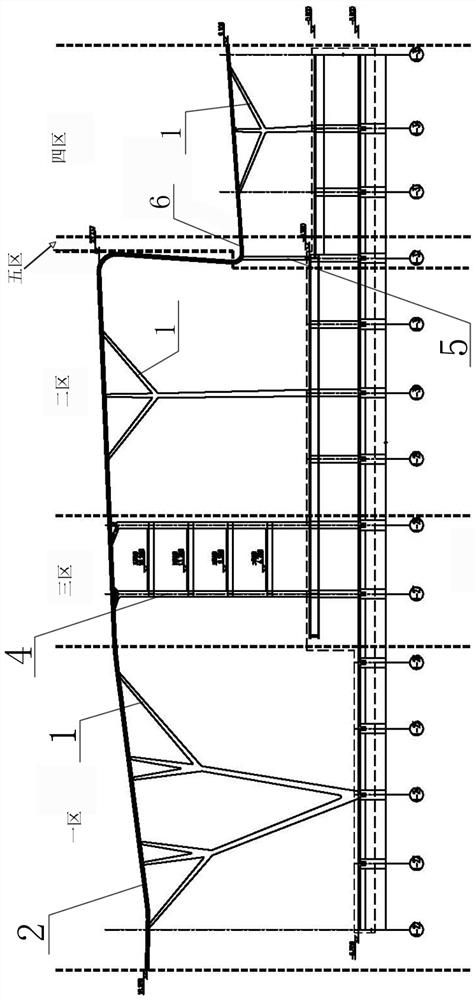

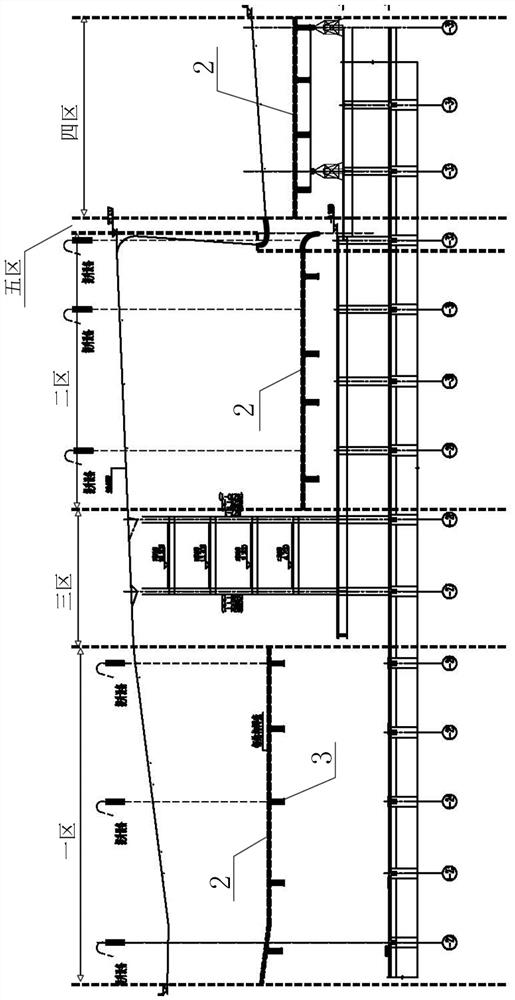

Construction method of Z-shaped large-span aluminum alloy frame roof

ActiveCN113756502AHigh precisionImprove precision control requirementsBuilding roofsBuilding material handlingShaped beamEngineering

