Patents

Literature

116results about How to "Short transformation period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively modifying saline and alkaline land

ActiveCN102172116AHighlight substantiveHighlight substantive featuresSoil lifting machinesOrganic fertilisersAlkali soilMicrobial agent

The invention relates to a method for comprehensively modifying saline and alkaline land. The method comprises the following steps: preparing a saline and alkaline land modifier from 50-80kg of 95wt% (percent by weight) potassium sulfate, 30kg of 98wt% zinc sulfate, 30kg of 95wt% aluminum sulfate, 20kg of 95wt% manganese sulfate, 20kg of calcium chelating agent, 40kg of 95wt% calcium borate, 100kg of microbial agent, 2,000kg of crop straw with the length of 3-10cm and 300-500kg of 39wt% humic acid; leveling soil, restoring ridges and digging ditches when the temperature is constantly stable and is over 15 DEG C; uniformly scattering the saline and alkaline land modifier on the surface of the land; turning up the soil so that the saline and alkaline land modifier is uniformly distributed in the deep soil layer of 0-20cm below the surface of the land; irrigating the land with water depth of 5cm for about 10 consecutive days; transplanting saline and alkaline resisting rice seedlings to the modified saline and alkaline land; applying a small amount fertilizer for multiple times without changing the total amount of the fertilizer; and keeping the water in the land shallow.

Owner:吉林省汇泉农业科技有限公司

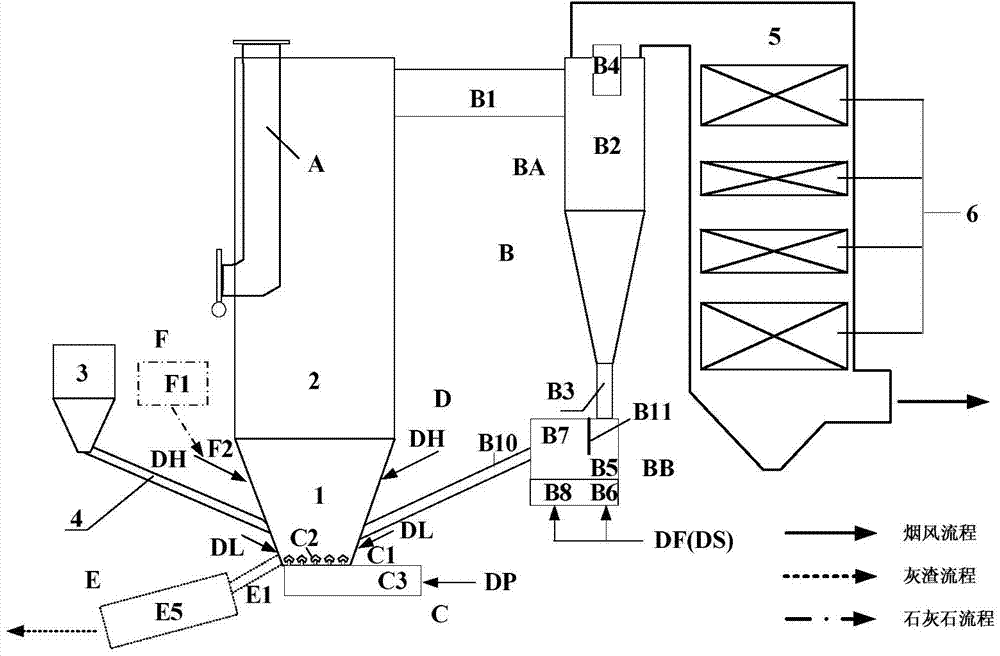

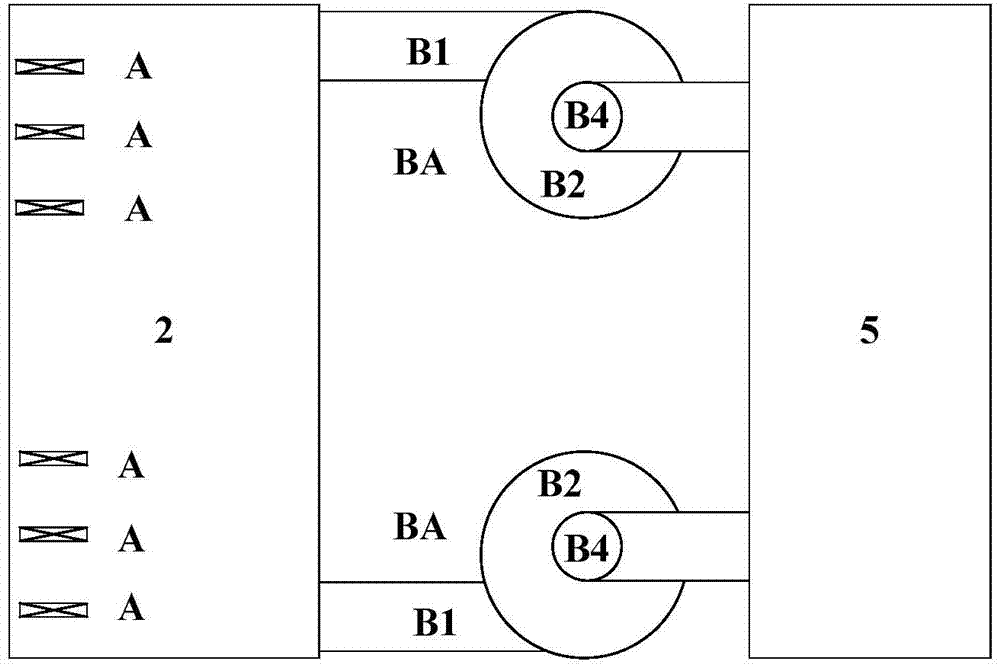

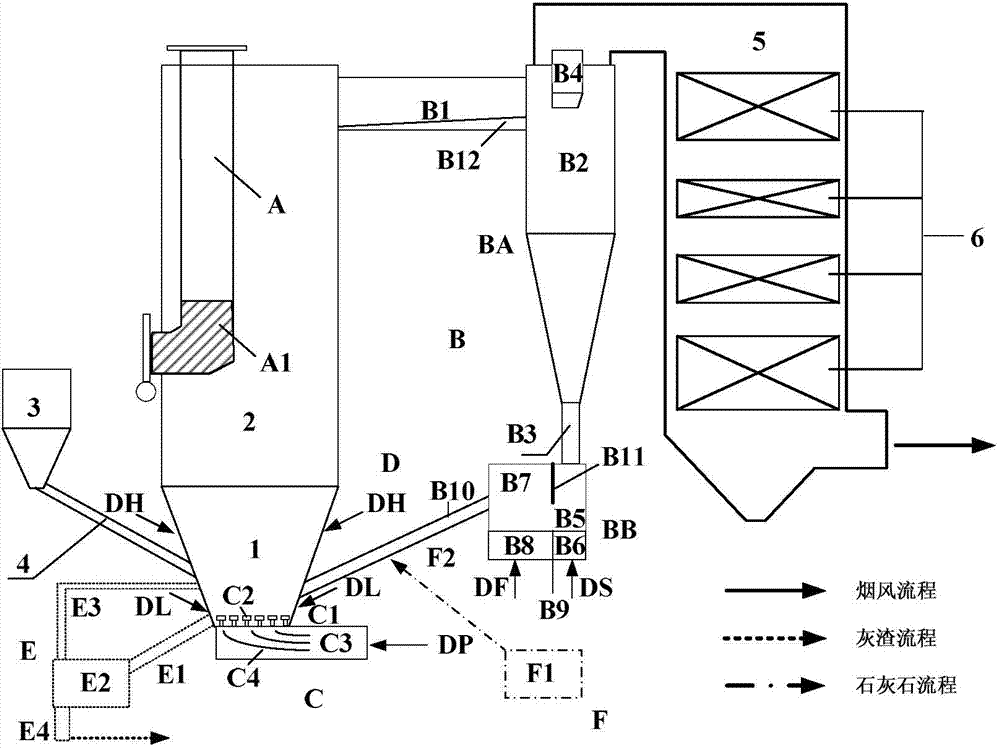

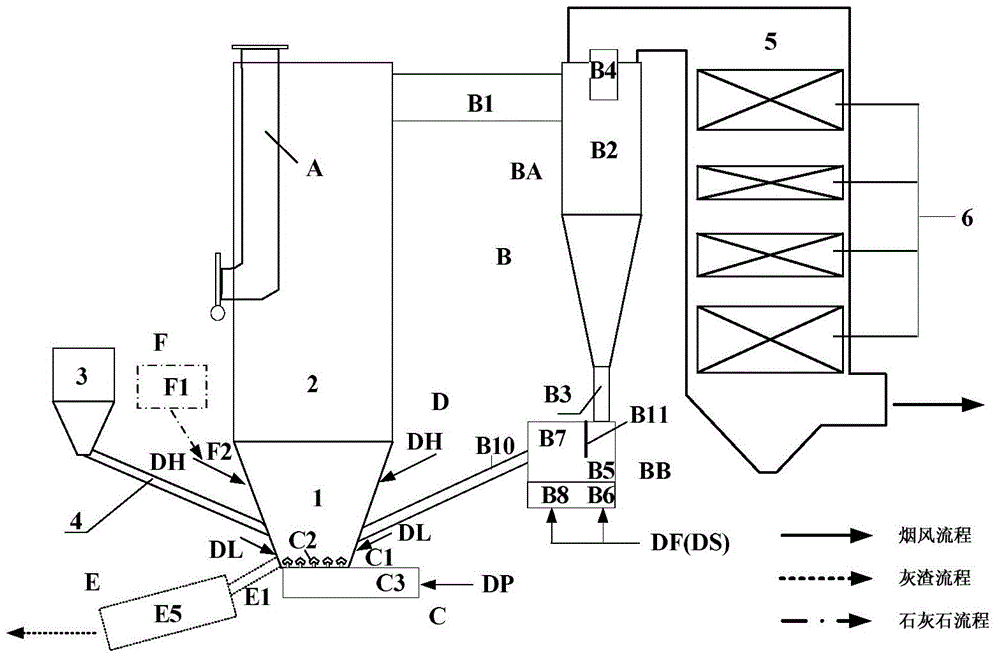

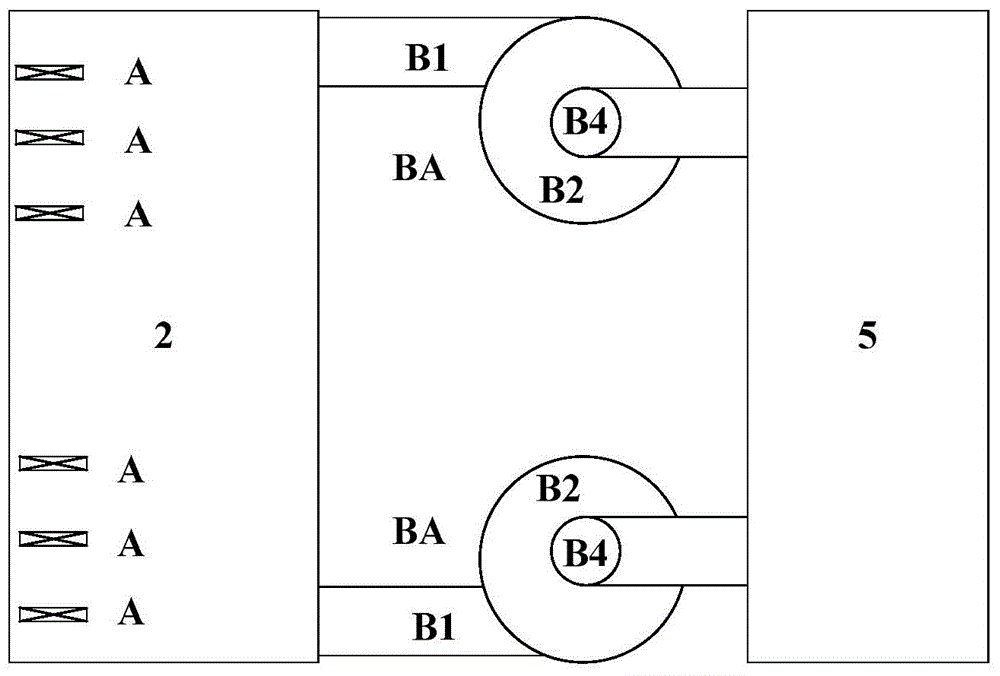

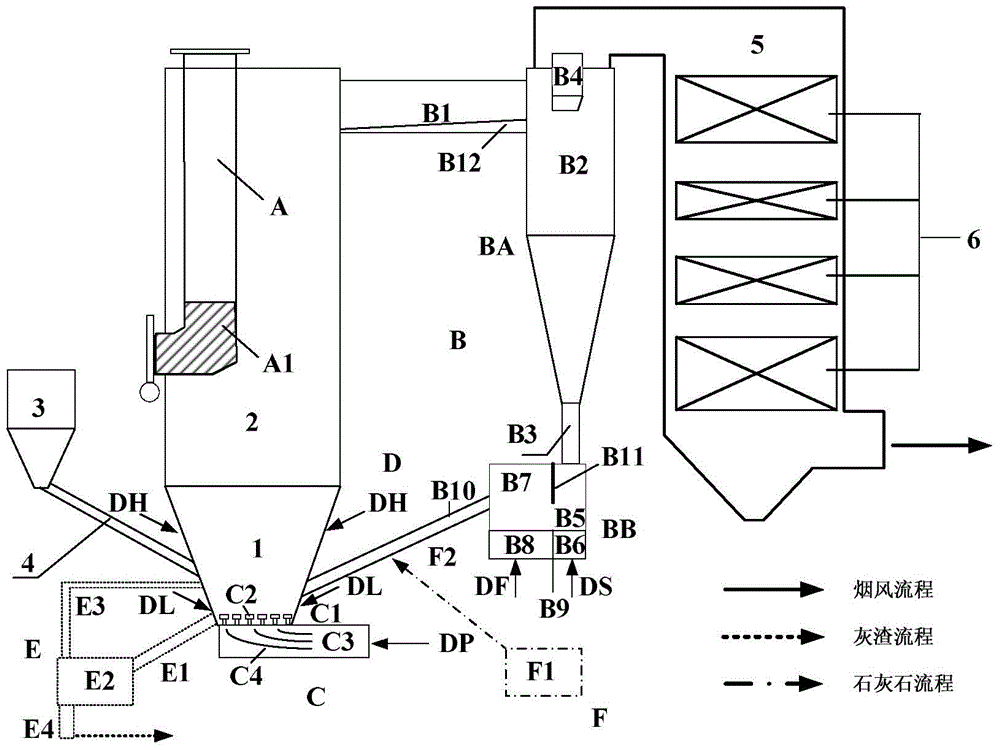

Integrated modification method for reducing pollutant emission of circulating fluidized bed boiler

ActiveCN103900077AReduce emission concentrationGood environmental benefitsFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses an integrated modification method for reducing pollutant emission of a circulating fluidized bed boiler. The modification method comprises the following steps: modifications on a screen type heating surface, a material return system, an air distribution system, a secondary air nozzle system, a slag cooling system and a desulfurizer adding system. Through the modifications, the concentration of SO2 and NOx in smoke is finally reduced to 30-70% of that before modifications, the fly ash concentration is reduced to 70-90% of that before modifications and the environmental protection characteristic of boiler operation can be remarkably improved without adding new equipment. The integrated modification method has the advantages of being small in investment cost, short in modification period and stable in boiler operation; at the time the integrated modification is performed, the problems existing in arrangement of the original heat surface, a funnel cap, a separator, a slag cooler and a lime stone transmission system of the boiler can be synchronously solved, and therefore the economy, stability and safety performance of boiler operation are comprehensively improved.

Owner:HUANENG CLEAN ENERGY RES INST

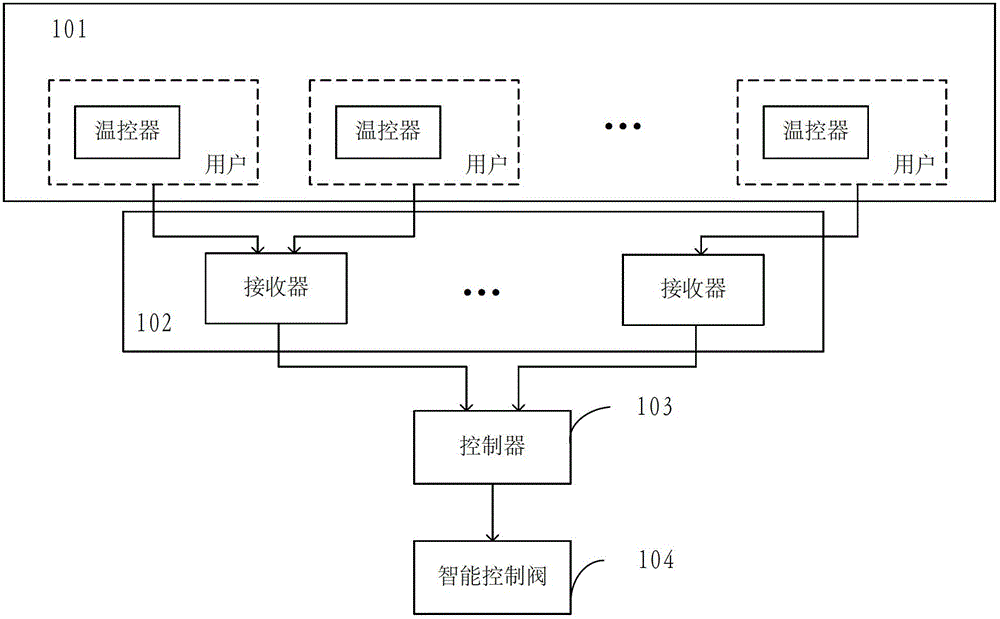

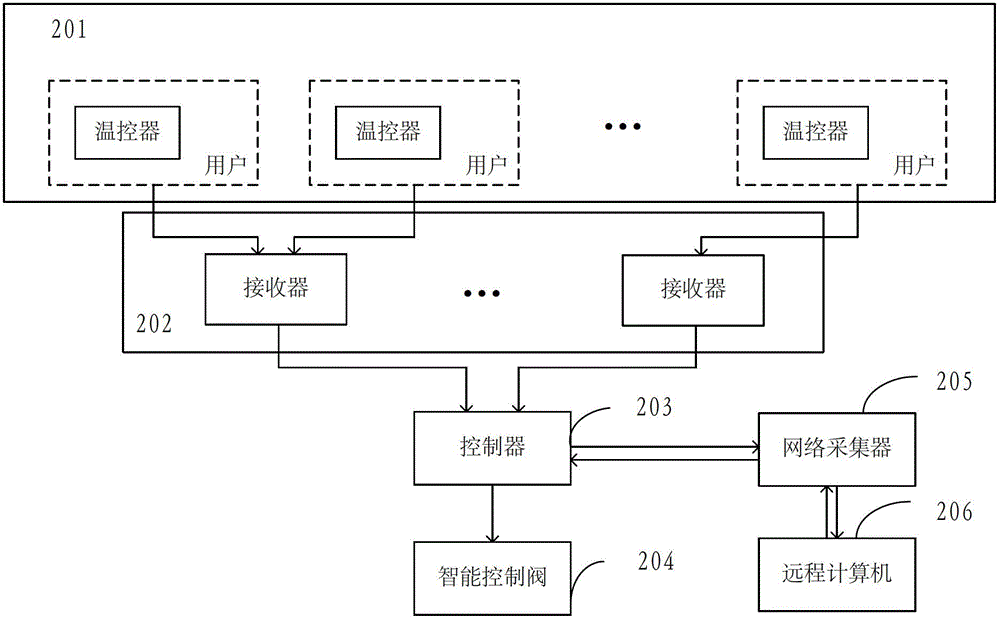

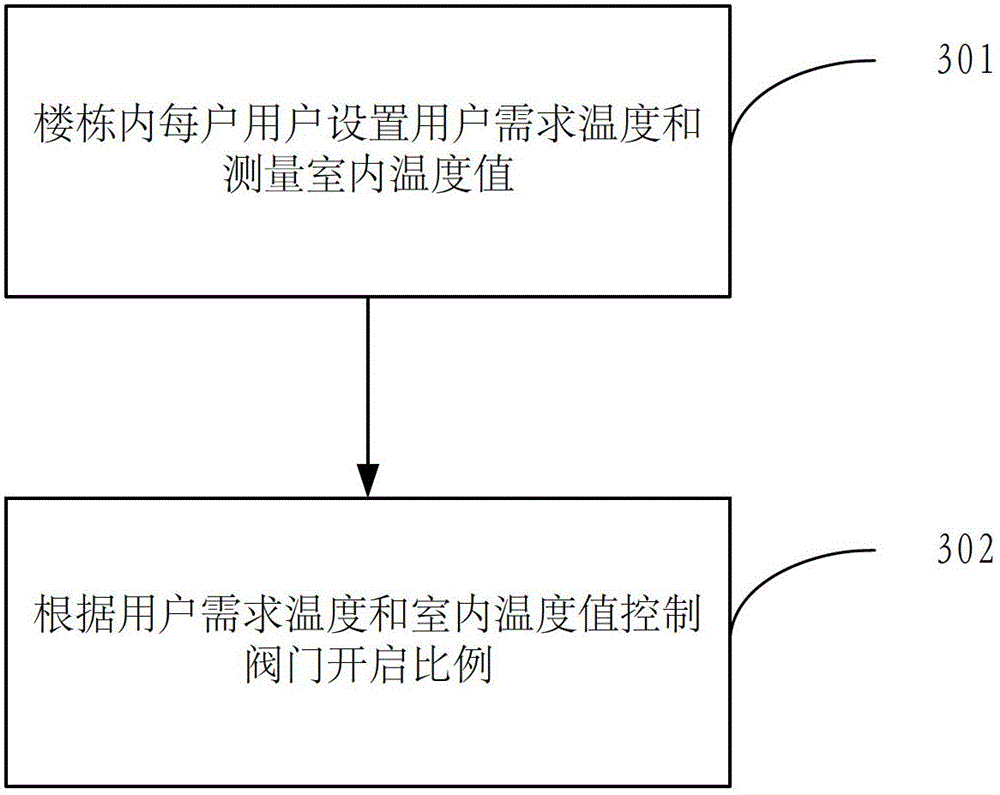

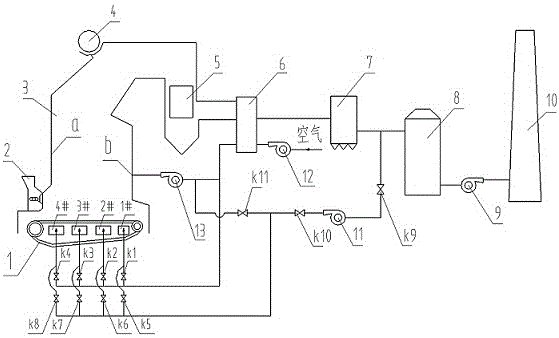

Concentrated heating system and method

ActiveCN103148537AShort transformation periodReduce construction difficultyLighting and heating apparatusSpace heating and ventilation detailsValue setProcess engineering

The invention provides a concentrated heating system and a concentrated heating method. The system comprises a temperature controller, at least one receiver, a controller and an intelligent control valve, wherein the temperature controller is arranged for each household and used for setting the demanded temperature of the user, measuring the indoor temperature value, and sending the demanded temperature and the indoor temperature value to the receiver; the receiver is used to receive the demanded temperatures and the indoor temperature values set by all temperature controllers within the coverage range of each receiver and send the demanded temperatures and the indoor temperature values set by all temperature controllers to the controller; the controller is used to receive the demanded temperature and the indoor temperature value sent by at least one receiver and send the demanded temperature and the indoor temperature value sent by the at least one receiver to the intelligent control valve; and the intelligent control valve is used to control the open proportion of a valve of a water inlet pipe of a building according to the demanded temperatures and the indoor temperature values sent by the controller. The concentrated heating system and the concentrated heating method realize transformation of the existing single-tube direct flow-type concentrated heating system to a simple concentrated heating system.

