Biochemical treatment process of coking wastewater

A technology for coking wastewater and biochemical treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in producing water to meet standards, achieve COD value reduction, high microbial Concentration, the effect of reducing water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

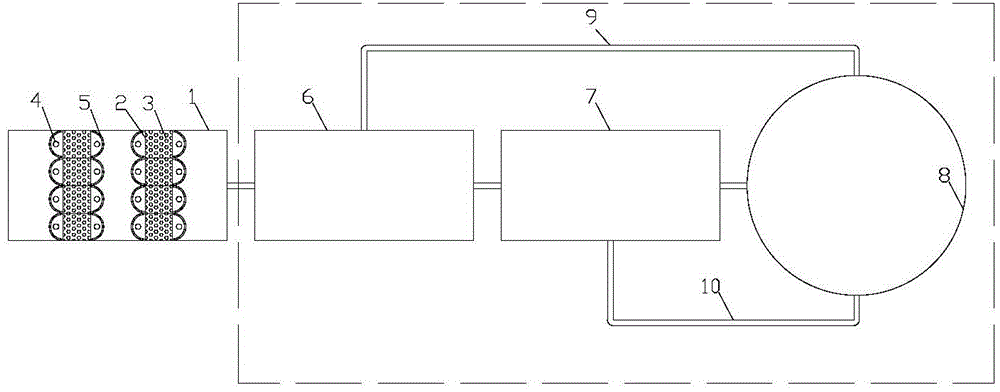

Embodiment 1

[0028]The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 500°C, the particle diameter of the filler is 0.5cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 1 according to the mass ratio of iron powder and carbon powder :3. Wherein coking waste water is 2 hours in anaerobic biofilter 1 residence time, is 20 minutes with filler 3 contact time; Coking waste water is 6 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 26 hours. The total residence time of the coking wastewater in the anaerobic biological filter 1, anoxic 6 and aerobic 7 is 34 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system flows back into the aerobic tank 7 with a return percentage of 40%, and the nitrification solution in the sedimentation tank 8 in the A-O biochemical reaction system returns to the anoxic tank 6 with a re...

Embodiment 2

[0032] The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 800°C, the particle diameter of the filler is 20cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 2 according to the mass ratio of iron powder and carbon powder: 3. Wherein coking waste water is 4 hours in anaerobic biofilter 1 residence time, is 30 minutes with filler 3 contact time; Coking waste water is 12 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 32 hours. The total residence time of coking wastewater in anaerobic biological filter 1, anoxic 6 and aerobic 7 is 48 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system is returned to the anoxic tank 6, and the return percentage is 100%. The nitrification solution in the sedimentation tank 8 is returned to the aerobic tank 7, and the return percentage is 300%.

[0033] The wa...

Embodiment 3

[0036] The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 1000°C, the particle diameter of the filler is 30cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 2 according to the mass ratio of iron powder and carbon powder: 1. Wherein coking waste water is 6 hours in anaerobic biofilter 1 residence time, is 80 minutes with filler 3 contact time; Coking waste water is 14 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 30 hours. The total residence time of the coking wastewater in the anaerobic biological filter 1, anoxic 6 and aerobic 7 is 50 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system flows back into the aerobic tank 7 with a return percentage of 150%, and the nitrifying liquid in the sedimentation tank 8 in the A-O biochemical reaction system returns to the aerobic tank 7 with a ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com