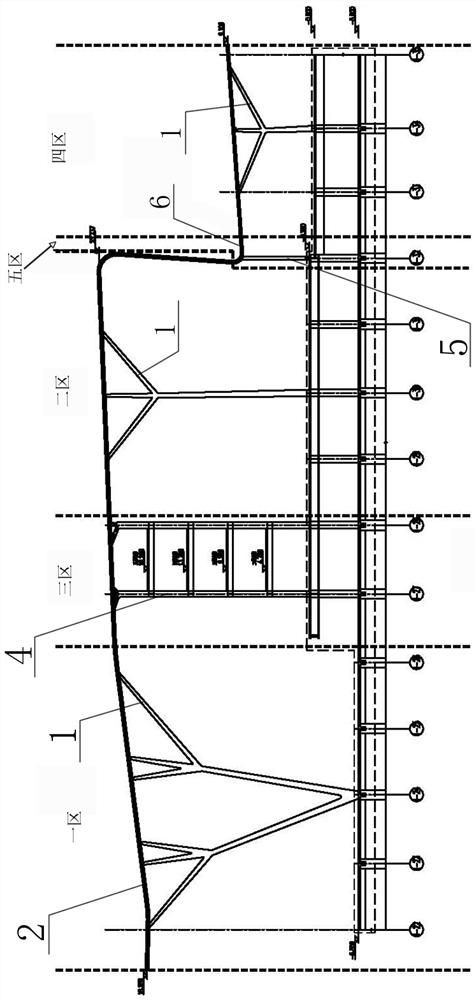

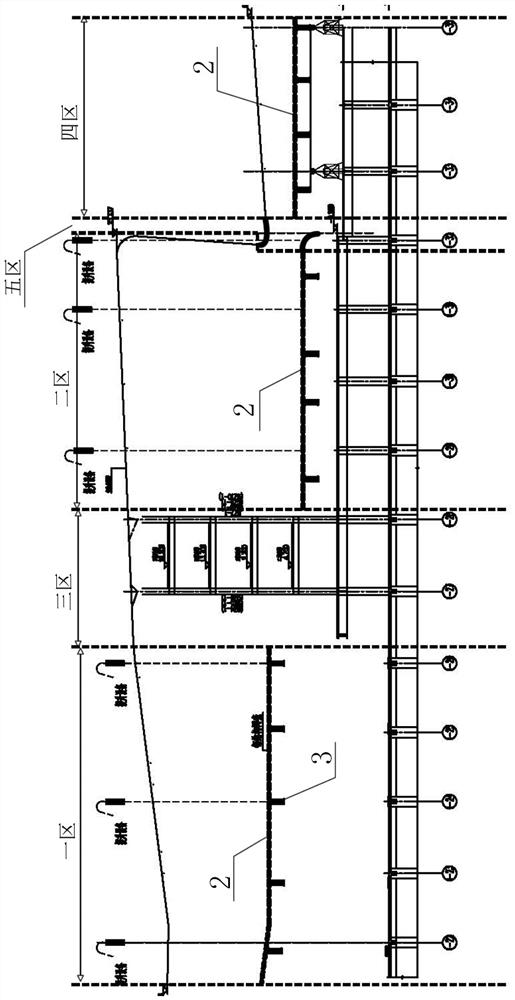

The invention discloses a construction method of a Z-shaped large-span aluminum alloy frame roof, and belongs to the field of buildings. The whole roof is sequentially divided into a first area, a third area, a second area, a fifth area and a fourth area from west to east. A latticed shell of the third area is firstly bulk-packed, then the latticed shell of the first area is integrally lifted in place and is folded with the latticed shell of the third area, then a special-shaped beam of the fifth area is installed, and then the latticed shell of the second area is integrally lifted in place and folded with the latticed shell of the third area and the special-shaped beam of the fifth area, and finally, the latticed shell of the fourth area is integrally jacked and folded with the special-shaped beam of the fifth area, different construction methods are adopted for different areas, and therefore the installation precision is improved, and the construction period is shortened. In addition, in the first area, the third area, the second area and the fourth area, latticed shells are firstly constructed, then tree-shaped supports are constructed, cross operation of installation of the aluminum alloy structure and the tree-shaped columns can be effectively achieved, two independent installation procedures are divided, the construction period is shortened, the installation precision is improved, and the accumulative error of the installation precision is reduced.

Owner:BEIJING CONSTR ENG GRP CO LTD

Grouting reinforcement construction method for foundation bottom disengaging

ActiveCN106884443AImprove grouting effectAct as a water-stop curtainFoundation repairCastingBuilding construction

The invention relates to a grouting reinforcement construction method for foundation bottom disengaging. According to construction specification requirements, a foundation line is measured and drawn, and the size of the foundation needing to be removed and dismantled is drawn; foundation surface cutting is carried out, and a rebuilt new equipment foundation is normally constructed according to working procedures; slip casting pipes are manufactured and buried according to requirements, and slip casting pipe protection is performed; earthwork layered compaction and backfill are carried out; the upper portion structure construction of the foundation continues to be carried out, and pressure slip casting is carried out on defective areas such as crack areas, collapsing areas and empty areas of an original foundation below the whole closed foundation; and the surplus slip casting pipes on the exposed foundation surface are cut, blocked and subjected to surface repairing. According to the grouting reinforcement construction method for the foundation bottom disengaging, the foundation is constructed firstly, then slip casting is carried out, and foundation construction can be accelerated; closed type pressure slip casting is carried out, the slip casting effect is remarkable, and the quality is guaranteed; cross-operation of structure construction and the slip casting working procedure is avoided; the technological process is simple, and workers carry out operation easily; and slip casting materials are local materials, the construction cost is saved, and the construction efficiency is improved.