Owner:HAILIN ENERGY TECH

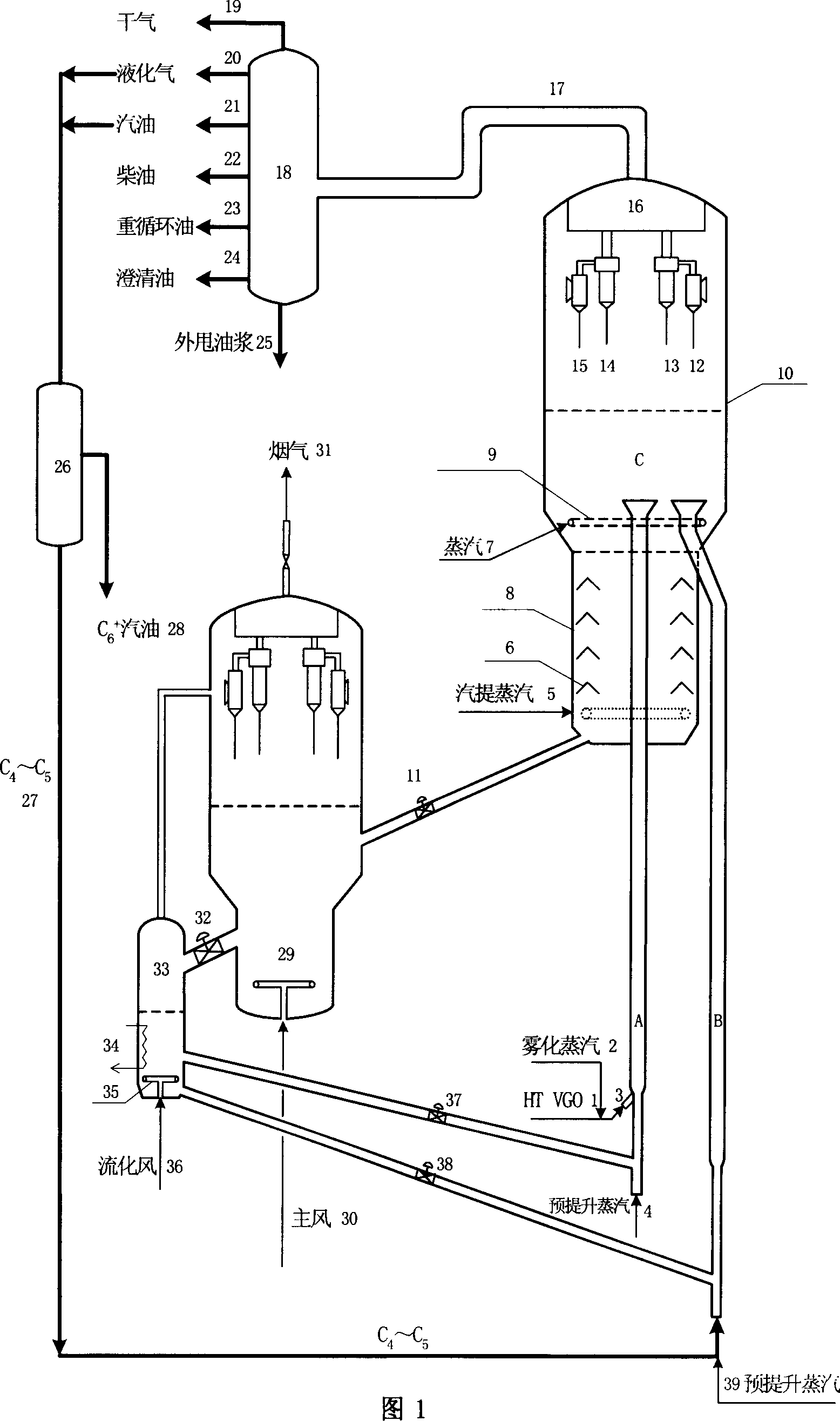

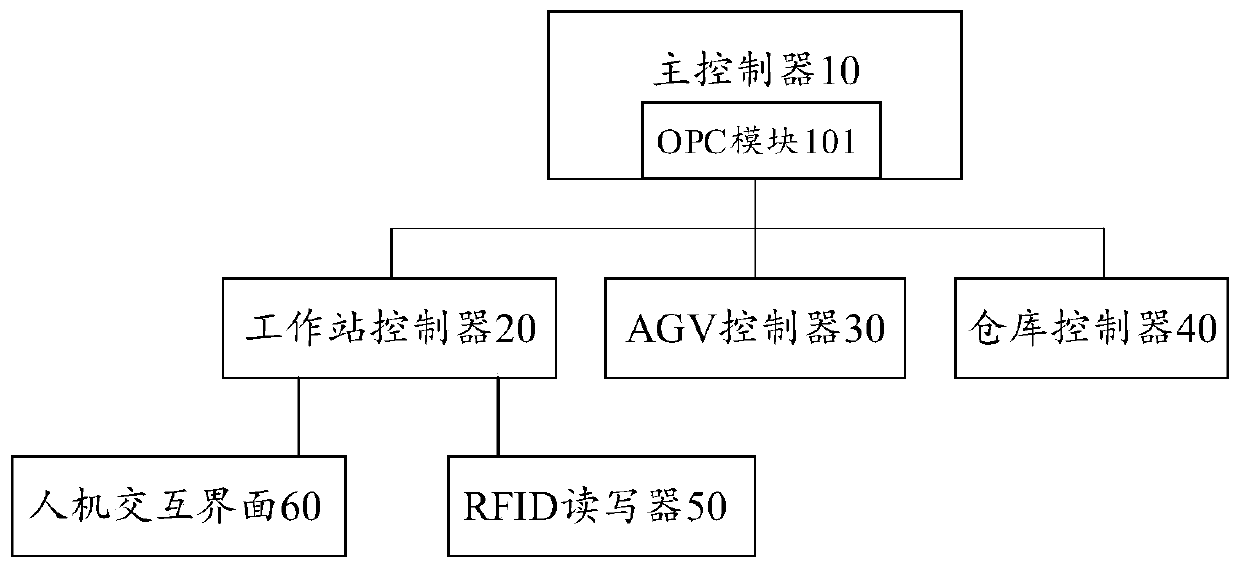

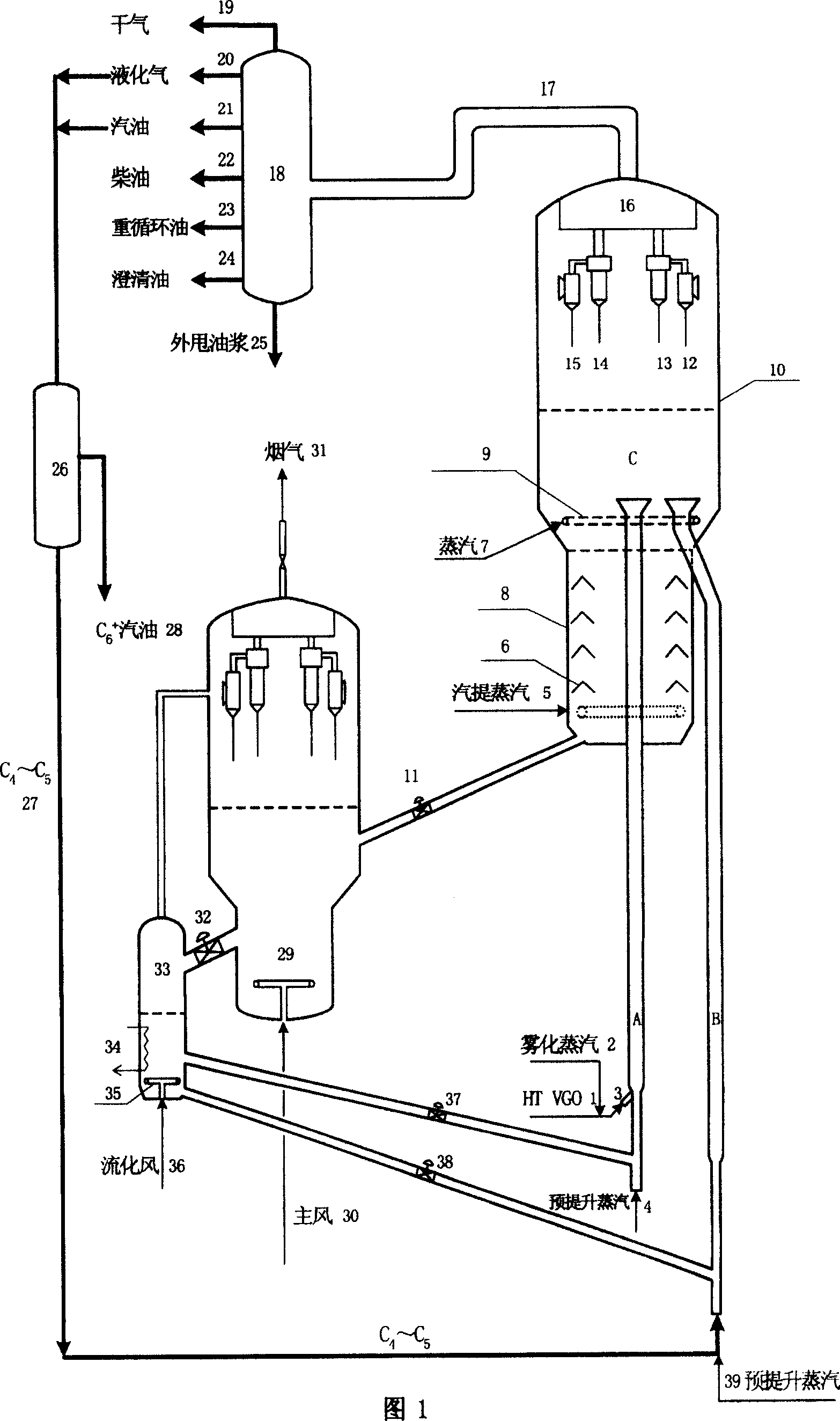

Catalytic conversion process for petroleum hydrocarbons

ActiveCN1690174AHigh yieldIncrease contentTreatment with plural serial refining stagesCatalytic transformationCarbon deposit

A method for catalytic conversion of petroleum hydrocarbon, which contains the following steps: (1) material of petroleum hydrocarbon into reaction area A of lift leg, contacting the regenerative agent inside and reaction, the mixture of the generated reaction oil gas and catalyst up-flowing along the lift leg, and entering into the reaction C of close phase bed; (2) the separated fraction of C4 and / or C5 from the separation part of the product being injected into reaction area B of lift leg, contacting the regenerative agent inside and reaction, the mixture of the generated reaction oil gas and catalyst up-flowing along the lift leg, and entering into the reaction C of close phase bed; (3) the mixture of the reaction oil gas and catalyst from reaction area A and B of the lift leg converging in reaction C of close phase bed, and reacting sequentially; (4) separating reaction oil gas from the catalyst depositing carbon after reaction, the reaction oil gas into the separation part of the product, and the carbon-deposited catalyst returning reaction part to serve circularly after striped, regenerated. With the method it can increase the yield of ethane, propone and BTX.

Owner:CHINA PETROLEUM & CHEM CORP +1

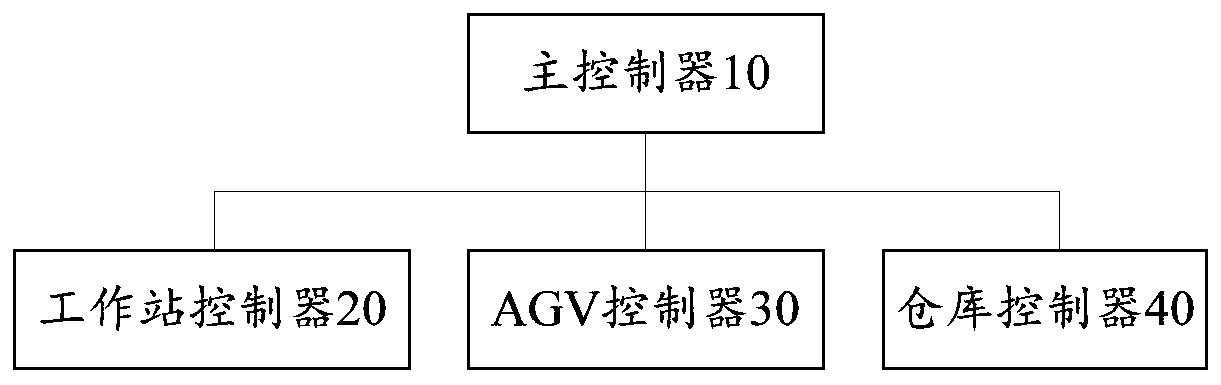

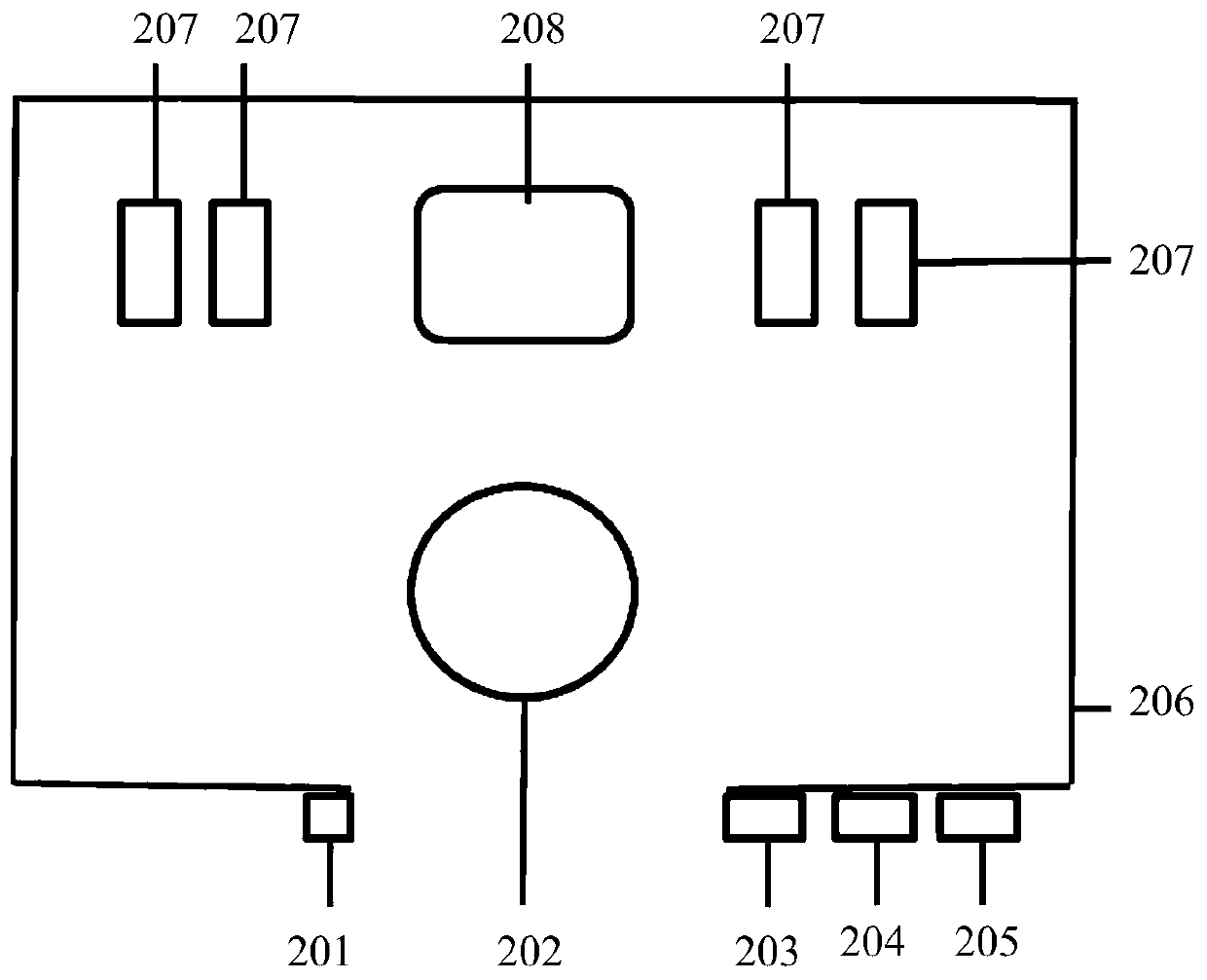

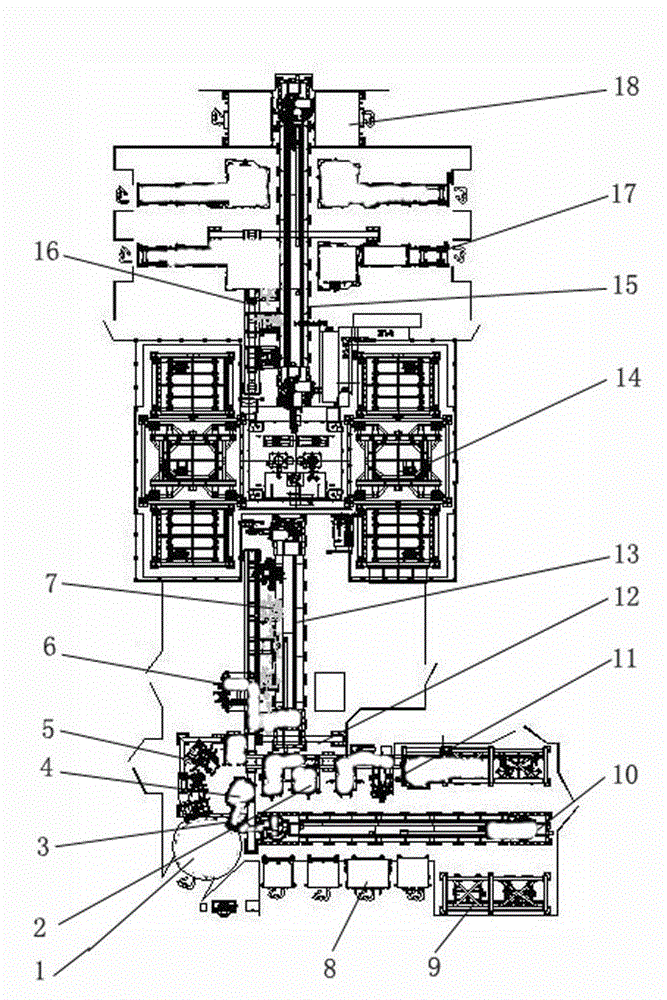

Production control system and method and production management system

ActiveCN109884996AIncrease productivityOptimize allocationElectric/hybrid propulsionTotal factory controlProduction lineControl system

The invention provides a production control system and method and a production management system, and relates to the technical field of intelligent production. The production control system comprisesa main controller, workstation controllers, an AGV controller and a warehouse controller, and the workstation controllers, the AGV controller and the warehouse controller are connected with the main controller. The production control system includes a plurality of workstations with the same configuration, the workstations are provided with workstation controllers, and the same configuration includes that the arrangement of the workstations is the same, the size of the workstations is the same and universal devices of the workstations are the same. The production control system and method and the production management system can timely transform a production line according to the state of the workstations, and shorten the transformation period to a certain extent to improve the production efficiency of the entire manufacturing system.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

Production plant of outside loop for slurry of polyethylene

A slurry outside circulation facility for polyethylene manufacture is disclosed here. The scheme adopted is that slurry inside the polymerization reactor is extracted from the bottom, pumped into a slurry cooler and then transmitted back into the polymerization reactor. The heat of slurry is removed by circular cooling outside the polymerization reactor, which increases the heat-exchange area and helps remove a part of the reaction heat generated during polymerization. By increasing the mass of polymerized polyethylene, the production capacity of original facilities can be promoted by over 50%. Compared to former technological alteration, the slurry outside circulation facility for polyethylene manufacture has the advantages of low investment cost, same area, low alteration period and convenient implementation.

Owner:SHANGHAI BOLONG EQUIP TECH CO LTD

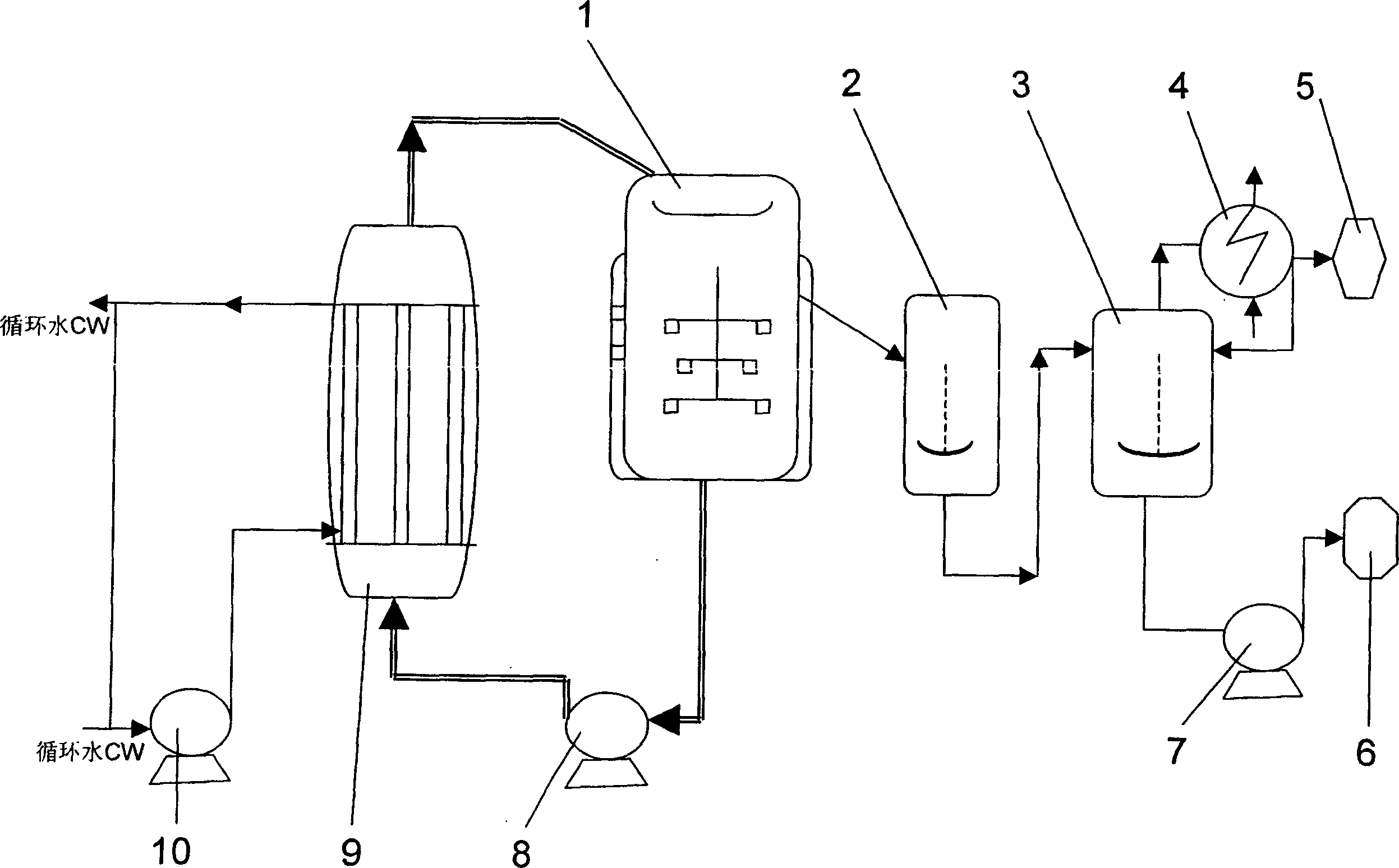

Coal thrower chain boiler for reducing NOx emission through flue gas recirculation

InactiveCN106051748AAchieve emission reductionLow investment costCombustion apparatusAir preheaterFlue gas

The invention discloses a coal thrower chain boiler for reducing NOx emission through flue gas recirculation. The coal thrower chain boiler comprises a chain grate stoker, a coal thrower, a hearth, a boiler barrel, a coal economizer, an air pre-heater, a dust remover, a desulfurization tower, an induced draft fan, a chimney, a primary air fan, a secondary air fan and a flue gas recirculation air fan. The lower portion of the chain grate stoker is provided with a plurality of primary air chambers. Air is sucked through the primary air fan, then is preheated through the air pre-heater, forms primary air and is fed into all the primary air chambers. The preheated air is extracted from a primary air pipeline by the secondary air fan, forms secondary air and is fed into the hearth and the coal thrower. A flue gas recirculation main pipeline is led out in the position, between the dust remover and the desulfurization tower, of a flue gas pipeline, and the flue gas recirculation air fan is installed in the flue gas recirculation main pipeline. Two recirculation flue gas branched pipelines are connected to the positions, at an outlet of the flue gas recirculation air fan, of the flue gas recirculation main pipeline and are used for feeding recirculation flue gas into the primary air chambers and an inlet of the secondary air fan correspondingly. According to the coal thrower chain boiler for reducing NOx emission through flue gas recirculation, the investment cost is low, the transformation period is short, and NOx emission can be reduced by 50% or above.

