Adjustable cord driving and switching mechanism of mine hoist

A mine hoist and drive conversion technology, which is applied to the lifting equipment, clockwork mechanism, hoisting device and other directions in the mine, can solve the problems of inability to get rid of the air pressure system, complex equipment links, and unsimplified equipment, and achieve system structure. The effect of compactness, simplification of equipment and short retrofit cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

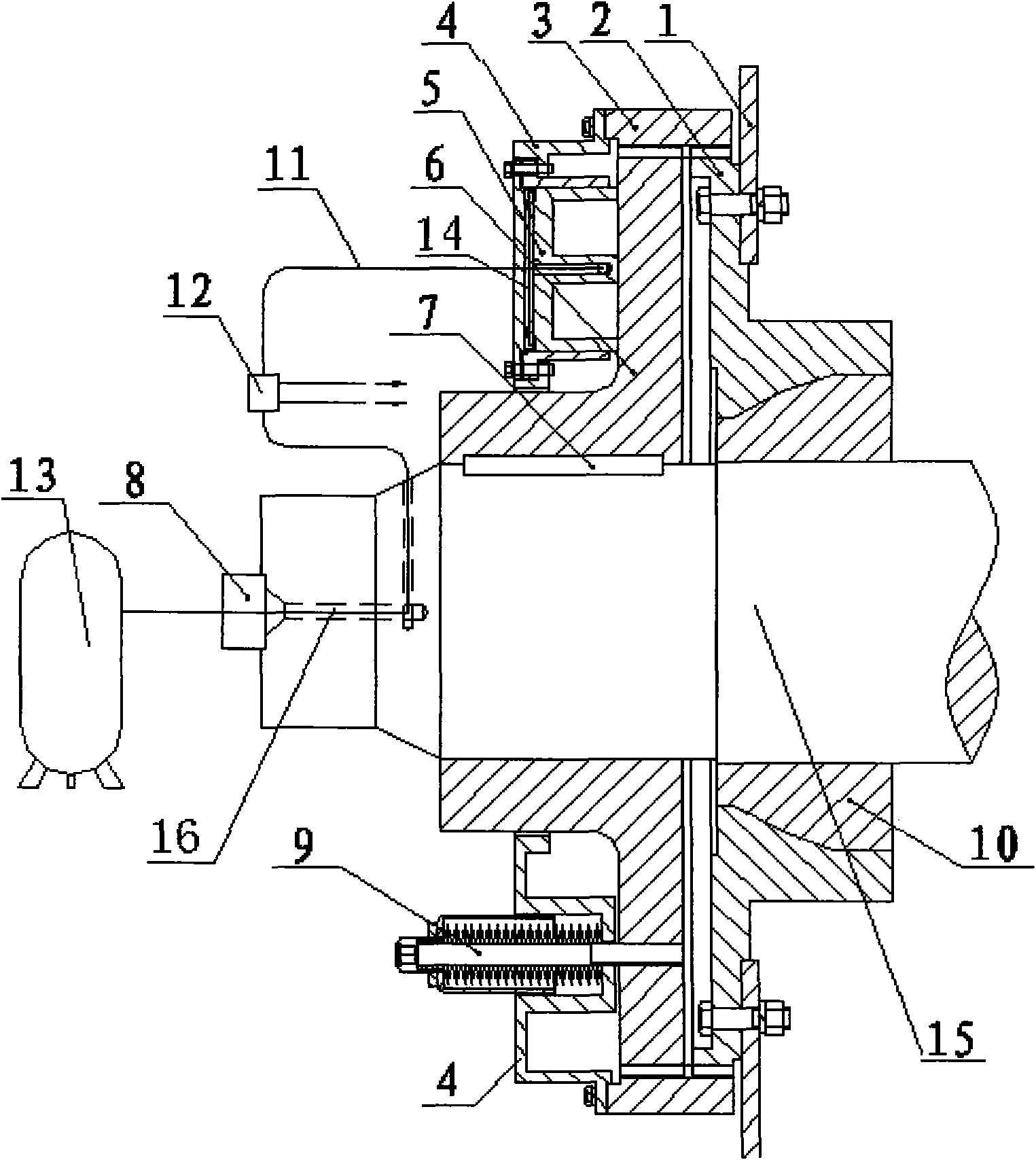