Owner:CHINA 22MCC GROUP CORP

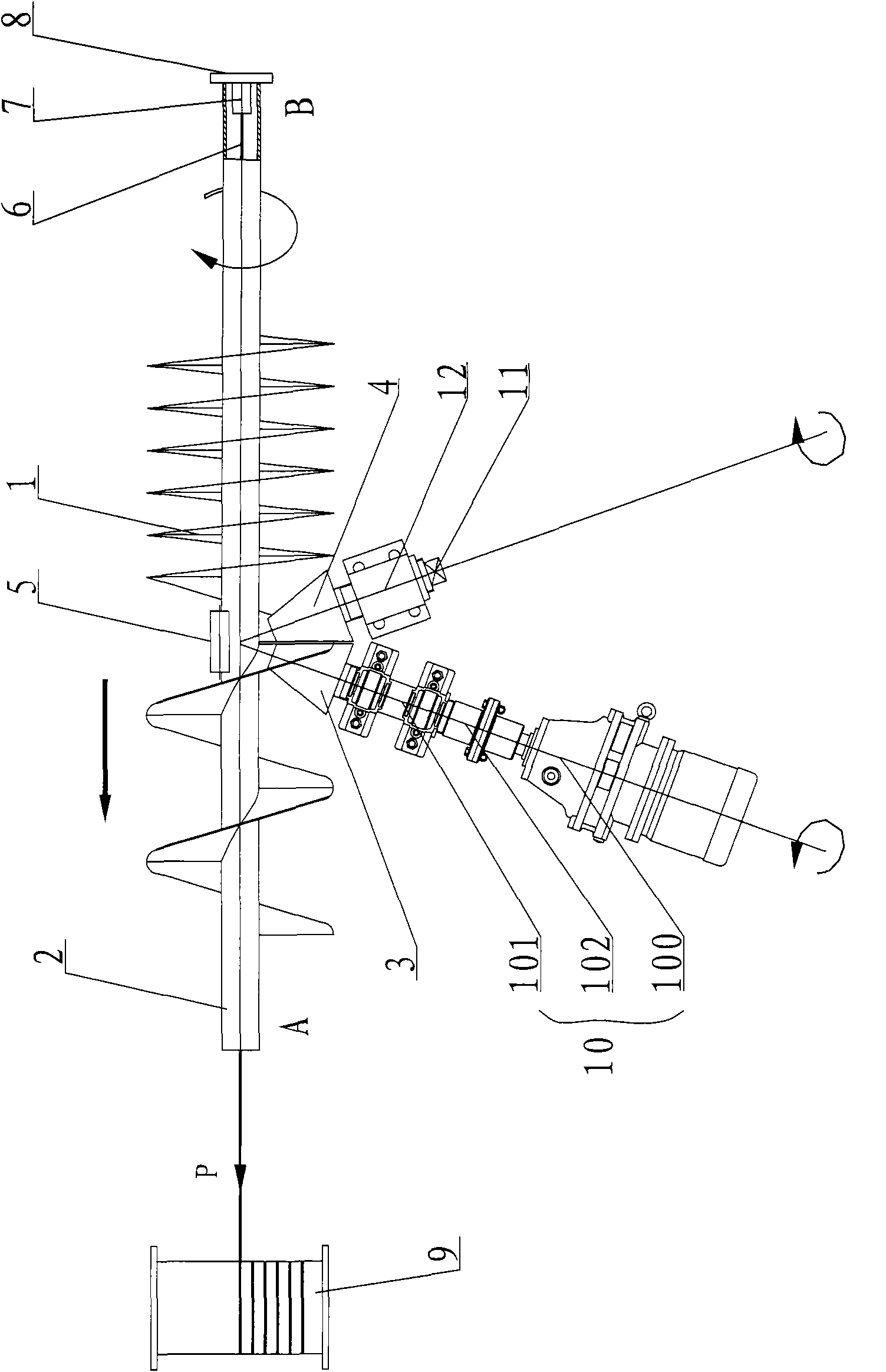

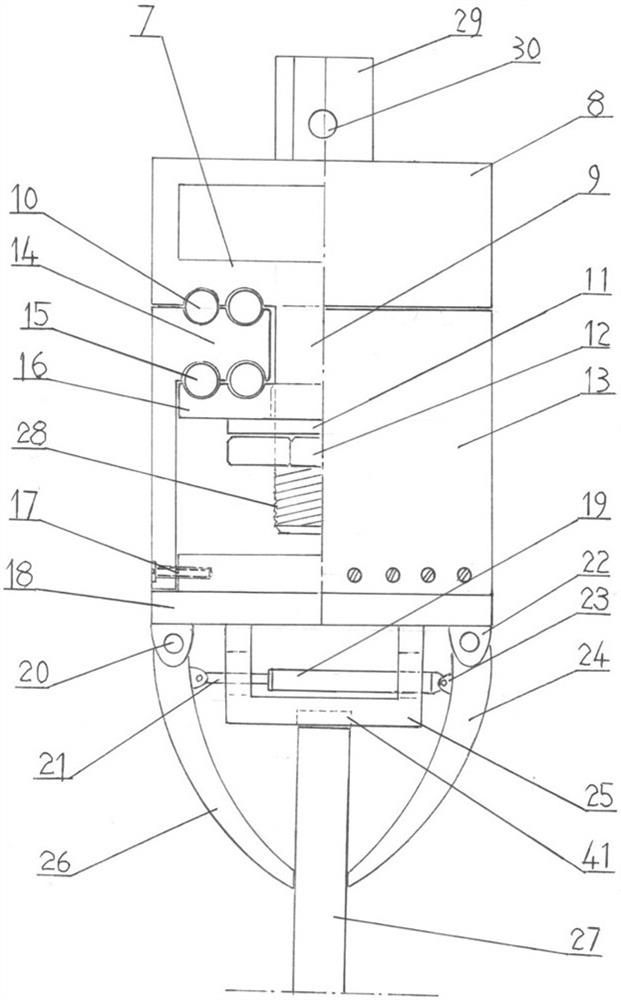

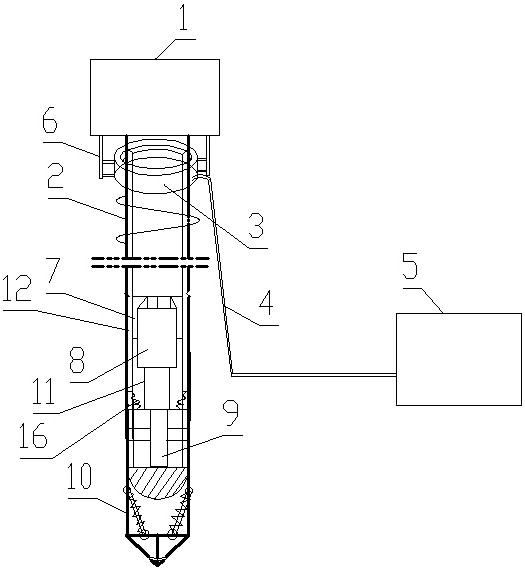

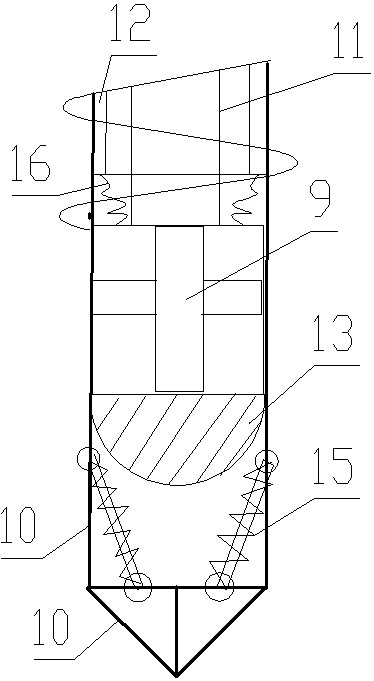

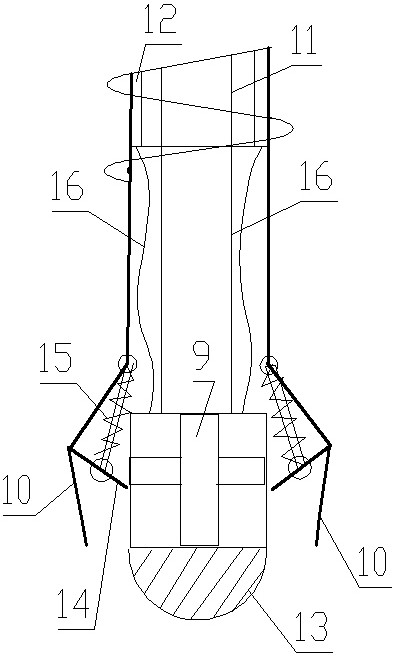

Drilling and tamping integrated long spiral drilling machine and drilling and tamping method

PendingCN113153138ALow costAvoid time costEarth drilling toolsDrilling rodsAir pumpStructural engineering

The invention discloses a long spiral drilling machine which is characterized in that an air guide pipe is connected to the top of a long spiral drilling rod through a rotary sealing joint, and an air pump is connected to the air guide pipe; an electric push rod is mounted at the lower part of the long spiral drilling rod; an extension rod of the electric push rod is downwards connected with an air hammer; an air guide hole is formed in the long spiral drilling rod in the vertical direction, the upper end of the air guide hole communicates with an air guide pipe through a rotary sealing joint, and the lower end of the air guide hole is connected with the air hammer through a hose; a plurality of drill bit frames are uniformly hinged to the long spiral drilling rod at the bottom end of a mounting cavity in the circumferential direction; an electric brush device is arranged on the long spiral drilling rod at the rotary sealing joint; and a connecting line of the electric push rod is led out of the long spiral drilling rod through the electric brush device and is connected with an electric control device in a cab. By using the drilling machine, cross operation of various mechanical equipment is not needed any more, so that the time for moving large equipment back and forth is saved, and the construction efficiency is greatly improved. A rammer compactor is not needed any more, so that the construction equipment cost is obviously reduced.