Owner:CHINA JILIANG UNIV

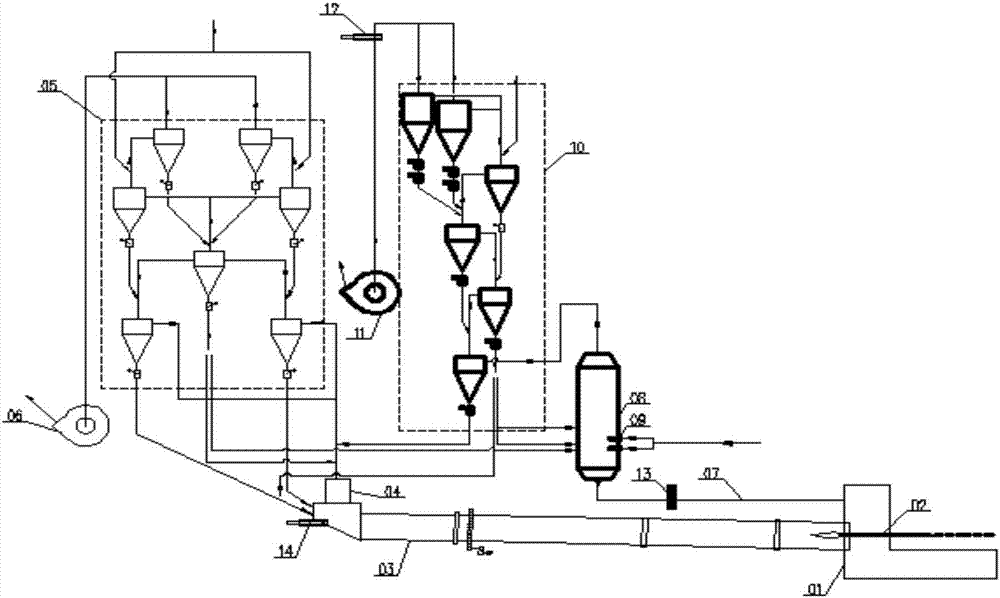

Energy saving and emission reduction transformation method for transforming cement cyclone preheater kiln into outside-kiln precalcining kiln

ActiveCN107084617AReduce workloadIncrease speedRotary drum furnacesPreheating chargesCycloneCombustor

The invention discloses an energy saving and emission reduction transformation method for transforming a cement cyclone preheater kiln into an outside-kiln precalcining kiln. A tertiary air duct (07), an offline calcining combustor (08), a calcining combustor burner (09), a five-stage preheater (10), a fresh air high-temperature fan (11), a normal temperature gas analyzer (12), a tertiary air gate valve (13) and a high temperature gas analyzer are newly built on the basis of an original cyclone preheater rotary kiln line, wherein a new preheater system and an old preheater system serve cement production jointly. The original kiln shutdown duration of eight months is shortened to 2-3 months, the cost of detaching of an old preheater is reduced, raw materials of the old preheater are wholly conveyed into the offline calcining combustor, the in-kiln calcining rate of the raw materials is increased to 90% or over from original 100% of in-kiln calcining through the offline calcining combustor, and the raw materials of the new preheater enter the kiln through an original feed-end chamber. After the cyclone preheater kiln is transformed into the precalcining kiln, 100% of fuel of a kiln head is reduced to 40%, the amount of NOx generated by the kiln head at a high temperature environment is reduced, and the method can quickly change the cement production process and achieve the yield increase, energy saving and emission reduction effects for a cement sintering system.

Owner:BEIJING TRIUMPH INT ENG

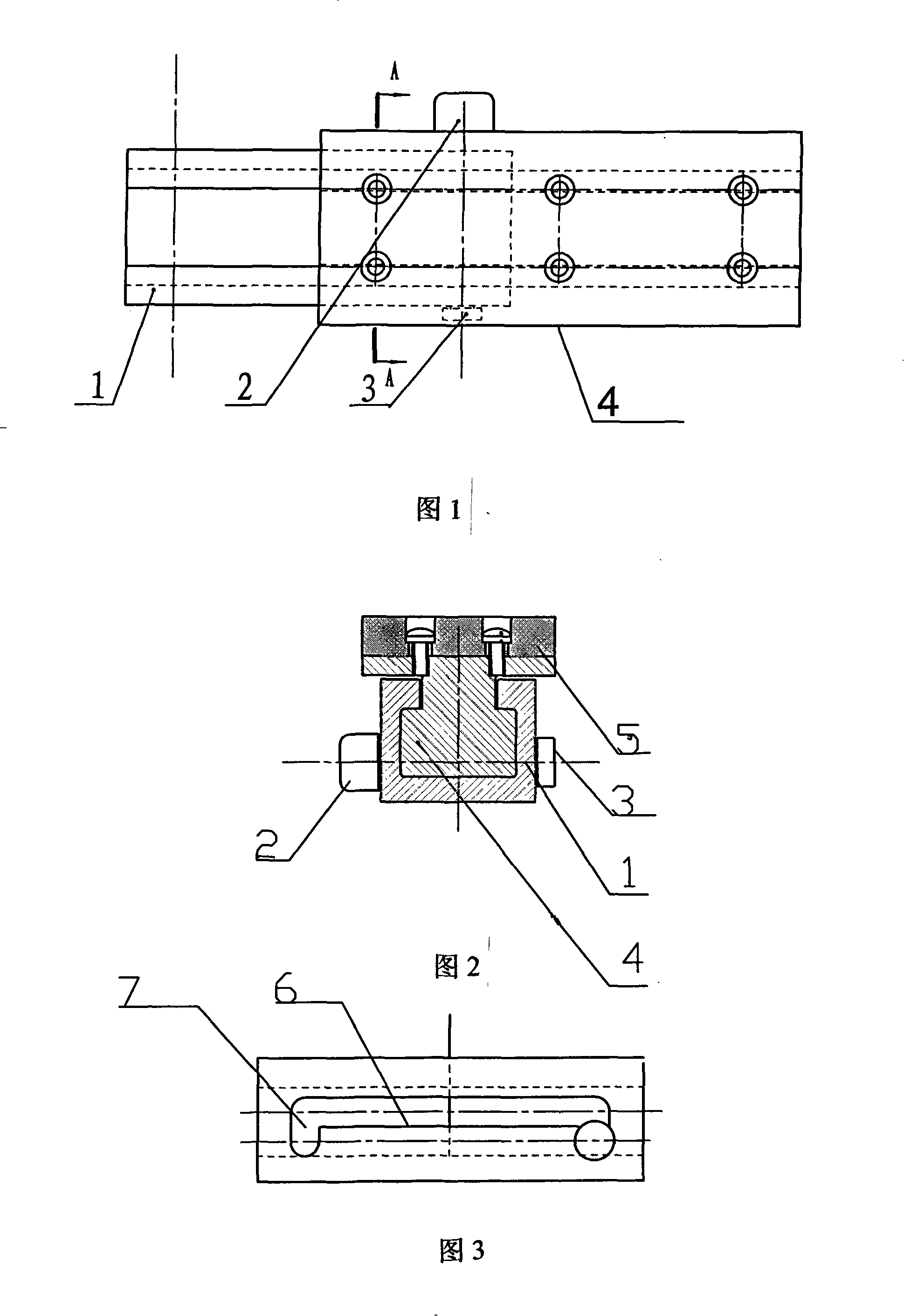

Holding tool shared quick changing support of the vehicle final assembly conveying system

The present invention provides a common fast exchanging hold tool support device of vehicle assembly transportation system and consists of a slide base, a slide block, a screw rod and a handle, etc, wherein, the slide base is welded on a support pallet on a back support arm, the middle of the sliding base is a dovetail chute, and the lower part of the slide block is arranged in the chute and has upper and lower displacement space in the dovetail chute; the two lateral walls of the slide base is opened with a long notch along the same direction of the dovetail chute, the long notch is connected downward with at least two position stop grooves, the screw rod horizontally gets through one of the position stop grooves and the slide block in the chute and is clipped in the position stop groove, and the terminal part is fastened by the handle. With the assembly of the slide base and the slide block, the screw drives the slide block to slide between the position stop grooves with position stop, the device can adjust the position of the slide block according to need, while supporting model with different platform and solving common transportation difficulty of different series of models with difference on wheel base, holding point and center of gravity.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Aged mango high-pile grafting method

InactiveCN101433170AShort transformation periodCultivating equipmentsHorticultureTree toppingEconomic benefits

The invention provides a high-pile variety changing method for aged mango trees, which is characterized in that: 1. in an earlier stage of grafting, an annular ditch which is 30 centimeters wide and 40 centimeters deep is dug on the periphery which is 1 to 1.5 meters away from the root of a mango tree, so as to cut off a root system, reduce the transport of moisture and nutrients and achieve the balance between moisture and nutrients after grafting; 2. a position on the mango tree, which is 0.8 to 1 meter away from the ground, is integrally cut once and for all and is grafted by a cut grafting method; 3. a scion and a pile body are sprayed with carbendazim 2 to 5 days after grafting, and a tree body is brushed with quicklime plus 4-6 mass percent table salt liquid after 7 to 9 days of grafting; and 4. when a new grafted survived treetop grows to 15 to 20 centimeters, the new tree top is pinched in time so as to promote branching and form a tree crown rapidly. The method ensures that the survival rate of grafting and changing the variety of the aged mango trees reaches more than 93 percent; a new tree crown in the second year after grafting can reach more than 2 meters; and single plant can bear more than 8 kilograms of fruits on the average. The method has the advantages of shortening the reformation period of aged mango orchards and improving the economic benefit of the orchards.

Owner:HUAPING COUNTY HUANONG TECH DEV

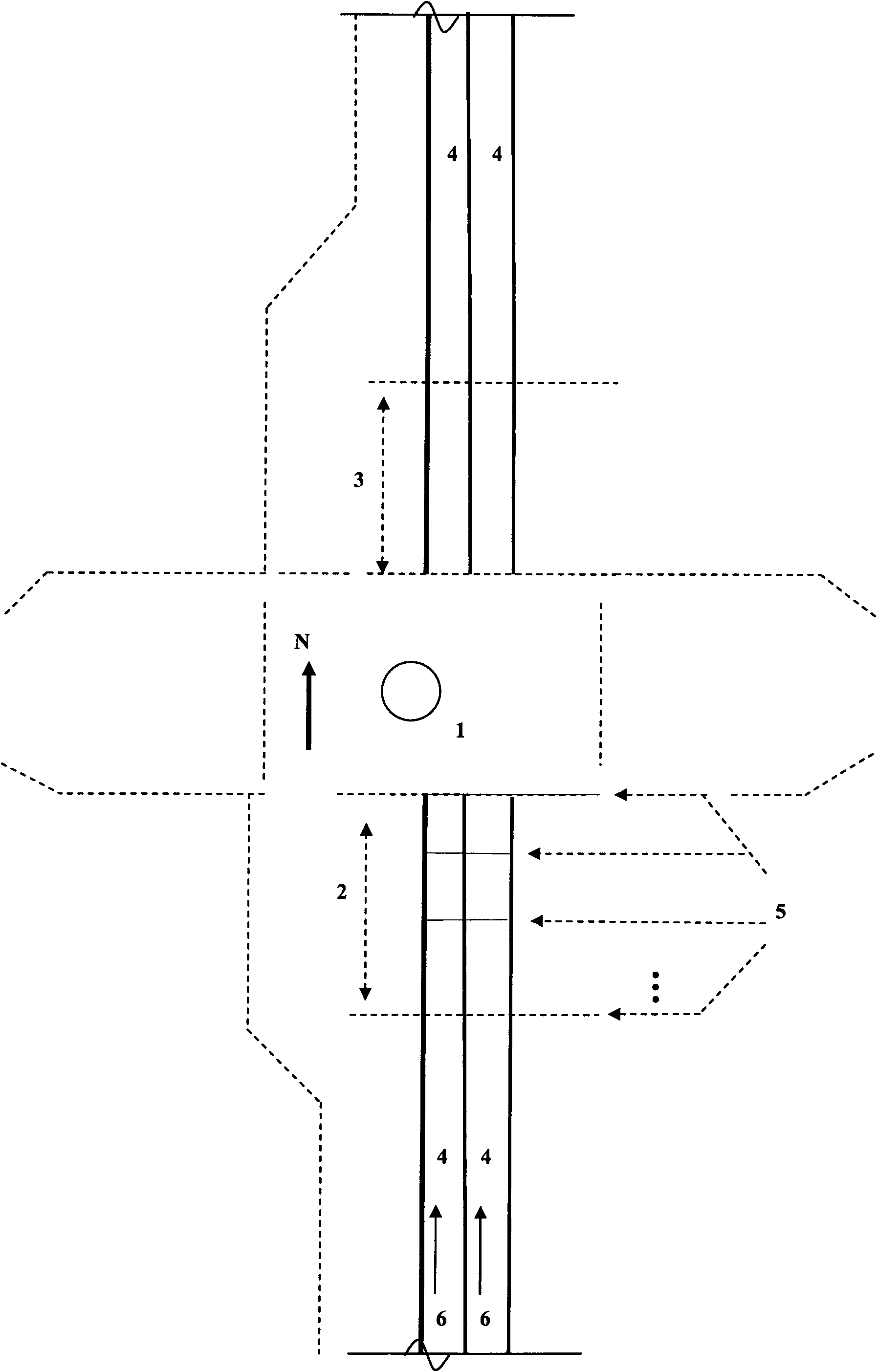

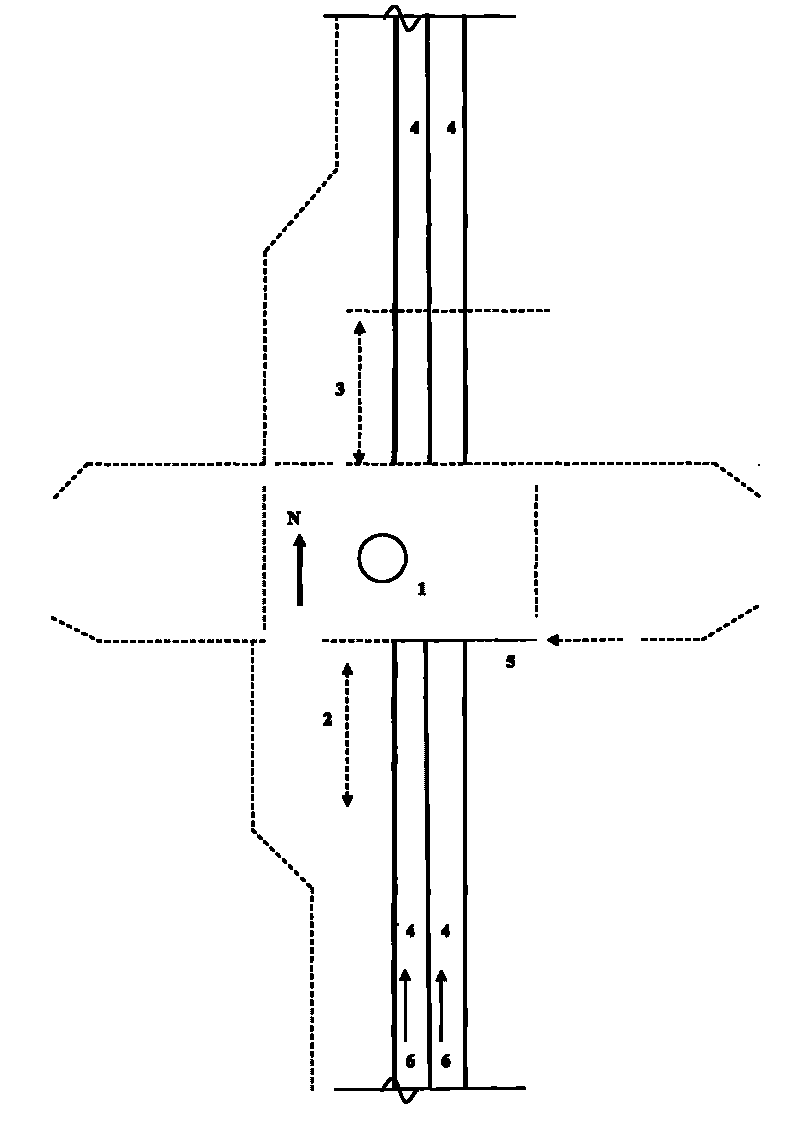

Method for increasing intersection vehicle flux

InactiveCN101630442ALess investmentSmall footprintRoad vehicles traffic controlTraffic signalsEngineeringGreen-light

The invention relates to a method for increasing the intersection vehicle flux. On various traffic lanes before intersections, except the prior common parking lines of adjoining intersections, various traffic lanes are provided with a plurality of parking lines towards the running direction of vehicles; a reasonable distance is arranged between two adjacent two parking lines to ensure that when red lights are changed into green lights, various vehicles parked before a plurality of parking lines can simultaneously start so as to reduce the waste of green light time due to the starting of vehicles one by one after running for a distance, so the vehicle flux when the green lights flash can be improved.

Owner:李幸超

Device for improving thickness of car body chassis electrophoresis film

ActiveCN106245097AControl pH balanceReduce or remove additionsElectrophoretic coatingsElectrophoresisEngineering

The invention discloses a device for improving thickness of a car body chassis electrophoresis film. The device includes an electrophoresis tank; the electrophoresis tank is internally provided with anodes and a tank liquid; a plurality of anodes are arranged on the side walls and the bottom surface of the electrophoresis tank, the anodes on the side walls are each externally provided with a protective separation film, and the anodes on the bottom surface are naked anodes; the superficial area of the anodes on the bottom surface is 0.4%-1.6% of the superficial area of an electrophoresis car body as a cathode, the superficial area of the anodes on the side walls is 20%-25% of the superficial area of the electrophoresis car body as the cathode. Through a method of transformation and increasing of related devices in the prior art, the thickness of the car body chassis electrophoresis film is increased, the transformation cost is low, the transformation period is short, at the same time, the thickness of the chassis film is increased on a basis of no increase of the thickness of films of other parts, and the increase of cost brought by the increase of the thickness of the chassis electrophoresis film is reduced to a greatest extent.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

