A biochemical treatment process for coking wastewater

A technology for coking wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Concentration, the effect of reducing water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

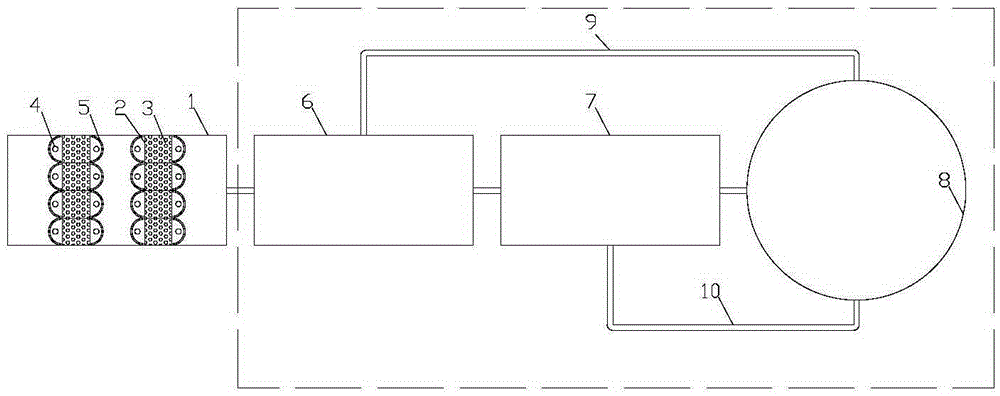

Embodiment 1

[0028]The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 500°C, the particle diameter of the filler is 0.5cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 1 according to the mass ratio of iron powder and carbon powder :3. Wherein coking waste water is 2 hours in anaerobic biofilter 1 residence time, is 20 minutes with filler 3 contact time; Coking waste water is 6 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 26 hours. The total residence time of the coking wastewater in the anaerobic biological filter 1, anoxic 6 and aerobic 7 is 34 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system flows back into the aerobic tank 7 with a return percentage of 40%, and the nitrification solution in the sedimentation tank 8 in the A-O biochemical reaction system returns to the anoxic tank 6 with a re...

Embodiment 2

[0032] The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 800°C, the particle diameter of the filler is 20cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 2 according to the mass ratio of iron powder and carbon powder: 3. Wherein coking waste water is 4 hours in anaerobic biofilter 1 residence time, is 30 minutes with filler 3 contact time; Coking waste water is 12 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 32 hours. The total residence time of coking wastewater in anaerobic biological filter 1, anoxic 6 and aerobic 7 is 48 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system is returned to the anoxic tank 6, and the return percentage is 100%. The nitrification solution in the sedimentation tank 8 is returned to the aerobic tank 7, and the return percentage is 300%.

[0033] The wa...

Embodiment 3

[0036] The inner electrolytic filler 3 is made by high-temperature sintering, wherein the sintering temperature is 1000°C, the particle diameter of the filler is 30cm, the firing raw materials are iron powder and carbon powder, and the firing ratio is 2 according to the mass ratio of iron powder and carbon powder: 1. Wherein coking waste water is 6 hours in anaerobic biofilter 1 residence time, is 80 minutes with filler 3 contact time; Coking waste water is 14 hours in anoxic pond 6 residence time of A-O biochemical reaction system, and aerobic pond 7 residence time is 30 hours. The total residence time of the coking wastewater in the anaerobic biological filter 1, anoxic 6 and aerobic 7 is 50 hours. The sludge in the sedimentation tank 8 in the A-O biochemical reaction system flows back into the aerobic tank 7 with a return percentage of 150%, and the nitrifying liquid in the sedimentation tank 8 in the A-O biochemical reaction system returns to the aerobic tank 7 with a ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com