Owner:河南云平环保科技有限公司

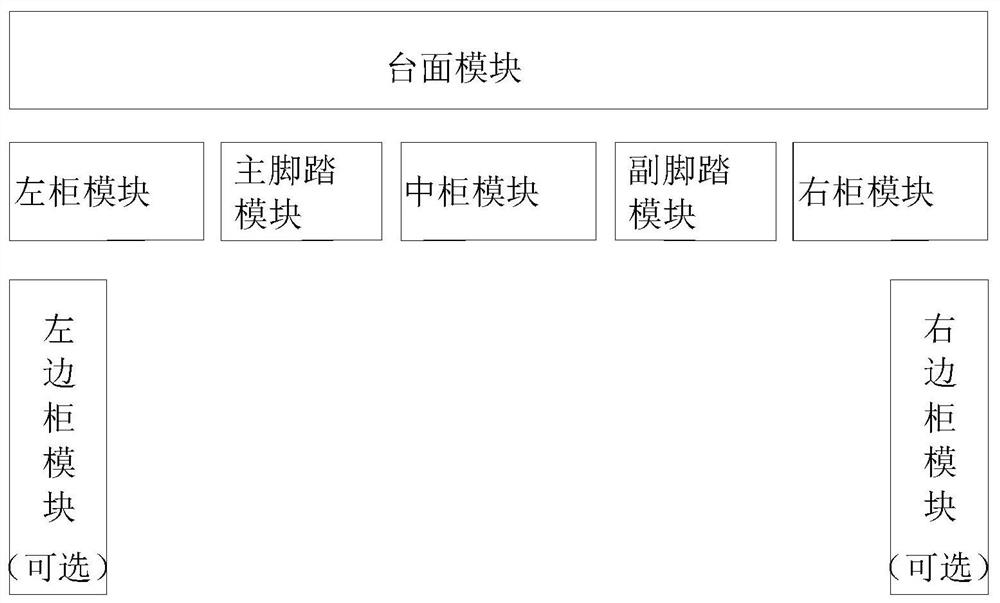

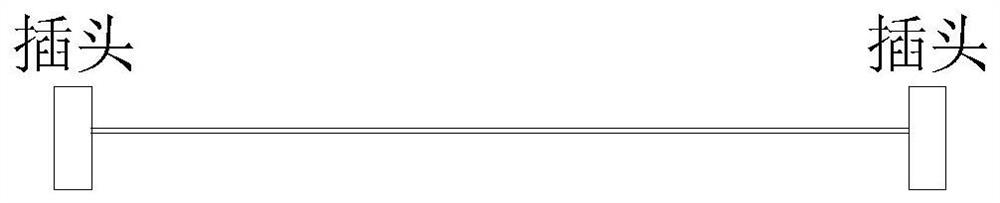

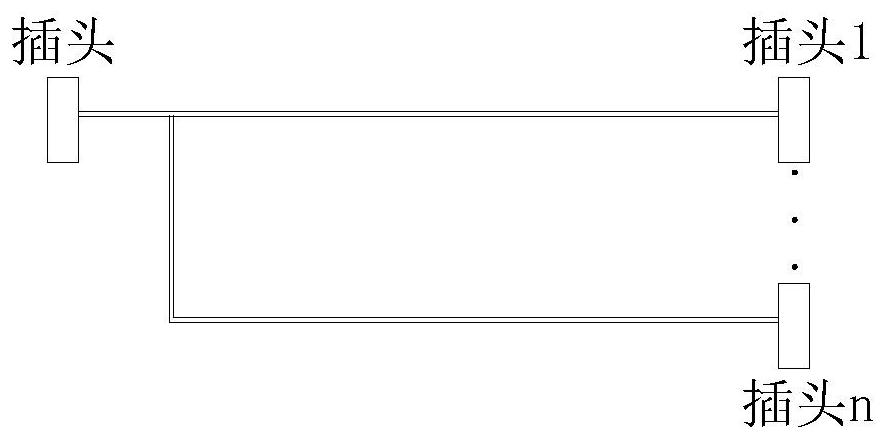

Modularized wiring structure of cab console and wiring method thereof

ActiveCN113501011AReduced wiring effortAvoid cross assignmentLocomotivesComputer hardwareEngineering

The invention provides a modularized wiring structure of a cab console and a wiring method thereof. The modularized wiring structure of the cab console comprises a plurality of independent functional modules, wherein the functional modules comprise at least the following modules: a tabletop module, a left cabinet module, a main pedal module, a middle cabinet module, an auxiliary pedal module and a right cabinet module; the functional modules are connected through pre-wiring harnesses; the interior of each functional module is wired by adopting the pre-wiring harness to form a wiring module; the table top module is connected with the left cabinet module, the middle cabinet module and the right cabinet module; the left cabinet module is connected with the main pedal module and the auxiliary pedal module; and a single-head-to-single-head mode or a single-head-to-multi-head mode is adopted at the position where the pre-wiring harness is connected with the functional modules. Compared with the prior art, the on-board wiring workload is reduced, the production time is saved, the efficiency is improved, and the design and production cost is reduced.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Manufacturing method of large steel box girder

InactiveCN112719795AEffectively control welding deformationAvoid cross assignmentCantileverWelding deformation

The invention relates to a manufacturing method of a large steel box girder. The manufacturing method comprises the following steps of: manufacturing a unit piece, assembling and pre-splicing girder sections, hoisting a steel box girder on a construction site, and performing welding, wherein the step of manufacturing the unit piece comprises: designing a drawing by using AUTOCAD software, performing modeling, determining a theoretical size, and determining welding and processing compensation amounts; and the step of manufacturability analysis comprises: A, welding manufacturability test, B, manufactured bridge actual measurement data and C, part machining requirements. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that a forward mounting method and a reverse mounting method are adopted, namely, bottom plate unit pieces are firstly assembled, then web unit pieces, diaphragm plate unit pieces, panel unit pieces and cantilever unit pieces are sequentially assembled, and the cantilever unit pieces adopt the reverse mounting method. The method has the advantage that most of weld joints are welded in a horizontal or climbing position. During welding, welding deformation is effectively controlled by utilizing the principles of constraint, self-constraint, strong constraint and flexible constraint, so that various geometric dimension deviations of all steel box girders are within a very small range.

