Wastewater treatment process for fine chemical pharmaceutical intermediates

A technology for wastewater treatment and chemicals, applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The effect of high energy consumption and removal of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

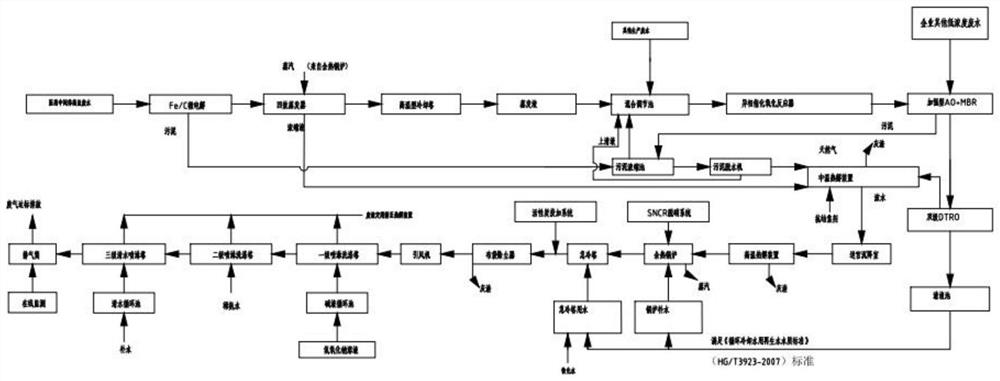

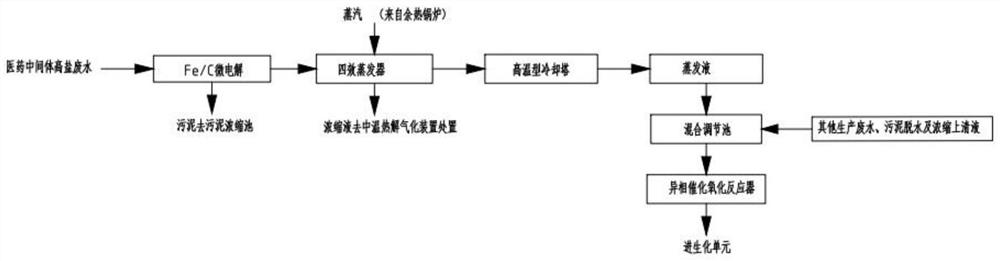

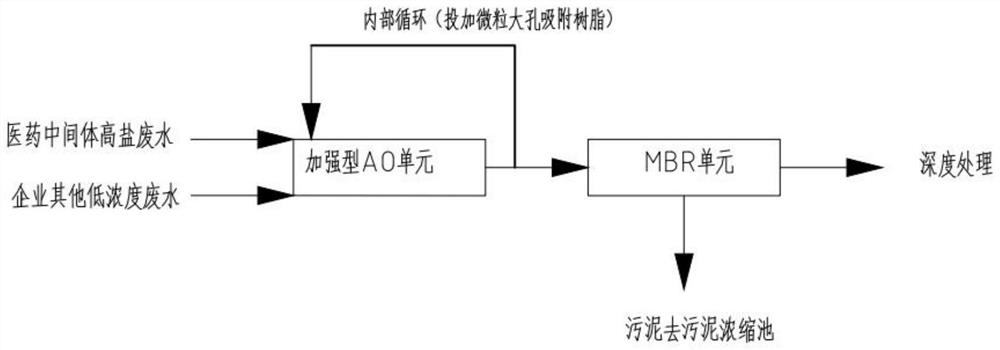

[0036] A preprocessing section for fine chemical pharmaceutical intermediate wastewater, including "Fe / C micro-electrolytic unit + multi-effect evaporation unit + advanced oxidation unit", "reinforced AO biological contact oxidation unit + MBR unit" The chemical section, "DTRO film method" depth treatment section, "sludge disposal unit" and "sludge disposal unit" and "concentrated salt heat dissipating unit + flue gas treatment unit" thermolyte sections, the process steps are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com