Production control system and method and production management system

A technology of production control and controller, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of long transformation period and affect the production efficiency of the manufacturing system, and achieve the effect of shortening the transformation period and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

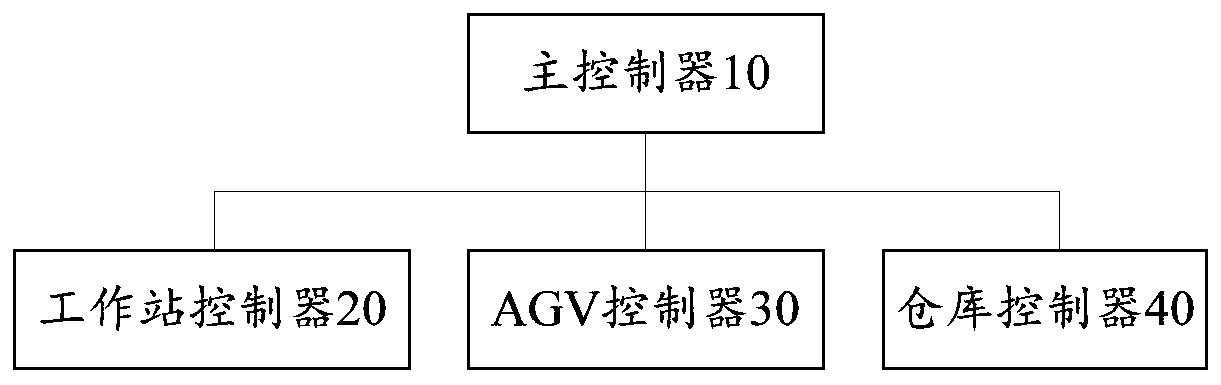

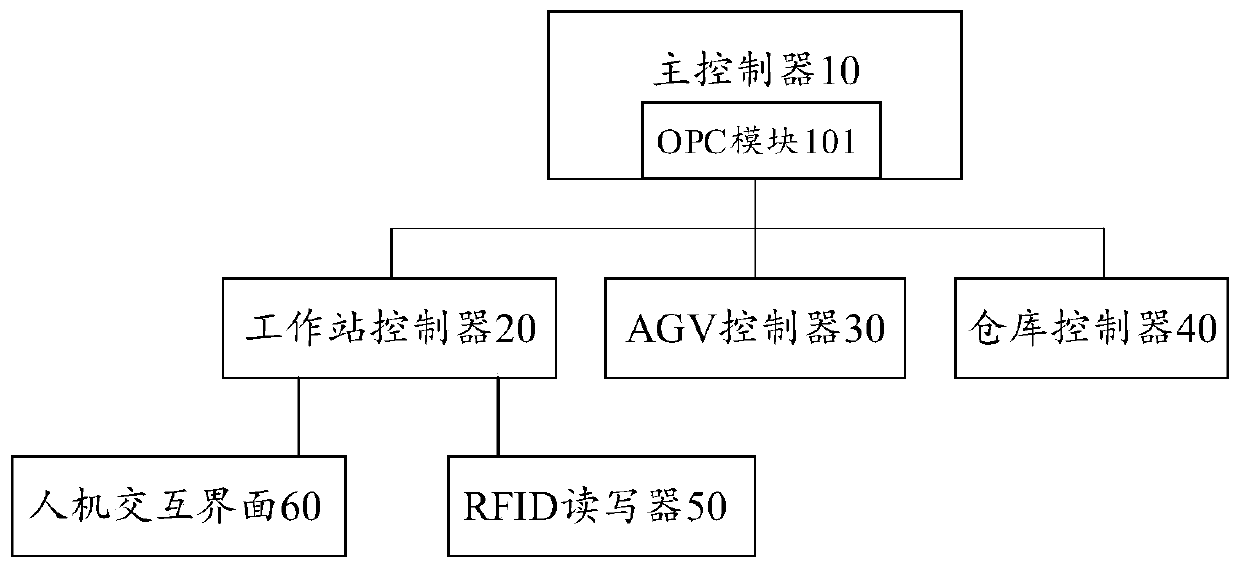

[0034] An embodiment of the present invention provides a production control system, such as figure 1 A structural block diagram of a production control system shown, the production control system includes: a main controller 10, and a workstation controller 20 connected to the main controller 10, an AGV controller 30 and a warehouse controller 40; wherein, the production The control system includes a plurality of workstations with the same configuration, and each workstation is provided with a workstation controller 20. The same configuration includes: the same arrangement of workstations, the same size of workstations and the same general equipment of each workstation.

[0035] During specific implementation, the above-mentioned main controller can be set in the management department of the production workshop, the workstation controller can be set in each workstation respectively, and the AGV (Automated Guided Vehicle, automatic guided vehicle) controller can be set in the AGV...

Embodiment 2

[0072] On the basis of the above-mentioned embodiments, an embodiment of the present invention also provides a production management system, the production management system includes a production execution system, and also includes the production control system described in the first embodiment above. In specific implementation, the production execution system and The production control system communicates via the workshop ring.

[0073] Wherein, the above-mentioned production execution system includes an MES server, which is used to issue production tasks to the production control system, so that the production control system can perform production work.

[0074] Further, an embodiment of the present invention also provides a production control method, which is used in the production control system described in the first embodiment above, and the production control system includes: a main controller, and a workstation connected to the main controller Controller, AGV controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com