Owner:江苏恒睿杰钢结构工程有限公司

Ball feeder control system based on DCS system platform

PendingCN111983982AAvoid problems that require a lot of manual handlingImprove physical and mental health indexTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention discloses a ball feeder control system based on a DCS platform, belongs to an ore dressing automatic control technology, and particularly relates to an automatic steel ball feeding system of a ball mill. The system comprises a steel ball counting and outputting device and a DCS detection control system. According to the system, a timing period new ore feeding amount automatic calculation unit, a steel ball demand quantity automatic calculation unit, an actual steel ball adding automatic control unit and an automatic period circulation control unit are arranged, the number of thesteel balls needing to be added is calculated, a command is sent out to enable the steel ball output device to add the steel balls into the ball mill, the adding amount is metered, and is fed back tothe actual steel ball adding automatic control unit, and the next adding period is entered after adding is completed. According to the invention, the labor cost is reduced, the safety production indexis improved, the direct production cost is reduced, the system operation difficulty and maintenance difficulty of operators and automation technicians are reduced, and the high efficiency of the steel ball adding system is improved.

Owner:云南迪庆有色金属有限责任公司

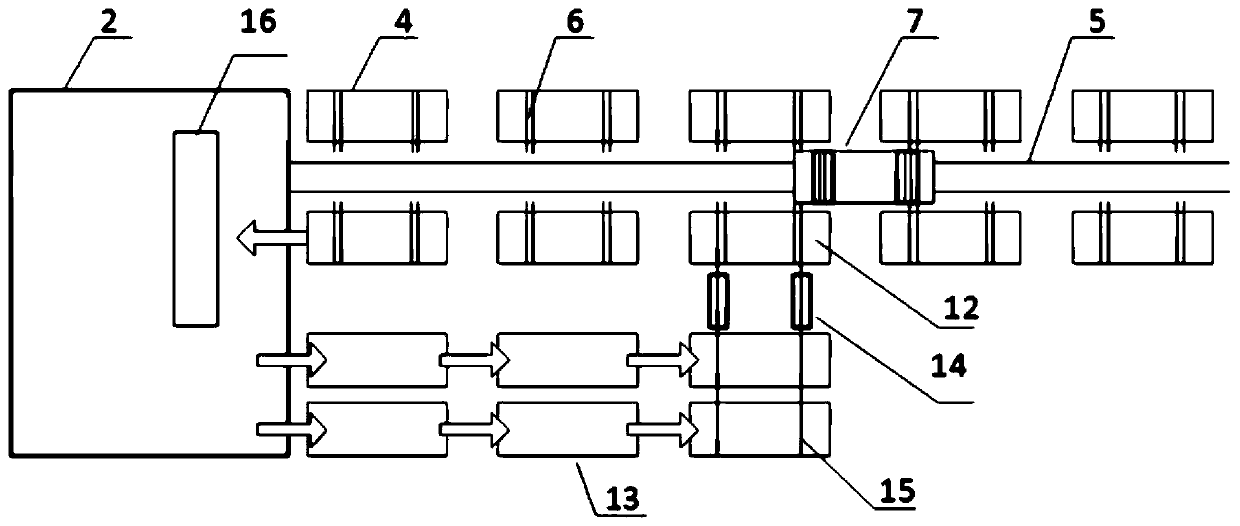

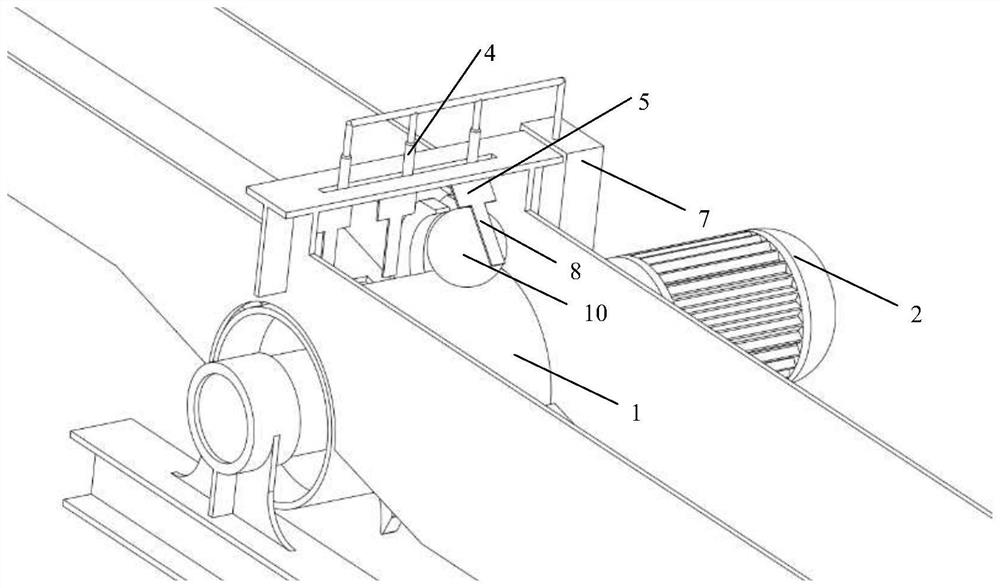

Construction system and method of factory type large aqueduct

ActiveCN107338768AFast constructionGuarantee the construction qualityHydro energy generationArtificial water canalsCombingGantry crane

The invention provides a construction system and method of factory type large aqueduct. A steel pedestal, a storage area of reinforcing steel spreader, a steam shed storage area, a groove pedestal and a storage slot pedestal are arranged near the pier; near a steel pedestal, a storage area of reinforcing steel spreader, a steam shed storage area, a groove pedestal and a storage slot pedestal are arranged with track. A slot machine and a gantry crane are arranged on the track. The construction methods include the following steps: a reinforcing cage is bandaged on the steel pedestal; a bottom