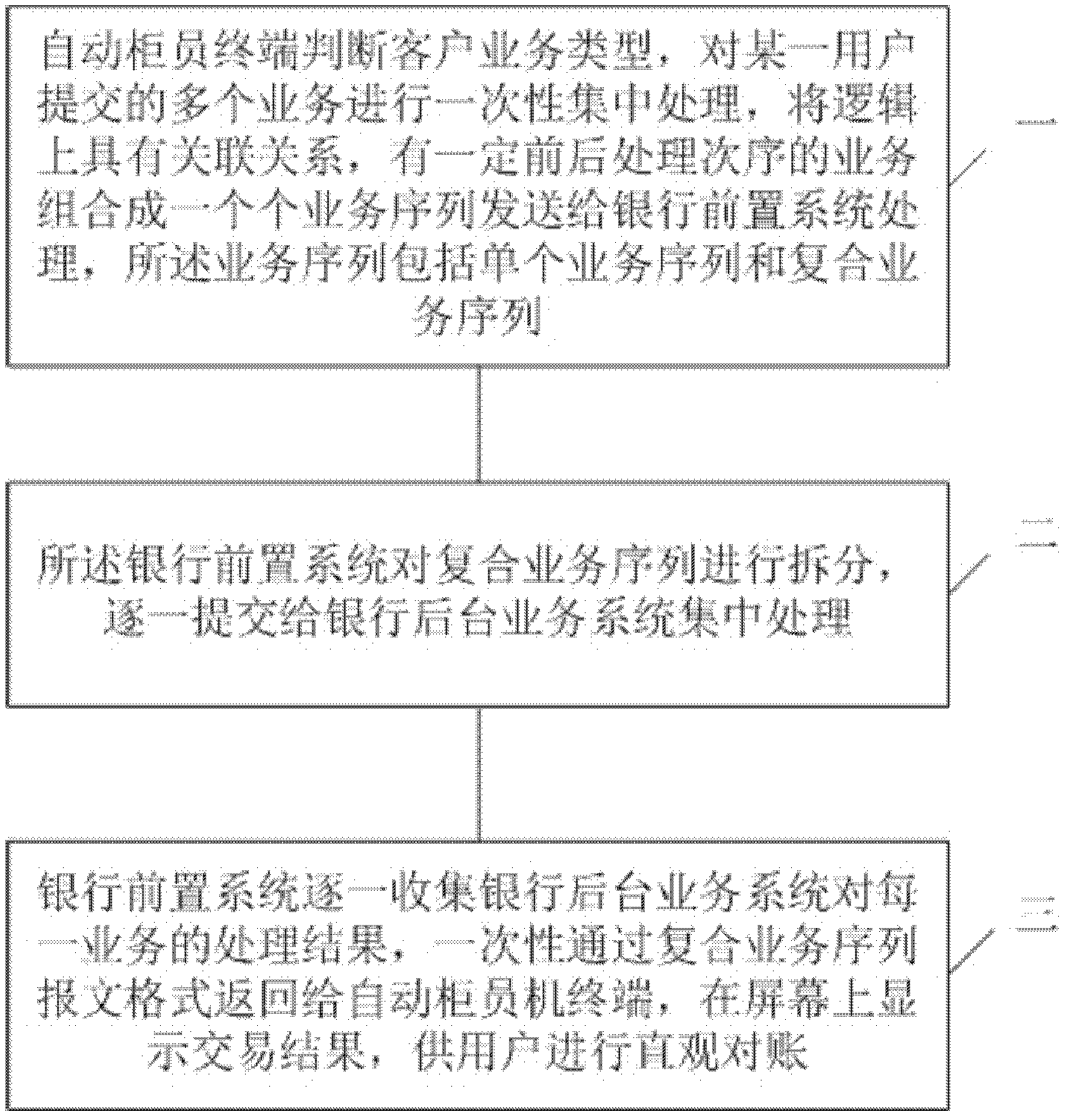

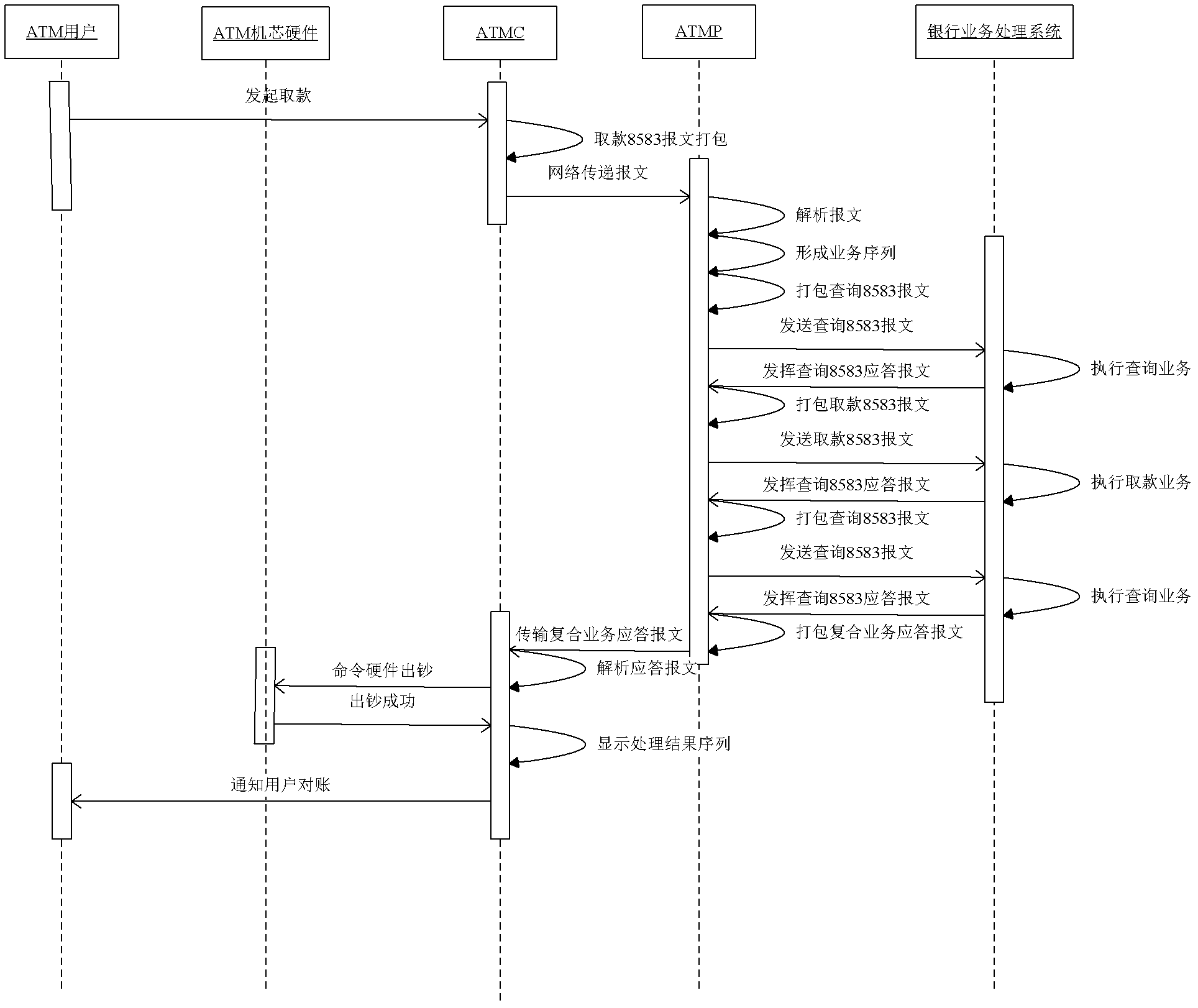

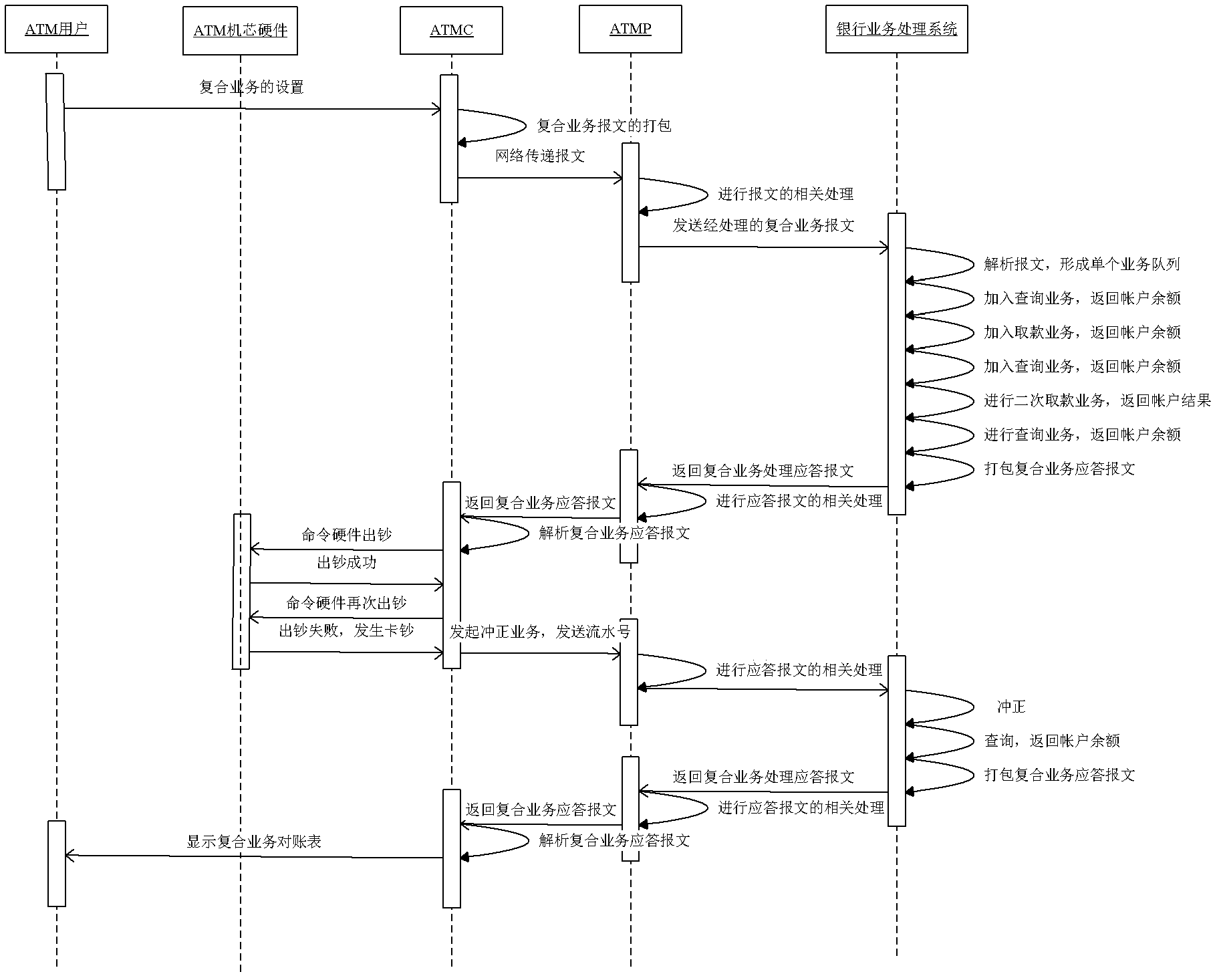

Business processing method and system of financial self-service equipment

InactiveCN102496219AReduce the number of transfersImprove performanceComplete banking machinesFinanceEnd systemComputer terminal

Owner:GRG BAKING EQUIP CO LTD

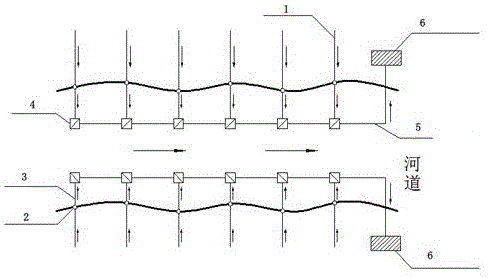

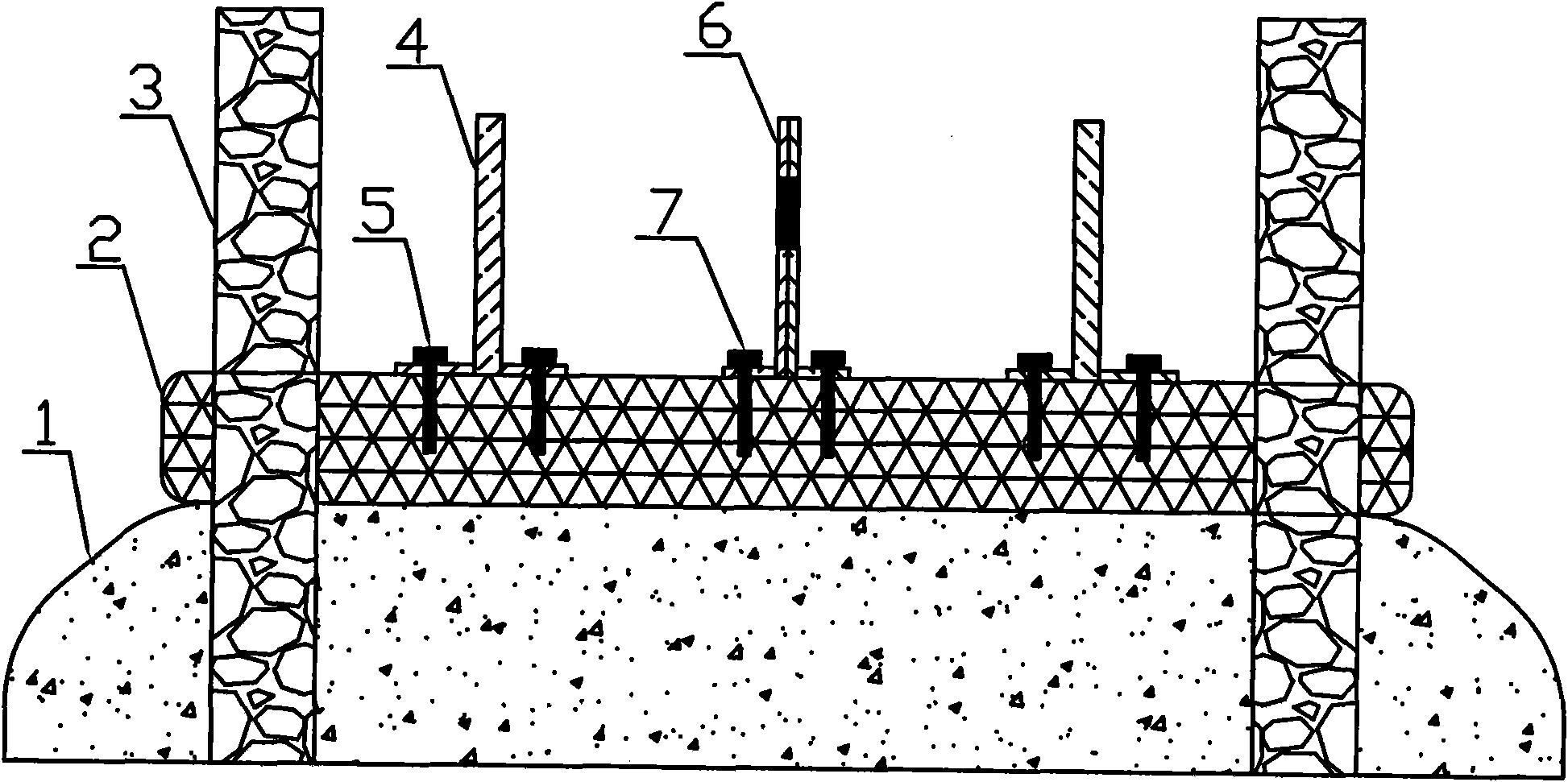

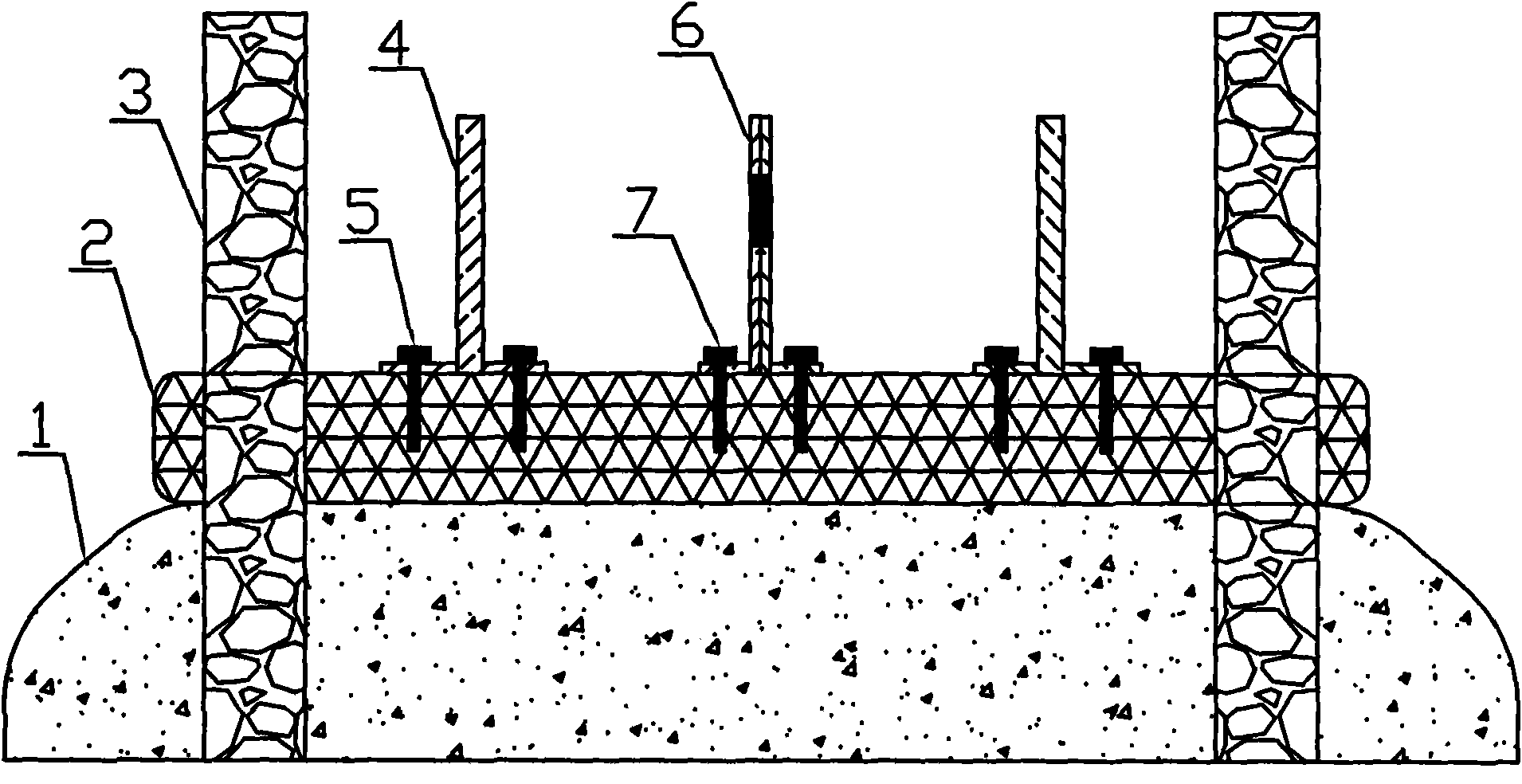

Series sewage intercepting collection pipe method for treating urban black and odorous water body

InactiveCN106545069AImprove collection effectComplete closureSewerage structuresSewage drainingMunicipal sewageRevetment

The invention discloses a series sewage intercepting collection pipe method for treating an urban black and odorous water body. According to the method, bearing mechanisms corresponding to confluent main pipes are arranged on a river channel revetment, or positions corresponding to the confluent main pipes in a river channel are piled, the bearing mechanisms or piles are used for supporting and jacking the confluent main pipes, a water outlet of each confluent main pipe is communicated with an intercepting branch pipe, an intercepting well is arranged at a water outlet of each intercepting branch pipe, all the intercepting wells are communicated with each other through pipelines to form intercepting main pipes, a water outlet of each intercepting main pipe is communicated with a municipal sewage pipe network, sewage and rainwater intercepted by the intercepting wells are conveyed to the municipal sewage pipe network through the intercepting main pipes, sewage of the municipal sewage pipe network is communicated to a water inlet of a sewage treatment plant for treating the received sewage, and treated effluent is drained into the river channel. The source of the black and odorous water body is treated, and the method is simple, efficient and low in investment cost.

Owner:NANJING UNIV OF TECH

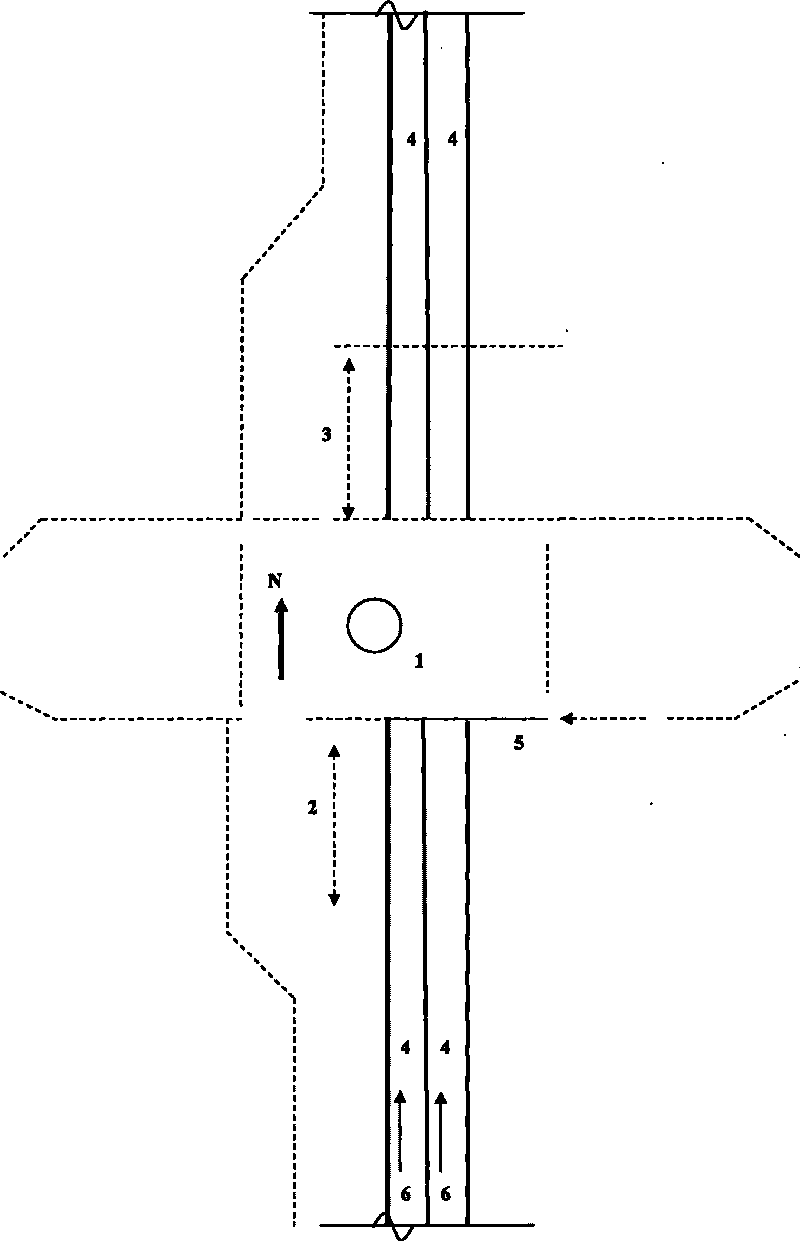

Method for keeping traffic flow in red light

InactiveCN101706992AIncrease traffic flowReduce negative impactArrangements for variable traffic instructionsTraffic volumeEngineering

The invention relates to a method for keeping traffic flow in red light. Traffic lanes are increased with equal quantity on a front-light road section (2) before a road reaches a crossroad and a post-light road section (3) after the road reaches the crossroad. When a red light is bright, vehicles stop on each traffic lane and wait, and when a green light is bright, the vehicles together pass through the crossroad to enter the behind-light road section (3), wherein vehicles on a prior traffic lane continue to go forwards, vehicles on other traffic lanes run slowly or stop to wait until the green light become red, vehicles which get across the traffic light on the prior traffic lane (6) pass over the traffic light, and then enter an original traffic lane to continue to go forwards, thereby the passing capability of traffic flow of the road is greatly improved.