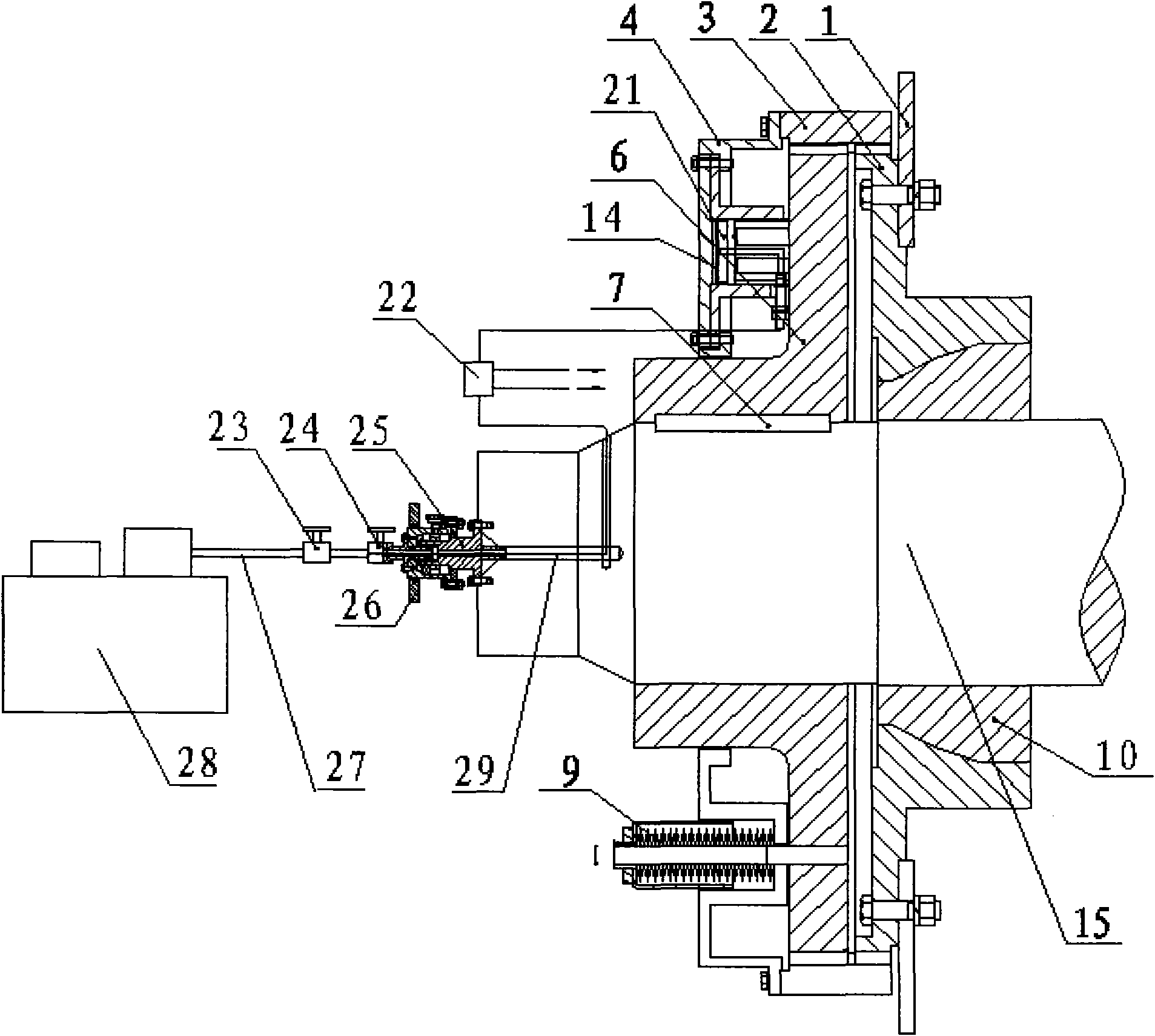

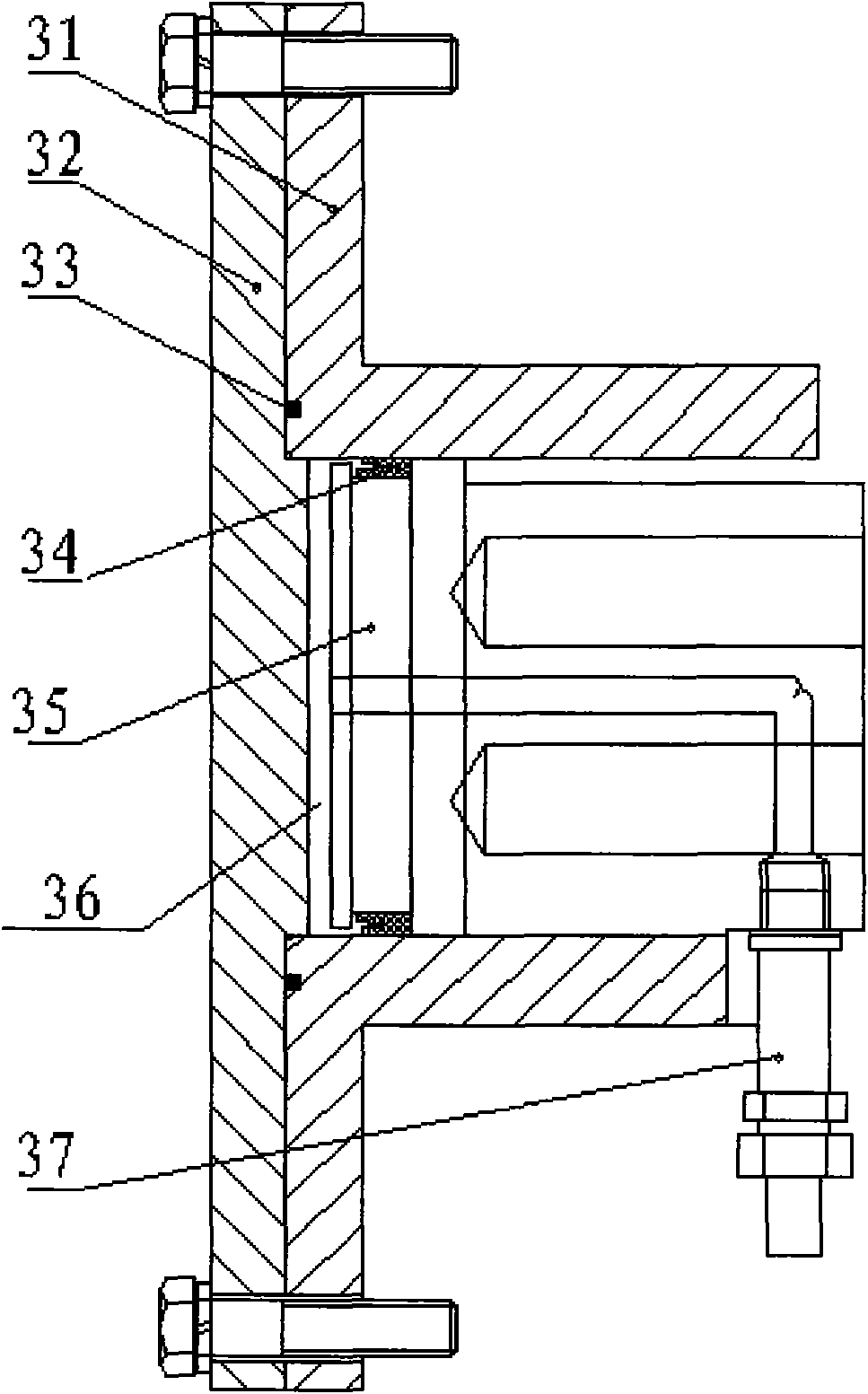

[0022] Such as figure 2 , 3 , shown in 4: a kind of mine hoist rope adjustment drive conversion mechanism of the present invention, the pressure oil provided by the hydraulic station passes through the hydraulic screw switch 23, the hydraulic screw switch 24 and the sealing head 25, enters the main shaft center hole oil circuit 29, and then Through the pipeline joint and the oil distributor 22, one is divided into three and enters the replacement oil cylinder 21. At this time, the replacement oil cylinder 21 is displaced to the left under the action of the oil pressure thrust, and at the same time, the disc spring 9 is compressed to connect with the replacement oil cylinder 21. The cover 4 together drives the gear sleeve 3 in the mechanism to move to the left. When the displacement is greater than the width of the upper gear on the left wheel hub 2 of the traveling reel, the rope adjustment drive conversion mechanism is disengaged, and the traveling drum is relatively station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com