die is arranged on the groove pedestal. The reinforcing cage is arranged on the bottom die of the groove pedestal through an integral hoisting device for reinforcing steel bar; concrete pouring; an aqueduct erection; the pipeline construction of the large aqueduct can achieve through the above steps. The device has the advantages of improving the construction speed and construction process, optimizing the safety management, and ensuring the construction quality of the aqueduct through the decomposition and combing of the aqueduct construction process, through the combination of the construction of the factory line construction and modular construction.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

A construction method of Z-shaped long-span aluminum alloy frame roof

ActiveCN113756502BReduce intensityGuaranteed damageBuilding roofsBuilding material handlingShaped beamLong span

The construction method of the Z-shaped long-span aluminum alloy frame roof of the present invention belongs to the field of construction. The present invention divides the entire roof from west to east into the first zone, the third zone, the second zone, the fifth zone and the fourth zone. Then the reticulated shell of the first area is lifted up as a whole and closed with the reticulated shell of the third area, and then the special-shaped beam of the fifth area is installed, and then the reticulated shell of the second area is generally lifted in place and combined with the reticulated shell of the third area and the fifth area. The special-shaped beams in the district are closed, and finally the reticulated shell in the fourth district is raised as a whole and closed with the special-shaped beams in the fifth district. Different construction methods are adopted for different areas, so as to improve the installation accuracy and shorten the construction period. In addition, in the first, third, second and fourth districts, the reticulated shell is constructed first, and then the tree-shaped support is constructed, which can effectively solve the cross operation of the installation of the aluminum alloy structure and the tree-shaped column, and divide it into two independent installation procedures, saving The construction period is improved, the installation accuracy is improved, and the cumulative error of installation accuracy is reduced.

