Construction method of trestle based on high-altitude crawler crane

A construction method and crawler crane technology, which are applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of hoisting equipment and hoisting schemes that do not have hoisting ability, cannot accommodate large equipment, heavy weight, etc., so as to improve the construction efficiency. The effect of hoisting efficiency, improving construction energy level, and quick and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

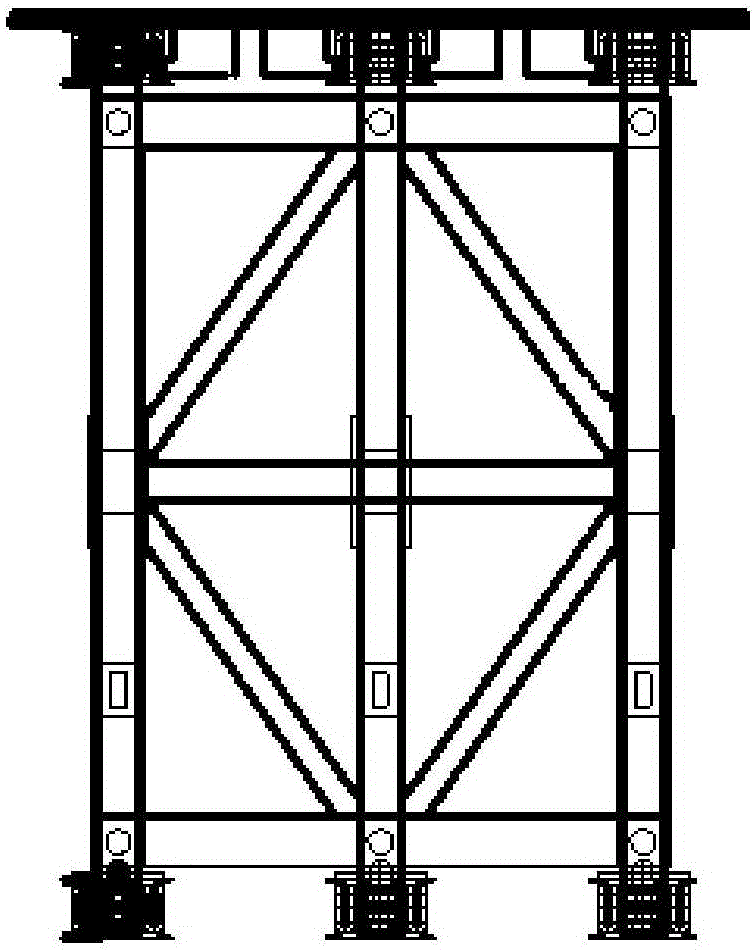

[0029] The express trestle bridge is composed of light and standardized truss unit components made of high-strength steel, beams, longitudinal girders, bridge decks, bridge seats and connectors, etc., and can be quickly assembled on site into truss beam bridges suitable for various spans and loads. Combined with the engineering characteristics of the electric power industry, after optimized design, it is applied to the high-altitude rapid layout of crawler cranes.

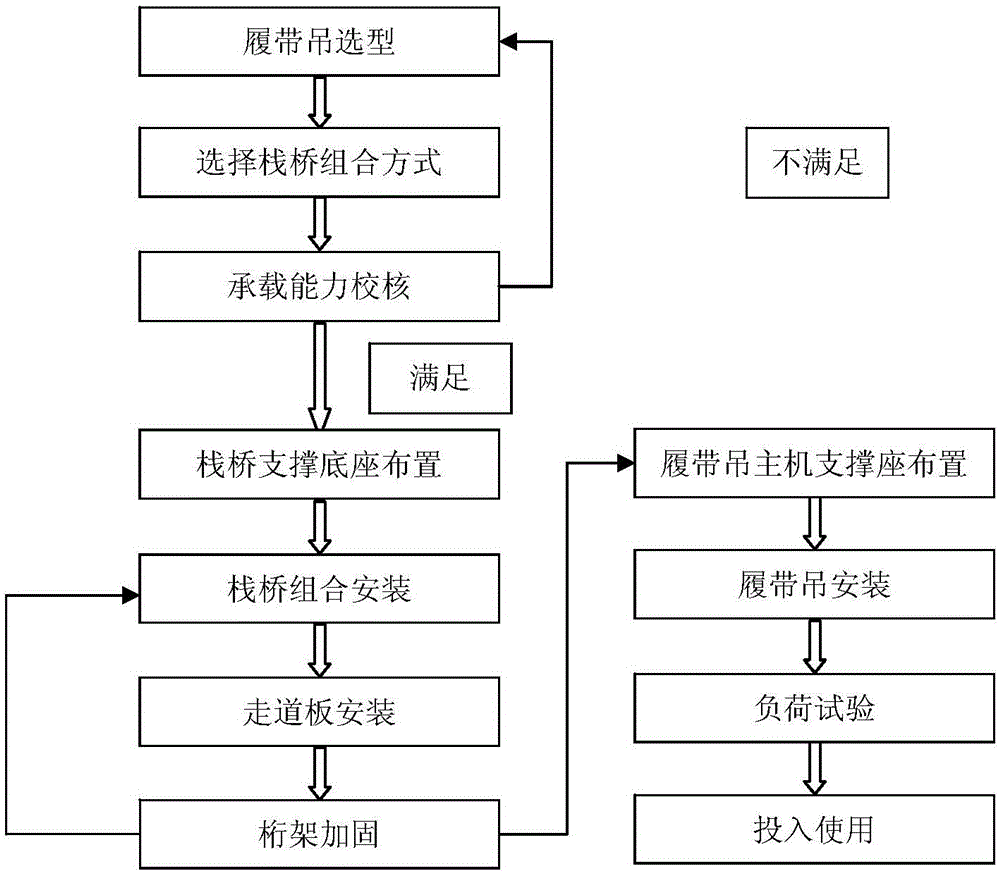

[0030] Such as figure 1 As shown, the construction method flow of trestle bridge based on high-altitude crawler crane is: crawler crane type selection → selection of trestle combination method → bearing capacity check → trestle support seat arrangement → trestle assembly installation → walkway plate installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com