Owner:李幸超

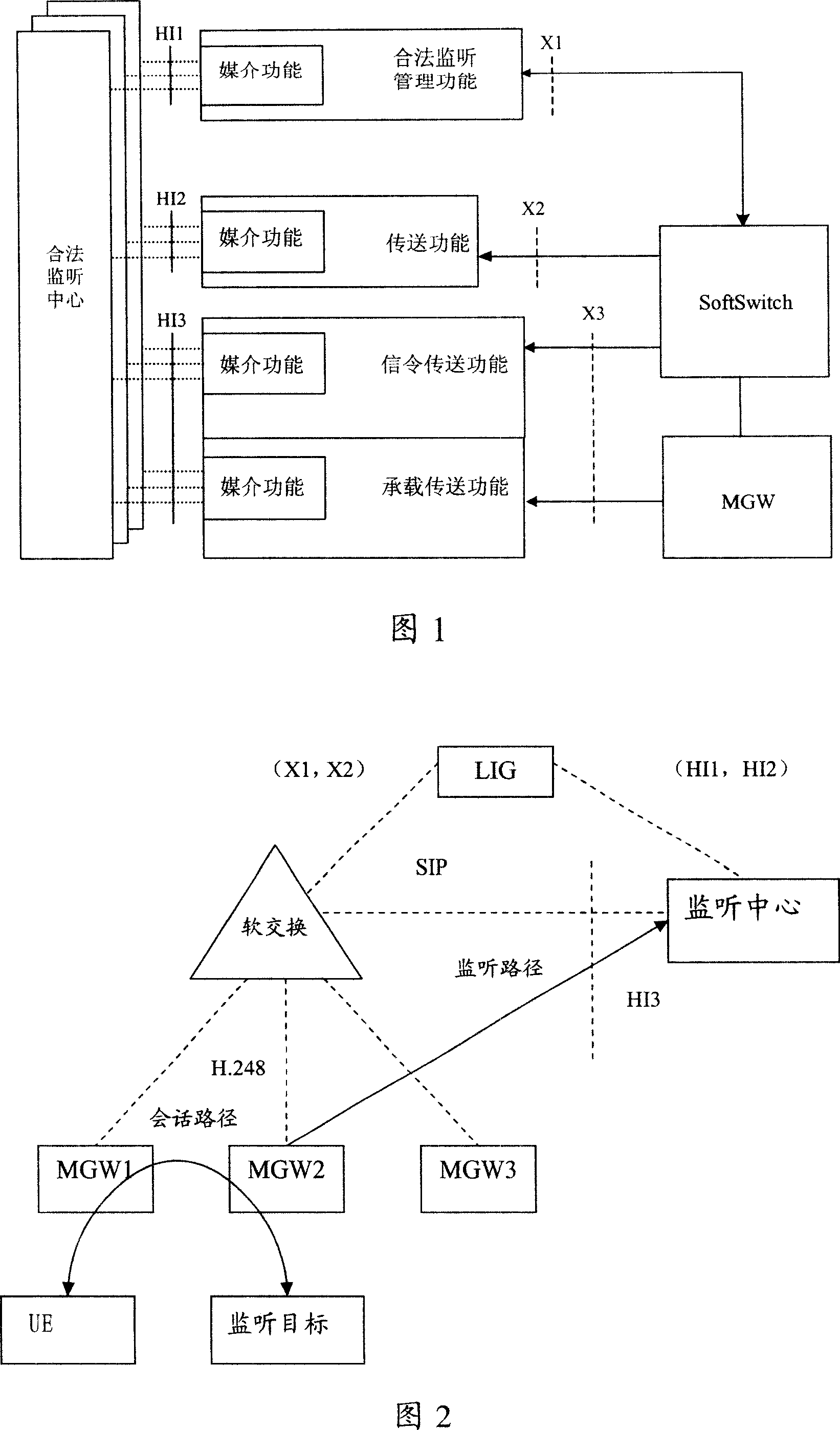

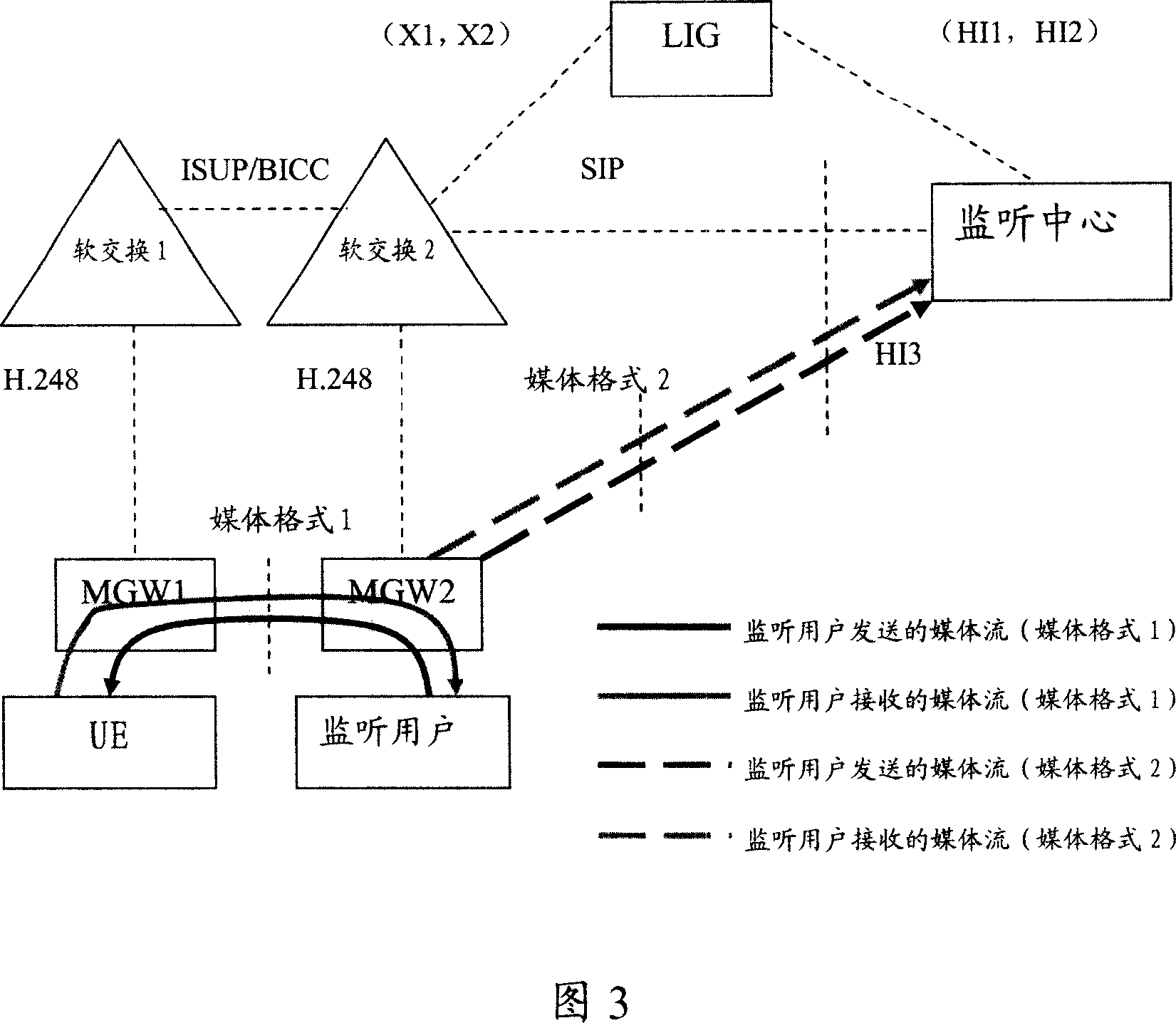

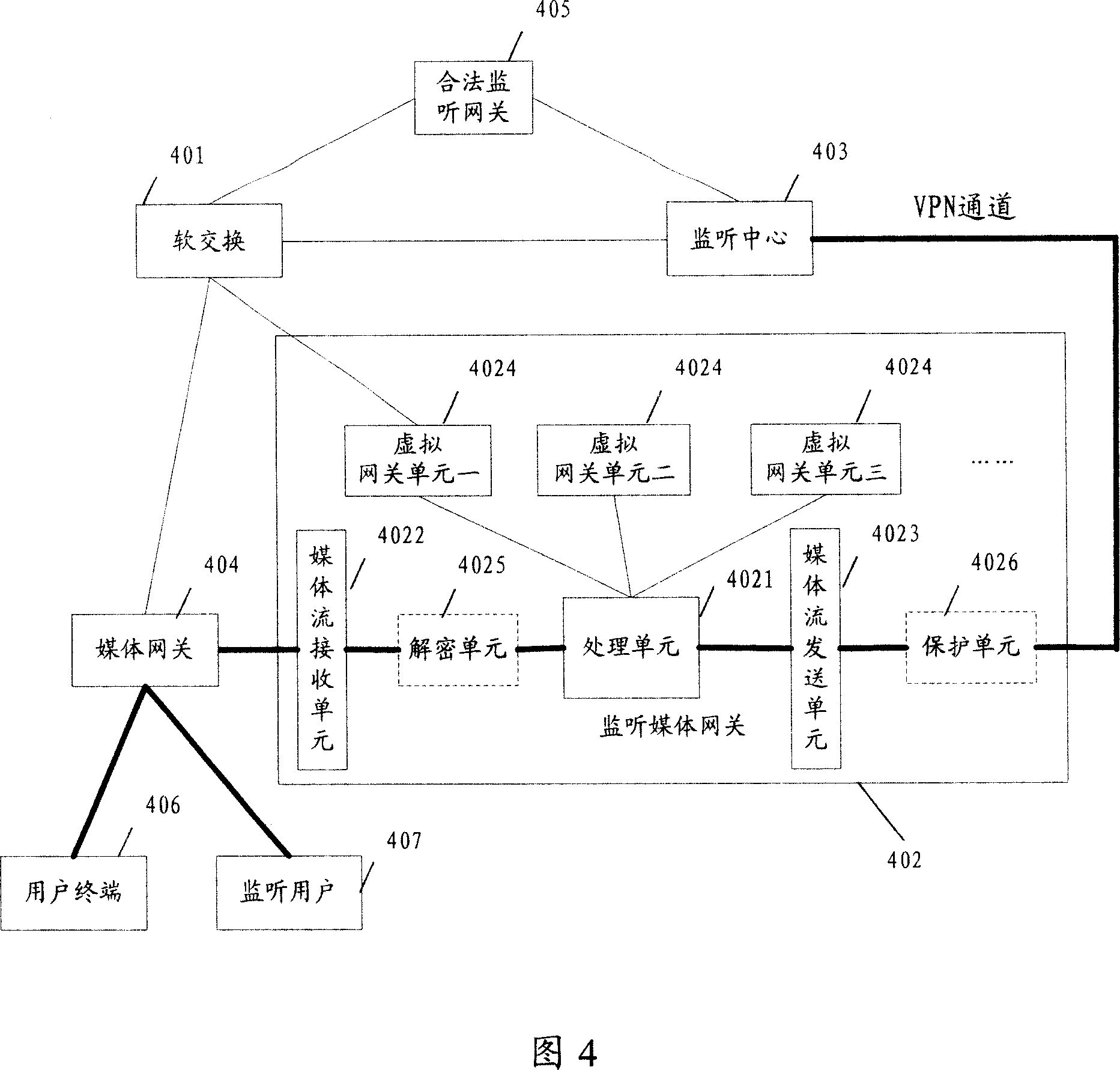

A method, system and monitoring media gateway for multimedia monitoring

ActiveCN101009605AReduce upgrade costsShort transformation periodSpecial service provision for substationNetwork connectionsUpgradeComputer network

The case in this invention for monitoring multimedia comprises exactly: A. the media gateway copies the monitored media flow to obtain and send the copied media flow to the monitoring media gateway; B. the latter converses the media format; and C. the monitoring media gateway transmits the conversed media to the monitor center. This invention reduces cost in technique upgrade, and saves MGW resource.

Owner:HUAWEI TECH CO LTD

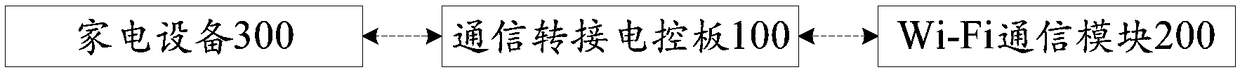

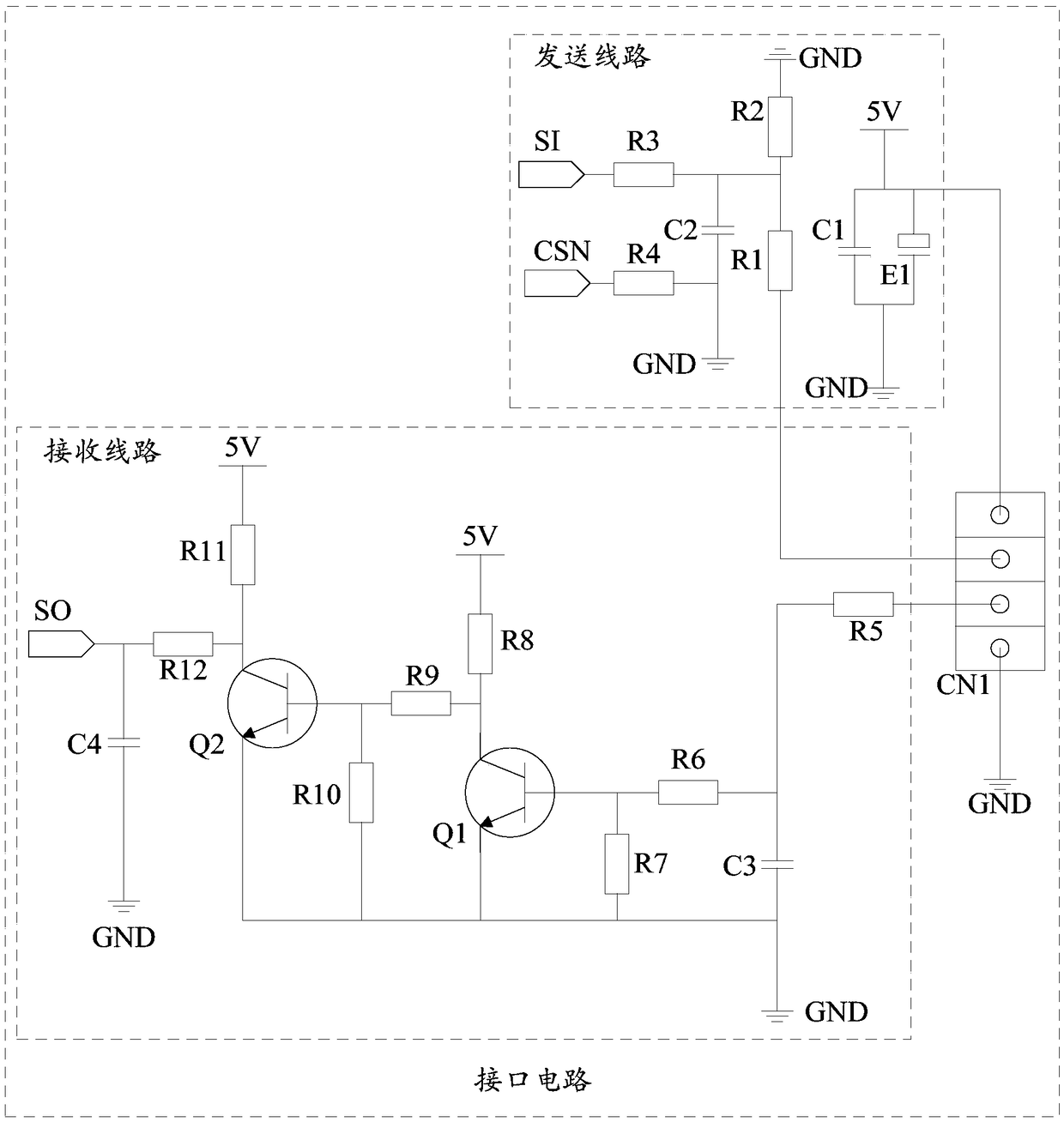

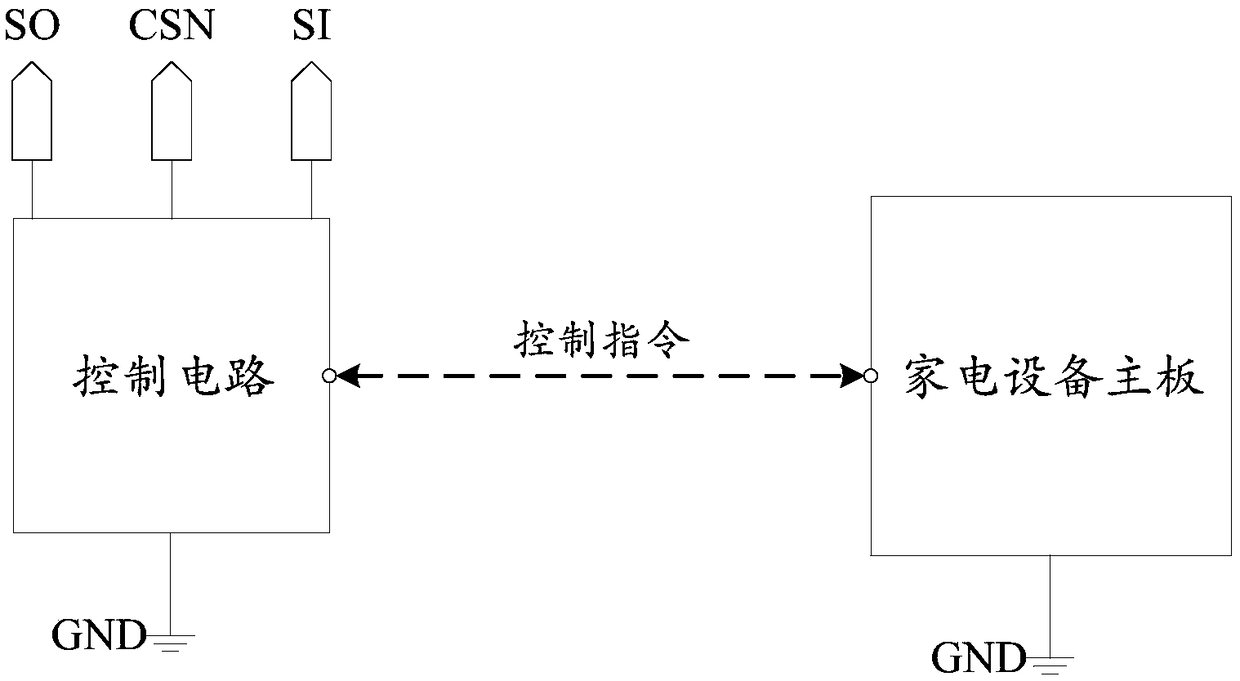

Communication transfer electric control boards, household appliance and household appliance control system

The invention provides communication transfer electric control boards, a household appliance and a household appliance control system. A communication transfer electric control board comprises an interface circuit which is used for accessing a Wi-Fi communication module and carrying out data instruction interaction with the Wi-Fi communication module, wherein a data instruction is configured as aninstruction capable of being analyzed by the Wi-Fi communication module; and a control circuit which is used for converting the data instruction and a control instruction, wherein the control instruction is configured as the instruction capable of being performed by the household appliance, and the control instruction is also configured to feed back an operation state of the household appliance.The data instruction sent by the Wi-Fi communication module is transmitted to the household appliance through the interface circuit and the control circuit in sequence. The control instruction sent bythe household appliance is transmitted to the Wi-Fi communication module through the control circuit and the interface circuit in sequence. Through application of the technical scheme provided by theinvention, a conventional air conditioner can be modified with low cost in the short term, the air conditioner is enabled to have a Wi-Fi communication function, a communication mode is expanded, andcommunication reliability and use experience are improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

Improved compound fertilizer for saline land grain crop plantation and improvement method thereof

InactiveCN106220412AReduce alkalinityLow costCalcareous fertilisersBio-organic fraction processingCompound organicMicroorganism

The present invention relates to the field of saline alkali soil improvement, and in particular to an improved fertilizer for saline land grain crop plantation. The fertilizer comprises the following components by weight: 260-380 parts of composite organic humus fertilizer, 60-80 parts of bean curd residues, 20-30 parts of microbial combination agent, 20-30 parts of swill, 40-50 parts of peat soil, 100-220 parts of an acidic soil combination agent, and 105-115 parts of the desulfurization gypsum. The invention also discloses an improvement method of the improved compound fertilizer for saline land grain crop plantation. The improved method comprises the following steps: S1, weighing the raw materials and preparing a compound organic humic fertilizer, S2: finishing saline surface soil; and S3: spraying compound organic humic fertilizer and leveling the soil. The formula of the invention adopts raw material of low prices, so the cost is low. Addition of the compound organic humic fertilizer reduces soil alkaline saline, so that saline land can plant grain crops. The scheme provided by the invention has simple steps, low cost, short cycle transformation, and is suitable for large popularization and usage in saline soil.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