Owner:BEIJING CONSTR ENG GRP CO LTD

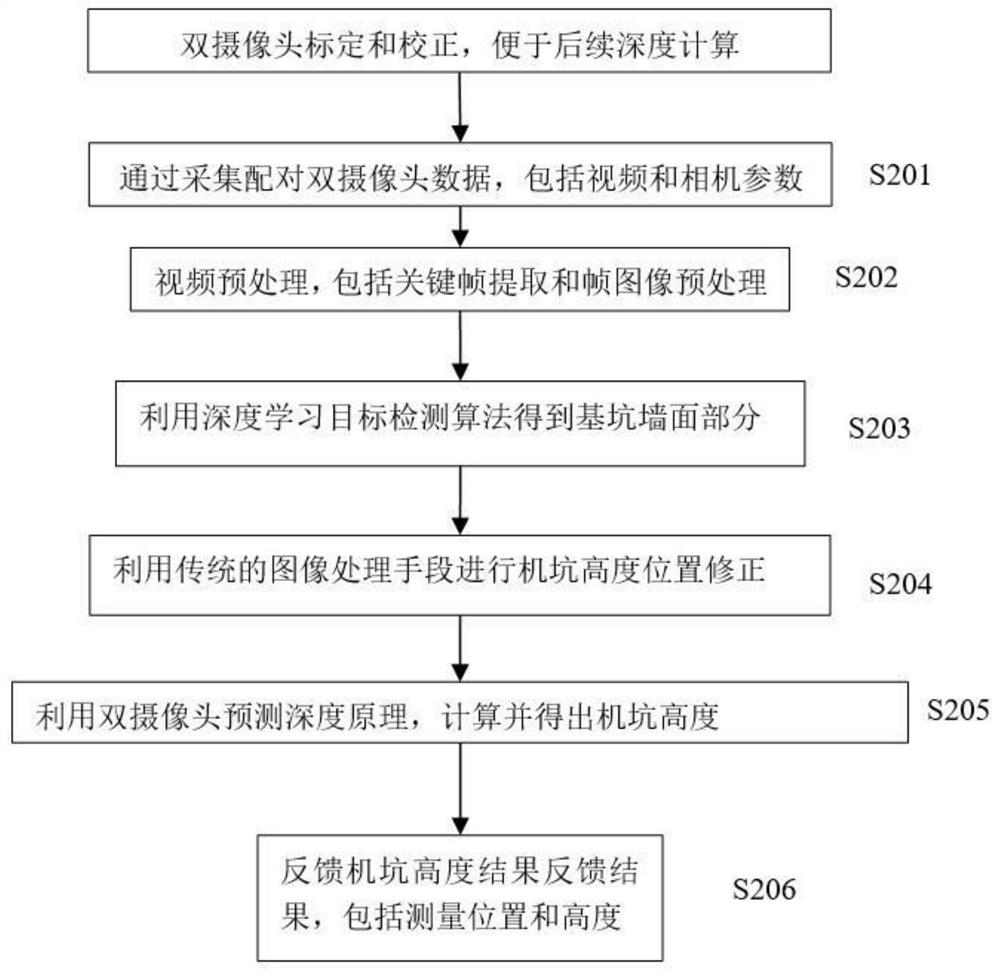

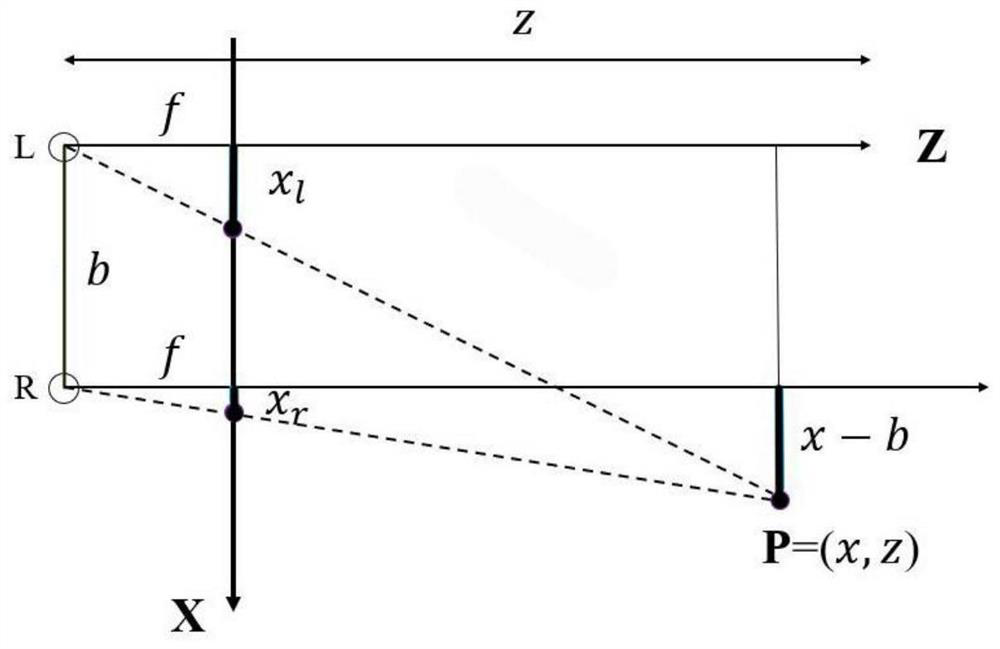

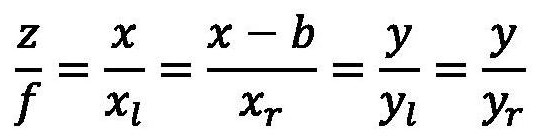

Method for identifying depth of foundation pit based on multiple cameras

ActiveCN113538350AReal-time monitoring of excavation depthGuaranteed accuracyImage enhancementImage analysisPattern recognitionCamera image

The invention discloses a method for identifying the depth of a foundation pit based on multiple cameras in the building field, and the method comprises the following steps: S201, collecting and obtaining paired dual-camera data, including position parameters of the cameras, videos of the cameras and calibration correction of the dual cameras; S202, preprocessing the acquired video data, wherein the preprocessing comprises key frame extraction and frame image preprocessing; S203, performing segmentation by using the trained deep semantic Faster RCNN segmentation network to obtain a foundation pit part. S204, obtaining the upper and lower edges of the foundation pit by using an edge detection algorithm image processing technology, and correcting the position of the part needing to be measured; S205, predicting the depth of a part needing to be measured by using a binocular camera imaging principle, and estimating the depth of the foundation pit. and S206, integrating the depth information of the foundation pit and the measured position information in the S204 and the S205, and visually feeding back the measured part and the estimated height.

Owner:河北深保投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com