Device for improving thickness of car body chassis electrophoresis film

An electrophoretic film and car body technology, applied in electrophoretic plating, electrolytic paint, coating and other directions, can solve the problems of weak anti-corrosion ability, the thickness of the electrophoretic film of the chassis cannot meet the needs of use, etc. Thickness, the effect of reducing the cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

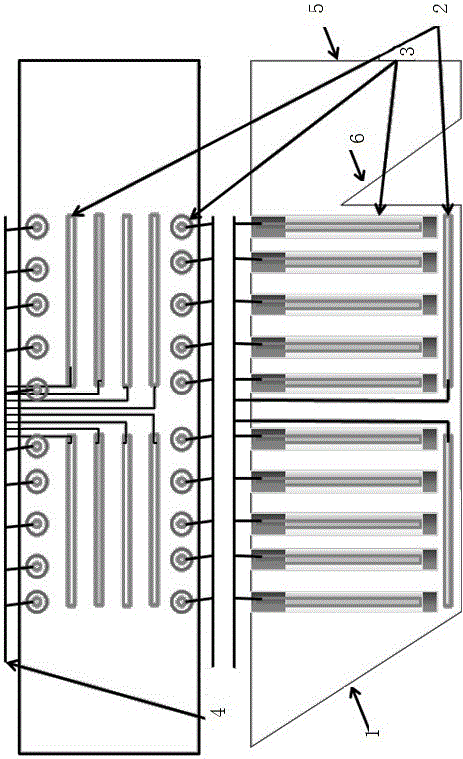

[0014] Embodiment: a kind of device that improves the electrophoretic film thickness of vehicle body chassis, its structural schematic diagram is as follows figure 1 Shown, comprise electrophoresis tank 1, be provided with anode and bath liquid in the electrophoresis tank, several anodes are arranged on the side wall and the bottom surface of electrophoresis tank, the anode 3 on the side wall is provided with protective membrane outside, on the bottom surface Anode 2 is a bare anode; the surface area of the anode on the bottom surface is 0.4%-1.6% of the surface area of the electrophoretic body as the cathode, and the surface area of the anode on the side wall is 20%-25% of the surface area of the electrophoresis body as the cathode %. The anodes are all connected to the cathodes through wires 4 . The anodes on the bottom surface include the left half group of anodes and the right half group of anodes. The left half group of anodes and the right half group of anodes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com