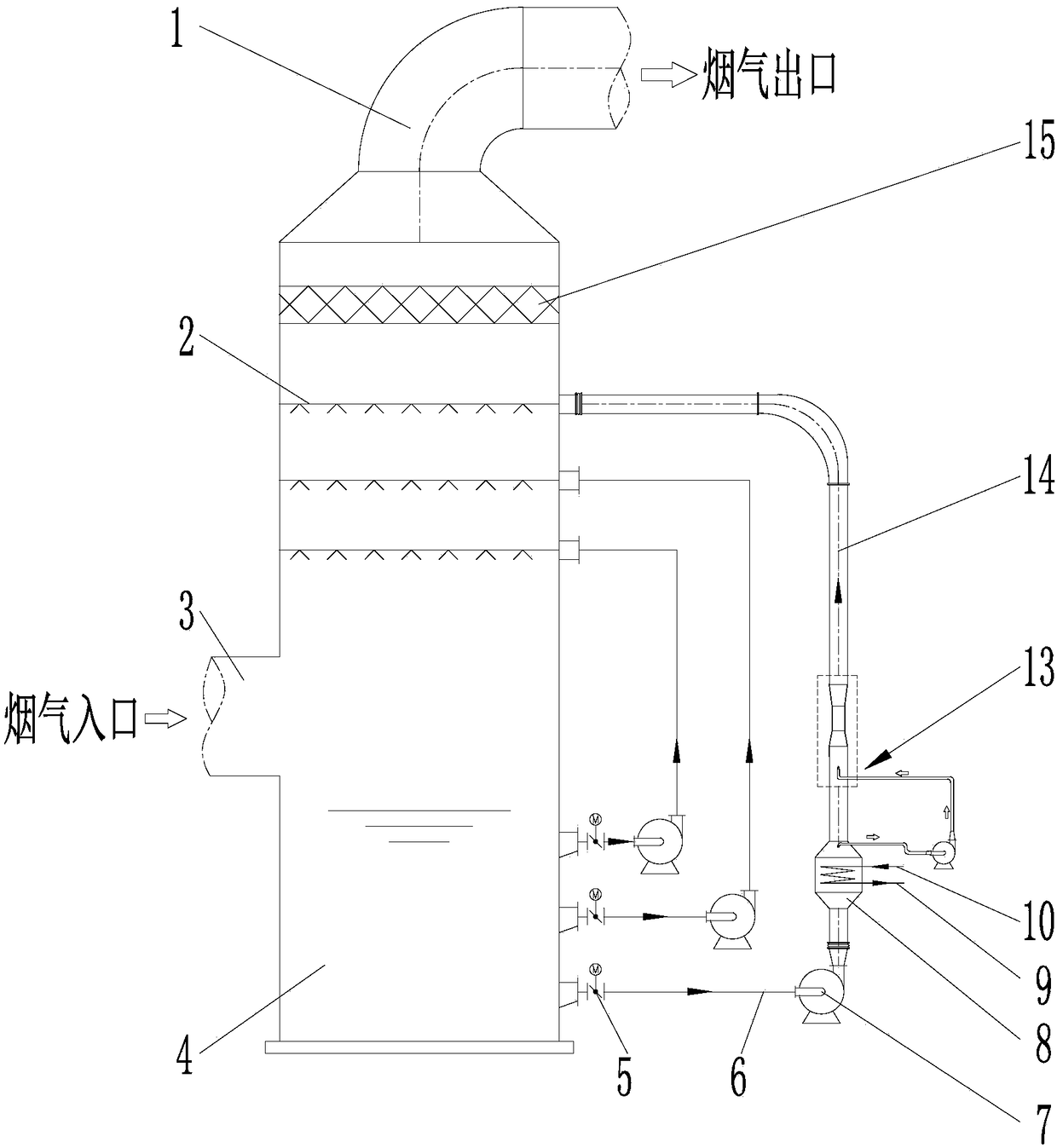

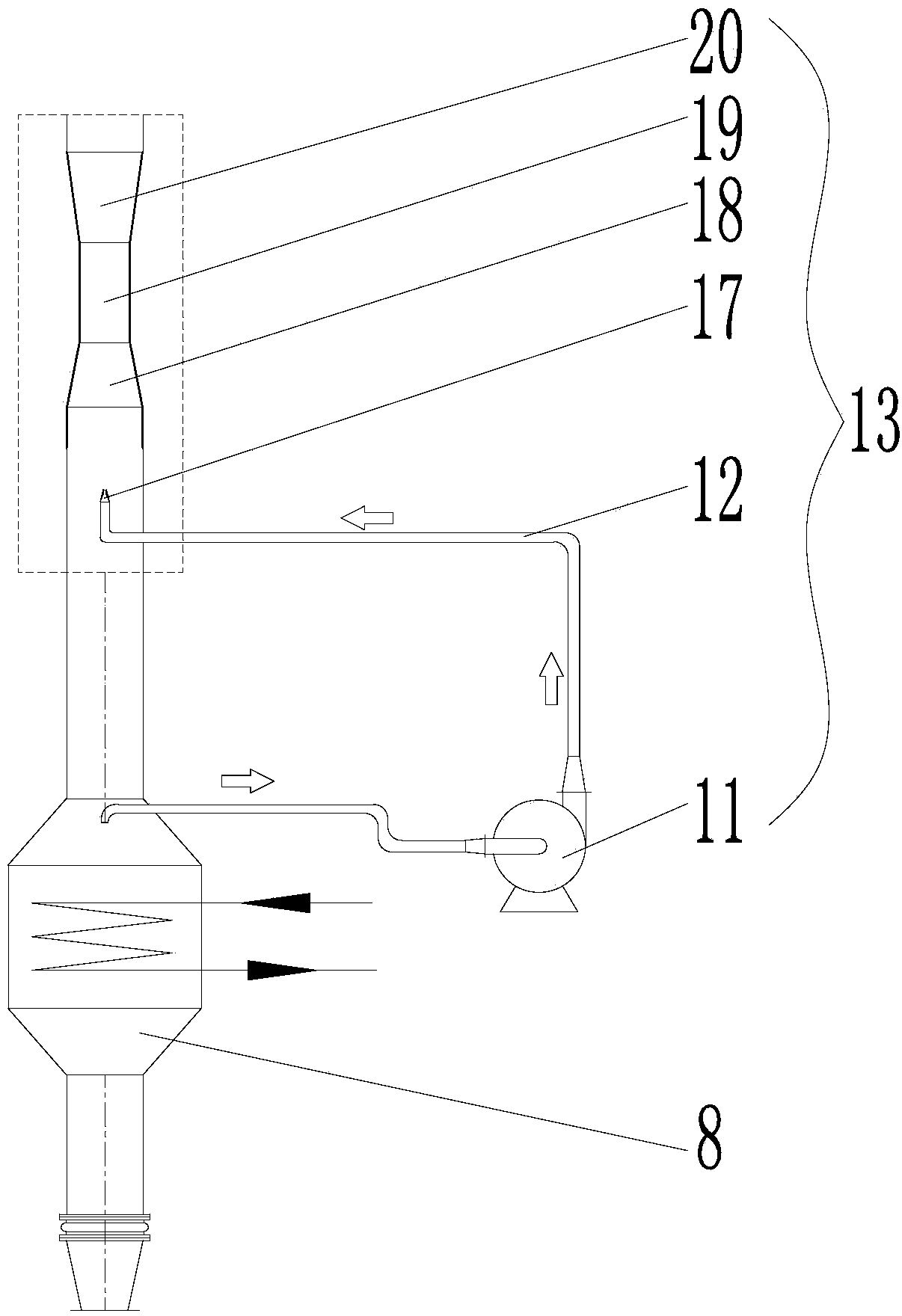

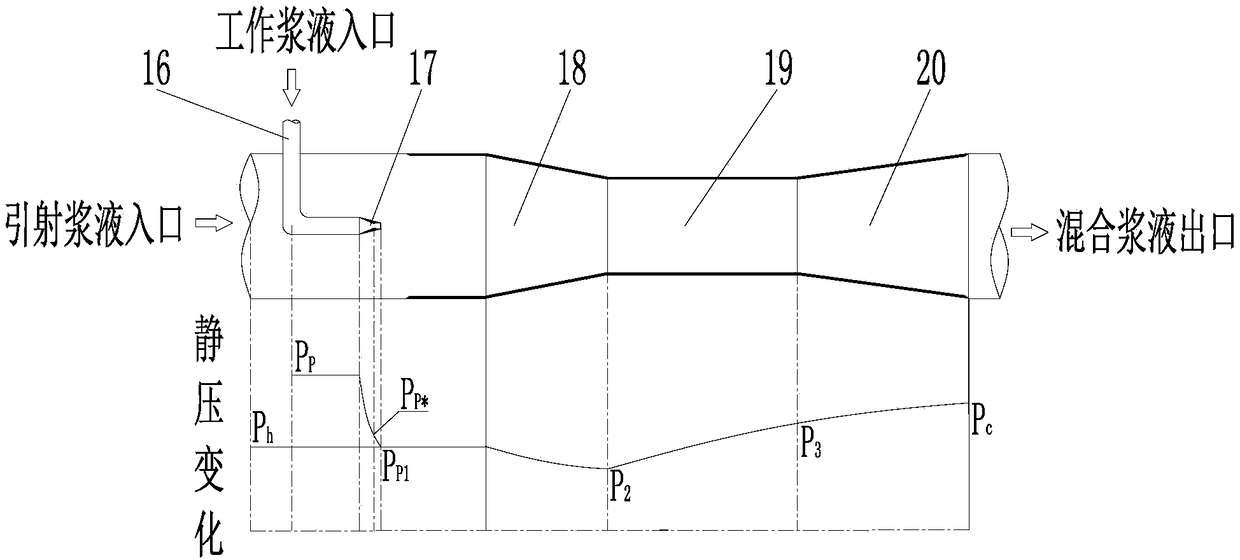

Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

ActiveCN108295633ASimple crafting systemShort transformation periodUsing liquid separation agentCombustion technology mitigationSlurryButterfly valve

The invention discloses cooling and white smoke eliminating device and method for circulating slurry for a desulfurizing tower of a thermal power plant, and belongs the fields of the flue gas purification and the white smoke elimination of utility boilers and metallurgical coking and relevant industrial boilers, and the like. The side surface of the bottom of the desulfurizing tower in the deviceis provided with electric butterfly valves; the electric butterfly valves, slurry circulating pump inlet pipes, slurry circulating pumps, a slurry cooler, a slurry jetting and boosting device, a slurry circulating pump outlet pipe and top-layer spray layers are connected in sequence. The device can be used for reducing the water replenishing amount of the desulfurizing tower, is used for decreasing the moisture content of flue gas, and is used for further eliminating white smoke. Meanwhile, the invention also provides the cooling and white smoke eliminating method for the circulating slurry for the desulfurizing tower of the thermal power plant. The latent heat of vaporization in the flue gas is recovered; the heat loss of the smoke exhausted from a boiler is further decreased; the moisture carried in the flue gas is reduced; the water resource is saved, and the white smoke from a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

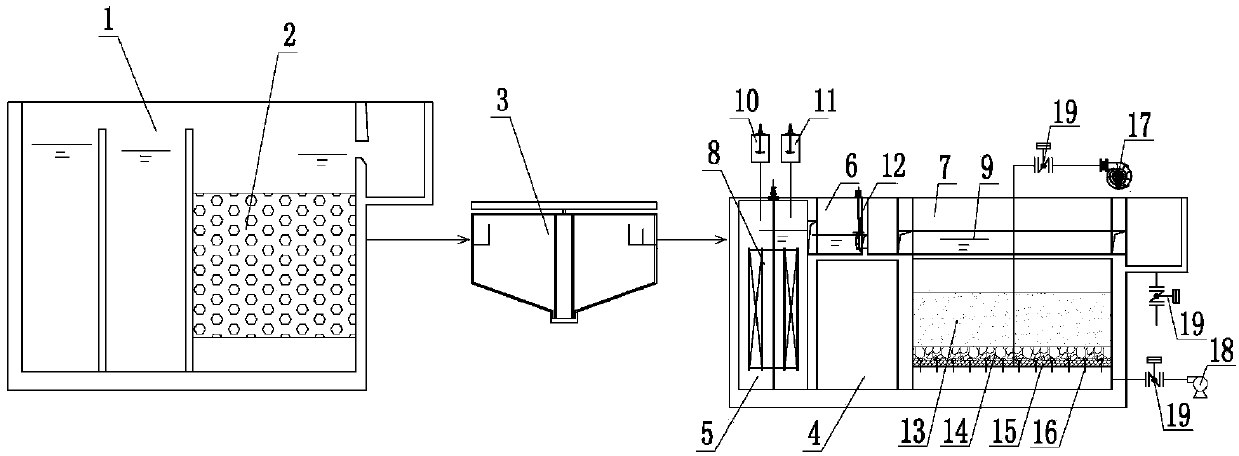

Biochemical pool MBBR process and denitrification deep-bed filter tank coupled nitrogen and phosphorus removal system and method thereof

PendingCN109650652APrecise Dosing Control MeasuresResistant to shock loadsWater contaminantsTreatment involving filtrationFlocculationControl valves

The invention relates to a biochemical pool MBBR process and denitrification deep-bed filter tank coupled nitrogen and phosphorus removal system and a method thereof. The system comprises a biochemical pool and a secondary sedimentation tank. The biochemical pool is divided into at least two chambers. In the chamber close to the outlet are arranged several suspended fillers. The denitrification deep-bed filter tank is located downstream the secondary sedimentation tank. The denitrification deep-bed filter tank comprises a flocculation basin, inside which a stirring mechanism is arranged and the top of which is provided with a carbon source dosing mechanism and a flocculating agent dosing mechanism. A water inlet main canal is connected downstream, and an intake gate is arranged in the water inlet main canal. A filter grid is arranged downstream. An intake canal is connected under the filter grid. A filter tank is arranged under the intake canal. Inside the filter tank, a filter layer,a supporting layer, a filter board and a filter head disposed on the filter board are successively arranged from top to bottom. The denitrification deep-bed filter tank also comprises a backwashing fan and a backwashing water pump. The outlet of the backwashing fan extends through a pipeline to the supporting layer, and the outlet of the backwashing water pump extends through a pipeline into the filter tank below the filter board. The pipelines are all provided with a control valve. The system of the invention can perform denitrification and physical interception to remove phosphorus.

Owner:浙江中昌水处理科技有限公司

Catalytic conversion process for petroleum hydrocarbons

ActiveCN1333046CHigh yieldIncrease contentCatalytic crackingTreatment with plural serial refining stagesCatalytic transformationCarbon deposit

A method for catalytic conversion of petroleum hydrocarbon, which contains the following steps: (1) material of petroleum hydrocarbon into reaction area A of lift leg, contacting the regenerative agent inside and reaction, the mixture of the generated reaction oil gas and catalyst up-flowing along the lift leg, and entering into the reaction C of close phase bed; (2) the separated fraction of C4 and / or C5 from the separation part of the product being injected into reaction area B of lift leg, contacting the regenerative agent inside and reaction, the mixture of the generated reaction oil gas and catalyst up-flowing along the lift leg, and entering into the reaction C of close phase bed; (3) the mixture of the reaction oil gas and catalyst from reaction area A and B of the lift leg converging in reaction C of close phase bed, and reacting sequentially; (4) separating reaction oil gas from the catalyst depositing carbon after reaction, the reaction oil gas into the separation part of the product, and the carbon-deposited catalyst returning reaction part to serve circularly after striped, regenerated. With the method it can increase the yield of ethane, propone and BTX.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production line used for gluing and edge covering of automobile door cover

ActiveCN104668322ACompact layoutSmall footprintLiquid surface applicatorsMetal-working feeding devicesProduction lineButt joint

The invention discloses a production line used for gluing and edge covering of an automobile door cover. The production line comprises a gluing production line and an edge covering production line which are in mutual butt joint, wherein the gluing production line comprises a combining platform; one side of the combining platform is provided with an inner plate tetrahedron rotating platform, a glue gun, a six-axis fixed robot and an inner plate gripper storing frame; the other side of the combining platform is provided with an outer plate positioning platform, a combining platform switching storage region, an outer plate seven-axis robot and an outer plate gripper storing frame; the edge covering production line sequentially comprises a special pre-edge-covering machine, a pressing machine and a special inner edge covering machine; a buckling gripper storing frame and a buckling seven-axis robot are arranged between the special pre-edge-covering machine and the pressing machine; an assembly seven-axis robot and an assembly gripper storage frame are arranged between the pressing machine and the special inner edge covering machine; the special pre-edge-covering machine is located behind the combining platform. The production line has the beneficial effects that gluing and edge covering processes of a plurality of types of automobile door covers are automatically finished by the machine; the quality of the product is stable and reliable, the automation degree is high and the commonality is strong.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

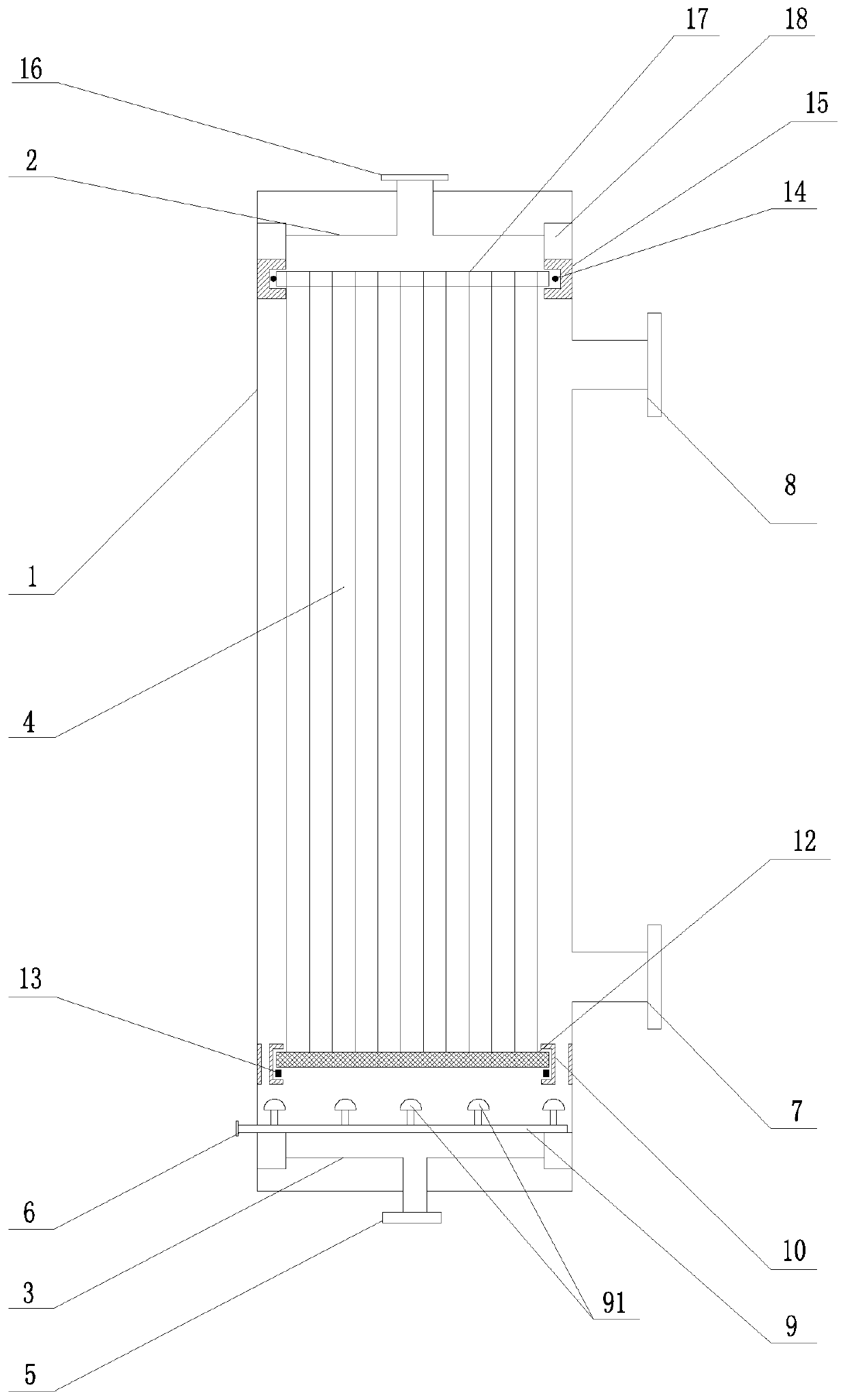

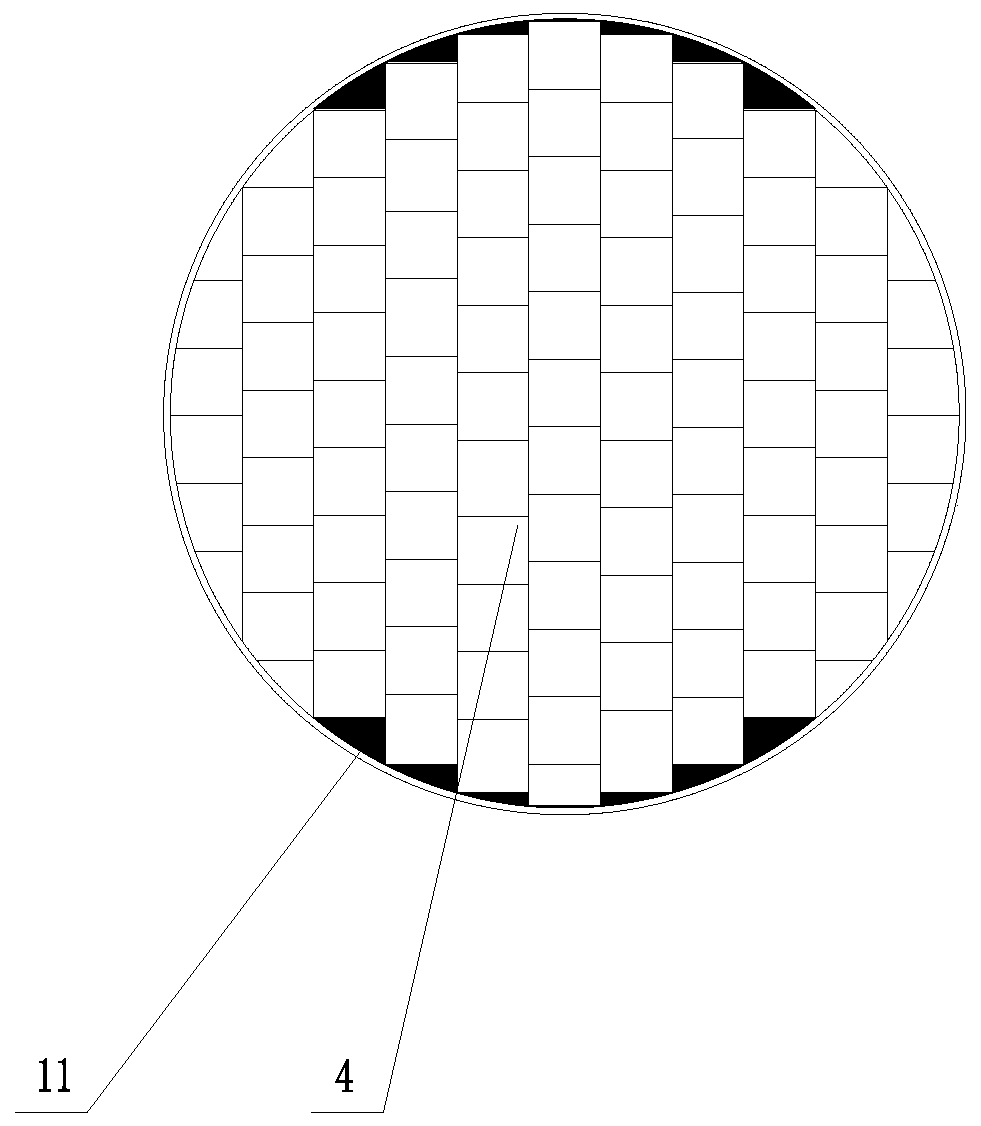

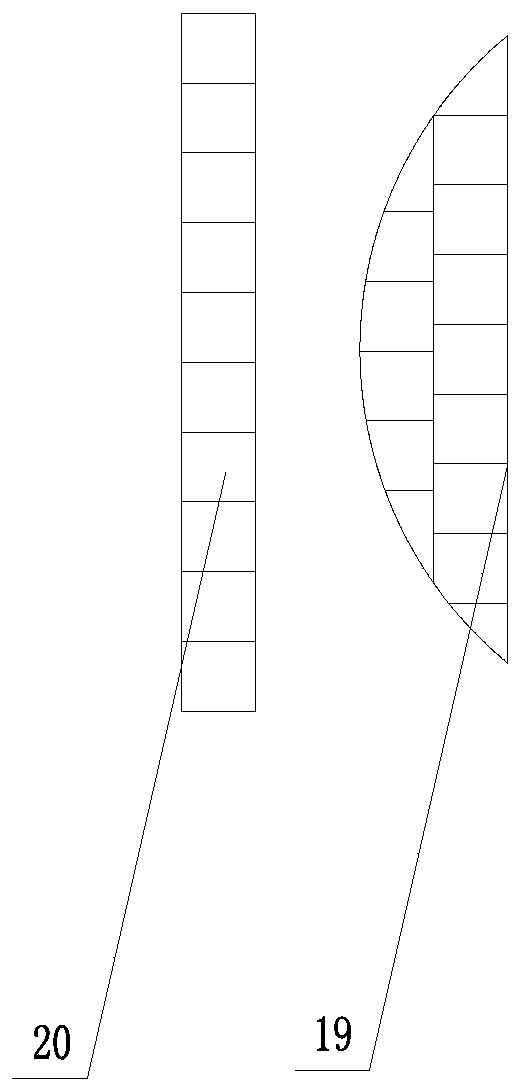

Inorganic ceramic membrane module

PendingCN111408274AReasonable structural designLarge coverage areaSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisWater productionCeramic membrane

The invention discloses an inorganic ceramic membrane module. The inorganic ceramic membrane module comprises a filter cartridge, an upper end cover positioned at the upper end of the filter cartridgeand a lower end cover positioned at the lower end of the filter cartridge, and a liquid inlet is formed in the side surface of the lower end of the filter cartridge; a liquid outlet is formed in theside surface of the upper end of the filter cartridge; a water production port is formed in the upper end cover; a drain outlet is formed in the lower end cover; and the filter cartridge is a cylinder, an inorganic ceramic membrane element is arranged in the filter cartridge, the inorganic ceramic membrane element comprises a flat sheet membrane group positioned in the middle and an arc-shaped membrane positioned on the side surface of the flat sheet membrane group, and the length extending directions of the flat sheet membrane group and the arc-shaped membrane are the same as the extending direction of the filter cartridge. According to the inorganic ceramic membrane module, the plate type ceramic membrane can be applied to an ultrafiltration system, the advantages of the ceramic membraneare fully utilized, and the existing hollow fiber membrane module is replaced with low cost and large area, so that the aims of improving the stability of the system, reducing the operation cost andprolonging the operation life of equipment are fulfilled.

Owner:SUZHOU NUCLEAR POWER RES INST +3

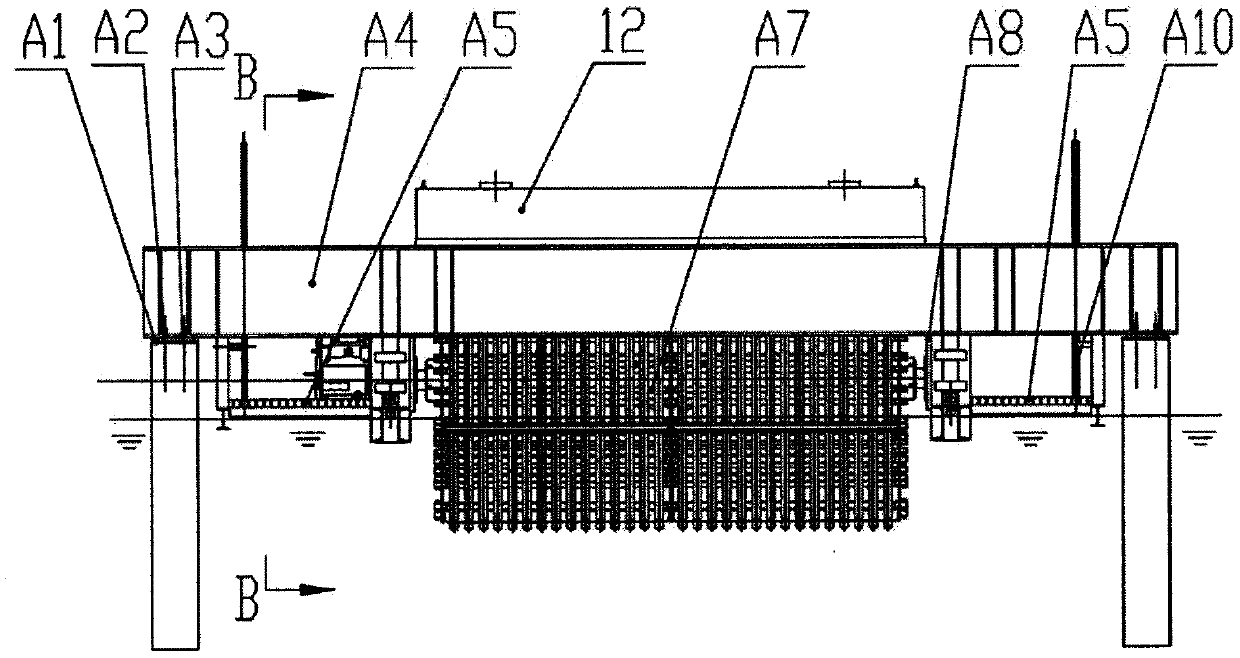

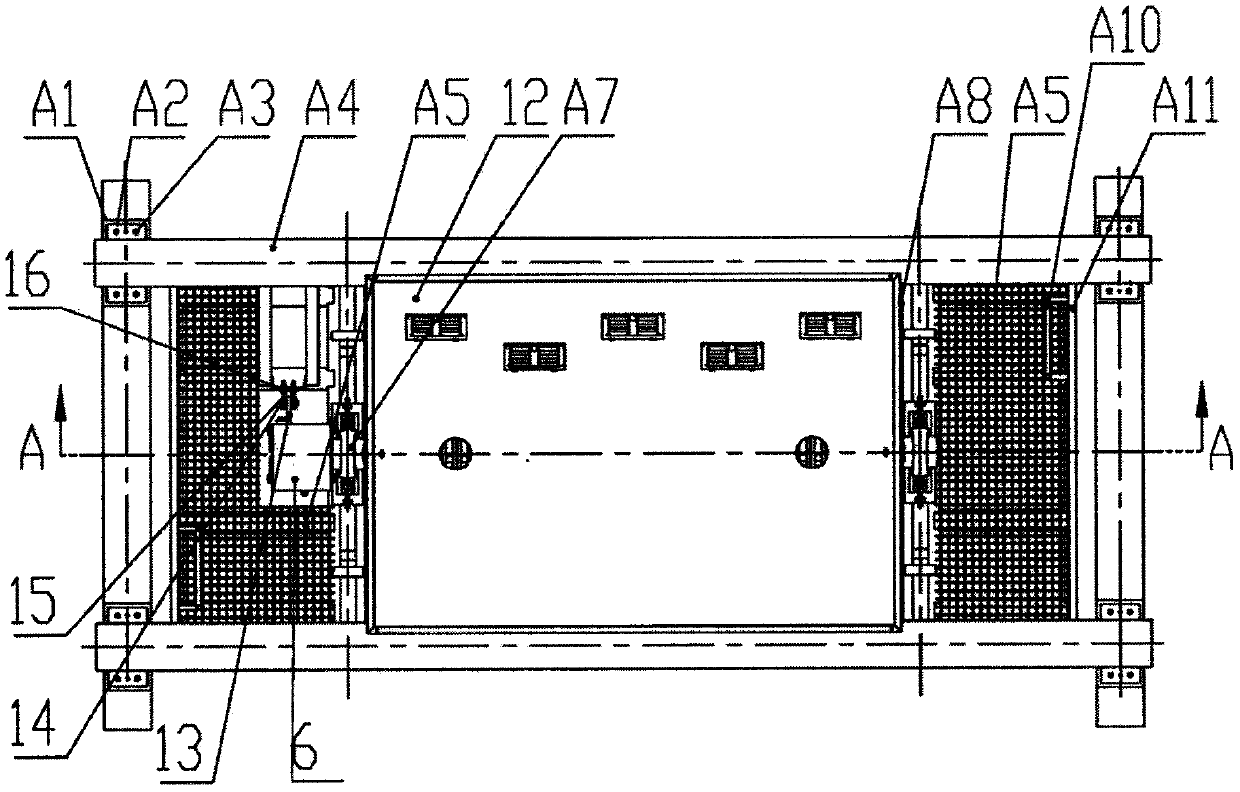

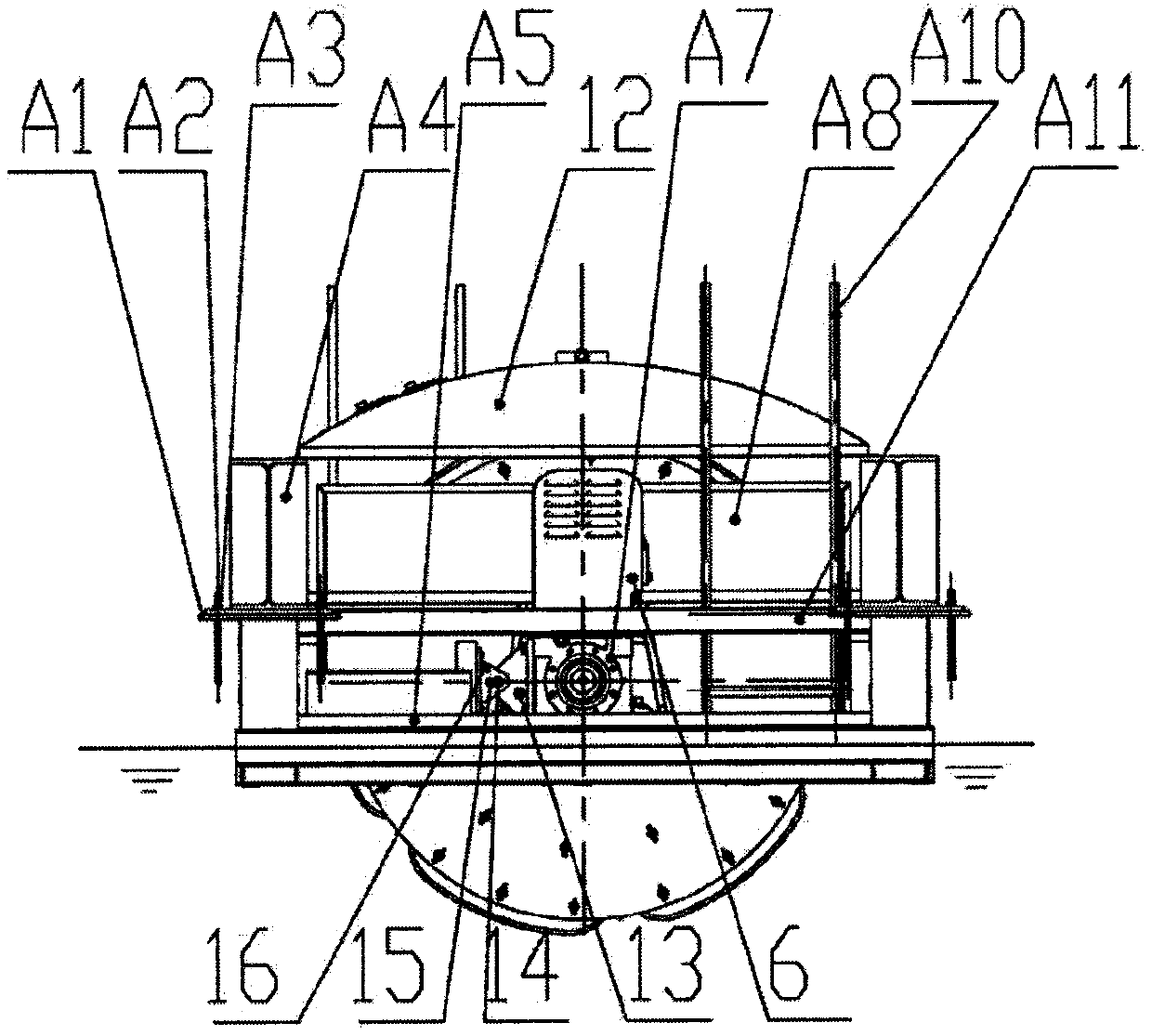

Three-dimensional rotary net-shaped contact body device, biological rotating disc tank and sewage treatment equipment

PendingCN110615528AReduce upfront investmentRealize non-stop production transformationTreatment with aerobic and anaerobic processesSustainable biological treatmentEngineeringAlloy

The invention discloses a three-dimensional rotary type net-shaped contact body device, a biological rotating disc tank and sewage treatment equipment, and relates to the technical field of environmental protection equipment. The three-dimensional rotary type net-shaped contact body device comprises a rotating disc body and a biological contact disc, wherein the biological contact disc is arrangedon the rotating disc body; the rotating disc adopts a welding structure, is made of high-strength low-alloy structural steel materials and is high in strength and long in service lifetime; a supporting shaft adopts a hollow stainless steel pipe welding structure, and is light in weight and high in strength; the biological contact body is axially fixed in a manner of compressing a connecting discwith internal and external threads, so that the biological contact body is more reliable in connection and convenient to disassemble, assemble and maintain. The biological rotating disc tank comprisesa tank body and a biological rotating disc, wherein a mixed solution is arranged in the tank body, bacillus is in the mixed solution, one part of the biological rotating disc is immersed in the mixedsolution, and the other part of the biological rotating disc is exposed in the air; the biological rotating disc comprises a main shaft and a membrane, and the membrane is of a three-dimensional netstructure and adsorbs the bacillus; a driving mechanism is connected to one end of a main shaft of the biological rotating disc and used for driving the main shaft to rotate.

Owner:青海洁神环境科技股份有限公司

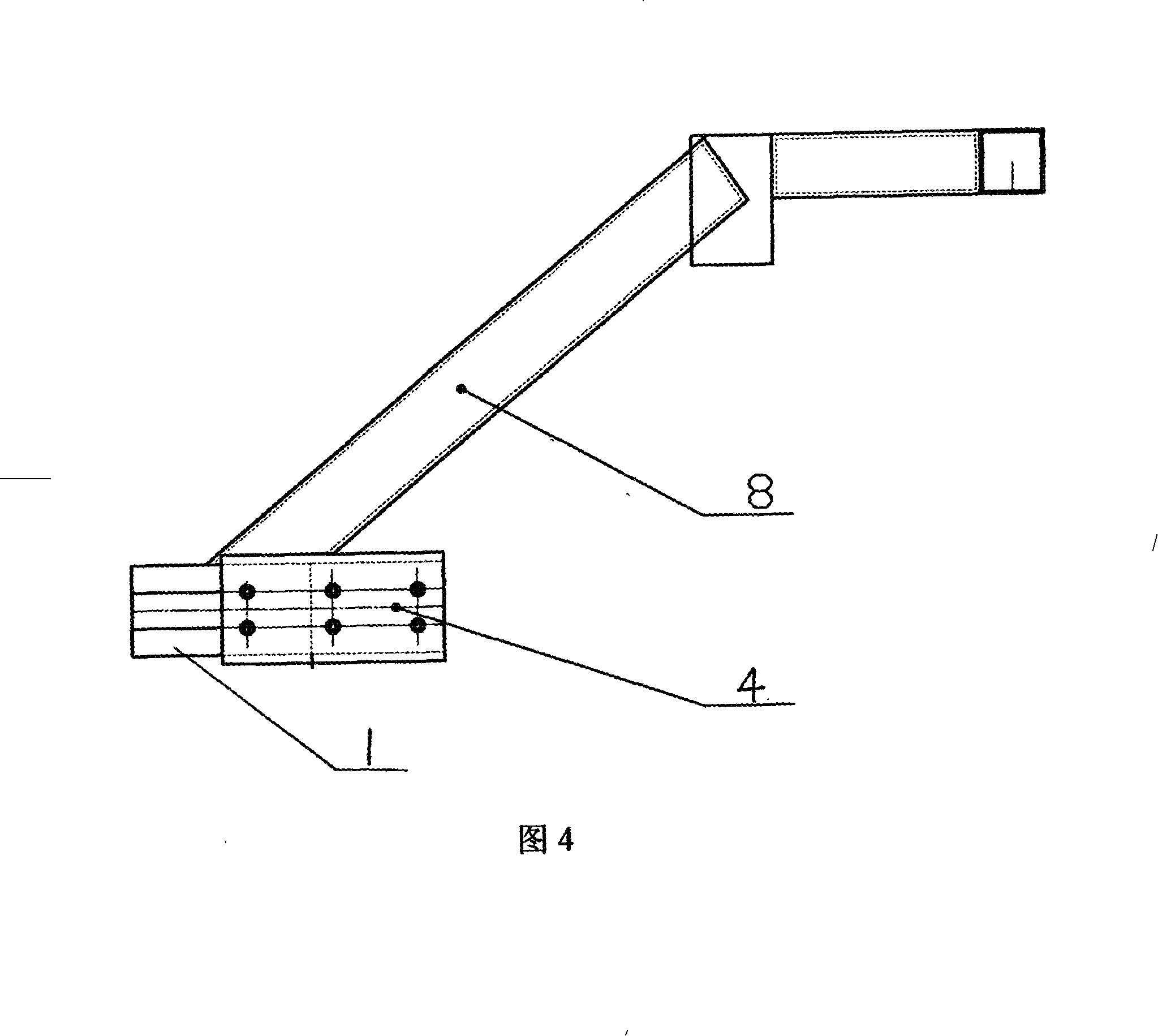

Method for building maglev train rail by utilizing conventional railway

InactiveCN101935966ASave land resourcesEven by forceRailway track constructionLand resourcesEconomic benefits

The invention discloses a method for building a maglev train rail by utilizing the conventional railway. The method comprises the following steps of: arranging a rail base of the maglev train rail above a railway bed of which tracks are removed; fixing a permanent magnet of the maglev train rail on the rail base; arranging a dynamic permanent magnet rail for pushing a maglev train to run in the middle of crossties; and arranging balance supporting plates at two sides of the maglev train rail to ensure that the maglev train is in a balance state in a running process. The method is used for rebuilding the conventional railway into the maglev train rail and has the advantages of avoiding requisition of land and saving precious land resources along with a short building period, low cost which is only 1 / 3 of the conventional cost and good economic benefit.

Owner:SHANGHAI QIMOU ENERGY SOURCE TECH DEV

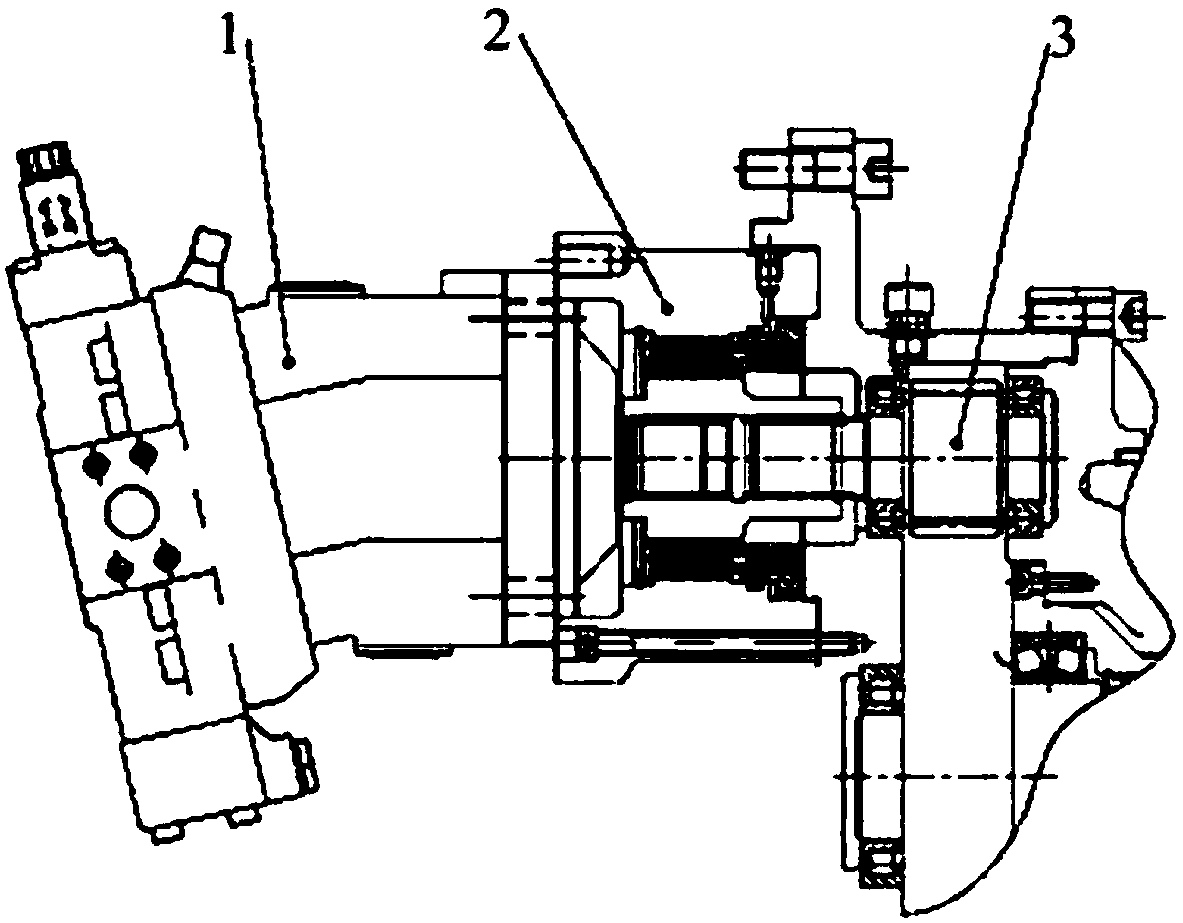

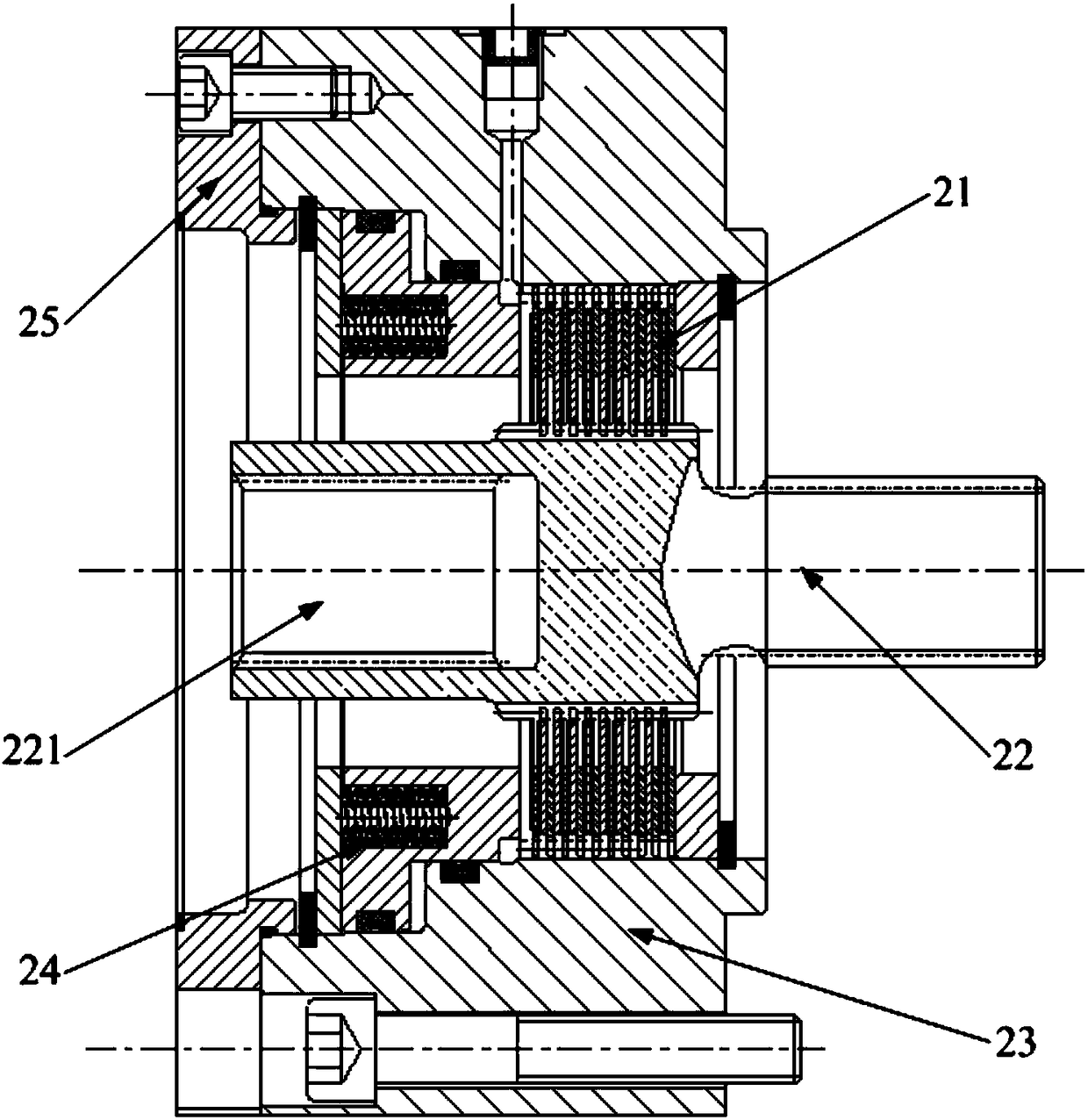

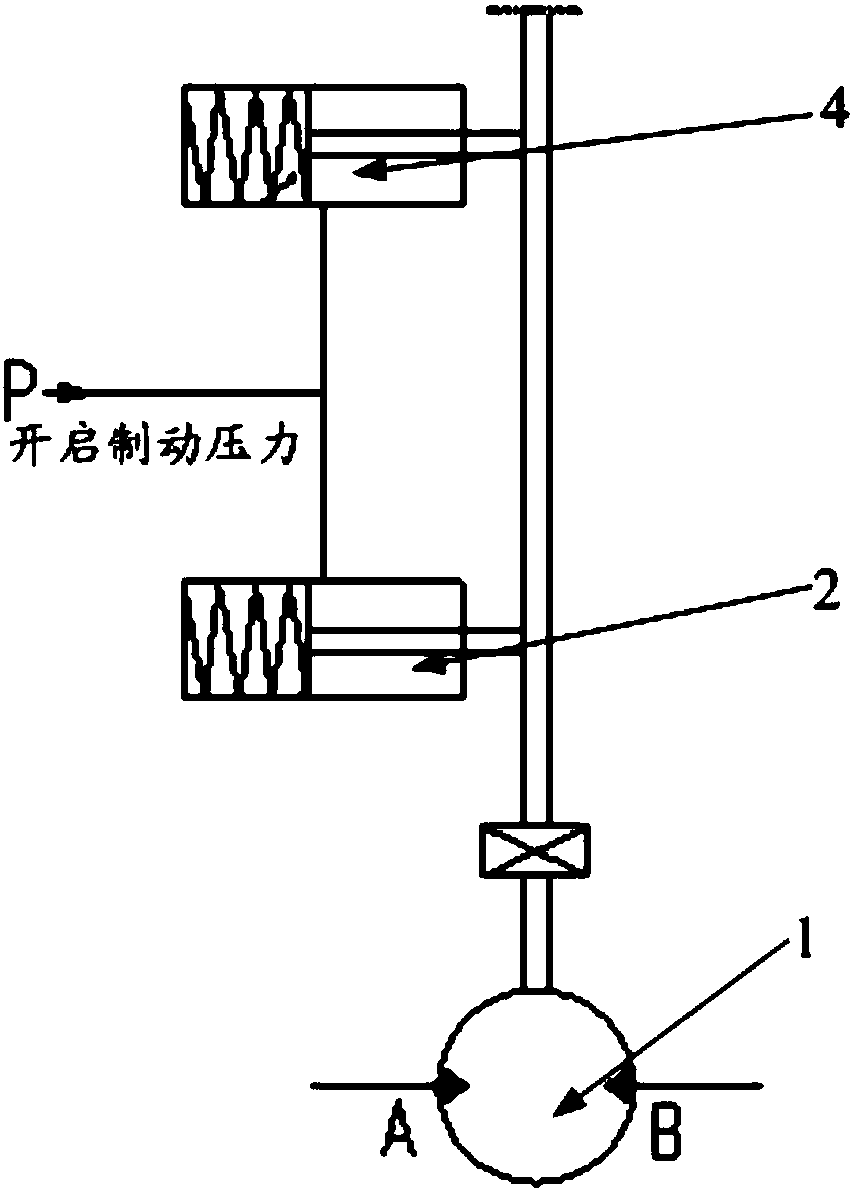

Rotary drilling rig and rotating system thereof

PendingCN108487855ALarge braking torqueAlleviate the left and right swing of the upper bodyConstructionsBrake actuating mechanismsBrake torqueReducer

The invention provides a rotary drilling rig and a rotating system thereof. The rotating system comprises a rotating motor, a rotating speed reducer, a main rotating brake and an auxiliary rotating brake; the main rotating brake is arranged in the rotating motor or the rotating speed reducer; the auxiliary rotating brake is connected with the output end of the rotating motor and the input end of the rotating speed reducer; and the auxiliary rotating brake and the main rotating brake provide braking torque simultaneously, so that an upper vehicle body of the rotary drilling rig is in a locked state. According to the rotary drilling rig and the rotating system thereof, one auxiliary rotating brake is additionally arranged between the output end of the rotating motor and the input end of therotating speed reducer, thus the auxiliary rotating brake and the main rotating brake are utilized to provide the braking torque simultaneously, the rotating braking torque of a whole vehicle is increased, the problem of accurate positioning of rotating of the drilling rig is solved, and the problem of left-right swinging of the upper vehicle body under the locked state of the upper vehicle body of the drilling rig during construction is relieved; and during reconstruction, the upper vehicle body with a special crawler chassis does not need to be changed, and thus the cost is reduced.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

Pavement multi-hammer rubblization construction method

InactiveCN108797298AFast constructionImprove structural uniformityRoads maintainenceEconomic benefitsArchitectural engineering

The invention discloses a pavement multi-hammer rubblization construction method. The pavement multi-hammer rubblization construction method comprises the following steps of (1) preparation before construction is performed; (2) trial pavement section setting is performed; (3) MHB crushing is performed; (4) compaction is performed; (5) bituminous seal is performed, specifically, emulsified bituminous seal is immediately constructed to pavement after the compaction, the solid content of emulsified asphalt is controlled to be 50%-55%, the using amount of the emulsified asphalt is 2.0-3.5kg / m<2>,then aggregate materials are evenly perfused on the surface of the emulsified bituminous seal, wherein the particle diameter of the aggregate materials is 4.75-9.5mm, Los Angeles abrasion loss is lessthan or equal to 28%, water absorption is less than or equal to 2.0% and silt content is less than 3%, and finally a pneumatic-tired roller is used for rolling compaction of the pavement for 2-4 times. The pavement multi-hammer rubblization construction method can realize full collection of parameters of the pavement, performs adjustment and monitoring in time, performs timely adjustment for different pavement conditions, performs various types of pavement rubblization construction, and has a stable crushing effect, good economic benefits and broad market promotion value.

Owner:广西驰胜农业科技有限公司

An integrated transformation method for reducing pollutant emissions from circulating fluidized bed boilers

ActiveCN103900077BReduce emission concentrationGood environmental benefitsFluidized bed combustionApparatus for fluidised bed combustionSlagFluidized bed

The invention discloses an integrated modification method for reducing pollutant emission of a circulating fluidized bed boiler. The modification method comprises the following steps: modifications on a screen type heating surface, a material return system, an air distribution system, a secondary air nozzle system, a slag cooling system and a desulfurizer adding system. Through the modifications, the concentration of SO2 and NOx in smoke is finally reduced to 30-70% of that before modifications, the fly ash concentration is reduced to 70-90% of that before modifications and the environmental protection characteristic of boiler operation can be remarkably improved without adding new equipment. The integrated modification method has the advantages of being small in investment cost, short in modification period and stable in boiler operation; at the time the integrated modification is performed, the problems existing in arrangement of the original heat surface, a funnel cap, a separator, a slag cooler and a lime stone transmission system of the boiler can be synchronously solved, and therefore the economy, stability and safety performance of boiler operation are comprehensively improved.

Owner:HUANENG CLEAN ENERGY RES INST

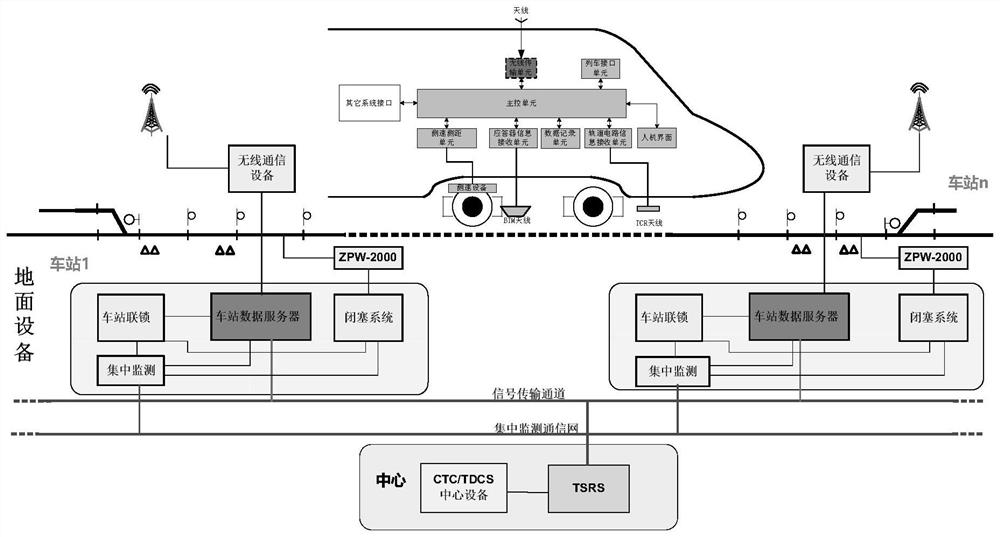

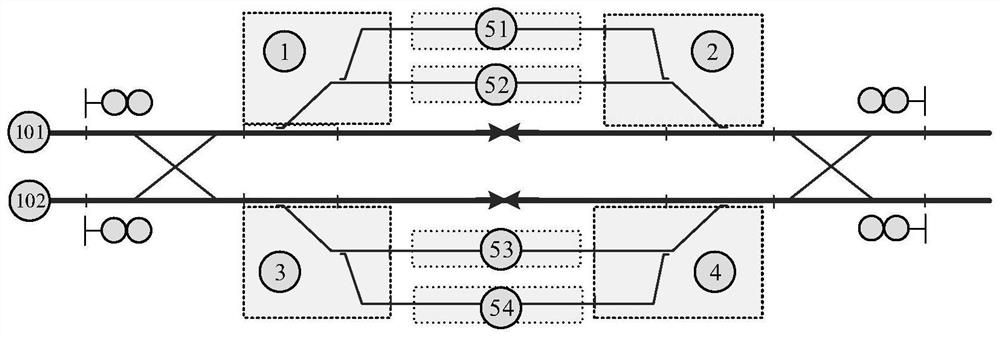

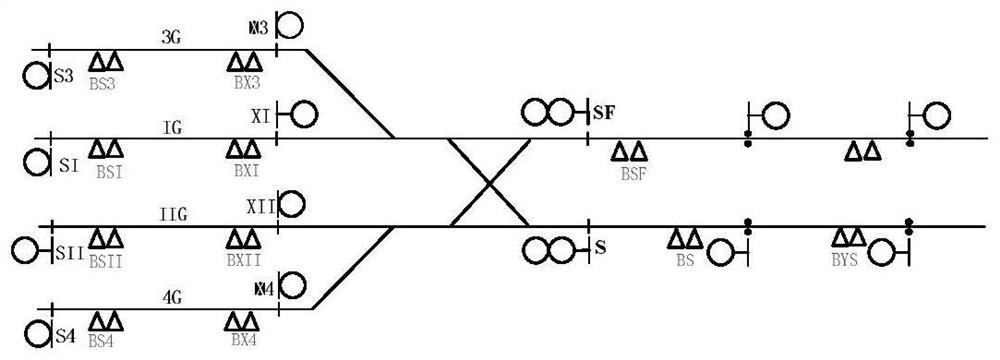

Train control system capable of enabling C3 high-speed rail motor train unit to run circuitously by utilizing common speed line

PendingCN114475707AReduce the impact of transportation orderTransportation order does not affectRailway traffic control systemsSignalling indicators on vehicleTelecommunicationsStation

A train control system capable of enabling a C3 high-speed rail motor train unit to run circuitously through a common speed line adopts a station data server to achieve centralized management of ground line data stations, and the train-mounted train selects wireless message information through serial numbers of ground passive transponders, so that later line data maintenance is facilitated. A wireless message is sent by adopting a 400MHz frequency special for a railway, four frequency points are used in total, the bandwidth is 12.5 kHz, the same-frequency interference between different radio stations is prevented, the operation requirement that the operation speed is below 200km / h is met, and the transportation organization is flexible. The temporary speed limit server has the management functions of temporary speed limit command storage, verification, deletion, splitting, setting, cancelling and the like, and can set temporary speed limit in any range in an interval or a station to meet the requirements of various operation scenes.

Owner:SIGNAL & COMM RES INST OF CHINA ACAD OF RAILWAY SCI +3

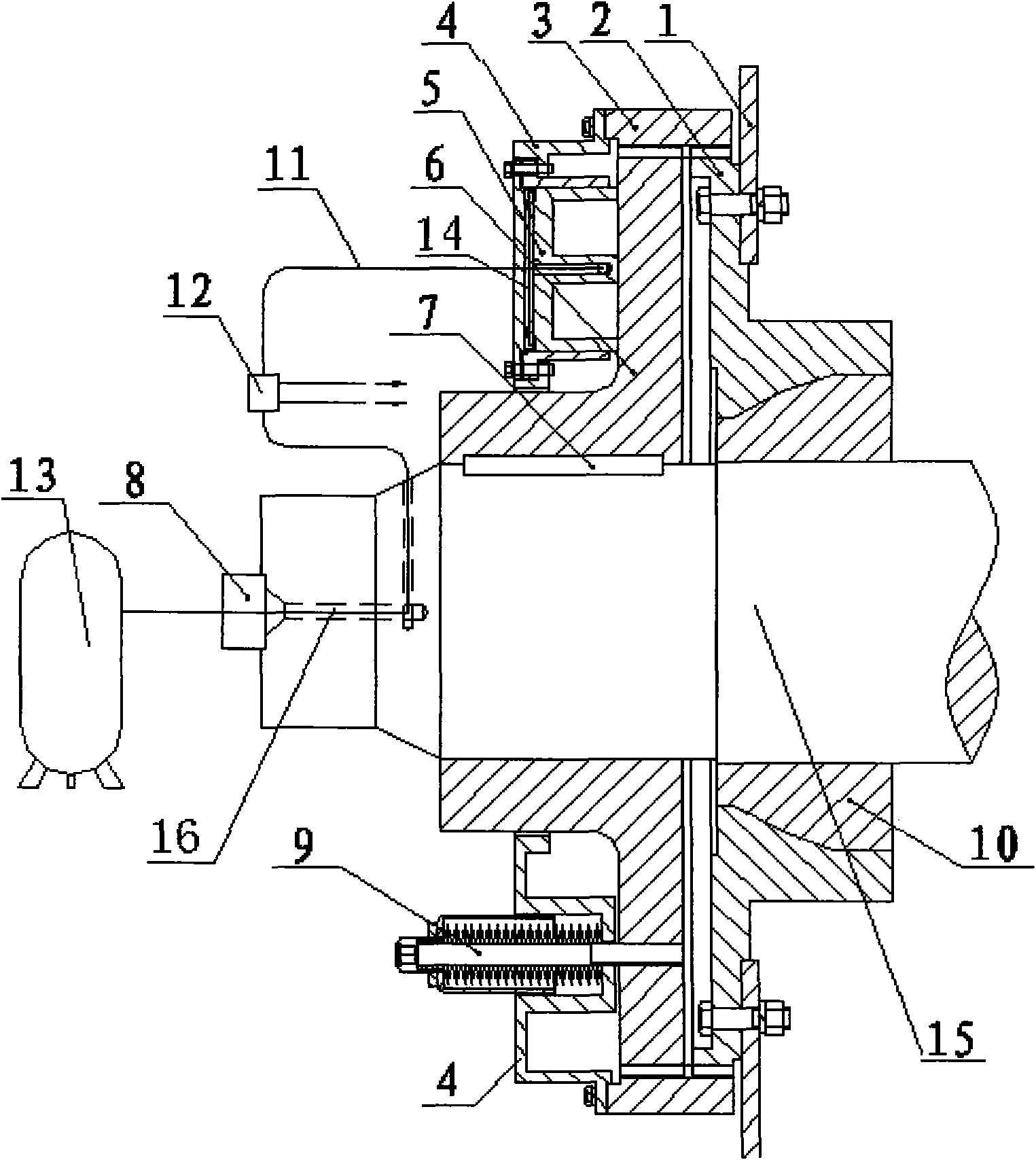

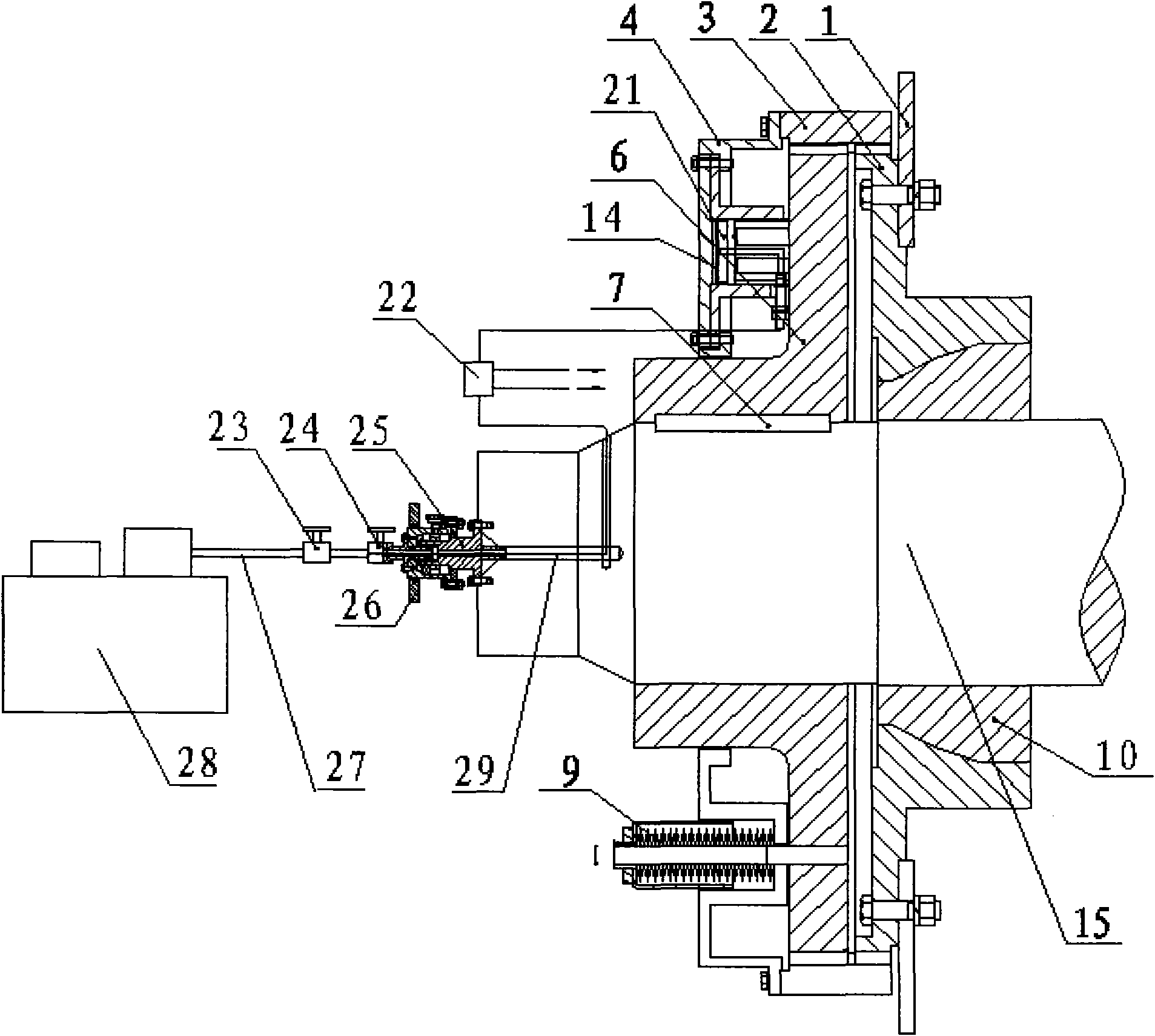

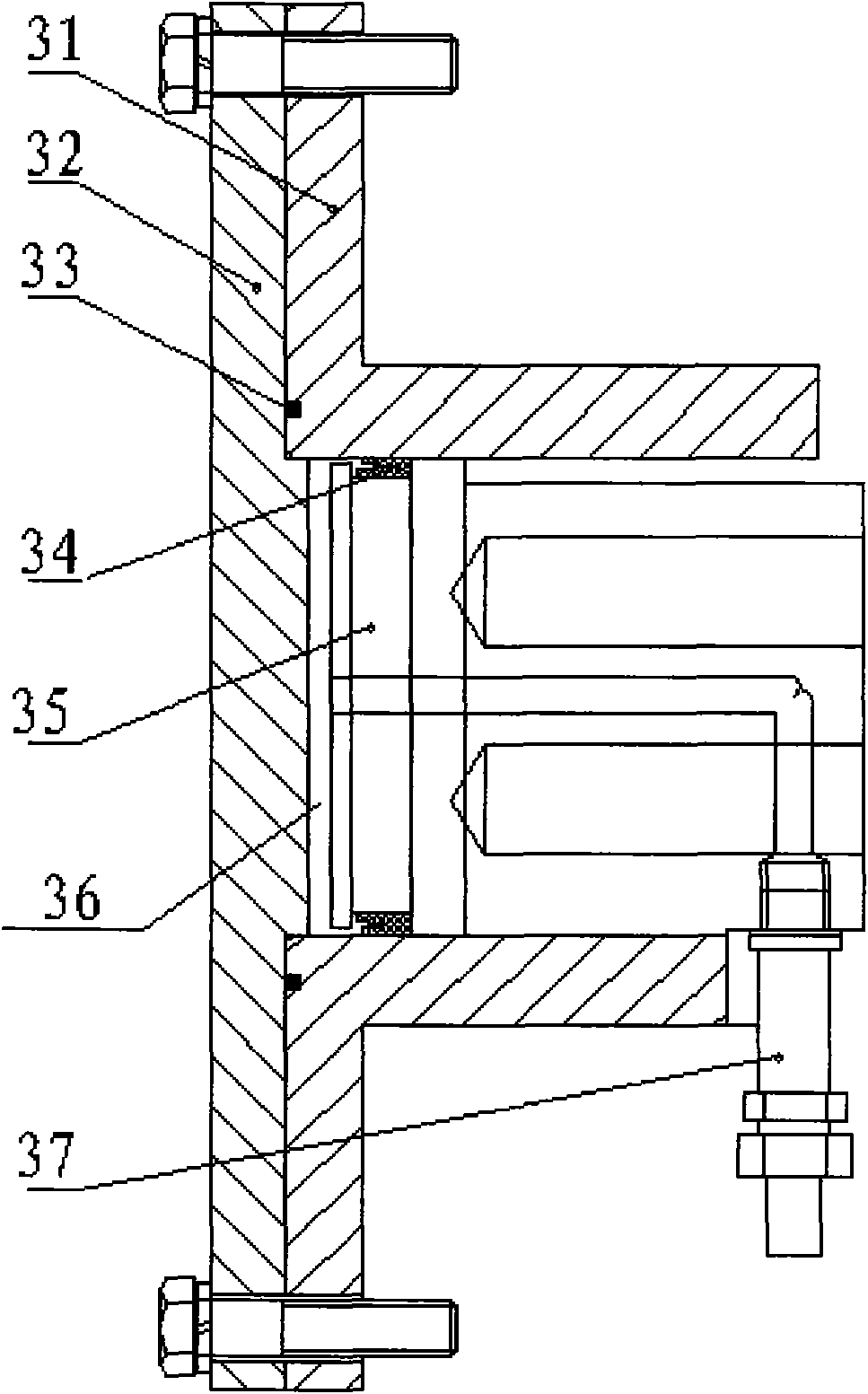

Adjustable cord driving and switching mechanism of mine hoist

ActiveCN101643172ACompact structureSuitable for efficient production scheduleWinding mechanismsMine liftsSpherical bearingCoil spring

The invention discloses an adjustable cord driving and switching mechanism of a mine hoist, comprising a walking drum web plate, a walking drum left hub, a gear sleeve, a cover, a gear, a triple coilspring, a spherical bearing, a pressure cavity, a main shaft, and the like and characterized by being controlled by hydraulic pressure and finishing the disengaging and engaging action by oil pressurethrust and the deformation force of the coil spring. The invention improves the barometric control of an original adjustable cord driving and switching mechanism into hydraulic control, integrates control sources of a brake system and an adjustable cord driving and switching mechanism into a hydraulic station, thoroughly discards an original barometric system, utilizes the functions of the hydraulic station and also achieves automatic cord adjustment, equipment simplification, simple and convenient operation, short modification period and time and labor saving.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com